are lcd touch screen controls better than touch controls manufacturer

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

It"s probably a little early to be warning of extinction, but in some new cars, buttons are becoming hard to find. Given that a screen has to go into the dashboard anyway (thanks to things like backup camera requirements) and the fact that people increasingly won"t consider a car without Android Auto or Apple CarPlay, touchscreens make life easier for automakers in terms of design and assembly.

It"s just that they don"t make life easier for drivers. Instead, we"re treated to bad interfaces that don"t create muscle memory but instead distract us while we should be driving. And now, Swedish car publication Vi Bilägare has the data to prove it.

VB tested 11 new cars alongside a 2005 Volvo C70, timing how long it took to perform a list of tasks in each car. These included turning on the seat heater, increasing the cabin temperature, turning on the defroster, adjusting the radio, resetting the trip computer, turning off the screen, and dimming the instruments.

VB says that "one important aspect of this test is that the drivers had time to get to know the cars and their infotainment systems before the test started." With my devil"s advocate hat on for a second, most drivers who drive regularly will regularly drive the same car, building more familiarity over months and years than a journalist will after even a week with a new model. But that kind of long-term adaptation is the user conforming to the vehicle"s wishes, and shouldn"t good design be the opposite of that? Advertisement

VB lays the blame for the shift from bottons to screens with designers who "want a "clean" interior with minimal switchgear." That"s fair, but I don"t think we can count out the accountants either. If everything can be achieved by touching the screen, then the company doesn"t also have to pay for the plastic and wires that buttons are made from, nor the time it takes someone to make that into buttons or install them in a car.

Even with touchscreens, though, we can see in the spread of scores VB gave to different all-touch cars that design matters. You"ll find almost no buttons in a Tesla Model 3, and we called out the lack of buttons in the Subaru Outback in our review, but both performed quite well in VB"s tests. And VW"s use of capacitive touch (versus physical) for the controls on the center stack appears to be exactly the wrong decision in terms of usability, with the ID.3 right at the bottom of the pack in VB"s scores.

I"m not surprised that the BMW iX scored well; although it has a touchscreen, you"re not obligated to use it. BMW"s rotary iDrive controller falls naturally to hand, and there are permanent controls arrayed around it under a sliver of wood that both looks and feels interesting. It"s an early implementation of what the company calls shy tech, and it"s a design trend I am very much looking forward to seeing evolve in the future.

Again, there are examples of automakers doing this better than others. Over the past couple of weeks I"ve spent time in an Acura MDX and Mazda CX-50, neither of which uses a touchscreen infotainment system. Neither managed to do better than 19 mpg either, which is frankly appalling in 2022, but the CX-50 did at least distinguish itself for ease of use when it came to the infotainment system. Advertisement

Mazda"s latest system has been criticized for being bare-bones, but odds are, a driver is using Apple CarPlay or Android Auto, and it"s actually quite easy to use with the rotary controller and its hard buttons, which, again, are right where your right hand expects them to be (or left hand, in a right-hand-drive car).

Volkswagen"s infotainment software in the ID.3 can be frustratingly laggy, and while there are permanent controls for the climate and audio, they"re capacitive touch, not real buttons or dials or knobs.

The more expensive Acura also places the infotainment screen far out of reach. It"s a much higher-resolution display befitting a much more expensive car, and the MDX"s infotainment system is much more capable than the CX-50"s in terms of apps and features. I also quite like the layout and fonts, although obviously that"s a pretty subjective thing.

I won"t subject you to the depth of my current feelings about Acura"s "true touchpad," just a high-level, mostly polite version. It has a 1:1 relationship between the screen and the pad, so it doesn"t work at all like any other trackpad in any other car you might have driven. And that means it requires a lot of concentration to use, particularly if you"re trying to interact with CarPlay. And it doesn"t need saying that "requires concentration to use" is likely the last quality anyone wants in an infotainment system.

I"m not that surprised that the old Volvo won, dating from a time when most functions were controlled by individual buttons and when infotainment didn"t really yet exist. And in some ways, the tests played to its strengths—there"s no Android Auto or CarPlay, and the only safe way your phone is showing you directions is if you bring a suction mount. Do be careful what you press if anyone"s sitting in the back seat, though. In Volvos of that vintage, one of those buttons drops the rear headrests, which are rather heavy and very much wish to return to a horizontal orientation with absolute disregard for the skulls of anyone sitting in their way.

LCD (liquid crystal display) is the technology used for displays in notebook and other automated industry computers. It is also used in screens for mobile devices, such as laptops, tablets, and smartphones.

Like light-emitting diode (LED) and gas-plasma technologies, LCDs allow displays to be much thinner than cathode ray tube (CRT) technology. LCDs consume much less power than LED and gas-display displays because they work on the principle of blocking light rather than emitting it.

Each LCD touch screen monitor contains a matrix of pixels that display the image on the screen. Early LCDs screen had passive-matrix screens, which controlled individual pixels by sending a charge to their row and column. Since a limited number of electrical charges could be sent each second, passive-matrix screens were known for appearing blurry when images moved quickly on the screen.

Modern LCDs display typically use active-matrix technology, which contains thin film transistors, or TFTs touch screen. These transistors include capacitors that enable individual pixels to "actively" retain their charge. Therefore, the active-matrix LCDs touch panel are more efficient and appear more responsive than passive-matrix displays.

The backlight in liquid crystal display provides an even light source behind the LCD screen. This light is polarized, meaning only half of the light shines through to the liquid crystal layer.

The liquid crystals are made up of a part solid, part liquid substance that can be "twisted" by applying an electrical voltage to them. They block the polarized light when they are off, but reflect red, green, or blue light when activated.

The touchscreen panel a display device that senses physical touch by a person’s hands or fingers, or by a device such as a stylus, and then performs actions based on the location of the touch as well as the number of touches.

Touch screen glass can be quite useful as an alternative to a mouse or keyboard for navigating a graphical user interface. Touch screens are used on a variety of devices such as computer and laptop displays, smartphones, tablets, cash registers, and information kiosks.

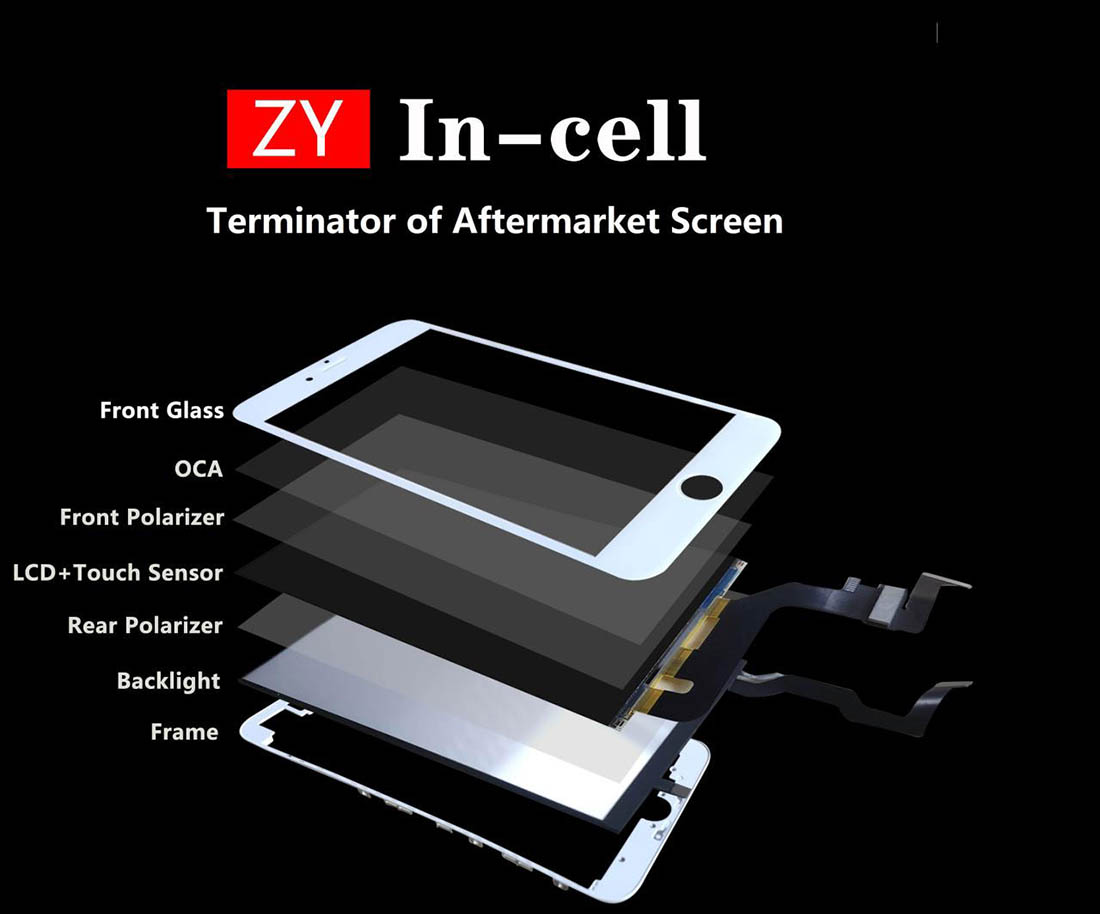

A touch-screen digitizer is one piece in a multilayered "sandwich." In modern devices, the screen that produces the images is found at the bottom layer; the digitizer is a transparent sheet that occupies a middle layer on top of the screen, and a thin sheet of hard, protective glass forms the top layer.

Touching the screen triggers touch sensors immediately under your fingertip; a specialized electronic circuit receives signals from these sensors and converts them into a specific location on the screen as X and Y coordinates. The circuit sends the location to software that interprets the touch and location according to the app you"re using.

For example, when you dial a phone number, your fingers touch the numbers on a virtual keypad on the phone"s screen. The software compares the locations touched against the keypad and generates a phone number one digit at a time.

Touch Screen Glass– The bottom layer is the ITO glass, typically thickness is between 1 and 3 millimetre. If you drop your device, the cracked glass ends up resembling an elaborate spiderweb.

Digitizer – The digitizer is located above the glass screen. It is the electrical force that senses and responds to touch. When you tap your fingertip or swipe it across the screen, the mere touch acts as data input to the device’s center. If your device fails to respond to touch, it’s time for a new digitizer.

The touch screen digitizer is an electrical mechanism that is fused with the glass screen; so if you need to replace the digitizer, you’ll have to replace the glass, too, and vice versa.

Touch Screen Panel- Touchscreen is the thin transparent layer of plastic, which reads the signal from the touch and transports it to the processing unit. It is the part that you can touch without disassembling the device.

LCD – LCD display is an acronym for liquid crystal display. The LCD is the visual component underneath the glass that displays the image on the screen. You can not get to the LCD without taking the device apart first.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Capacitive surface touch screens work by using the electrical signal from the operator’s finger instead of force to complete the action of the interface.

The key benefits of using a capacitive touch screen is that they are temperature resistant and waterproof. Many home appliances like refrigerators and dishwashers use capacitive touch keypads.

However, while capacitive touch screens can only be used with the user’s finger, Projective Capacitive Touch Screens are the new standard for capacitive touch screens and allow for users to control the device even while wearing gloves.

While technically a type of Capacitive Touch Screen by its name, Projective Capacitive (PCAP) Touch Screens are the most common type and the ones used most on the market today.

PCAP touch screens get their name from the way they “project” a small electric field out past the top layer which senses the user’s input even before they come into contact with the screen. In a way, they function much like a proximity sensor. They have mutual capacitance which supports multi-touch activation.

Because of this, users can control the device with a stylus or while wearing thin surgical gloves, food service gloves, or cotton gloves. They also support excellent clarity with high light quality. They’re a great option for incorporating into outside equipment or machinery, as users don’t need to remove their gloves in a cold or rainy climate, and can still see the screen well in the sun.

They can be used in control panels, industrial automation, consumer devices, and commercial applications in retail, gaming, and signage. They are more costly than resistive touch screens.

Touch control and display technology is becoming an indispensable part of industry and today almost all industrial embedded solutions have some sort of graphical user interface. Manufacturers now integrate commercial PC technologies to provide customised solutions for users. This is achieved by incorporating the latest technology solutions and control automation methods into commercial products, manufacturing equipment and test stations.

Transparency Market Research (TMR) says that industries, such as automotive manufacturing and food and beverages, are the main drivers for these touch-screen displays. Key players include: Advantech Co., Ltd, Cypress Semiconductor Corporation, Dell, Inc., B&R Industrial Automation GmbH, Elo Touch Solutions, Inc., Fujitsu Ltd., Hewlett Packard Enterprise, LG Electronics, Panasonic Corporation, Planar Systems, Kontron AG, Schneider Electric S.E., Siemens AG, Beckhoff Automation GmbH & Co. KG, Captec Ltd., and American Industrial Systems.

At the end of February, Bopla Gehäuse Systeme GmbH, the East Westphalia Germany based developer and producer of touch screens and membrane keyboards will showcase in Nuremberg its latest examples of products that integrate displays and touch-screens in industrial embedded applications. The company says it supports its customers through all procurement, manufacturing, assembly and integration steps up to the finished, functional and ESD-compliant device.

“We specialise in the implementation of complex HMI [human machine interface] projects and integrate screens with input functions into housings. In the case of capacitive touch displays, we can print the glass pane as well as connect the pane and display using optical bonding,” it says.

At the end of January, Emerson the technology and engineering company announced that it had released a new display for industrial applications. The new portfolio of RXi industrial display and panel PC products for monitoring are designed to work with both Emerson’s programmable logic control (PLC) and programmable automation control (PAC) solutions, and third-party control systems. The display portfolio features standardised physical designs to minimise the variety of enclosure cut-outs required for OEM applications, making each display easily replaceable and upgradeable in the field with no need to modify existing cabinets or install new ones.

Displays are available in sizes ranging from seven to 24 inches, providing a single, scalable platform for a multitude of operations and applications. Key features for all models include vivid projective capacitive multi-touch screens that can operate in temperatures from 20 to 65 degrees Celsius and optional sunlight readable screens on select sizes. The portfolio carries multiple certifications and is IP66-certified for protection against dust and strong jets of water.

At the end of last year,GSR Technology Europe Limited, provider of standard and custom made optoelectronic solutions, introduced the new 7.8-inch High Resolution thin film transistor (TFT) module with projective capacitive multi-touch technology as an optional extra. The extremely compact design makes it suitable for many industrial applications. It also introduced two new high resolution TFT modules. The 5.0 inch and 8.0-inch modules come with projective capacitive multi-touch technology as standard.

GSR Technology also works closely with its partner EETI, the Taiwan based provider of eGalaxTouch touch technologies, to provide a full range of touch controllers that are designed to optimize the performance of projected capacitive touch technology. The EXC range of touch controllers and IC chips are specifically designed for commercial, industrial and medical applications. EETI touch controllers support USB, RS232 and IC interfaces and offer high voltage driving signal to achieve high signal-noise-ratio and better interference susceptibility for demanding applications.

Display Technology is supplying TFT LCD monitors to a rail company for its CCTV system. It has so far supplied 300 of its ‘Litemax’ 1068E, 10.4 TFT LCD, LED Backlight 1600 displays. A further 500 is to be supplied over the next 2 years. The display comes with 4 options: Finished monitor; Open frame monitor; Full AD Card Kit with no metalwork; and Panel only plus LED driver. The company has alsosupplied and fitted 12.1-inch industrial touch monitors for use in cranes at Felixstowe Docks.“We made various design improvement suggestions which the customer decided to implement.

This included connector exit position, change in analogue pot, and stronger umbilical conduit. After pre-production the touch-screen was mounted using an alternative method to increase ruggedness in such a harsh operating condition,” Display Technology said.

The analysis by TMR predicts a CAGR of over 6.5% in the global industrial touch-screen display market to 2026. This would give it a valuation of $835.3 million. Among end-use industries, the automotive segment is anticipated to constitute a significant market share. It is expected to be driven by rising demand for ‘next-generation’ touch-screen display panels that can withstand harsh environments as well as a rise in demand for custom touch panels with full display enhancements such as sunlight readability and custom rugged cover glass with logos and graphics.

The ever-increasing reliance on touch screens in cars is a controversial topic. With each new product release, the comment sections of articles and youtube videos are filled with negative remarks. Yet, carmakers are totally committed to the race of creating ever-bigger screens. If public opinion is so against touch interfaces in cars, why do car companies use them? I dove into this topic and confirmed my hypothesis: touch screens are not the problem per se, but car companies" design execution is.

The CRT touch display was not that bad, but it took some decades before touch screens were good enough to be widely adopted in cars. After Tesla launched the Model S with its 17" touch screen, carmakers have been eager to design increasingly bigger touch screens. Today, it is an exception if a car is not fitted with one. There are many reasons why this is happening. To dive into those, we first have to define the different types of interactions that occur while driving and how they evolved over time.

The first set is the primary interactions. They include all the functions that are directly related to driving and safety. Examples are monitoring the speed, turning on the indicators, and operating the windscreen wipers.

The secondary interactions are actions that occur frequently but take little time to accomplish. These can be changing the music volume, changing cabin temperature, or turning on the airconditioning.

The tertiary interactions are the opposite of the secondary ones. They are infrequent but require a high cognitive load and take longer to accomplish. Examples are filling in a destination in the navigation system or changing personal settings in the car.

Over time, these sets of interactions have evolved in mostly the same way. The interior of the Volkswagen Golf is an excellent demonstrator. The first generation Volkswagen Golf has a simple interior. The primary actions are limited to two gauges, some buttons, and a stalk for the indicators. The same goes for the secondary settings, consisting of three sliders to control the temperature and some volume controls. The only tertiary interaction is to find and set a radio channel.

All three sets of interactions increase in quantity, even the primary ones. In the Golf, for example, instead of some basic gauges and controls, the latest generation"s primary interactions now also include adaptive cruise control, speed limit warnings, and a range of other safety systems. Even something as simple as turning on the windscreen wipers or lights has increased in complexity with different modes, sensors, and settings.

Similarly, the secondary controls include countless different ways to set the right cabin temperature. There are buttons for heated seats and windows, airconditioning, individual climate control, and more.

Initially, all these interactions were controlled via indirect, physical controls. But over time, with each generation, the display grows in size, and the number of physical controls decreases.

The latest generation Golf is another important step because even the secondary interactions are not moved to the touch interface. Most of the physical buttons that remain are the ones that are legally required.

Over time, just like most in-car infotainment systems, BMW adjusted iDrive for use with touch interaction as well. Why did they decide to include touch interaction in the later version?

A lot of it has to do with the increasing complexity of tertiary interactions. As the number of these interactions increases with each generation, indirect controls seem to perform worse than touch interaction, especially in two areas: task completion time and adoption.

Even compared to other possible interaction techniques like gesture interaction and voice interaction, touch interaction performs equal, if not better.

Naturally, task completion time is only one way to measure the success of an interaction model. Touch screens score differently when it comes to visual attention, lane deviation, reaction time, and others. Carmakers have to weigh the time it takes to complete the tasks versus the gravity of the distraction. In a lot of scenarios, touch interactions are the preferred method.

The second solid argument is the adoption rate of touch interfaces. Once drivers enter their cars, their focus is on driving and not on learning a new system. So one way to decrease driver distraction is to make the interaction as close to other familiar digital products as possible. As such, touch screens are preferred over indirect controls.

The next reason why car makers use touch screens has to do with decluttering. It is a term that is often heard in design departments. It means to reduce the visual overload or perceived complexity of the interior. Getting into a car and seeing a dashboard full of buttons gives a busy, overwhelming look. Instead, a calm-looking interior with few buttons has a positive impact on comfort and perceived quality.

Additionally, many customers relate a big touch screen to a technologically advanced car. As an interior designer, you don"t want your car to be perceived as old-fashioned so fitting a giant screen shows your brand is futuristic.

Compared to a dashboard full of different buttons, knobs, and screens, a single touch screen is a much more straightforward part to design, spec, and maintain. Therefore, carmakers may prefer to fit a standardized touch screen instead of a range of custom buttons and knobs because of the development cost.

Another advantage is the possibility to modernize the interior of the car by updating the UI design. Digital design trends move much faster than interior design trends. Tesla has shown that updating the interface of the Model S helps to delay an expensive redesign or new model introduction because the car looks less outdated.

In mobile environments, like cars, the users" primary focus is on controlling the vehicle. So touch interfaces not only have to be usable and accessible, but they also have to ensure road safety. As discussed before, even though task completion time is the fastest with touch interaction, there are other driver distraction measures where touch interaction is not the preferred method.

One of those is visual attention. When interacting with a touch screen, drivers need to move their visual attention from the road to the screen to find the object they want to select. Furthermore, they have to coordinate their finger to that object without any tactile objects guiding it. With physical controls much less visual attention is needed to perform the interaction, leading to less distraction.

What is the impact of this difference in visual attention between touch controls and indirect controls? Experiments have shown that reaction times are slower, and there is a higher variance in driving behavior like lane departure and maintaining speed

Other disadvantages are the lack of haptic feedback when selecting an object and the display"s placement, which is a trade-off between readability and reachability.

When weighing the positives with the drawbacks of touch screens, they are the right solution for tertiary interactions in most cases if they are optimized for task completion time.

Designing a touch interface is difficult, especially in the context of driving. As task completion time is the most significant advantage of touch screens, you would expect it to be one of the main acceptance criteria. Yet, many car companies don"t seem to focus on that enough.

The perfect example of that is the latest trend of including secondary controls in the touch interface. For secondary interactions, the task completion time is already at a minimum with physical controls. On top of that, the physical controls require less visual attention. By moving those to a touch screen, both the task completion time and visual attention are compromised. It is not only annoying for end-users, but it is also dangerous.

Carmakers may do this because of decluttering and cost-saving. The aesthetics are important and may persuade customers to buy a car when they first see it. But good design is finding the right balance between ergonomics and aesthetics. When considering the dangers of driving, the first job of the designer should be to minimize distraction.

On top of that, the added benefit of prioritizing safety is that the controls will be more intuitive and easy to use. An interior will look super slick in the dealership if it has no physical buttons. Still, most buyers will find out very quickly after purchasing their car that it is annoying to have to divert visual attention to simply turn on the heater if before they could do it blindly. In moving the secondary controls to a touch interface, the balance is leaning too much towards aesthetics than ergonomics.

The second example of carmakers making suboptimal design decisions is the interface design itself, which is often needlessly complicated. They are filled with features that make you wonder why you would need them in a vehicle, like the possibility to check social media, order a pizza from the car, find movie times, or set custom wallpaper.

To carmakers, offering a lot of features equals customer value. But as many tech companies have shown, customer value is actually created by ensuring users achieve their goals. Having too many features stands in the way of that, and research confirms that. Year after year, infotainment systems are the biggest frustration in new car ownership, and the majority of problems are design-related.

It may explain the popularity of Apple CarPlay and Android Auto. These systems are optimized for task completion time and restrict access to certain features and apps that are deemed too dangerous. As a result, they are less distracting than native infotainment systems.

Customers want the latest technology and apps to be available in their car. Designing an infotainment system in such a way that it is not distracting is impossible. In theory, touch screens are a valid technology to facilitate these interactions. However, car companies should be minimizing the risks of distraction. Today, there are significant steps to be made to get to that point. But there are reasons to be optimistic about the future.

The interior of the car is always transforming, and so are touch screens. There is a lot to be optimistic about. Lately, the hardware powering the infotainment systems has seen significant improvements, leading to better screens and faster interfaces. There will be more innovations like haptic feedback and new input types like gestures and better voice interaction in the next years. These will help to mitigate some of the disadvantages of touch screens.

Most carmakers are also getting serious about over-the-air updates, which will allow more iterations on the interface design to weed out usability issues.

In the end, it will be vital that they tip the balance more towards usability than aesthetics. But once they optimize their interfaces, and when combined with physical controls and other modalities, touch screens in cars will be a great solution.

Intuitive: Buttons are very intuitive, you see a button you know it is there to be pressed. Touchscreens need content that makes it clear that the display is touch-sensitive and where to touch.

Dynamic function: With a touch screen it is relatively easy to make the button function context sensitive. Buttons can have on-screen descriptions (as with ATM cash machines) but that can lead to alignment issues.

Selecting the most suitable type of touch screen for your project can improve device functionality and durability, which can mean a significant increase in customer adoption.

This article highlights the unique advantages and drawbacks of common touch screen technology, to help product design engineers make an informed decision.

Resistive touch is a legacy form of touch screen technology that was broadly popular for many years, but has been replaced by capacitive touch for many applications. Currently, resistive touch has a smaller range of common uses, but can still capably address certain needs.

The core elements of a resistive touch screen are two substrate layers, separated by a gap filled with either air or an inert gas. A flexible film-based substrate is always used for the top layer, while the bottom layers substrate can be either film or glass. A conductive material is applied to the inner-facing sides of the substrate layers, across from the air gap.

When a user applies pressure to the top surface, the film indents and causes the conductive material on the top layer to make an electrical contact with the conductive surface of the bottom layer. This activity creates a difference in voltage that the system registers as a touch. The location of this contact is pinpointed on the X and Y axes, and the touch controller then interprets the action. Because physical force is needed for a resistive touch screen to function, it is similar to a mechanical switch.

Resistive touch screens must be calibrated before they are used to ensure accurate and reliable operation. A user must apply pressure to the four corners of the screen, and sometimes on its center, to calibrate the screen with the rest of the system via a lookup database.

Because resistive touch screens interpret physical pressure as a touch, they are effective in a variety of environments using single touch. Any object capable of applying force to the screen can be used with the same result. For example, in applications where end users wear gloves, resistive touch screens offer reliable single-touch functionality.

Since resistive touch screens area actuated via mechanical force, they continue to function as intended even when liquids or debris are present on the surface. This makes them especially useful in situations where substances could disrupt the function of other types of touch screens. For example, on single-touch applications within agricultural equipment, boats and underwater machinery.

Besides the functional advantages of resistive touch screens, price is a common reason why OEMs select this option. In projects where cost is a top concern, companies can use this option to realize savings that may not be possible with alternatives.

The configuration of a resistive touch screen removes the possibility of gestures, such as pinching and zooming, or any actions requiring multi-touch functionality. These screens cannot determine the location of a touch if more than one input is present.

In terms of visibility, the film substrate commonly used as the top surface in resistive touch screens is less transmissive than glass. This leads to reduced brightness and a certain level of haze compared to touch screens with a top layer of glass. The film layer can also expand or contract based on temperature, which alters the distance between the two layers and affects touch accuracy. Additionally, the film substrates are susceptible to scratches and can start to wear away with repeated use, necessitating occasional recalibration or replacement over time.

Capacitive touch screens were invented before resistive touch screens. However, early iterations of this technology were prone to sensing false touches and creating noise that interfered with other nearby electronics. Due to these limitations, resistive touch screens and other options, like infrared touch screens, dominated the industry.

With more development and refinement of controller ICs, projected capacitive (PCAP) touch screens became the preferred touch technology for a majority of applications. For example, this technology is now commonly used on tablets, laptops and smartphones. Though PCAP stands for “projected capacitive (PCAP) touch”, it’s more commonly referred to as “capacitive touch”.

The foundation of PCAP touch screens is an array of conductors that create an electromagnetic field. As a user touches a PCAP screen, the conductive finger or object pulls or adds charge to that field, changing its strength. A touch controller measures the location of this change and then instructs the system to take a certain action, depending on the type of input received.

For a device with PCAP touch technology to acknowledge an input, users simply need to touch the screen. No physical pressure is required, unlike resistive touch screens.

Another key difference from resistive touch technology is that PCAP screens can accommodate a variety of inputs, with different gestures and more contact points instructing the system to take a variety of actions. PCAP touch can support multi-touch functionality, swipes, pinches, and zoom gestures which aren’t possible with resistive touch screens.

A PCAP touch screen is very similar to a solid state switch, as its mechanism of action requires a change in the electrical field over a control point.

The value that comes with recognizing multiple inputs is a clear and positive differentiator for PCAP touch screens. Users can initiate a variety of commands, providing more functionality in devices where this technology is used. Consider how consumers now expect smartphones, tablets, and interactive laptop screens to support actions requiring two fingers, like pinching and zooming. In more specialized settings, such as multi-player gaming applications, PCAP touch screens can support more than 10 inputs at a single time.

PCAP touch screens do not require initial calibration, offering a simpler experience than resistive touch screens. Additionally, PCAP touch screens are highly accurate even as they support a variety of gestures and subsequent actions by the system.

Since their top layer is usually made of glass, PCAP touch screens offer a high degree of optical transmission and avoid the appearance of haze to users. Additionally, the glass top layerprovides improved durability compared to the film top layer of resistive touch screens – even for the largest sizes of up to 80 inches (and growing).

Operation in environments where a PCAP screen may be exposed to liquids or moisture — including conductive liquids like salt water — is possible through specialized controller algorithms and tuning. PCAP technology has evolved to support medical glove and thick industrial glove operation, as well as passive stylus operation.

PCAP touch screens can be customized with different cover lens materials (soda lime, super glasses, PMMA) based on application specific needs. Cover lenses can be ruggedized with chemical strengthening and substrates that improve impact resistance. This can be especially valuable for public-facing applications, like ATMs, gas pump displays, and industrial applications. Specialized films or coatings – such as AG (anti-glare), AR (anti-reflective), AF (anti-fingerprint) – can be added to the cover lens substrate to improve optical performance.

Unlike resistive touch screens, PCAP touch screens depend on variations in an electrical field to operate. While a passive stylus can activate this screen, a non-conductive tool like a pencil can’t.

If cost is a top concern for a project, PCAP may not align with budget limits. It is a more expensive technology than resistive screens, although it continues to grow more accessible in terms of price as the technology advances and improves.

The below table compares the advantages and disadvantages of projected capacitive touch vs resistive touch screens.CharacteristicsPCAP TouchResistive TouchRequires calibrationNoYes

As a leading manufacturer of touch and display products, New Vision Display can help you determine the specific needs of your project and tune your PCAP touchscreen controllers to meet them. Our PRECI-Touch® products are based primarily on PCAP touch technology and can be customized for a variety of applications using a wide range of materials, stacks, and controllers.

Whether your product will be used in a life-saving medical device, the center console of an automobile, or the navigation controls on a yacht – we can deliver an effective solution for your application. To get started on your project, contact our specialists today.

Ready to get started or learn more about how we can help your business? Call us at +1-855-848-1332 or fill out the form below and a company representative will be in touch within 1 business day.

Projected capacitive touch screen contains X and Y electrodes with insulation layer between them. The transparent electrodes are normally made into diamond pattern with ITO and with metal bridge.

Human body is conductive because it contains water. Projected capacitive technology makes use of conductivity of human body. When a bare finger touches the sensor with the pattern of X and Y electrodes, a capacitance coupling happens between the human finger and the electrodes which makes change of the electrostatic capacitance between the X and Y electrodes. The touchscreen controller detects the electrostatic field change and the location.

A resistive touch screen is made of a glass substrate as the bottom layer and a film substrate (normally, clear poly-carbonate or PET) as the top layer, each coated with a transparent conductive layer (ITO: Indium Tin Oxide), separated by spacer dots to make a small air gap. The two conducting layers of material (ITO) face each other. When a user touches the part of the screen with finger or a stylus, the conductive ITO thin layers contacted. It changes the resistance. The RTP controller detects the change and calculate the touch position. The point of contact is detected by this change in voltage.

Resistive touch screens still reign in cost-sensitive applications. They also prevail in point-of-sale terminals, industrial, automotive, and medical applications.

Projected Capacitive Touch Panel (PCAP) was actually invented 10 years earlier than the first resistive touchscreen. But it was no popular until Apple first used it in iPhone in 2007. After that, PCAP dominates the touch market, such as mobile phones, IT, automotive, home appliances, industrial, IoT, military, aviation, ATMs, kiosks, Android cell phones etc.

If you have any questions about Orient Display capacitive touch panels. Please feel free to contact: Sales Inquiries, Customer Service or Technical Support.

Interactive touch screens have become such an integral part of everyday life that they’re almost as likely to be found in the playroom of a preschool-age child as on the factory floor or in the field. And as touch screens become increasingly integrated with consumer and industrial IoT, their demand continues to grow across every market sector.

At Pivot International, we are the global one-source partner helping companies worldwide successfully design, engineer, manufacture, distribute, and deploy the latest in consumer and industrial touch screen technologies and IoT innovations. With more than 50 years of experience, in-house DFM expertise that spans fourteen industries, and 320,000 square feet of tricontinental manufacturing capability (including domestic options), we deliver a smooth, seamless, highly collaborative approach to NPD and successful product launch.

There are five types of touch screen technologies: resistive, capacitative, near-field imaging, infrared, and ultrasound. Each is differentially suited for various consumer and industrial applications. Let’s take a look at each.

Resistive touch screens are the most common industrial touch screen technology. They are constructed of two interfacing glass sheets or specialized films that respond to direct pressure. Traditionally, the glass sheets or films used in this type of touch screen are coated with indium tin oxide (ITO), a transparent conductive material. But this material is increasingly being replaced with more advanced materials, including copper microwires, silver metal mesh, silver nanowires, and graphene.

The switch from ITO to these other materials results from the need to integrate touch functions into the LCD panel rather than manufacturing a transparent touch screen overlay. This makes for a thinner, lighter device with enhanced optical benefits. Because resistive touch screens respond to pressure, they are more reliably responsive to touch than the capacitative versions we’ll discuss below. However, resistive touch screens offer lower resolution image quality than their capacitative counterparts. They are also slower to respond to touch and can register only one pressure point at a time, therefore precluding multi-touch functionality.

Capacitive touch screens were first invented in the 1960s but didn’t appear in the consumer market until the advent of the iPhone. The strength of capacitative technology lies in its instant responsiveness and superior image quality. Capacitive touch screens function on electrical conductivity that alters the screen’s electrical field. Multi-touch functions (think “pinch-to-zoom”) are made possible by triangulating electrical alterations to calculate paired coordinates that “read” the touch location. Unlike resistive touch screens, capacitive touch screens are unresponsive to touch that does not emit an electrical charge. (Which is why it’s almost impossible to use an iPhone while wearing a glove.)

Some capacitive touch screens include a protective layer that protects the display from moisture, extreme temperature, impacts, and solvents, making it suitable for industrial and outdoor applications. For example, our teams at Pivot created a control system for dairy farms with IoT data reporting and touch screen technology that controls milk tank temperatures and wash cycles.

Like capacitative touch screens, near-field imaging touch screens read touch commands by measuring an electrostatic field. The difference is that NFI touch screens feature a corner-configured electrostatic charge, making them more responsive to touch from almost any source. (Even if you’re wearing a glove, NFI devices will instantly register and respond.) A primary advantage of NFI touch screens is that they can withstand extreme field conditions. This makes them a perfect fit for the industrial and security and defense applications that Pivot brings specialized experience in.

Infrared touch screens rely on a grid of LEDs and light-detector photocells placed at opposing positions. The LEDs beam an infrared matrix across the screen that, when “broken” by touch, provides the basis for the device to detect the input location. Infrared touch screens require dozens of components and precision manufacturing. Despite being more expensive to produce, they are often the ideal product solution for applications that include ticketing kiosks, ATMs, office automation, medtech, and even beverage dispensers like the one Pivot created with an integrated processor and customizable I/O system.

Ultrasound technology has enjoyed cross-industry applications for more than a century. But today’s surface acoustic wave touch screens are light years beyond their earlier incarnations and make it possible to make almost any surface responsive to touch. SAW touch screens work by projecting ultrasound waves across the surface of a screen. As the soundwaves are absorbed by whatever comes in contact with the surface, the screen’s controller chip can instantly identify, read, and accurately respond to commands.

You interact with a touch screen monitor constantly throughout your daily life. You will see them in cell phones, ATM’s, kiosks, ticket vending machines, manufacturing plants and more. All of these use touch panels to enable the user to interact with a computer or device without the use of a keyboard or mouse. But did you know there are several uniquely different types of Touch Screens? The five most common types of touch screen are: 5-Wire Resistive, Surface Capacitive touch, Projected Capacitive (P-Cap), SAW (Surface Acoustic Wave), and IR (Infrared).

We are often asked “How does a touch screen monitor work?” A touch screen basically replaces the functionality of a keyboard and mouse. Below is a basic description of 5 types of touch screen monitor technology. The advantages and disadvantages of type of touch screen will help you decide which type touchscreen is most appropriate for your needs:

5-Wire Resistive Touch is the most widely touch technology in use today. A resistive touch screen monitor is composed of a glass panel and a film screen, each covered with a thin metallic layer, separated by a narrow gap. When a user touches the screen, the two metallic layers make contact, resulting in electrical flow. The point of contact is detected by this change in voltage.

Surface Capacitive touch screen is the second most popular type of touch screens on the market. In a surface capacitive touch screen monitor, a transparent electrode layer is placed on top of a glass panel. This is then covered by a protective cover. When an exposed finger touches the monitor screen, it reacts to the static electrical capacity of the human body. Some of the electrical charge transfers from the screen to the user. This decrease in capacitance is detected by sensors located at the four corners of the screen, allowing the controller to determine the touch point. Surface capacitive touch screens can only be activated by the touch of human skin or a stylus holding an electrical charge.

Projected Capacitive (P-Cap) is similar to Surface Capacitive, but it offers two primary advantages. First, in addition to a bare finger, it can also be activated with surgical gloves or thin cotton gloves. Secondly, P-Cap enables multi-touch activation (simultaneous input from two or more fingers). A projected capacitive touch screen is composed of a sheet of glass with embedded transparent electrode films and an IC chip. This creates a three dimensional electrostatic field. When a finger comes into contact with the screen, the ratios of the electrical currents change and the computer is able to detect the touch points. All our P-Cap touch screens feature a Zero-Bezel enclosure.

SAW (Surface Acoustic Wave) touch screen monitors utilize a series of piezoelectric transducers and receivers. These are positioned along the sides of the monitor’s glass plate to create an invisible grid of ultrasonic waves on the surface. When the panel is touched, a portion of the wave is absorbed. This allows the receiving transducer to locate the touch point and send this data to the computer. SAW monitors can be activated by a finger, gloved hand, or soft-tip stylus. SAW monitors offer easy use and high visibility.

IR (Infrared) type touch screen monitors do not overlay the display with an additional screen or screen sandwich. Instead, infrared monitors use IR emitters and receivers to create an invisible grid of light beams across the screen. This ensures the best possible image quality. When an object interrupts the invisible infrared light beam, the sensors are able to locate the touch point. The X and Y coordinates are then sent to the controller.

We hope you found these touch screen basics useful. TRU-Vu provides industrial touch screen monitors in a wide range of sizes and configurations. This includes UL60601-1 Medical touch screens, Sunlight Readable touch screens,Open Frame touch screens, Waterproof touch screens and many custom touch screen designs. You can learn more HERE or call us at 847-259-2344. To address safety and hygiene concerns, see our article on “Touch Screen Cleaning and Disinfecting“.

There are a variety of touch technologies available today, with each working in different ways, such as using infrared light, pressure or even sound waves. However, there are two touchscreen technologies that surpass all others - resistive touch and capacitive touch.

There are advantages to both capacitive and resistive touchscreens, and either can be suited for a variety of applications dependent on specific requirements for your market sector.

Resistive touchscreens use pressure as input. Made up of several layers of flexible plastic and glass, the front layer is scratch resistant plastic and the second layer is (usually) glass. These are both coated with conductive material. When someone applies pressure to the panel, the resistance is measured between the two layers highlighting where the point of contact is on the screen.

Some of the benefits of resistive touch panels include the minimal production cost, flexibility when it comes to touch (gloves and styluses can be used) and its durability – strong resistance to water and dust.

In contrast to resistive touchscreens, capacitive touchscreens use the electrical properties of the human body as input. When touched with a finger, a small electrical charge is drawn to the point of contact, which allows the display to detect where it has received an input. The result is a display that can detect lighter touches and with greater accuracy than with a resistive touchscren.

If you want increased screen contrast and clarity, capacitive touch screens are the preferred option over resistive screens, which have more reflections due to their number of layers. Capacitive screens are also far more sensitive and can work with multi-point inputs, known as ‘multi-touch’. However, because of these advantages, they are sometimes less cost-effective than resistive touch panels.

Although capacitive touchscreen technology was invented long before resistive touchscreens, capacitive technology has seen more rapid evolution in recent years. Thanks to consumer electronics, particularly mobile technology, capacitive touchscreens are swiftly improving in both performance and cost.

At GTK, we find ourselves recommending capacitive touchscreens more regularly than resitive ones. Our customers almost always find capacitive touchscreens more pleasant to work with and appreciate the vibrancy of image that cap touch TFTs can produce. With constant advancements in capacitive sensors, including new fine-tuned sensors that work with heavy duty gloves, if we had to pick just one, it would be the capacitive touchscreen.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Touch panel technologies are a key theme in current digital devices, including smartphones, slate devices like the iPad, the screens on the backs of digital cameras, the Nintendo DS, and Windows 7 devices. The term touch panel encompasses various technologies for sensing the touch of a finger or stylus. In this session, we"ll look at basic touch panel sensing methods and introduce the characteristics and optimal applications of each.

Note: Below is the translation from the Japanese of the ITmedia article "How Can a Screen Sense Touch? A Basic Understanding of Touch Panels"published September 27, 2010. Copyright 2011 ITmedia Inc. All Rights Reserved.

A touch panel is a piece of equipment that lets users interact with a computer by touching the screen directly. Incorporating features into the monitor like sensors that detect touch actions makes it possible to issue instructions to a computer by having it sense the position of a finger or stylus. Essentially, it becomes a device fusing the two functions of display and input.

It"s perhaps not something we think of often, but touch panels have integrated themselves into every aspect of our lives. People who enjoy using digital devices like smartphones interact with touch panels all the time in everyday life—but so do others, at devices like bank ATMs, ticket vending machines in railway stations, electronic kiosks inside convenience stores, digital photo printers at mass merchandisers, library information terminals, photocopiers, and car navigation systems.

A major factor driving the spread of touch panels is the benefits they offer in the way of intuitive operation. Since they can be used for input through direct contact with icons and buttons, they"re easy to understand and easily used, even by people unaccustomed to using computers. Touch panels also contribute to miniaturization and simplification of devices by combining display and input into a single piece of equipment. Since touch panel buttons are software, not hardware, their interfaces are easily changed through software.

While a touch panel requires a wide range of characteristics, including display visibility above all, along with precision in position sensing, rapid response to input, durability, and installation costs, their characteristics differ greatly depending on the methods used to sense touch input. Some typical touch-panel sensing methods are discussed below.

As of 2010, resistive film represented the most widely used sensing method in the touch panel market. Touch panels based on this method are called pressure-sensitive or analog-resistive film touch panels. In addition to standalone LCD monitors, this technology is used in a wide range of small to mid-sized devices, including smartphones, mobile phones, PDAs, car navigation systems, and the Nintendo DS.

With this method, the position on screen contacted by a finger, stylus, or other object is detected using changes in pressure. The monitor features a simple internal structure: a glass screen and a film screen separated by a narrow gap, each with a transparent electrode film (electrode layer) attached. Pressing the surface of the screen presses the electrodes in the film and the glass to come into contact, resulting in the flow of electrical current. The point of contact is identified by detecting this change in voltage.

The advantages of this system include the low-cost manufacture, thanks to its simple structure. The system also uses less electricity than other methods, and the resulting configurations are strongly resistant to dust and water since the surface is covered in film. Since input involves pressure applied to the film, it can be used for input not just with bare fingers, but even when wearing gloves or using a stylus. These screens can also be used to input handwritten text.

Drawbacks include lower light transmittance (reduced display quality) due to the film and two electrode layers; relatively lower durability and shock resistance; and reduced precision of detection with larger screen sizes. (Precision can be maintained in other ways—for example, splitting the screen into multiple areas for detection.)

Capacitive touch panels represent the second most widely used sensing method after resistive film touch panels. Corresponding to the terms used for the above analog resistive touch panels, these also are called analog capacitive touch panels. Aside from standalone LCD monitors, these are often used in the same devices with resistive film touch panels, such as smartphones and mobile phones.

With this method, the point at which the touch occurs is identified using sensors to sense minor changes in electrical current generated by contact with a finger or changes in electrostatic capacity (load). Since the sensors react to the static electrical capacity of the human body when a finger approaches the screen, they also can be operated in a manner similar to moving a pointer within an area touched on screen.

Two types of touch panels use this method: surface capacitive touch panels and projective capacitive touch panels. The internal structures differ between the two types.

Surface capacitive touch panels are often used in relatively large panels. Inside these panels, a transparent electrode film (electrode layer) is placed atop a glass substrate, covered by a protective cover. Electric voltage is applied to electrodes positioned in the four corners of the glass substrate, generating a uniform low-voltage electrical field across the entire panel. The coordinates of the position at which the finger touches the screen are identified by measuring the resulting changes in electrostatic capacity at the four corners of the panel.

While this type of capacitive touch panel has a simpler structure than a projected capacitive touch panel and for this reason offers lower cost, it is structurally difficult to detect contact at two or more points at the same time (multi-touch).

Projected capacitive touch panels are often used for smaller screen sizes than surface capacitive touch panels. They"ve attracted significant attention in mobile devices. The iPhone, iPod Touch, and iPad use this method to achieve high-precision multi-touch functionality and high response speed.

The internal structure of these touch panels consists of a substrate incorporating an IC chip for processing computations, over which is a layer of numerous transparent electrodes is positioned in specific patterns. The surface is covered with an insulating glass or plastic cover. When a finger approaches the surface, electrostatic capacity among multiple electrodes changes simultaneously, and the position were contact occurs can be identified precisely by measuring the ratios between these electrical currents.

A unique characteristic of a projected capacitive touch panel is the fact that the large number of electrodes enables accurate detection of contact at multiple points (multi-touch). However, the projected capacitive touch panels featuring indium-tin-oxide (ITO) found in smartphones and similar devices are poorly suited for use in large screens, since increased screen size results in increased resistance (i.e., slower transmission of electrical current), increasing the amount of error and noise in detecting the points touched.

Larger touch panels use center-wire projected capacitive touch panels in which very thin electrical wires are laid out in a grid as a transparent electrode layer. While lower resistance makes center-wire projected capacitive touch panels highly sensitive, they are less suited to mass production than ITO etching.

Above, we"ve summarized the differences between the two types of capacitive touch panels. The overall characteristics of such panels include the fact that unlike resistive film touch panels, they do not respond to touch by clothing or standard styli. They feature strong resistance to dust and water drops and high durability and scratch resistance. In addition, their light transmittance is higher, as compared to resistive film touch panels.

On the other hand, these touch panels require either a finger or a special stylus. They cannot be operated while wearing gloves, and they are susceptible to the effects of nearby metal structures.

Surface acoustic wave (SAW) touch panels were developed mainly to address the drawbacks of low light transmittance in resistive film touch panels—that is, to achieve bright touch panels with high levels of visibility. These are also called surface wave or acoustic wave touch panels. Aside from standalone LCD monitors, these are widely used in public spaces, in devices like point-of-sale terminals, ATMs, and electronic kiosks.

These panels detect the screen position where contact occurs with a finger or other object using the attenuation in ultrasound elastic waves on the surface. The internal structure of these panels is designed so that multiple piezoelectric transducers arranged in the corners of a glass substrate transmit ultrasound surface elastic waves as vibrations in the panel surface, which are received by transducers installed opposite the transmitting ones. When the screen is touched, ultrasound waves are absorbed and attenuated by the finger or other object. The location is identified by detecting these changes. Naturally, the user does not feel these vibrations when touching the screen. These panels offer hi

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey