naked lcd panel quotation

With a brightness of 5,000 nits, delivers images and videos that attract public attention, making it the ultimate display for outdoor visibility. This display uses Quarter Wave Panels (QWP) to ensure clear visibility, even through polarized lenses.

Shenzhen highlight special display technology Co., Ltd. is a professional manufacturer specializing in R & D, production and sales of highlight LCD display field. The company has a huge technical research and development, office space of more than 2500 square meters, specializing in the production and operation of outdoor super bright display, semi outdoor highlight display and military high requirements professional display; providing full-size (7-82) LCD module, LCD scheme design service Our company is mainly engaged in the customization, R & D, sales, after-sales service and other comprehensive businesses of high-quality LCD screen. It is one of the enterprises with product line Z in the field of LCD display in China, and has established long-term and stable business cooperation with many well-known enterprises at home and abroad.

We adopt advanced LED driving backlight technology, which can meet the large-scale production and manufacturing of customers, OEM / ODM OEM cooperation, and also meet the personalized customization needs of different customers. All product shapes, sizes and interfaces can be seamlessly replaced with LCD products with traditional CCFL backlight, greatly reducing the development cost and cycle of new products. We can develop the unique LCD backlight system according to the customer"s requirements. Whether it"s TV screen or ultra narrow edge splicing screen, it can achieve the brightness you are satisfied with and suitable for. We will always adhere to the tenet and principle of "independent innovation, integrity and mutual benefit, quality service, customer first"; highlight and show sincerity and look forward to communication and long-term cooperation with our customers. As always, we will pay close attention to the development trend of highlighted LCD products, especially the international splicing display technology, constantly develop new highlighted products, optimize and upgrade traditional products, meet market demand, guide market consumption, make the enterprise sustainable development, add new impetus to the development of the enterprise, and become the leader in the industry.

We engaged in high brightness LCD Screen industry with more than 8 years, understand the market, performance and application of LCD Screen, to provide customers with the best solution.

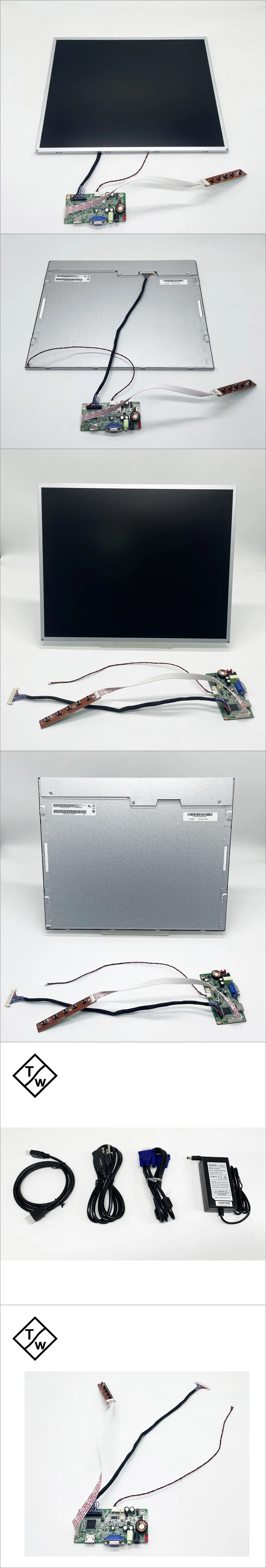

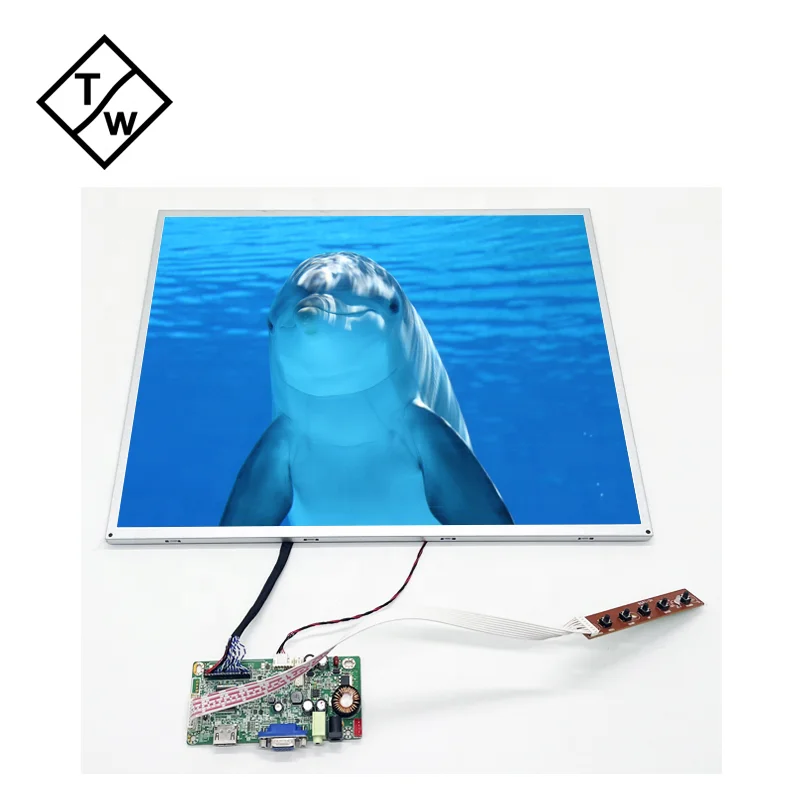

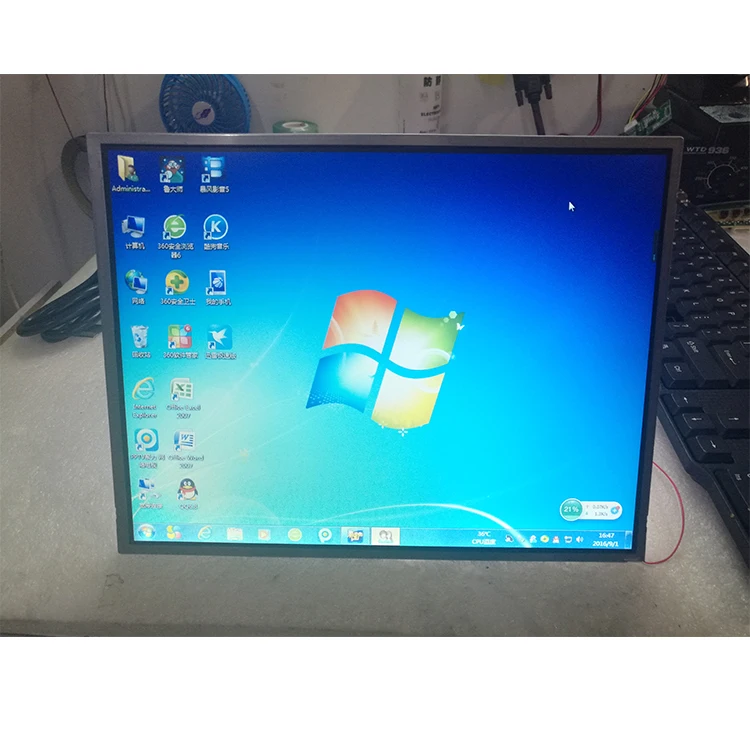

You can happily pick up the panel via the ribbon cables. These are actually very strong. All the manhandling done during its naked photoshoot didn"t hurt it. I reassembled it and use it as a secondary monitor.

Overall I dislike LCD technolgy it truely feels like jumping back to 16bit colour days. The banding is terrible. I did a lot of side by side image testing with a 21" CRT vs 22" LCD. DVD"s and HD images alike. At first, I honestly thought the LCD was faulty.

yep vectrex homebrew stuff is very nice, atari vcs/2600 is also extremely active and probably the most active in the scene... I just had a thought: did anyone tried to use a naked lcd panel as a filter screen to add colors to the vectrex?

Why can outdoor 3D LED displays attract people"s attention again? The reason is nothing more than that this type of 3D LED screen incorporates a new design concept, combined with naked-eye 3D LED display technology, to give people a supernatural and extremely ornamental visual sensory experience.

It is reported that the naked-eye 3D large-screen of Spaceship on Taikoo Li Chengdu was a Hot Search. The project takes into account the design concept of integrating "architectural aesthetics and business district environment". While looking forward to the prosperous city, it also puts people"s vision in the best viewing area in order to bring people an immersive visual experience.

From the “wave” of the wave tank LED display in Seoul, South Korea to the various naked-eye 3D LED displays that have recently appeared in China and all the LED display made by Chinese Manufacturer & Suppliers with Wholesale price, it can be seen that the visual sensory experience is gradually becoming a “hard indicator” in the development of LED displays, which is accepted by enterprises. As one of the main application scenarios of LED display, stage rental is also inseparable from the performance of visual sensory experience. It is foreseeable that the visual sensory experience will cover the entire LED display industry in the future.

Back in 2016, to determine if the TV panel lottery makes a significant difference, we bought three different sizes of the Samsung J6300 with panels from different manufacturers: a 50" (version DH02), a 55" (version TH01), and a 60" (version MS01). We then tested them with the same series of tests we use in all of our reviews to see if the differences were notable.

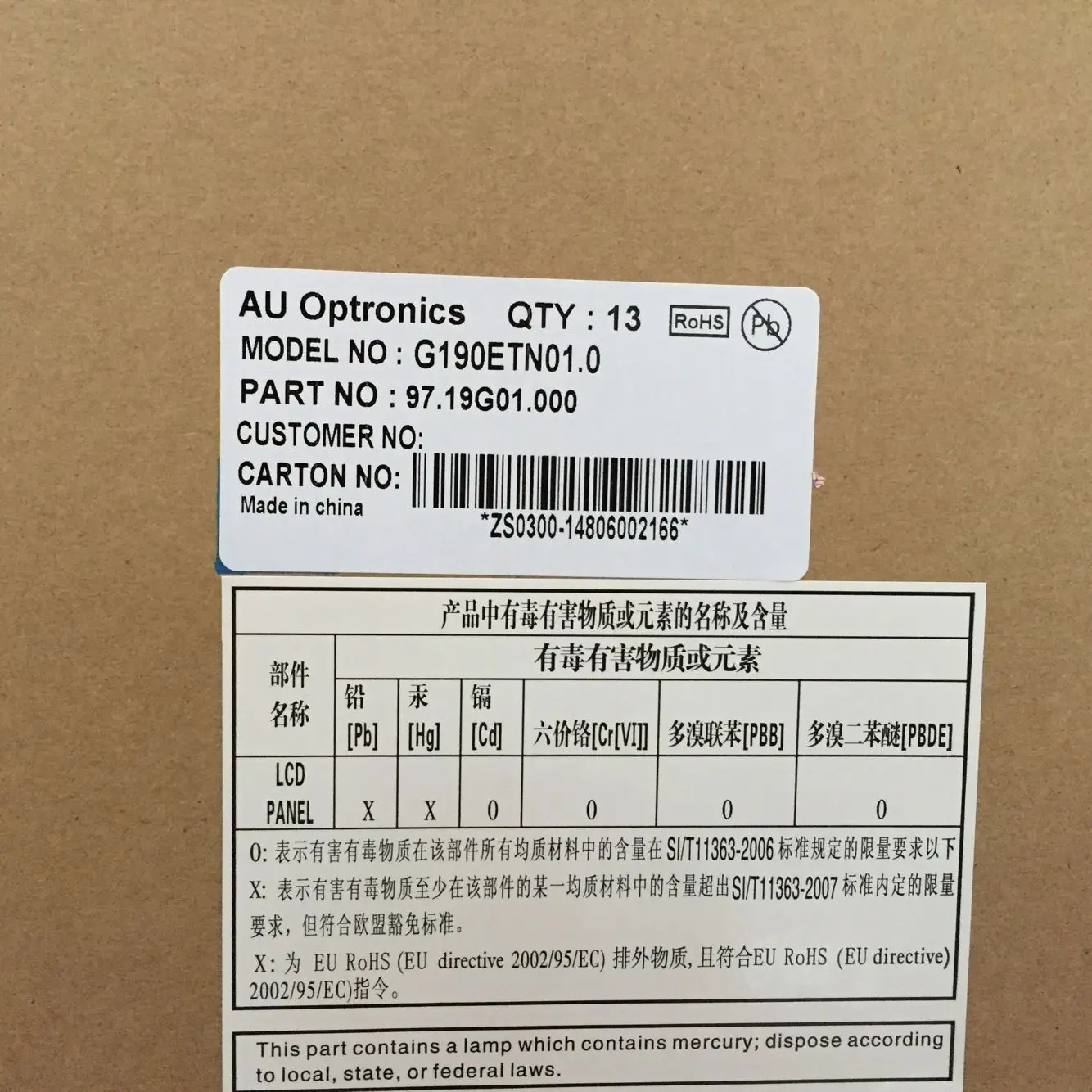

Our Samsung 50" J6300 is a DH02 version, which means the panel is made by AU Optronics. Our 55" has an original TH01 Samsung panel. The panel in our 60" was made by Sharp, and its version is MS01.

Upon testing, we found that each panel has a different contrast ratio. The 50" AUO (DH02) has the best contrast, at 4452:1, followed by the 60" Sharp (MS01) at 4015:1. The Samsung 55" panel had the lowest contrast of the three: 3707:1.

These results aren"t really surprising. All these LCD panels are VA panels, which usually means a contrast between 3000:1 and 5000:1. The Samsung panel was quite low in that range, leaving room for other panels to beat it.

The motion blur results are really interesting. The response time of the 55" TH01 Samsung panel is around double that of the Sharp and AUO panels. This is even consistent across all 12 transitions that we measured.

For our measurements, a difference in response time of 10 ms starts to be noticeable. All three are within this range, so the difference isn"t very noticeable to the naked eye, and the Samsung panel still performs better than most other TVs released around the same time.

We also got different input lag measurements on each panel. This has less to do with software, which is the same across each panel, and more to do with the different response times of the panels (as illustrated in the motion blur section). To measure input lag, we use the Leo Bodnar tool, which flashes a white square on the screen and measures the delay between the signal sent and the light sensor detecting white. Therefore, the tool"s input lag measurement includes the 0% to 100% response time of the pixel transition. If you look at the 0% to 100% transitions that we measured, you will see that the 55" takes about 10 ms longer to transition from black to white.

All three have bad viewing angles, as expected for VA panels. If you watch TV at an angle, most likely none of these TVs will satisfy you. The picture quality degrades at about 20 degrees from the side. The 60" Sharp panel is worse than the other ones though. In the video, you can see the right side degrading sooner than the other panels.

It"s unfortunate that manufacturers sometimes vary the source of their panels and that consumers don"t have a way of knowing which one they"re buying. Overall though, at least in the units we tested, the panel lottery isn"t something to worry about. While there are differences, the differences aren"t big and an original Samsung panel isn"t necessarily better than an outsourced one. It"s also fairly safe to say that the same can be said of other brands. All panels have minute variations, but most should perform within the margin of error for each model.

Micro-LED display is considered to be the most promising display technology, and naked-eye 3D display represents the most advanced frontier of display. Naked-eye 3D micro-LED display has both the advantages of micro-LED display and the characteristics of naked-eye 3D display. Only conceptual solutions for 3D micro-LED display have been reported so far. The effect of luminescence distribution and the direction of micro-LED devices on crosstalk in the naked-eye 3D display is not clear. In this paper, we first investigated the chip-shaping effect on the emission characteristics, mainly the luminescence distribution and direction of the micro-LED, and then we investigated the influence of luminescence distribution and direction of micro-LED on the pixel crosstalk in naked-eye micro-LEDs 3D display. Our work should advance the micro-LED display, especially the micro-LED 3D display.

4. In terms of hardware—–Compared with traditional LED products, naked-eye 3D LED screens pay more attention to high refresh, high grayscale, high dynamic contrast. And the smooth transition between curved surfaces and corners. In addition, the playback server needs to be connected to a professional graphics workstation and configure a multi-graphics frame synchronization card.

With the rapid development of a new generation of information and communication technology, as a terminal device, smart phones, tablet PCs, smart homes and other products, the market demand continues to grow, LCD panel production scale has increased dramatically, becoming one of the pillars of the information industry. The rise of the LCD panel industry has led to a surge in demand for panel quality inspection. Traditional defect detection is mainly identified by the human eye, which brings great difficulties to enterprises to control production quality and improve production efficiency. In view of this, the adoption of a new panel quality inspection method to replace manual inspection is an urgent technical problem to be solved.

Thin film transistor liquid crystal display (TFT-LCD) has the advantages of high resolution and low power consumption, so it is widely used in the display industry. The production process of TFT-LCD display includes coating, etching, developing, panel combination, crystal filling and sealing, and driver chip installation, etc. The complex process leads to defects, including point defects, line defects and Mura defects. The word “Mura” comes from Japanese and translates to spot, dirt, also known as “cloud spot”, which is one of the most difficult defects to detect in display defects. The traditional Mura inspection method is achieved by manual visual inspection, mainly by naked eye discrimination. This method is inefficient and prone to visual fatigue, which leads to a lower correct result rate. Machine vision-based LCD panel inspection can be realized to detect defects generated by each production process of LCD panels, including Array (array) process, CF (color film) process, CELL (boxing) process, Module (module) process, crack (crack), broken (broken), chip (chipped), scratch (scratch), burr (burr). We can effectively detect and distinguish defects such as crack, broken, chip, scratch, burr and drop.

LCD panel production process will be probable chipping, breakage, cracks, scratches and other defects, if not found and dealt with in a timely manner, into the next production process of the main equipment, may occur during the production process in the equipment inside the glass breakage phenomenon, so that the main equipment must be shut down for maintenance and cleaning, resulting in economic losses of production downtime.

In recent years, many computer vision-based panel defect detection systems have emerged, but the defect detection algorithms utilized by various manufacturers are basically more traditional vision methods. However, as the production process continues to progress, the detection requirements are subsequently increased, the detection accuracy requirements are also increasing, and the real-time requirements for the algorithms are greatly improved. With the rise of deep learning, for such difficult-to-detect defects, we use convolutional neural networks (CNN) for the detection of screen defects. For the detection problem, there are many existing target detection algorithms that can achieve higher accuracy and real-time detection, effectively identifying and classifying LCD panel defects – achieving defect detection for chipped edges, cracks, dirt, water drops, scratches, etc., and interfacing with the main production equipment, detecting defects and then automatically making, according to the type of defect Feedback judgment: stop or alarm, no need for real-time monitoring by staff on site.

Using line array camera, lens, according to the detection demand items, choose to match the backlight, coaxial light or high bright line light source for LCD panel image acquisition, in the process of scanning pictures, intelligent algorithms simultaneously processing images, real-time display of the panel defect information, determine whether the surface has foreign objects, scratches, different colors, convex bags, dents, pinholes, burrs, bright spots, for defective glass, real-time linkage of the main equipment to stop and other related operations to prevent the main equipment downtime due to broken glass in the production process.

1、Open the product into 180°, place the LCD screen horizontally on the carrier table; 2、Start inspection: the carrier table moves and the camera starts to acquire images; 3、After the acquisition, the carrier table is reset; 4、Inspection software: analyze the quality of the LCD screen; 5、According to the analysis result, give the OK and NG evaluation result of the product; 6、Operator: according to the result, carry out binning operation and reinspection operation;

As you increase your display resolution, it gets harder to pick out individual pixels with the naked eye, and the clarity of the picture increases in turn.

It"s also worth considering your own eyesight and desktop setup. If you have 20/20 vision and your eyes are around 20” from your screen, a 27” 4K panel will provide an immediate visual upgrade. However, if you know your eyesight is worse than 20/20, or you prefer to sit more than 24” away, a 1440p panel may look just as good to you.

Use caution when LCDs advertise very high “dynamic contrast ratios”, which are achieved by changing the behavior of the backlight. For gaming or everyday use, the standard “static” contrast ratio discussed above is a better marker of the monitor"s quality.

Black LevelIn all LCD screens, light from the backlight inevitably leaks through the liquid crystal. This provides the basis for the contrast ratio: For example, if the screen leaks 0.1% of the illumination from the backlight in an area that"s supposed to be black, this establishes a contrast ratio of 1,000:1. An LCD screen with zero light leakage would have an infinite contrast ratio. However, this isn"t possible with current LCD technology.

“Glow” is a particular issue in dark viewing environments, which means that achieving low black levels is a major selling point for LCD monitors. However, an LCD screen can’t reach a black level of 0 nits unless it’s completely turned off.

Some inexpensive LCD panels use 6-bit color along with “dithering” to approximate 8-bit color. In this context, dithering means the insertion of similar, alternating colors next to one another to fool the eye into seeing a different in-between color that the monitor cannot accurately display.

Monitors advertising "99% sRGB" are claiming the screen covers 99% of the sRGB color gamut, which is often considered indistinguishable from 100% when viewed with the naked eye.

In LCD screens, the backlight and color filters determine the color space. All of the light created by the backlight passes through a color filter with red, green, and blue spots. Narrowing the “band-pass” of this filter restricts the wavelengths of light that can pass through, increasing the purity of the final colors produced. Although this lessens the screen"s efficiency (as the filter now blocks more of the backlight"s output), it creates a wider color gamut.

For LCD displays, a high-end backlight feature called local dimming is critical to HDR quality. Dimming zones for the backlight behind the screen control the brightness of groups of LEDs; more dimming zones means more precise control, less “blooming” (where light areas of the image brighten dark ones), and generally improved contrast.

Full Array Local Dimming (FALD), a more high-end option, uses far more dimming zones (typically hundreds) directly behind the panel rather than just at the edges of the screen. It can give more finite control of the HDR content and dimming of the screen as a result.

Both LCDs and OLEDs "sample and hold", displaying moving objects as a series of static images that are rapidly refreshed. Each sample remains onscreen until it"s replaced with the next refresh. This "persistence" causes motion blur, as the human eye expects to track objects smoothly rather than see them jump to a new position. Even at high refresh rates, which update the image more often, the underlying sample-and-hold technology causes motion blur.

This mimics the operation of older CRT monitors, which worked differently than current LCD technology. CRT screens were illuminated by phosphors that rapidly decayed, providing brief impulses of illumination. This meant that the screen was actually dark for most of the refresh cycle. These quick impulses actually created a smoother impression of motion than sample-and-hold, and motion blur reduction features work to replicate this effect.

Liquid Crystal Display (LCD)In TFT LCDs (thin-film-transistor liquid crystal displays), a backlight shines light through a layer of liquid crystals that can twist, turn, or block it. The liquid crystals do not emit light themselves, which is a key difference between LCDs and OLEDs.

Older LCDs used Cold-Cathode Fluorescent Lamps (CCFLs) as backlights. These large, energy-inefficient tubes were incapable of controlling the brightness of smaller zones of the screen, and were eventually phased out in favor of smaller, energy-efficient light-emitting diodes (LEDs).

LCD panels are available in a range of technologies and can vary widely in color reproduction, response time, and input lag, especially among high-end options. However, the following generalizations about panels usually hold true:

Oldest and most affordable LCD panel type. High refresh rates and response times for high-speed gaming such as first-person shooters or fighting games.

Vertically aligned liquid crystals line up with two polarizers, rather than twisting, as in a TN panel. When in a resting state, the crystals can more effectively block illumination than TN panels.

Often slow response times, particularly on black-to-gray color transitions, often resulting in “black smearing” in motion. Wider viewing angles than TN panels, but often less than IPS panels. Some VA panels suffer significant color shift when viewed off-axis.

Widest viewing angles. Most stable image quality. Deeper blacks and better contrast ratios than TN panels. Most are 6-bit+2, but 8-bit and 8+2 panels exist. Often highly rated premium panels.

Pale glow, known as “IPS glow” visible when viewing screens in dark rooms from off-center angles. Response times usually worse than TN panels, but better than VA panels. Lower contrast ratio than VA panels.

Organic Light-Emitting Diode (OLED)OLED screens are emissive, meaning they create their own light, rather than transmissive screens that require a separate light source (like LCDs). Here, the application of electric current causes a layer of organic molecules to light up on the front of the screen.

Backlights may be imperfectly blocked by the liquid crystals in an LCD, causing black areas of an image to appear gray. Because OLEDs have no backlight, they can achieve “true black” by simply turning off a pixel (or at least 0.0005 nits, the lowest measurable brightness).

OLEDs therefore boast very high contrast ratios and vibrant color. The elimination of the backlight also makes them slimmer than LCDs. Much as LCDs were a thinner, more energy-efficient evolution of CRTs, OLEDs may prove a thinner evolution of LCDs. (They can also be more energy-efficient when displaying dark content, like movies, but less energy-efficient with white screens, such as word processing programs).

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey