lcd panel white spot factory

It"s not a dead pixel it"s a bright little spot. The colors still work normally but on a white background the spot appears especially bright and on a black background it"s a little subtle bright dot. (On a black background it appears like a greyish color.) It"s not a single pixel, it looks like about 3 pixels and it sort of fades, it"s not a sharp 3 pixel block that immediately stops it fades out over the course of about 3 pixels.

Thanks guys! I just replaced the leds for my tcl 55 inch tv and after bout a week I started seeing the bulbs on the left side of the screen. Since the tv was an awesome find and the bulbs were like 30 bucks on eBay I’m fighting the inevitable being going back in and fixing that plastic deflector post. The screen is extremely fragile so if u don’t wanna pay 14 bucks at Home Depot for them window suction cups that were well worth the money For loners like myself lol, make sure u get another person to help u with the screen panel once it’s been dislodged . Especially if it’s a big honker. Nothing more scary than popping it out by urself and get stuck in a very bad situation as in u can almost hear the crackin of the screen Or knowing that I’d u take one more step this here screen will crack .

A high-quality picture of digital television depends on the correct setup of the equipment, a good receiver, and the correct operation of the monitor. Over time, even the quality models of Sony, Samsung, LG equipment, white spots may appear on the TV screen. To eliminate them, you need to find out the cause of the breakdown, decide if you can fix the TV by yourself or if you should refer the equipment to professionals.

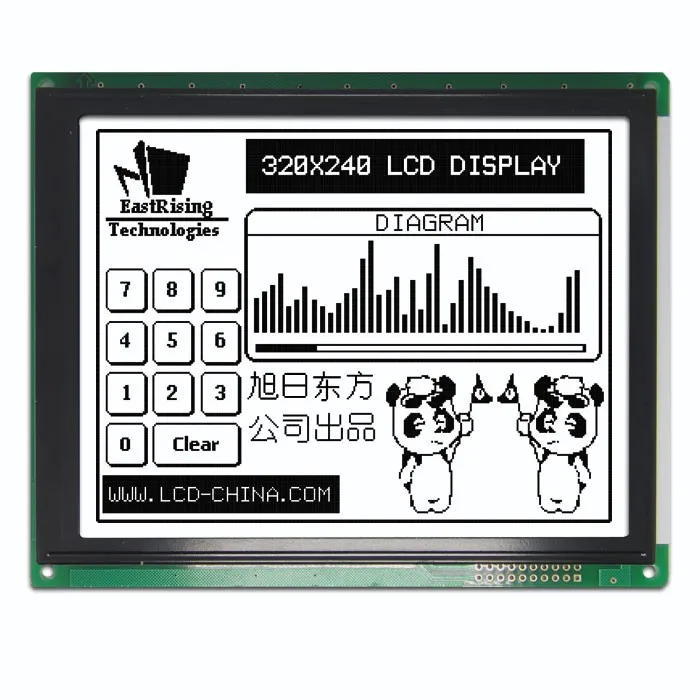

So What Are White Spots on TV?LCD TV Screens are comprised with thousands of tiny pixels, and they cycle through 3 basic colors; blue, red, and green and they create an image. The problem arises when a pixel gets stuck in the “on” position, and it appears as a white dot. Hot pixels come with defined edges and they are either square or straight lines.

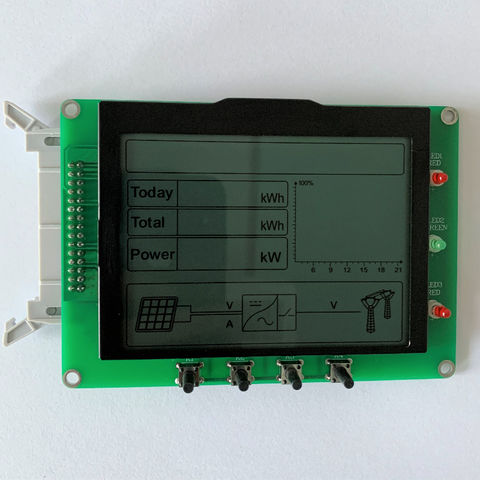

White spots (or dots) on the TV screen are the result of a damaged processor and the overheating process during warm summer temperatures.Another reason that can be the cause of white spots on the TV screens is spikes or surges as electricity supplies can vary throughout the year.On top of every LED of your TV, there sits the reflector. These white dots on your TV screen are the results of a fallen reflector. The number of dots has corresponded to the number of fallen reflectors.

To eliminate the problem of white spots on your screen, you just need to carry out simple manipulations at home. Keep in mind that only professionals can fix more complicated failures. Regardless of the place where the repair can be, the reasons for white spots include:

If light spots appear on the LCD TV screen, you will need a clean soft cloth and remote control to remove them. The second thing to do is adjust the TV settings. This can be done by adjusting the backlight and screen brightness:

Important! In the process of changing the brightness level, the intensity of the white spots should change. If they remain unchanged, the settings are not the cause of the defect.

If wiping the screen, checking that the brightness and contrast settings are correct, and loosening the screws did not get rid of the white spots on the LCD TV screen, you can replace the matrix. It is better to contact specialists for this, but if you have experience with television equipment, you can carry out repairs on your own.

Important! It is best to carry out repairs with soft cotton gloves. You need to disconnect the cables carefully and smoothly. If you damage them during the repair process, you will have to replace them or buy a new plasma, LCD TV.

If your TV is under warranty and white spots appear during this period, take it to a service center. Masters will diagnose, exclude, or confirm the presence of a factory defect. The TV will be repaired for free or with a big discount.

Black spotsand most of the streaks are removed in other ways. The general repair option is possible only in case of system failureswhen a reboot of the equipment or restoration of factory settings is required.

White spots are something that can appear on any TV whether it is new or used. What you need to know is that you need to react in a timely manner and know how to deal with them. In this article, we have described the detailed procedure, and guided you through the entire process. If you have a warranty, use it. I hope you have understood the cause of white spots and that you will solve it with the help of this article.

All HP and Compaq notebook LCDs adhere to strict quality and reliability specifications. A small percentage of LCD panels may have minor cosmetic manufacturing anomalies or irregularities such as bright or dark dots in the viewable area. These cosmetic imperfections are common to all LCD panel types and are not specific to any HP model or product line. For more information please refer to this HP article.

Dell offers a Premium Panel Exchange that ensures zero "bright pixel" defects on Dell Consumer, Professional, UltraSharp, and Gaming including Alienware monitors.

Unyielding commitment to quality and customer satisfaction has driven Dell to offer a Premium Panel Exchange as part of the standard limited hardware warranty. Even if one bright pixel is found, a free monitor exchange is supported during the limited hardware warranty period.

Premium Panel Exchange is available for Dell Consumer, Professional, UltraSharp, and Gaming (including Alienware) monitors that are sold with computers or as stand-alone units, with a standard 1-year or 3-year limited hardware warranty. Customers who purchase an extended warranty can also take advantage of this coverage during the limited hardware warranty period.

A defective pixel is a pixel on a liquid crystal display (LCD) that is not functioning properly. The ISO standard ISO 13406-2 distinguishes between three different types of defective pixels,

Similar defects can also occur in charge-coupled device (CCD) and CMOS image sensors in digital cameras. In these devices, defective pixels fail to sense light levels correctly, whereas defective pixels in LCDs fail to reproduce light levels correctly.

A dark dot defect is usually caused by a transistor in the transparent electrode layer that is stuck "on" for TN panels or "off" for MVA, PVA, and IPS panels. In that state, the transistor places the liquid crystal material so that no light ever passes through to the RGB layer of the display.

A bright dot defect or hot pixel is a group of three sub-pixels (one pixel) all of whose transistors are "off" for TN panels or stuck "on" for MVA and PVA panels.

A tape automated bonding fault (TAB fault) is caused by a connection failure from the TAB that connects the transparent electrode layers to the video driver board of an LCD.

TAB is one of several methods employed in the LCD-manufacturing process to electrically connect hundreds of signal paths going to the rows and columns of electrodes in layer 6 (the transparent electrode layer) in the LCD to the video integrated circuits (ICs) on the driver board that drives these electrodes.

If an LCD is subjected to physical shock, this could cause one or more TAB connections to fail inside the display. This failure is often caused by horizontally flexing the chassis (e.g., while wall-mounting or transporting a display face up/down) or simple failure of the adhesive holding the TAB against the glass. TAB faults require the replacement of the LCD module itself. If these connections were to fail, the effect would be that an entire row or column of pixels would fail to activate. This causes a horizontal or vertical black line to appear on the display while the rest of the display would appear normal. The horizontal failure runs from edge to edge; the vertical failure runs from top-to-bottom.

In LCD manufacture, it is common for a display to be manufactured with several sub-pixel defects (each pixel is composed of three primary-colored sub-pixels). The number of faulty pixels tolerated before a screen is rejected, is dependent on the class that the manufacturer has given the display (although officially described by the ISO 13406-2 standard, not all manufacturers interpret this standard the same way, or follow it at all).

Some manufacturers have a zero-tolerance policy with regard to LCD screens, rejecting all units found to have any number of (sub-)pixel defects. Displays meeting this standard are deemed Class I. Other manufacturers reject displays according to the number of total defects, the number of defects in a given group (e.g., one dead pixel or three stuck sub-pixels in a five-by-five pixel area), or other criteria.

“Lots of variations on the color and brightness you use will impact the life of the diode,” explains Izatt. “For instance, black doesn’t use any of the diodes at all. And if your content is using lots of gray, that’s a much lower power output than white.”

To help businesses transition from LCD to longer-lasting LED signage, Samsung has launched a trade-in program. Samsung will come on site to remove your existing display and provide a discount on a new LED bundle kit.

Traded-in LCD displays that are still operating will be refurbished and resold, and your business will receive a cash rebate. Nonworking displays will be recycled and their parts reused.

There are two versions of the new MacBook Pro and we"ve got the 16-inch version, although the 14-inch model"s display is very similar just smaller and with a different resolution. Apple calls this particular display a "Liquid Retina XDR display" which is typical Apple marketing speak. If I translate this into what Apple actually means, they are giving you a high resolution full array local dimming mini-LED LCD with true HDR functionality.

If we dive deeper into the specs, the 16.2-inch panel has a resolution of 3456 x 2234 which continues Apple"s tradition of using non-standard resolutions across their line-up. Apple doesn"t disclose the exact technology used here, but it"s an LCD panel which appears to be IPS-like in design. The backlight has 10,000 mini-LEDs for impressive zone density at this size, allowing for a contrast ratio of 1,000,000:1 and peak brightness up to 1,600 nits in the HDR mode on paper.

As for refresh rate, Apple are offering up to 120Hz with adaptive sync, which they"ve rebranded into "ProMotion" although this sort of functionality has been available for many years now in other laptops and displays. The combination of everything though is a first, and the only rivals to this sort of panel are the latest wave of 4K OLED panels seen in a few high-end Windows laptops.

I tried a couple of the other modes as well, here is the BT.709 mode which is perfect for mastering SDR video content. Accuracy is great, not quite as good as the sRGB mode but still excellent for content creation with confidence that it"s correct. Apple also does a decent job with the DCI-P3 mode if you need to create video content in that color space, nailing the green-tinted white point and delivering decent gamma except for one flaw in the low gamma range.

In any case, the mini-LED backlight is active at all times, even in SDR content, to improve the contrast ratio in SDR scenes. There are so many zones here that it"s unlikely you"ll spot much blooming in practice, I found it negligible for SDR use even in tricky desktop apps with harsh edges between light and dark areas. The dimming algorithm is tweaked nicely to avoid this situation and there are simply more than enough zones to prevent lingering issues. This sort of attention to detail is what I"d love to see more in the standalone monitor space, along with higher zone counts, of course.

In the HDR mode, brightness is extremely impressive. There"s no major difference between sustained and peak brightness, so there"s no automatic brightness limiter that activates after a short period to dim the screen in intensely bright scenes. Brightness is as high as 1670 nits at small window sizes, and over 1500 nits at 50%, before dropping to around 1150 nits for a full screen sustained white window. That"s impressive, although it does come with a corresponding increase to power consumption, so running the display at over 1000 nits all the time isn"t advisable on battery.

This performance also destroys basically any other LCD based monitor I"ve looked at before. On the standalone monitor side, it"s virtually unheard of right now to see LCD zone counts higher than a couple of thousand. This limits worse case contrast to around 12,000:1 in the case of the 2,000-zone Samsung Odyssey Neo G9 with VA technology, or just 4,000:1 in a checkerboard test.

Apple choosing to use 5-10x the zone count massively improves the achievable contrast ratio in tricky situations and I"d say this amount of zones - and the density of zones - is what is required as a minimum for the best HDR experience with an LCD panel. Even Apple"s own ridiculously overpriced Pro Display XDR doesn"t compare as it has a paltry 576-zone backlight and it was criticized at launch for poor blooming compared to professional level HDR mastering displays. The MacBook Pro"s display will be far better for producing HDR content, aside from the small size.

So from one perspective it"s easily one of the best LCD-based HDR experiences I"ve seen, but on the other hand it isn"t a self-lit panel like an OLED which is completely free of blooming and in some situations OLED still delivers better HDR. Of course, OLEDs have other drawbacks such as lower brightness levels and the risk of burn in so I can understand why Apple would opt for LCD instead. Besides this one complaint though the HDR experience is excellent, especially for a laptop.

Unfortunately there is a major drawback to the Liquid Retina XDR display used on the new MacBook Pros, and that"s the motion performance. While it"s nice to see Apple upgrade the refresh rate to 120Hz compared to the 60Hz they were using previously, the display being used here doesn"t have the appropriate level of response times to keep up with that 120Hz refresh rate. The panel is actually very, very slow, which is a disappointment.

In a full black to full white transition, gamma corrected as per our current test methodology, the MacBook Pro"s display is exceptionally slow, taking nearly 100ms to complete this rise. Even if we apply exceptionally generous tolerances and only measure 60% of the total transition time, it still takes 39ms to transition, which is one of the worst results I"ve ever measured.

This is exacerbated by using a combination of IPS-like LCD technology, and an always-active mini-LED backlight, noting that both the LCD layer and mini-LED need to change to transition fully.

Luckily full transition fall times aren"t as horrific, though still reasonably poor at over 15ms even with our very generous 20% tolerance. The real transition time is more like 35ms, so less than half that of the rise time, but far slower than most other LCDs out there. The best laptop grade OLED panels can perform these transitions in under 2ms with the same test conditions, making them an order of magnitude faster.

I tested a few more transitions of varying degrees and typically the MacBook Pro would fall between 20 and 40ms, though luckily there is no overshoot to speak of. When viewing UFO test results, you can see the product of these horrific response times: a substantial blur trail behind moving objects. Even though the panel can feel somewhat smooth to use because it has a moderate refresh rate of 120Hz, the actual clarity in motion is terrible and this impacts the usefulness of the higher refresh rate.

Right next the MacBook Pro we have the Aero 15 OLED"s panel which has half the refresh rate at just 60Hz, but massively faster response times. You"ll see here that even though the MacBook Pro"s display is twice as fast in refresh rate, the extremely slow response behavior limits motion clarity to more like a 60Hz monitor or worse. The level of smearing is insane and I"m not sure how a modern LCD could end up this slow, Apple really should have experimented with some sort of overdrive.

Now, all Apple fans are probably sitting here annoyed that I"m criticizing the display for motion performance because the MacBook Pro isn"t a gaming laptop. And they"re right, it"s not a gaming laptop. But motion performance is relevant beyond gaming, it impacts things as basic as scrolling through websites or even watching videos. Fast moving video content like sports is affected due to slow transition times, and scrolling through text can show really bad ghosting trails, especially with white text on a black background. But really anything on this display that moves, especially stuff that moves fast, can quickly become a blur fest.

The Liquid Retina XDR display has impressive HDR specifications and performance. A mini-LED backlight zone count of 10,000 is the star of the show in this respect, significantly reducing blooming compared to other LCD-based HDR monitors, and providing exceptionally high brightness. The level of performance is good enough for both enthusiast level mastering and HDR playback, so the MacBook Pro is a great device for video editing on the go when you also factor in its overall performance.

A few nitpicks aside, the major downside to the display is motion performance. This display is exceptionally slow even for an LCD, despite packing a 120Hz refresh rate. This affects areas including web browsing and any work with text as you scroll through content, and blur trails can be visible across a wide range of use cases, not just gaming. It"s not bad enough to negate the benefits you get elsewhere, but Apple needs to put a lot of work into optimizing how quickly their panels transition. I also feel the lack of HDMI 2.1 on the MacBook Pro is a bit puzzling, going HDMI 2.0 for external monitors (in addition to Thunderbolt) is a bit annoying.

The only real competition right now are OLED panels, which come with their own set of strengths and weaknesses. There are a few other mini-LED laptop options on the Windows side, like the screen you get in the Acer Predator Helios 500, but that display only has 512 zones, not the 10,000 on offer here. So it"s a battle between the MacBook and the OLEDs you see in products like the Gigabyte Aero 15 OLED.

The reasons to get an OLED display over this LCD would be in terms of its self-lit pure HDR experience with zero blooming, significantly faster response times for better motion clarity, and wider color gamut allowing for accurate work in the Adobe RGB color space as well as P3 and Rec.709. However, the drawbacks are also significant, including a 60Hz refresh rate limitation with current 4K offerings, the risk of permanent burn in, and significantly lower brightness. Actual implementations we"ve seen also lack the calibration Apple is offering.

One of today’s modern technological wonders is the flat-panel liquid crystal display (LCD) screen, which is the key component we find inside televisions, computer monitors, smartphones, and an ever-proliferating range of gadgets that display information electronically.What most people don’t realize is how complex and sophisticated the manufacturing process is. The entire world’s supply is made within two time zones in East Asia. Unless, of course, the factory proposed by Foxconn for Wisconsin actually gets built.

Liquid crystal display (LCD) screens are manufactured by assembling a sandwich of two thin sheets of glass.On one of the sheets are transistor “cells” formed by first depositing a layer of indium tin oxide (ITO), an unusual metal alloy that you can actually see through.That’s how you can get electrical signals to the middle of a screen.Then you deposit a layer of silicon, followed by a process that builds millions of precisely shaped transistor parts.This patterning step is repeated to build up tiny little cells, one for each dot (known as a pixel) on the screen.Each step has to be precisely aligned to the previous one within a few microns.Remember, the average human hair is 40 microns in diameter.

On the other sheet of glass, you make an array of millions of red, green, and blue dots in a black matrix, called a color filter array (CFA).This is how you produce the colors when you shine light through it.Then you drop tiny amounts of liquid crystal material into the cells on the first sheet and glue the two sheets together.You have to align the two sheets so the colored dots sit right on top of the cells, and you can’t be off by more than a few microns in each direction anywhere on the sheet.The sandwich is next covered with special sheets of polarizing film, and the sheets are cut into individual “panels” – a term that is used to describe the subassembly that actually goes into a TV.

For the sake of efficiency, you would like to make as many panels on a sheet as possible, within the practical limitations of how big a sheet you can handle at a time.The first modern LCD Fabs built in the early 1990s made sheets the size of a single notebook computer screen, and the size grew over time. A Gen 5 sheet, from around 2003, is 1100 x 1300 mm, while a Gen 10.5 sheet is 2940 x 3370 mm (9.6 x 11 ft).The sheets of glass are only 0.5 - 0.7 mm thick or sometimes even thinner, so as you can imagine they are extremely fragile and can really only be handled by robots.The Hefei Gen 10.5 fab is designed to produce the panels for either eight 65 inch or six 75 inch TVs on a single mother glass.If you wanted to make 110 inch TVs, you could make two of them at a time.

The fab is enormous, 1.3 km from one end to the other, divided into three large buildings connected by bridges.LCD fabs are multi-story affairs.The main equipment floor is sandwiched between a ground floor that is filled with chemical pipelines, power distribution, and air handling equipment, and a third floor that also has a lot of air handling and other mechanical equipment.The main equipment floor has to provide a very stable environment with no vibrations, so an LCD fab typically uses far more structural steel in its construction than a typical skyscraper.I visited a Gen 5 fab in Taiwan in 2003, and the plant manager there told me they used three times as much structural steel as Taipei 101, which was the world’s tallest building from 2004- 2010.Since the equipment floor is usually one or two stories up, there are large loading docks on the outside of the building.When they bring the manufacturing equipment in, they load it onto a platform and hoist it with a crane on the outside of the building.That’s one way to recognize an LCD fab from the outside – loading docks on high floors that just open to the outdoors.

LCD fabs have to maintain strict standards of cleanliness inside.Any dust particles in the air could cause defects in the finished displays – tiny dark spots or uneven intensities on your screen.That means the air is passed through elaborate filtration systems and pushed downwards from the ceiling constantly.Workers have to wear special clean room protective clothing and scrub before entering to minimize dust particles or other contamination.People are the largest source of particles, from shedding dead skin cells, dust from cosmetic powders, or smoke particles exhaled from the lungs of workers who smoke.Clean rooms are rated by the number of particles per cubic meter of air.A class 100 cleanroom has less than 100 particles less than 0.3 microns in diameter per cubic meter of air, Class 10 has less than 10 particles, and so on. Fab 9 has hundeds of thousands of square meters of Class 100 cleanroom, and many critical areas like photolithography are Class 10.In comparison, the air in Harvard Square in Cambridge, MA is roughly Class 8,000,000, and probably gets substantially worse when an MBTA bus passes through.

The Hefei Gen 10.5 is one of the most sophisticated manufacturing plants in the world.On opening day for the fab, BOE shipped panels to Sony, Samsung Electronics, LG Electronics, Vizio, and Haier.So if you have a new 65 or 75-inch TV, there is some chance the LCD panel came from here.

When it comes to cleaning, flat-screen TVs and LCD screens require special care and a gentle touch. With the wrong technique, you can easily scratch the screen or damage the surface"s antiglare coating. Even rubbing too hard can cause pixels (the tiny dots that compose images on computer monitors and TV screens) to burn out and stop working permanently. Most household cleaning products are too harsh to use on electronic devices with LCD or OLED screens, so choose your TV cleaning strategy carefully. These tips on how to clean a TV screen will help protect your device while ridding it of dust, smudges, fingerprints, and streaks.

Samsung Display will stop producing LCD panels by the end of the year. The display maker currently runs two LCD production lines in South Korea and two in China, according to Reuters. Samsung tells The Verge that the decision will accelerate the company’s move towards quantum dot displays, while ZDNetreports that its future quantum dot TVs will use OLED rather than LCD panels.

The decision comes as LCD panel prices are said to be falling worldwide. Last year, Nikkei reported that Chinese competitors are ramping up production of LCD screens, even as demand for TVs weakens globally. Samsung Display isn’t the only manufacturer to have closed down LCD production lines. LG Display announced it would be ending LCD production in South Korea by the end of the 2020 as well.

Last October Samsung Display announced a five-year 13.1 trillion won (around $10.7 billion) investment in quantum dot technology for its upcoming TVs, as it shifts production away from LCDs. However, Samsung’s existing quantum dot or QLED TVs still use LCD panels behind their quantum dot layer. Samsung is also working on developing self-emissive quantum-dot diodes, which would remove the need for a separate layer.

Samsung’s investment in OLED TVs has also been reported by The Elec. The company is no stranger to OLED technology for handhelds, but it exited the large OLED panel market half a decade ago, allowing rival LG Display to dominate ever since.

Although Samsung Display says that it will be able to continue supplying its existing LCD orders through the end of the year, there are questions about what Samsung Electronics, the largest TV manufacturer in the world, will use in its LCD TVs going forward. Samsung told The Vergethat it does not expect the shutdown to affect its LCD-based QLED TV lineup. So for the near-term, nothing changes.

One alternative is that Samsung buys its LCD panels from suppliers like TCL-owned CSOT and AUO, which already supply panels for Samsung TVs. Last year The Elec reported that Samsung could close all its South Korean LCD production lines, and make up the difference with panels bought from Chinese manufacturers like CSOT, which Samsung Display has invested in.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey