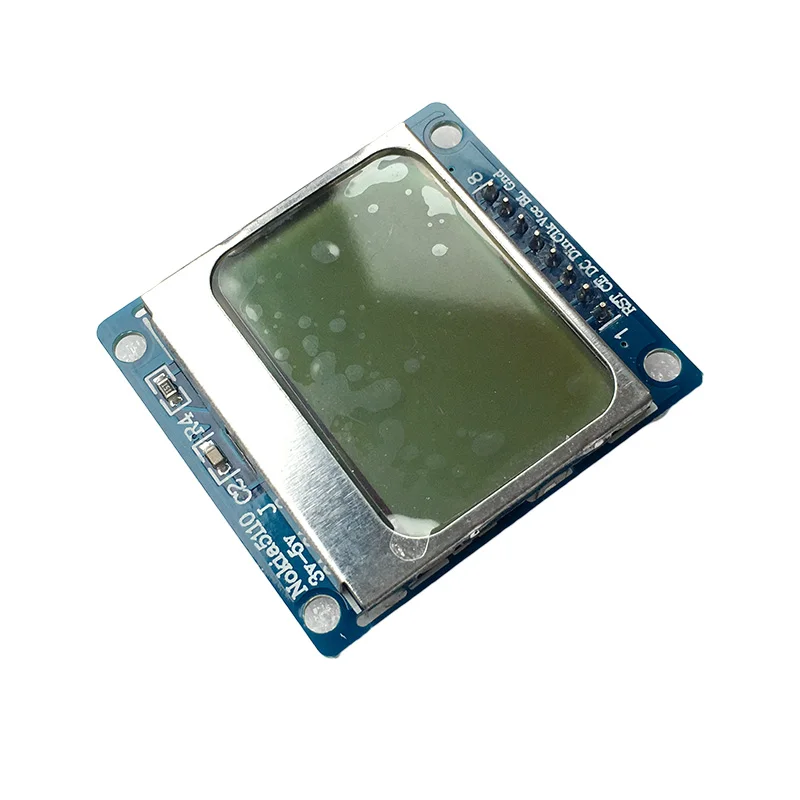

84 48 lcd module free sample

In the previous tutorial I showed how to build a weather station using DHT11 and BMP180 with an Arduino. However, the project has a downside which is the power consumption of the 16X2 LCD. If we were building a battery powered project with the desire to last for several weeks and probably several months, like a weather station for instance, then we’ll have to replace the LCD keypad shield from the previous tutorials and go for something like the low powered Nokia 5110 84×84 LCD display. In this tutorial I will be showing you how to drive this display with the Arduino and thus build projects with longer battery life.

The Nokia 5110 display is basically a graphic LCD display useful for a lot of applications. It was intended originally to be used as a screen for cell phones and was used in lots of mobile phones during the 90’s. This display uses a low powered CMOS LCD controller/driver PCD8544, which drives the graphic display of size 84×48. It is very cheap and costs about 3$. You can get one here.

The Nokia 5110 LCD can display text, graphics as well as bitmaps. When this display is fully lit, it draws about 10mA but with the backlight off, it draws as low as 0.4mA. The power consumed by this display is very low compared to that of the keypad LCD shield used in the previous tutorial. I will be using the Arduino Mega for this tutorial as usual and you can buy one here. You can also buy jumpers, breadboards and power bank which you will be needing for this tutorial.

Before we start writing the code for this project, first we need to download the 5110 LCD graph library that was made by rinky-dink electronics. The library does most of the heavy lifting and makes it easy for us o use the LCD. Click here to visit the download page and then download the LCD5110_graph zip file. When done, unzip the file to your preferred location and then rename the unzipped folder to something simple like “LCD5110”. Copy and paste this folder in your arduino library folder, then run your arduino IDE.

Click on the file, then on examples and then click on LCD5110. Since we are using the Arduino Mega, under the LCD5110 drop down click on Arduino (AVR) and the open up the LCD graph demo file.

The first line after the comment section, the LCD5110 library was included and after that a myGLCD object was created with the numbers being the pins to which the LCD is connected. The last two values in the myGLCD object is the RST and CS values which has been changed as explained initially.

with this done, we move to the setup function. In the setup function, the InitLCD method is used to initialize the display and this method takes in a parameter for the display contrast. The contrast value is between 0-127 and since we didn’t pass in any value the default value which is 70 will be used. Next, the setFont method is called which sets smallFont as the display font style is called and lastly, the randomSeed function which is used to initialize the random number generator using analogRead on an unconnected pin as a random input.

Most of the functions used in the project have names that are self-explanatory like myGLCD.drawLine needs no explanation for instance as its clear the function draws a line.

Here is the full code for this project. Its an example from the Library named LCD5110_Graph_Demo and how to get to it has been described at the beginning of this section.

I had a project that needed some live data display, and looking for the cheapest low-power solution for our loggers lead me to the Nokia 5110 LCD. Once you get the backlight current under control, you can power the entire display from a digital pin, and if you use shiftout for soft SPI you can then get rid of the Reset and CS control lines. This brings the display down to any four wires you can spare on your build (incl. the power pin) and a ground line. This is much more manageable than what you see with the standard hookup guides if your mc is I/O limited like our pro-mini based loggers:

This LCD (I have the old-old kind) is absolutely my favorite. Yes, it has a board-to-glass connector that ranges from bad to abysmal, but it offers such a simple interface and so many pixels for so little money (obviously less if you buy only the panel.) Here are some clever things I"ve discovered:

Will fully operate on as little as 2.0V. That"s power (Vdd) and i/o. It can be driven at 2MHz at these speeds; in fact, the LCD will work at even lower voltages but the contrast fades quickly and your microcontroller will likely approach its lower voltage limit too.

The LCD will work with the chip-select pin (SCE) tied to ground. This means that if it"s the only device on the SPI bus, don"t bother framing the i/o with a chip-select pin. If the bus is shared, frame the entire transaction, not every individual byte you send to the LCD. Interestingly, the display also seems to work fine with a floating Vdd pin - it must draw sufficient power just from i/o via clamping diodes; not surprising when you consider how low-power it is.

The Vout pin: Looks like you don"t have to worry about it on this product, but the bare LCD will generate positive 6-9V on that pin. This wasn"t totally clear to me from reading the datasheet.

(5) If you are using a PIC to run ths thing, and using the PIC"s USART or EUSART in a synchronous mode, be sure to note that the LCD controller expects the MSBit of each byte to be transmitted first on the serial line. The PIC 18F EUSART transmits the LSBit first. For now, I have lots of extra code space, so I"ve wasted a 256-byte section on a lookup table that reverses the bits in a byte. This way, I just write my initialization code normally, and I have a TransmitCommandByte() function that looks up every byte it sends so I don"t have to think about that.

Thank you! I"m not quite sure I do want an LCD yet, to be honest, I"m just considering the different options available. I"ll check out the Sharp component, thanks!

Advice for others: It took me quite a while to get this working on an ARM Cortex. Since there is no way to read from the LCD, it is very hard to know if SPI is working without doing everything perfectly. SO:

If the LCD module is soldered to another board and the two top screws installed and tightened carefully to pull the bow out of the module it seems to prevent (or solve) the problem.

I"m using voltage dividers to supply 3V in the inputs of the LCD, because of the Arduino works in 5V. LCD Vcc and LED are powered from the 3.3V output of the Arduino. The LCD only displayed something when I used: R1=470K,R2=820K. I have tried several values to obtain 3V, but the LCD showed nothing. I don"t understand that.

I"m interfacing this LCD with ATMEGA 32. Its been more than a week that I"ve been trying to get it right. All I get is the LED dimming effect. Here is my initialization code..CE=1;

I have a similar board made by mib-instruments and bought from ebay years ago. It has been my standard spi test tool because it"s so easy to work with. http://www.ebay.com/itm/Nokia-5110-LCD-84x84-dot-martix-backlight-PCB-RED-/320684678723 (specs http://i1119.photobucket.com/albums/k636/mib_instruments/diy/LCDC2A0SPEC.jpg)

I almost have it working satisfactorily but I find that the bottom 1/5th of the screen does not function correctly. Sometimes it has some random blocks that are black, most of the time it is blank. I am not sure what would cause this. Is it safe to assume it is a defect on this module?

These LCD"s need cleaning. I have an average failure rate of about 15-20% on delivery. The most common problem is that the contrast is too high, and there"s constant flickering / changing of contrast compared to the other 80% of them.

The solution is fairly simple, unclip the LCD from it"s board and clean the pads on the PCB with 99% IPA. Then remove the lcd back plate and contact bar. Sometimes the contact bar is stuck fairly well to the glass, peel off carefully. Clean the contacts on the LCD glass with IPA, if any residue from the contacts is left on, rub it off carefully with IPA / tissue.

I love this little display! I wanted to be able to create images for it but nothing I saw did exactly what I wanted. So I wrote a processing sketch that creates 84x48 squares on the screen and allows you to click to turn them on or off. Also has buttons to invert, move up/down/left/right, and flip horizontally/vertically. Then, it saves the hex data to a text file to copy to your code. You can also load an image (any size, any colors) and it will scale it, convert to b/w, then put it in the rest of the program so that you can alter the pixels or move it. It isn"t perfect for every occasion but I"ve found it useful and I hope others might too. It is heavily commented so it should be easy to figure things out and change them if you want something different. http://thewanderingengineer.com/2014/07/12/nokia-5110-screen-photo-to-bitmap-converter/

Anyone taken these things apart yet? You know the flexible rectangular blocky thing that connects the contact pad on the board to the LCD itself? What are these called?

Got mine running last night and found two problems with the code, one of which was the backslash a couple of others have already noted. Second was that the LCDCharacter() writes two blank vertical lines, one before the character and a second after, when only one is needed. Without the extra blank you get at least one additional character on each line. I"ll probably also move the ASCII font table to PROGMEM space to save on RAM and then start to work on some big digits for a clock.

I"m using this LCD for a large Arduino UNO project, but I"m running out of SRAM memory space. I was wondering if I used PROGMEM on the LCD ASCII array if that would help. If so, does anyone know what the right code for this would be? After looking through a lot of PROGMEM examples, I"m not advance enough to really grasp everything that"s going on. Any help you can give would be a great help. Thanks in advance!

I used one of these LCDs with an Arduino to display GPS information. I wrote a few functions that can display large numbers (28 px high) if anyone is interested, this lets me display speed, heading etc. A writeup of my project is here: http://mechinations.wordpress.com/2014/04/07/gps-sailing/

These are great displays. I ran into a problem using them with the nRF24L01+ radio transciever, which requires the use of the SPI bus. If one attaches both the radio and the display MOSI and SCK pins to pins 13 and 11 as instructed in the hookup guide, the SPI traffic of the other device (in this case the nRF24L01+ radio) will prevent the display from functioning. The easy solution is to move the Nokia 5110 MOSI and SCK pins to any other digital pin. This should be made clear in the hookup guide, where it says there is no choice but to use the hardware SPI pins for the display. I found out that is not true at all. I hope his helps others with the same problem. Despite the occasional bad display these carry much more information that the comparably prices 16 x 2 LCD and use fewer pins too boot. What a deal!

This is a great display for the money, certainly the best bang for the buck of you can live with B&W and lower res graphics. I have a lcd driver for Arduino I will post on http://www.marchdvd.com/5110 so take a look there it draws text aligned on pixels boundaries of 8 and draws lines and has invert video options.

I just started messing around with this LCD using a STM32F103 microcontroller running at 72MHz... it works great. The only problem I had, and I suspect others might have if they are using fast processors, is that you have to deliberately introduce the setup and hold time delays on the DC pin... if you don"t you will get spurious pixels written to the display. I used a delay of 10uS, although the spec says 100nS is fine.

I just spent the last couple hours struggling with this LCD because of something very stupid of me. I was using an atmega328p in AVR-GCC and using hardware SPI. Thinking i didn"t need MISO I hooked it to DC. The LCD worked absolutely fine until I tried to set the x and y position in the ram. It started acting weird every time I tried it. Finally I put dc to another pin and BAM NO PROBLEMS. Looking back I feel pretty stupid but hopefully this post will save someone else the same mistake. Other than that great LCD for my projects

The Energia folks have an example program for this LCD and the TI Launchpad written using their Arduino style tooling. I"ve updated their example and added the ability to report back the temperature over a UART. It is a very simple hardware setup since both systems are 3.3v. http://joe.blog.freemansoft.com/2012/08/digital-thermometer-with-ti-lanchpad.html

I tried using the "LCDAssistant" package to create a logo from a graphic that I resized to a b&w jpg of 84x48 but every byte generated was 0x00 so that was not right. I tried fiddling with the settings (flying blind) but still got nowhere - does anybody know the settings for LCDAssistant and this display and has used it successfully?

One of the things that I test regularly is a commercial item that features a 16x4 (HD44780) display. Currently I have a 20x4 on a flying lead that I plug in to determine if a display failure is down the lcd display or the main board.

Might I suggest you (SFE) source some of the Electronic Assembly"s LCD Dog-S series. I think they would be a step up from these at a reduced price. I don"t think that they website is up to date, but their part number is LED39x41-GR.

I finally got around to running this LCD on my 3310 PCB. It is working fine with one minor problem. The SF 3310 display hides to first line of bytes for some reason and I had to offset everything to compensate. The 5110 doesn"t do this as behaves as expected. I haven"t heard anyone else report this so maybe my initialization code is different.

Using a 3V source, my LCD often worked OK using bias 0x14 like the other examples, but sometimes it would appear gray and faded. The fading would lessen if I touched the panel lightly with my hand for a few seconds, then let go, so maybe it"s a temperature-dependent thing?

0x14 is not 1:48 bias. If you read the datasheet on the top of page 16, 0x14 corresponds to a bias of 1:40/1:34. If you want 1:48 bias as the comment says, use 0x13. The 0x15 value I"m using corresponds to 1:24 bias.

Ack! After two days of working nicely with 0x15 bias, I reset the board today, and the LCD appeared way over-dark. I changed the bias back to 0x14 and it looks perfect. What the heck?! I think there must be some temperature-sensing or temperature-dependence going on, so the same init values may produce good-looking results one day but not the next.

Does anyone know whether this can be stripped of its backing so it can be used in transmission? I would love to use this as a modulator for a laser beam. Or if someone knows a similarly cheap transmission LCD that would be fine too.

Stuck. Blank LCD. Added 0x20, changed Vop to 0xB3. Guessing connections may be the issue? 3.3v for LED and VCC. GND to GND. Remainder connected to Arduino via voltage dividers. What am I doing wrong?

This is a great little lcd. When I first wired it up, the backlight was shorted (accidentally) against my 5v rail, so i got some magic smoke, and burnt to LEDs but it re-soldered the offending joints and it works very well now. Something to note: the refresh and write times are much, much slower if you use 5 volt logic. I stuck in a logic level converter and it ran at least 5x faster.

You can also use FastLCD to convert your bitmaps - google it. It outputs BASIC code, but you just search and replace &h to 0x and you"re grand. It has the added advantage of being an editor for touching up output.

I recently obtained a virtually identical LCD from a Nokia 5160, and although its backlight LEDs are green, not white and conversely use different voltages, I had success hooking up the LEDs" Vcc pin to a PWM capable pin on the microcontroller, allowing me to control backlight intensity (I didn"t need a current limiting resistor for this either, but adding one will help reduce current drain on the controller).

Seems like the PCD8544 library does it"s own SPI bit managing and it really doesn"t like me using the SD library (also talks SPI) at the same time. I"ve made sure I"ve got all the SPI pins matching for both libraries (MISO, MOSI, Clock are the same and each device has it"s own Select), but it looks like the SD.begin() call just breaks the SPI bus for the 5110 and it becomes non-responsive. The LCD works just fine if I don"t initialize the SD library and the SD card works fine if I do initialize the SD card.

I"m pretty sure I tracked down the problem- the PCD8544 library uses software SPI while the SD library uses hardware SPI and I"m pretty sure the Arduino can"t do both over the same SPI clock/miso/mosi pins. Anyone know if this LCD will work with hardware SPI?

I"ve had issues with the LCD not showing anything intermittently. You got to make sure that all the connections are secure, and for the reset pulse, be sure to have a delay that"s 30-50 milliseconds long.

As much as I love SFE products and will continue to order from them, this is one product I would not recommend. The connection between the LCD unit itself and the carrier board is via those rubber polymer connectors. All the planets must line up properly for them to work. In this case, the carrier board was warped preventing the connection from working. You will find other such remarks in the comments area.

Don"t do this. Each divider will be burning 20x the entire amount of current that the display needs to function, and the whole assembly will waste 100x the LCD"s needed power and many, many times more than even the atmega needs to run at full speed. This will kill battery life.

Hi, I just bought this wonderful LCD but I"m having huge huge problems connecting it..could anyone please point me in the right direction? Since there are pins that aren"t metioned in the code, for example the 6 - DNK(MOSI)...

Does anyone know the diode rating and package size, also does anyone know where to get the rubber ferroius connector behind the LCD mine is defective. Has anyone come into issues with the breadboard the LCD is connected to, a few aren"t working for me.

Yes, we have noticed that the PCB was bowing and as a result the LCD now only works when we press down on the metal strip at the top. I hope that only a small number of these LCDs have this problem. We"re expecting a shipment to arrive today, I will be running more tests.

Edit: After leaving glue to dry overnight, LCD simply does not turn on anymore. All the connections are good, but absolutely nothing shows on the LCD now at all. Only the LEDs come on.

Did you get either of the LCDs to display anything, at any time? Is it possible that the connections were OK, but you were not initializing or driving them correctly? Or did they start to work at one point, and then fail at some later point?

Note that the backlight LED"s are soldered onto the breakout board, and have nothing to do with the circuitry of the controller and LCD. So just because the backlights are shining doesn"t tell you anything about the operability of the LCD itself.

It depends on the code that you are using to control the LCD. If you are using the Arduino example above, the pins are defined in the beginning of the code.

FWIW I have connected this LCD with a 5V power supply to a 5V Arduino board with no level conversion and it worked. Presumably this may reduce the lifetime of the LCD.

I am attempting to use this with a Duemilanove (ATmega328). Up til now, I have been powering it with the 3.3V line, including the LED. The datasheet for the LDC claims: "VDDmax = 5 V if LCD supply voltage is internally generated (voltage generator enabled)." The logic levels should be kept from 2.7V to 3.3V. Since the Duemilanove uses 5V logic levels, I am using a simple voltage divider on the communication line with no issues.

The maximum logic value of 3.3 volts made me cautious of driving the LCDs at the native 5 volts of my Teensy AVR. That said, running purely off 5 volts seems to do no harm to the LCD.

For those interested, I have taken a few measurements of the current draw of the LED backlight of my LCD. As I said earlier, powering the LED with 5V external has caused permanent damage to one, perhaps two of the four LEDs. So, use the following graph at your own risk.

Is there any more documentation available for the additions to the LCD? For example, the datasheet has no information (that I could find, at least) on the LED. Everything seems fine on 3.3V, but what is the current limit on the LED? (note: if it wasn"t for work, I would just mess around with it myself.)

Here is a PicBasic Pro example for the 3310, which should be compatible with the 5110. http://www.picbasic.co.uk/forum/content.php?r=174-Using-Nokia-3310-LCD

If anyone doesn"t have experience with this LCD, take a peak at the Arduino example link above to see just how easy it is to use. If you use plain C on your AVRs, I have sample code on http://tinkerish.com.

Below is a snippet of the example LCD control code. This small novella of a sketch shows off an array of graphics driver functions, character drawing tools, and other useful functions to help you get started using the LCD. You will need to include the LCD_Functions.h header in the same directory as the sketch folder from the download. Otherwise, your code will not compile when uploading to Arduino.

Heads up! If the display is not showing pixels even with the correct logic levels and example code, it may just have slight variances in the way that they were manufactured. You can see the pixels faintly on the screen at an angle or pushing down on the LCD. You will need to try and set the contrast where it says setContrast(40) on line 87 to a value of 60. There is probably some variances in the LCD’s contrast which might explain why certain LCDs have issues displaying defined pixels on the screen.

Once uploaded to your Arduino, the sketch will begin by running the demo -- a set of basic animations and graphics functions. To begin, we"ll draw some random pixels on the screen ("It"s full of stars..."). Then we"ll move on to examples of drawing lines, rectangles, and circles. Throughout there are examples of drawing characters and strings. Finally the demo closes out with an homage to a monochrome comic which seems a perfect fit for this little monochrome LCD.

After the demo runs its course, the sketch will enter into a serial echo mode. Open the serial monitor (set the baud rate to 9600 bps), and type stuff over to the Arduino. It should start printing everything you send it onto the LCD.

If you"re intrigued by the possibilities of drawing bitmaps on the screen, check out the next page! We"ll show you how to import your own 84x48 bitmap and draw it on the screen.

It uses the PCD8544 controller, which is the same used in the Nokia 3310 LCD. The PCD8544 is a low power CMOS LCD controller/driver, designed to drive a graphic display of 48 rows and 84 columns. All necessary functions for the display are provided in a single chip, including on-chip generation of LCD supply and bias voltages, resulting in a minimum of external components and low power consumption. The PCD8544 interfaces to microcontrollers through a serial bus interface.

10.5US $ |Arduino 5110 Free Shipping Smart Electronics LCD Module Display 84X48 84x84 LCD Module Red backlight adapter PCB for Nokia 5110|pcb adapter|pcb for arduinopcb module - AliExpress

84×48 pixel graphic LCD (Nokia 5110) for Arduino, Raspberry and Co., incl. header. A very easy-to-use LCD screen, with 84 x 48 pixel resolution. These displays debuted in the Nokia 5110 cell phone, well known for their high contrast and bright backlight. These small screens are incredibly popular again, because of their easy programming and low price.

This post aims to be a complete guide for Nokia 5110 LCD with Arduino. I’ll explain what it does, show its specs and share an Arduino project example that you can take and apply to your own projects.

The Nokia 5110 LCD is very popular among the Arduino tinkerers. These modules are used on wide variety of applications that require some sort of interface or display data to the user.

The Nokia 5110 LCD operates at 3.3V. So you can’t connect the Arduino Uno digital pins directly. Read this blog post to learn how you can level shift the signals from 5V to 3.3V.

The Freedom KL25Z board has a great price of less than $15. Adding a typical LCD usually will add a multiple of that price to the budget. But hey, there is a way to add a LCD to that board at almost no costs! With the idea that I have an old outdated Nokia phone, and the cost of a small capacitor plus some wires are considered as ‘zero’ ;-).

The Nokia 3310 and similar models are still available today in second-hand markets for a handful Euros. Or even available free of charge if you collect them from recycling stations. what is of interest for me are the displays: the phone features a 84×48 graphical LCD display.

So instead of using metal contacts, it is using such conductive material to connect to the board. For this, the LCD display is pressed on the front side contacts of the board:

With these phones, the phone plastic cover is pressing the LCD on the base board. So for this kind of display another approach had to be used: a PCB with the connectors replicated and the capacitor on it:

I’m able to get a free-of-charge used Nokia phones, or very cheap replacement parts from the internet. With this and the Processor Expert component created, it is very easy to integrate a small graphical LCD display to my FRDM-KL25Z board (or any other board). Which is a great thing and enhancements of my Freedom board for many projects. I hope you enjoy it as I do.

PDC8544 48×84 pixels matrix LCD controller/driver, Philips Semiconductor, 12-Apr-1999: http://www.sparkfun.com/datasheets/LCD/Monochrome/Nokia5110.pdf

This tutorial on "How to use a NOKIA 5110 LCD screen" is different from the all the tutorial that are available online because I"m not going to use any library in this tutorial(No worries!! it"s pretty easy,which i figured out after trying without libraries). I"m not using any libraries just because it makes it easy to understand how the LCD screen works. I mean what block of code(or a command, u"ll know in the upcoming steps) does. It makes it easy to control the graphics on the LCD screen. I"m going to write another tutorial after this tutorial on how to play "SNAKE GAME" using this NOKIA 5110 LCD screen.

The NOKIA 5110 LCD screen has a resolution of 84x48(or 48x84, however you read it) i.e. the screen has pixels arranged in 84 rows and 48 columns making a total of 4032 pixels (84*48=4032). So, since a NOKIA 5110 LCD screen is called a "Graphical LCD screen", one has access to all the pixels, i mean, access to control each and every pixel individually(you know what I mean) unlike some of the LCD screens which are named as "Alphanumeric LCD Displays" where one can access a block of pixels, generally 7x5 and place only a single alphabet or a number in that block of 7x5. If you have already worked with some alphanumeric LCD screens earlier(without any libraries), you are half-way done. In case, you haven"t worked with one earlier, no probs. I"ll let you know every possible detail I know.

So, as said earlier, the above image shows the arrangement of pixels in 48 rows and 84 columns( or vice-versa). Just like how each block in a alphanumeric LCD screens is addressed by a unique 8-bit code, every 8 pixels in the NOKIA 5110 LCD screen are assigned with a unique 8-bit address. So, let me explain about this 8 pixels grouping in the NOKIA 5110 LCD screen. Every 8 pixels vertically is grouped, as shown above and let"s call it a block(different from the alphanumeric LCD screen"s block). So, each block has a unique address to access it.

Some NOKIA 5110 LCD screens operate at 3.3V as Vcc while some can work with both 5V and 3.3V. Mine is a 5V version which works even when plugged to 3.3V.

NOKIA 5110 LCD screen uses SPI protocol as one can find a DIN pin which can also be call as MOSI(Master-Out Slave-In). So, all we gonna do is just pass commands with a couple of 8-bit data through the DIN pin while using the other pins(like DC, CE and CLK pins) simultaneously and appropriately.

This is the total code which displays two rectangular boxes on the LCD screen as shown below. If you are having trouble getting the output, feel free to ping me or comment down below.

This line means that when ever i type "LCD_CE" anywhere in my code, it gets replace with "7", which is the pin of arduino to which I"ve connected the CE pin of LCD screen. And similarly, all the other pins. I"ve also declared LCD_C and LCD_D which I"ll explain in the upcoming steps.

The elements in this array are the one which decide the graphics that are displayed on the LCD screen. As I"ve said earlier, every 8 bits on the LCD screen are grouped together, every element in this array are 8-bit(2-digits in hexadecimal). Suppose, let us consider the first element of the element as 0xF0. 0xF0 in hexadecimal is equivalent to 0b11110000 in binary. So, when the 0xF0 is sent to the LCD screen(i"ll discuss about it in the next step), the first four pixels in the first group of 8-vertically grouped pixels(as discussed in STEP-1) are made dark(black) as the first four bits in the input data are "1" and similarly, the remaining 4-bits are not darkened as they are "0".

As I said earlier, the NOKIA 5110 LCD screen can be communicated with SPI or through the MOSI pin i.e. DIN pin on the LCD screen. So, we need to send 8-bit commands or data to work with the display. The commands are so simple. One need not prefer to remember them if you can refer to datasheet of NOKIA 5110 LCD screen when ever needed. I"ve included a page of the data sheet in the next step.

So, as mentioned in the datasheet, before sending the data or command to the LCD screen, we need to make the CE(chip enable) pin low and make it high again after sending the command.(Basically, CE pin is an active low pin. So, make it low to use the LCD screen). also, we need to make the DC(data/command) pin low for command and high for data.

The LCD_Write command takes in two parameters, 1. Data/Command and 2. 8-bit data. Depending on the Data/Command, the DC pin is made low or high for command or data respectively. shiftOut() is a function available in SPI.h but is also included by default and so we need not include the SPI.h library seperately.

First, setting up the CE, RESET, DC, DIN, CLK as outputs, we continue to reset the LCD screen just to make sure all the garbage values in the pixels are cleared. Next we send some commands, which set-up the LCD screen. You can have a look at all the commands in the data sheet.

After initialization, ofcouse, we need to execute this LCD_Initialise() function in the setup() function of the arduino. Also need to setup serial communication using Serial.begin(9600) where 9600 is the baud rate. After that, we are ready to go to display the graphics on LCD screen.void LCD_Initialise(void){

So, we know how to initialize the LCD screen, we know how to communicate with the LCD screen, we know how the LCD screen works, but we don"t know how to display the graphics of our owe choice. To do that, we need to know how to convert any image into bitmap. The image must be in "BLACK AND WHITE", if not conver it into B&W using some software.

Generally, I use GIMP and LCDAssistant(and paint.net) softwares. Again, try getting Google"s help in knowing how to use GIMP to convert a B&W image to Gray scale and I"m going to tell you about LCD Assistant and paint.net.

This software is used to draw any image which you want to display on the LCD screen. Sounds cool, isn"t it?? For example, you can display your name in your handwriting or some cool stuff. Again, go to Google and find a video which can help you with until I post a video.

Now, you are ready to use a NOKIA 5110 LCD screen.Do comment bellow if you have any doubts.Do comment bellow if I"ve gone wrong somewhere.Do comment bellow your experience, if you have done one.

I"m working on the LCD screen. I"m already working on some games that can be played with this LCD screen. Will surely try to do it and put it up here.

The Nokia 5110 is a basic graphic LCD screen for lots of applications. It was originally intended for as a cell phone screen (before the smart-phone fad turned every cell phone into a TV). It"s a 84x48 pixel monochrome LCD display. These displays are small, only about 1.5" diagonal, but very readable and come with a white backlight. This display is made of 84x48 individual pixels, so you can use it for graphics, text or bitmaps. These displays are inexpensive, easy to use, require only a few digital I/O pins and are fairly low power as well and mounted on an easy to solder PCB.

It uses the PCD8544 controller, which is the same used in the Nokia 3310 LCD. The PCD8544 is a low power CMOS LCD controller/driver, designed to drive a graphic display of 48 rows and 84 columns. All necessary functions for the display are provided in a single chip, including on-chip generation of LCD supply and bias voltages, resulting in a minimum of external components and low power consumption. The PCD8544 interfaces to microcontrollers through a serial bus interface.

The LCD is connected to the PCB by means of a conductive rubber strip; this sometimes causes contact problems and a black screen. Restoring the connection doesn"t help; the LCD must be re-initialized by manually restarting the Arduino. This is inconvenient. The LCD application can be made more robust by initializing the LCD repeatedly with an interval of about 2s. This allows disconnecting and reconnecting the LCD during operation. I have changed the Adafruit-PCD8544-Nokia-5110-LCD-library to add this functionality.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey