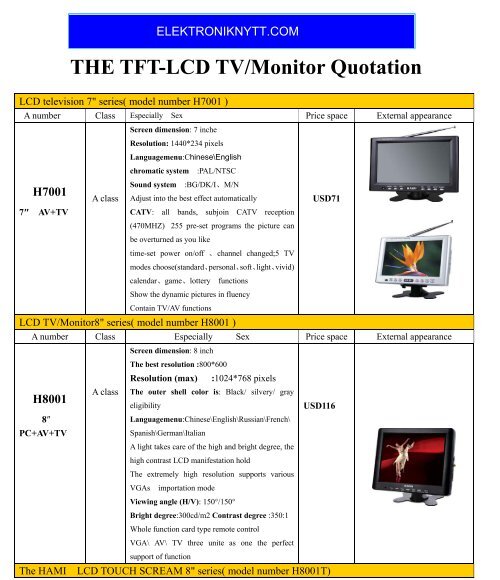

tft lcd application note quotation

Microtips Technology provides displays in many different industries around the world. Because of this, we have become familiar with certain requirements that are necessary in these different markets. Our team can guide and advise on what displays will be best for your particular application. We can also tune any of our standard displays to work better for your environment. We offer anything from wide-temperature fluid for automotive applications to display module ruggedization for harsh or humid environments to tuning our capacitive touchscreen with glove and stylus support in mind.

This application note was validated against specific versions of the kit only. It may not work with other versions. Supported versions are listed in the History section.

This application note describes the interfacing of Ampire AM-800480STMQW-TA1 display to BoraEVB and BoraXEVB. Main characteristics of this 7" TFT LCD panel are:

integrates a pad (denoted as TP1) that is used to connect 5V power supply generated by MOD2 PSU of BoraEVB. This additional power rails is required by display backlight circuitry.

In case of BoraXEVB, no adapter board is needed. LCD panel is directly connected to J26 connector where PL bank 13"s signals implementing LVDS interface are routed (see page 14 of the schematics). I/O voltage of bank 13 is set to 2.5V by configuring JP25 as shown in the following table.

To implement frame buffer, a portion of main SDRAM is used. This area is allocated at runtime by linux frame buffer driver. Even if LCD is 18 bpp, each pixel is represented by 32-bit word in memory. In fact each pixel is in RGB666 format, so for each colour only the six most significant bits of the frame buffer RGB888 are used to drive the display.

(*) This signal is used to control backlight. It is usually driven by a PWM signal whose duty cycle is proportional to backlight intensity. For the sake of simplicity, in this project this signal is driven by a GPIO, thus only two intensity levels are supported (0% and 100%). This is a CMOS 2.5V level signal. Make sure that voltage levels of this signal are compatible with LCD backlight input.

(*) This signal is used to control backlight. It is usually driven by a PWM signal whose duty cycle is proportional to backlight intensity. For the sake of simplicity, in this project this signal is driven by a GPIO, thus only two intensity levels are supported (0% and 100%). This is a CMOS 2.5V level signal. Make sure that voltage levels of this signal are compatible with LCD backlight input.

Put the binaries on the first (FAT32) partition of your BELK SD card, overwriting the original one if needed. Please note that you need the following files:

Once the kernel has completed boot, frame buffer can be accessed from user space applications via /dev/fb0 device file (for more details please refer to https://www.kernel.org/doc/Documentation/fb/framebuffer.txt).

Focus LCDs can provide many accessories to go with your display. If you would like to source a connector, cable, test jig or other accessory preassembled to your LCD (or just included in the package), our team will make sure you get the items you need.Get in touch with a team member today to accessorize your display!

Focus Display Solutions (aka: Focus LCDs) offers the original purchaser who has purchased a product from the FocusLCDs.com a limited warranty that the product (including accessories in the product"s package) will be free from defects in material or workmanship.

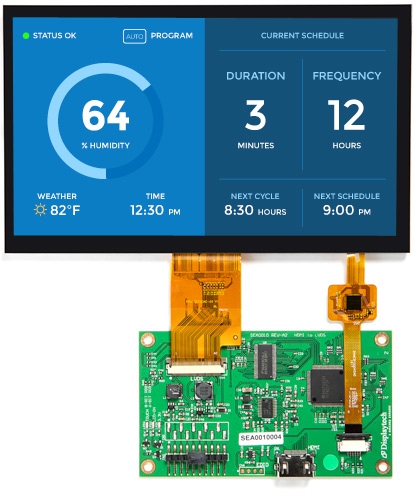

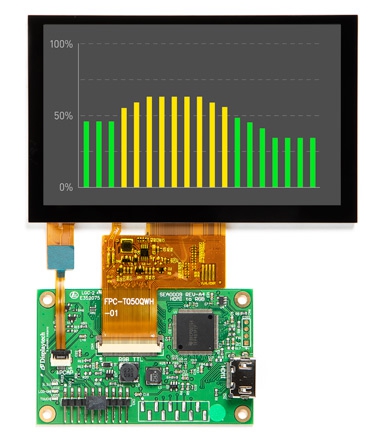

Showcase high quality graphics and images on our 800 x 480 7” TFT display! The DT070CTFT LCD module is an upgraded version to our DT070ATFT module. Compared to the previous model, this new 7 inch display offers improved viewing angle and brighter LEDs. The DT070CTFT also uses the Himax HX8264E + HX8664B display drivers. This LCD display is available with a resistive or capacitive touchscreen panel.

Please see the DT028CTFT for reference designs. The schematics between the A and the C are the same with the exception that the A does not have the IPS interface.

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

This application note describes GT-VP module’s touch panel features, USB communication setting up guide, touch sensitivity reference, and more useful information. To install the GT-VP module into your application smoothly, please refer this document first.

Two metallized layers(x-y) are overlaid onto an LCD screen. These thin-film metallic panels have a lower impedance than typical ITO** touch panels. This allows for a higher S/N ratio, wider touch sense margin, and better overall sensitivity.

I. Choi, H. Shim, and N. Chang, “Low-power color TFT LCD display for hand-held embedded systems,” Proc. of Symp. on Low Power Electronics and Design, Aug. 2002, pp. 112–117.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey