tn cob lcd module supplier quotation

A. We are a professional manufacturer, which specializes in TN, HTN, STN, FSTN, VA/BTN monochrome LCD, Micro OLED Screen, Color TFT Display Panels, LED Backlights, LCD Moduleslocated in Shenzhen and Jiangxi.

Dr Pan: Hello, Greg. COB is the abbreviation for chip on board. It is a technology, which IC is bonded directly onto PCB. COB technology is usually used in LCD module with sophisticated and complex functions.

There is a misunderstanding about COB LCD module. Since it is very stable, people would use this structure no matter what. But COG LCD module is very stable, too. It can totally replace simple COB LCD module with only display function and much cheaper for large quantity.

For the sophisticated LCD module with complex functions, COB technology may be the cheapest solution since it integrates all the components on one board and it can reduce the number of IC and board. But every coin has two sides. Even though it is very stable and there is a very small chance that it will malfunction, it will be irreplaceable if it does. There is why we recommend hybrid structure which integrate COB technology and COG technology together. It has all the merits of both technologies.

Dr Pan: Hello, Greg. TN is the abbreviation for Twisted Nematic. The main difference between TN, HTN, STN and FSTN LCD is the view angle. From the definition, the maximum view angle of TN LCD is 90°. Take this TN positive LCD for example. The view angle is 6 o’clock direction and it can be seen very clearly in the 6 o’clock direction and the front side.

Theoretically, we can add a blue film to TN negative LCD, it may look like this. Actually, from our experience, no one has done it before since HTN or STN negative LCD with blue background looks better with wider view angle.

TN LCD is the most commonly used since it is the cheapest. The maximum COM is 4, so it can’t display too many segments, and it can’t be used in the high end devices. But it performs very well in the simple display content: calculator and alarm clock.

industrial LCD PANEL, lcd inverter , touch screen monitor , touch glass , Control board, , Keypad, servo drive and motor, PLC, Encoder , lcd inverter , fan, ECT...

Follow listed sections and review the LCD basic knowledge with us! Orient Display also has a friendly and knowledgeable team of technical support staff to help you with any specific questions you might have. Feel free to

In 1888, liquid crystals were first discovered in cholesterol extracted from carrots by Austrian botanist and chemist, Friedrich Reinitzer. In 1969, twisted-nematic (TN) mode of operation was discovered, which gave LCD the first commercial success. Learn more.

LCD stands for Liquid Crystal Displays which are commonly used in TVs and Computer monitors. it is also used as mobile device screens such as laptops, tablets and smartphones. Learn more.

Liquid crystals were actually discovered over 100 years ago, but they did not find commercial applications until the invention of the twisted nematic (TN) LCD by Schadt and Helfrich in 1971 (Schadt and Helfrich, 1971).Learn more.

The biggest problem with early multiplexed LCDs was the reduction in contrast ratio with number of addressed lines. This problem was essentially eliminated with the invention of the film compensated super-twisted nematic (FSTN) LCD in the early 1980s. Learn more.

When selecting a Liquid Crystal Display Module or LCD Glass Panel, it is very important to identify the the range of its environmental temperature. Outlined in this section are the normal and wide temperature ranges of the LCD Modules and LCD panels offered by Orient Display. Learn more.

The display resolution of a LCD is the number of distinct pixels in each dimension that can be displayed. It is usually quoted as width × height, with the units in pixels. Learn more.

Is AMOLED technology ready to offer a better alternative to TFT-LCDs for industrial applications? Are advances in TFT keeping up with the clarity offered?Learn more.

Passive LCD, Active LCD and PMOLED , AMOLED are everywhere these days, but what’s the difference & which is better. Learn about the difference between Passive matrix LCD, Active matrix LCD and PMOLED, AMOLED, so next time you are starting a project, you know which one you need. Learn more.

Passive matrix LCDs does not reduce the digital transmitting area with transistor structures, so there is more space for both reflective and transmisive elements with in each sub pixel of a transflective color display.

Excel Display provides color STN displays for E-Book, PDA, Mobile Phone, Hand PC, Web Pad, Screen Phone, IP Phone and Smart Phone among other applications.

These modules are currently supplied with a default I2C address of either 0x27 or 0x3F. To determine which version you have check the black I2C adaptor board on the underside of the module. If there a 3 sets of padsread more...

Our company is committed to the customization service, R&D, sale and after-sales service of LCD and TFT display products.At present, our company has a team of more than 100 employees. Our products include monochrome LCD (TN and STN), color LCD (CSTN and TFT) and LCD modules (both COG and COB).

Tri T offer a wide range of standard Character LCD Modules for a variety of applications using a multitude of LCD and LED backlight colour combinations ideal for achieving the perfect look for any product.

As a leading manufacturer of small-to-medium-sized LCDs, we at Tri T offer a complete range of solutions for a wide range of applications, from automotive and industrial to other applications.

Liquid Crystal Displays or more commonly known as LCDs are one of the most common electronic components which help us interact with an equipment or a device. Most personal portable equipment and even gigantic industrial equipment utilize a custom segment display to display data. For many portable consumer electronics, a segment LCD display is one of the biggest contributors to the overall cost of the device, hence designing a custom segment display can drive the cost down while also utilizing the display area in the most optimum manner. These displays have the lowest cost per piece, low power requirements, and a low tooling fee too.

At first thought, designing a custom segment LCD might look like a Herculean task, but trust me that it is easier than it seems. In this article, we have summarised and compared the display types and available technologies which are required to construct a custom segment LCD. We have also provided a flowchart that can act as a step-by-step guide while you design your own custom LCD. We have also provided the process we followed, a require gathering sheet we used for communicating our needs to the manufacturer, and a few other data and the quotation we received from the manufacturer.

LCD Bias– It denotes the number of different voltage levels used in driving the segments, static drives (explained later in this article) only have 2 voltage levels or 2 bias voltage while multiplex drives have multiple voltage levels. For example, 1/3 will have 4 bias voltages.

LCDs utilizes the light modulating properties of liquid crystals which can be observed by using polarizing filters. Polarizing filters are special materials that have their molecules aligned in the same direction. If the light waves passing through polarisers have the same orientation as the filter, then the molecules of lights are absorbed by the filter, hence reducing the intensity of light passing through it, making it visible.

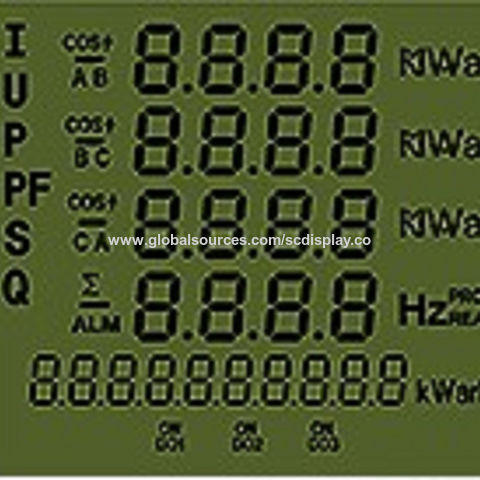

A custom LCD is important for maximizing the efficiency of the display area by adding custom symbols and characters. It also helps in reducing the cost and improving energy efficiency of the product. A higher number of custom symbols and specified placement of numerical and alphanumerical characters make the display more informative and readable for the user. This makes it look better than the plain old boring displays we get in the market. Furthermore, we can specify the viewing angle, contrast, and other specifications which can increase durability or give a better value for money for our intended usage. A typical Custom Segment display is shown below, we will also show you how to design and fabricate the same further in the article.

The LCD display doesn’t emit any light of its own, therefore it requires an external source of illumination or reflector to be readable in dark environments.

While designing a custom segment LCD display, we have the leverage of choosing a lot of parameters that affect the final product. From the color of the display to the illumination technique and color of illumination as well as the type of input pins. Some important considerations we need to take while designing a custom 7 segment display are - the type of display, i.e. positive or negative, illumination method, driving technique, polarising type, and connection method. All these design criteria are explained below:

So, which one should you choose? When the displays are to be used in areas with higher ambient light, we should select positive segment LCD display as it has better visibility than negative segment LCD displays without using a backlight.

As we know that LED displays don’t emit any light, hence to illuminate it and make it visible in a dark environment, we can use different methods of illumination. The most common LCD Illumination methods are compared below:

For displays that need to be used for budget-friendly devices that should be small and rugged, LED lights are preferred for the displays due to the high durability and low cost of operations. For high brightness, CCFL and Incandescent lights can be used.

A polarizer film is the most important component of an LCD display, which makes it possible to display characters by controlling the light. There are 3 types of polarizers that can be used in the LCD display, the properties and difference are given below:

If your displays have fewer segments, then static LCD drive is preferred as it is easier to control and cheaper to construct, and has a better contrast ratio. But let’s say that if the number of segments in the display are more than 30-40 then a multiplex LCD drive should be preferred as it has multiple common pins, hence reducing the total number of pins required to drive the display.

Choosing a connector type!!! For the prototyping phase or if you need to connect your LCD display on a Microcontroller directly, a pin type connector is the best and most economical option you have. If you need to connect your LCD display in a final product with a high volume of production which also requires to be extremely durable, but at the same time should not take up a lot of space, a Flex type LCD Connector will work best for you

LCDs have limited viewing angles and when seen from an angle they lose contrast and are difficult to be observed. The viewing angle is defined by the angles perpendicular to the center of the display towards its right, left, up, and down which are denoted by the notations 3:00, 9:00, 12:00, and 6:00 respectively. The viewing angle of LCD can be defined as the angle w.r.t. to the bias angle at which the contrast of segments is legible.

To improve the viewing angle in an LCD, a Bias is incorporated in the design which shifts the nominal viewing angle with an offset. Another technique is to increase the Voltage, it affects the bias angle, making the display crisper when viewed from a direction.

For example, the viewing angle of a TN type TFT LCD is 45-65 degrees. Extra-wide polarising film (EWP) can increase the viewing angle by 10 degrees, using an O film polariser can make the viewing angles 75 degrees but these come at a cost of reduced contrast.

LCD Control chip or LCD driver chips can be mounted on the flex cable, display, or externally on a PCB. The placement of LCD control chip can affect the cost and size of the display. The 2 most common methods of chip placement are-Chip of Board (COB)and Chip on Glass(COG) which are described below:

COG can be used as it is cheaper and makes the assembly process simpler, but if the dimensions are a constraint, then the COB is also a viable option.

We planned to design an air quality monitoring system for which we needed a custom segment LCD panel for an air quality monitoring device. Our product needs to display the following data: 2.5-micron and 10-micron particulate matter (PM) suspended in the air; the units should be in parts per million (PPM). CO2 in the air in PPM along with total volatile organic compounds present in the air in parts per billion (PPB). To make the product more usable, we included time in 24-hour format, Temperature in ºC, Battery status, loudspeaker status, Bluetooth status, and Wi-Fi status. And for some personal touch, we also added how good the air quality in the room is by using 3 different smileys.

We realized that it was impossible to provide all these data in a generic LCD available in the market, thus decided to build a custom LCD for our project.

A step-by-step flowchart is shown below to walk you through each and every step of selecting components and getting your custom segment LCD manufactured.

Since the device was meant to be used inside houses and offices, which are more often than not well lit and protected from environmental conditions, we opted for a positive mode display. For superior contrast ratio and better viewing angle, we chose a Film Super Twisted Nematic Display (FSTN) with a drive condition of 1/8 Duty and bias of 1/4.

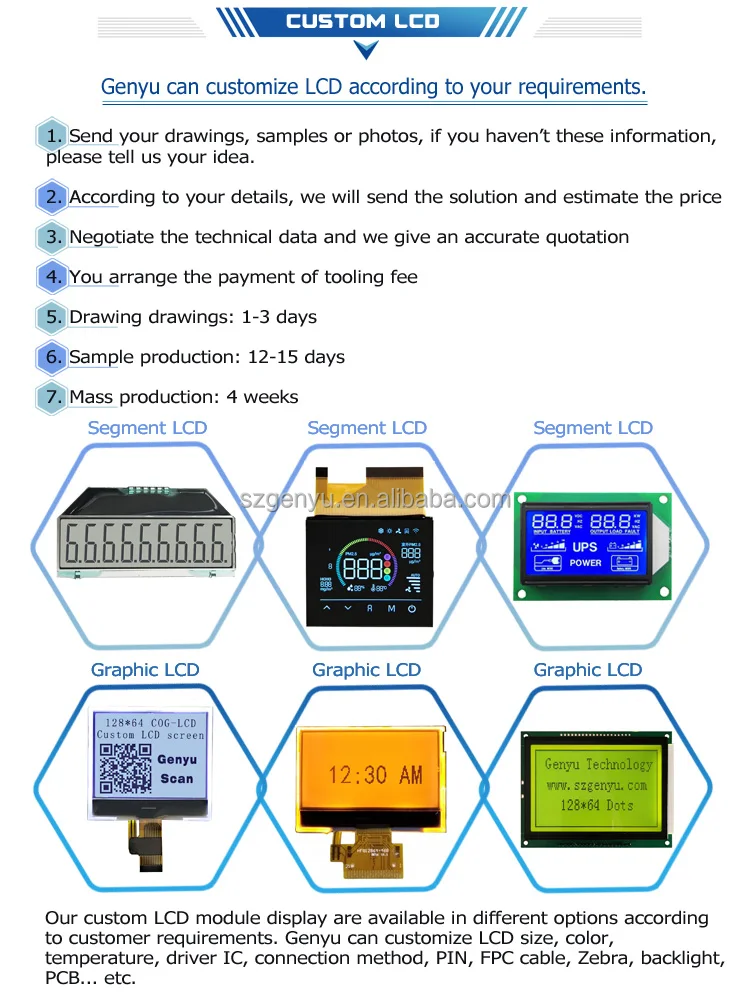

We mailed our requirements to multiple LCD manufacturers, (you will find a lot of LCD manufacturers on the Internet). Most LCD manufacturers have competitive pricing, and reply within a week. A sample requirement sheet is shown above which a customer needs to fill to specify all the details to the manufacturer.

This is a sample Custom Segment LCD quotation we got from one of the manufacturers. As you can see, the cost is based on the quantity. Higher the quantity, lower the cost. Apart from the cost per quantity, there is one more component called tooling fees. Tooling fee is a one-time fee charged by the manufacturer. It is for the technical design, support, and customization of the product. Customization of PCB or tooling of LCD can drive the tooling price higher or lower.

A custom segment LCD can help you personalize your product while also saving the overall cost of your product. The whole process will take you around 2-3 months, which will include the designing phase, prototyping phase, and getting your custom segment LCDs delivered to your doorstep. Higher ordering quantity will reduce the cost per piece of each unit, thus driving down the cost of your final product.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey