tft display burn in factory

TFT LCD image retention we also call it "Burn-in". In CRT displays, this caused the phosphorus to be worn and the patterns to be burnt in to the display. But the term "burn in" is a bit misleading in LCD screen. There is no actual burning or heat involved. When you meet TFT LCD burn in problem, how do you solve it?

Burn in is a noticeable discoloration of ghosting of a previous image on a display. It is caused by the continuons drive of certain pixels more than other pixels. Do you know how does burn in happen?

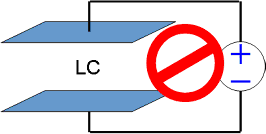

When driving the TFT LCD display pixels Continously, the slightly unbalanced AC will attract free ions to the pixels internal surface. Those ions act like an addition DC with the AC driving voltage.

Those burn-in fixers, screen fixer software may help. Once the Image Retention happened on a TFT, it may easy to appear again. So we need to take preventive actions to avoid burn in reappearing.

For normal white TFT LCD, white area presenting minimal drive, black area presenting maximum drive. Free ions inside the TFT may are attracted towards the black area (maximum drive area)

When the display content changed to full screen of 128(50%) gray color, all the area are driving at the same level. Those ions are free again after a short time;

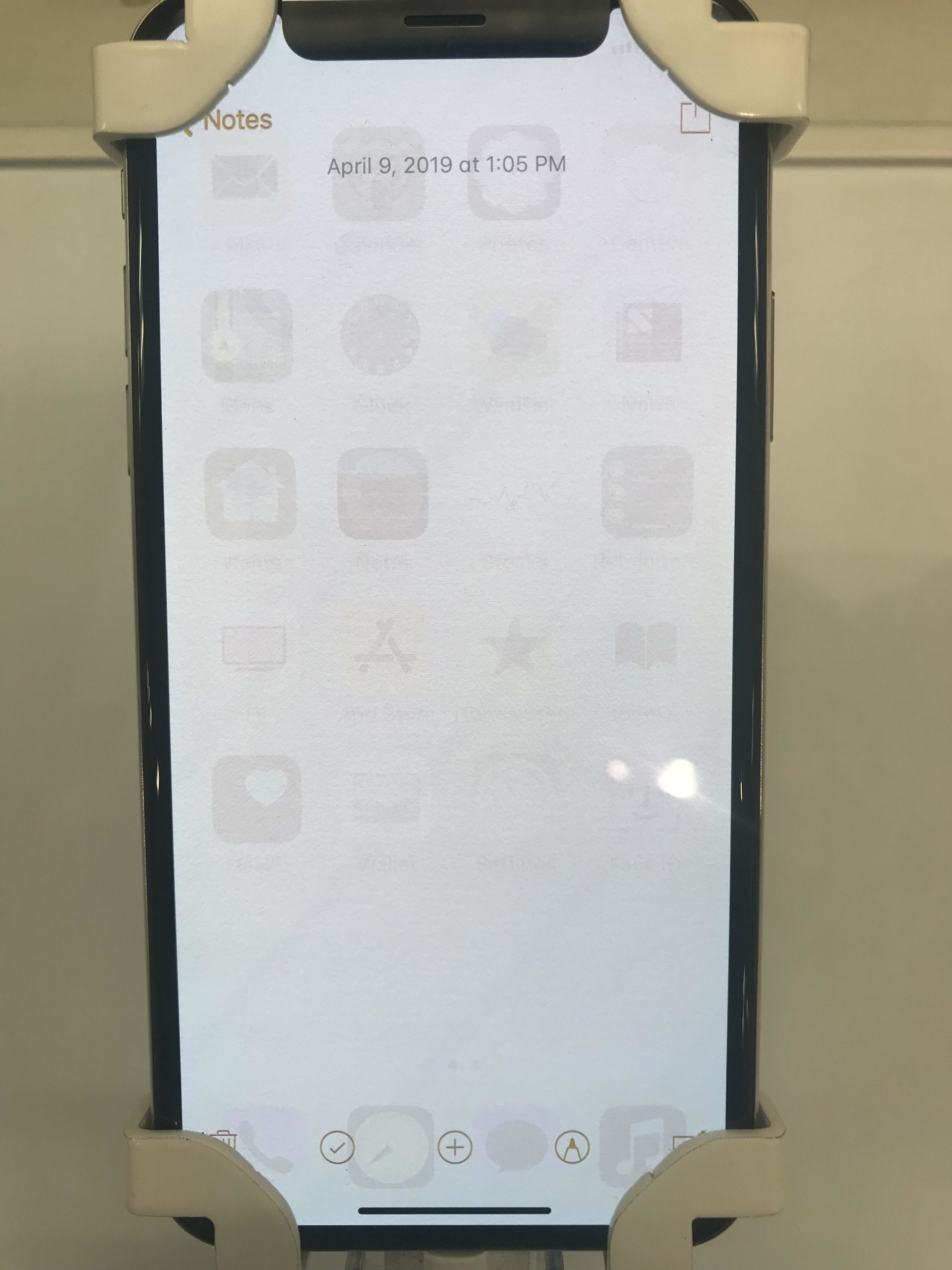

If you"ve ever left your LCD monitor on a single static screen for an extended period, say 24 hours or more, and then changed the on-screen image and seen a "ghost" of the previous screen, you"ve experienced Image Persistence. You can also sometimes see this phenomenon while traveling through an airport and seeing the flight status monitors. The good news is that the persistence is not permanent, unlike previous technologies such as plasma displays or CRTs.

The previous technologies of plasma displays and CRTs are phosphor-based, and extended static images create a "burn-in" that affects the properties of the phosphor material and create permanent damage. The damage is called burn-in, whereas static image "ghosts" on an LCD are Image Persistence. Image Persistence is not permanent damage and is reversible. Modern LCDs include design, driver ICs and chemical improvements that minimize these effects.

To understand why image persistence happens, we must first understand the basic structure of an LCD TFT. Within the TFT, a voltage is applied to the liquid crystal material to align or twist the crystals in each pixel to allow light to pass through or block light, thus creating the on-screen image. By allowing a static image to remain on screen for an extended duration, the polarity of that voltage on the crystals remains. During this time, ions within the liquid crystal fluid will migrate to either the + or – electrode of the transistor (source or drain). As these ions accumulate on the electrodes, the voltage applied to the crystals to align or twist is no longer sufficient to completely change the image on-screen, resulting in a "ghost effect" from the previous image.

The best method for preventing Image Persistence is to avoid having any static images on the screen for an extended time. If the image changes periodically, the ion flow will never have an opportunity to accumulate on any internal electrode. However, depending upon the use of the display, it is not always possible to avoid static images on the screen. In cases such as these, there are steps that you can do to reduce the chance of persistence.

Switching off the displayduring periods of inactivity (sleeping mode) and arousing at necessary image changes would also be reflected as a positive side effect providing lower power consumption.

Panel manufacturers specifically test for the phenomenon and have designed the TFT cell and improved the purity of the liquid crystal fluid to minimize any effect of image persistence.

If you have a project that is considering taking advantage of any display technology, US Micro Products can provide a solution designed for your application. Send us an email at sales@usmicroproducts.com.

In my application, the same data will/can be kept on the TFT LCD display for a long time e.g couple of days or even for months and I can"t run any screen saver. I have read that this causes pixel burn or damage.

Does your Company offer any solution in terms of Industrial Grade Displays for Panel Monitoring with long long life ( Back-light as well as pixel safety)?.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

LCD (liquid crystal display) is the most widely used display technology. They are used for automotive, appliance, telecommunication, home appliance, industrial, consumer electronic, military etc. But LCD displays have some drawbacks, such as slow response, narrow viewing angle, lower contrast etc. One annoying phenomenon often complained about by users is image sticking.

If a fixed image remains on a display for a long period of time, the faint outline of that image will persist on the screen for some time before it finally disappears. Normally, it happens to LCD and plasma screens, but for the purpose of our discussion, we will focus on TFT LCD displays. Image sticking is also referred to as “image persistence”, “image retention”, “ghosting” or “burn-in image.”

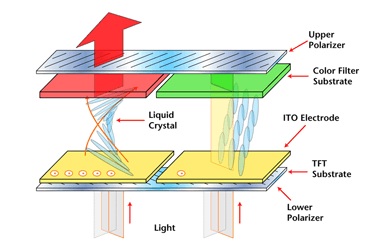

An LCD screen includes a thin layer of liquid crystal material sandwiched between two electrodes on glass substrates, with two polarizers on each side. A polarizer is an optical filter that lets light waves of a specific polarization pass through while blocking light waves of other polarizations. The electrodes need to be transparent so the most popular material is ITO (indium tin oxide). Since an LCD can’t emit light itself, normally a backlight is placed behind an LCD screen in order to be seen in a dark environment. The light sources used for a backlight can be LED (light emitting diode) or CCFL (cold cathode fluorescent lamps). The LED backlight is the most popular. Of course, if you want a color display, a layer of RGB color filter can be made into an LCD cell. A touch panel can also be added in front of an LCD display.

When an electric field is applied to the liquid crystal molecules, they become untwisted. When the polarized light reaches the layer of liquid crystal molecules, the light passes straight through without being twisted. When it reaches the second polarizer, it will also pass through, meaning the viewer sees the display as bright. Because LCD technology uses electric fields instead of electric current (electron passes through), it has low power consumption.

The cause of LCD image sticking is due to an accumulation of ionic impurities inside the liquid crystal materials. When slight DC voltage occurs, the charged impurities will move the electrodes and build up a reversed voltage field. When the power is removed, the reversed voltage will kick in to make the LCD molecules twisted different from the other part of the LCD, which shows up as the image sticking. The longer the time, the more impurities will migrate, the larger the reversed voltage will be, and the imaging sticking will appear worse.

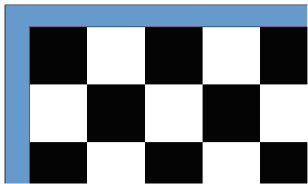

Using the black/white chess board image shown above: Static image it for 2 hours, then change to 50% gray for 1 min. Use an 8% neutral density filter to check if it is OK.

If a static image must be displayed, try to use block patterns instead of distinct border lines. Try to use medium gray hues and use colors that are symmetric to the middle grey level at the boundary of two different colors. Gradually shift the border lines once in a while.

For LCD manufacturers, try to protect liquid crystal materials exposed to the air by using nitrogen gas or dried air to avoid absorbing moisture that can create a huge amount of impurities in the liquid crystal material, as water is an excellent solvent. Controlling the humidity of the fab is also very important, as is selecting the right liquid crystal materials and their manufacturers. Different liquid crystal materials have different moisture absorbing abilities. Different liquid crystal material factories have different capabilities in terms of controlling impurities. Despite the fact that high purity can mean high in cost, using higher purity liquid crystal materials and designing the circuitry to get rid of DC in LCD display drivers can avoid an image sticking issue.

Unlike the “burn-in” issue common with CRTs, an image sticking issue is not permanent. It will eventually recover after some time. One way to expedite erasing a retained image is to have a screen on in an all-black pattern for 4-6 hours. If you want to make it even faster, the display can be put into an environment with a temperature of around 35 to 50°C for 1-2 hours. As this elevated temperature is within the working temperature range, it will not damage the LCD panels.

:max_bytes(150000):strip_icc()/Emerson-McDonalds_CNN_Burn-In-5692ad0d3df78cafda81df58-5c619daec9e77c0001d92fc1.jpg)

DGBELL"s burn-in chamber is widely applied to electronic and electric products, components and materials by constant high low temperature, temperature shock and rapid temperature change reliability test.

With high precision perfect external design, external with double sides cold rolled plate electrostatic powder coated material, internal with SUS#304 high temperature resistant stainless steel. Insulation material adopts fire resistant high strength glass fiber thermal insulating material. The Control system and control circuit all introduced with the famous brand.

DGBELL"s burn-in chamber is widely applied to electronic and electric products, components and materials by constant high low temperature, temperature shock and rapid temperature change reliability test.

With high precision perfect external design, external with double sides cold rolled plate electrostatic powder coated material, internal with SUS#304 high temperature resistant stainless steel. Insulation material adopts fire resistant high strength glass fiber thermal insulating material. The Control system and control circuit all introduced with the famous brand.

Steven Van Slyke and Ching Wan Tang pioneered the organic OLED at Eastman Kodak in 1979. The first OLED product was a display for a car stereo, commercialized by Pioneer in 1997. Kodak’s EasyShare LS633 digital camera, introduced in 2003, was the first consumer electronic product incorporating a full-color OLED display. The first television featuring an OLED display, produced by Sony, entered the market in 2008. Today, Samsung uses OLEDs in all of its smartphones, and LG manufactures large OLED screens for premium TVs. Other companies currently incorporating OLED technology include Apple, Google, Facebook, Motorola, Sony, HP, Panasonic, Konica, Lenovo, Huawei, BOE, Philips and Osram. The OLED display market is expected to grow to $57 billion in 2026.

AMOLED (Active Matrix Organic Light Emitting Diode) is a type of OLED display device technology. OLED is a type of display technology in which organic material compounds form the electroluminescent material, and active matrix is the technology behind the addressing of individual pixels.

An AMOLED display consists of an active matrix of OLED pixels generating light (luminescence) upon electrical activation that have been deposited or integrated onto a thin-film transistor (TFT) array, which functions as a series of switches to control the current flowing to each individual pixel.

Typically, this continuous current flow is controlled by at least two TFTs at each pixel (to trigger the luminescence), with one TFT to start and stop the charging of a storage capacitor and the second to provide a voltage source at the level needed to create a constant current to the pixel, thereby eliminating the need for the very high currents required for PMOLED.

TFT backplane technology is crucial in the fabrication of AMOLED displays. In AMOLEDs, the two primary TFT backplane technologies, polycrystalline silicon (poly-Si) and amorphous silicon (a-Si), are currently used offering the potential for directly fabricating the active-matrix backplanes at low temperatures (below 150 °C) onto flexible plastic substrates for producing flexible AMOLED displays. Brightness of AMOLED is determined by the strength of the electron current. The colors are controlled by the red, green and blue light emitting diodes. It is easier to understand by thinking of each pixel is independently colored, mini-LED.

IPS technology is like an improvement on the traditional TFT LCD display module in the sense that it has the same basic structure, but with more enhanced features and more widespread usability compared with the older generation of TN type TFT screen (normally used for low-cost computer monitors). Actually, it is called super TFT. IPS LCD display consists of the following high-end features. It has much wider viewing angles, more consistent, better color in all viewing directions, it has higher contrast, faster response time. But IPS screens are not perfect as their higher manufacturing cost compared with TN TFT LCD.

Utilizing an electrical charge that causes the liquid crystal material to change their molecular structure allowing various wavelengths of backlight to “pass-through”. The active matrix of the TFT display is in constant flux and changes or refreshes rapidly depending upon the incoming signal from the control device.

N2 - This paper describes a thorough investigation to identify the root cause of an LCD panel burn-in failure induced by an LCD source driver, which is observed in a large-scale LCD factory producing more than one million LCD panels per month. The investigation demonstrates the effectiveness of the circuit simulation to precisely locate the defective spot which is caused by a metal slice originated from outer rings of an LCD COG (chip-on-glass) source driver. With the aid of emission microscope (EMMI), Energy Dispersive Analysis X-Ray (EDAX), and Chip Probing (CP) tester, the root cause of the failure is well explained. The formation mechanism of metal slice from the outer rings is thoroughly studied. A solution to completely eliminate the source of metal slices from the outer rings during wafer processing is also proposed.

AB - This paper describes a thorough investigation to identify the root cause of an LCD panel burn-in failure induced by an LCD source driver, which is observed in a large-scale LCD factory producing more than one million LCD panels per month. The investigation demonstrates the effectiveness of the circuit simulation to precisely locate the defective spot which is caused by a metal slice originated from outer rings of an LCD COG (chip-on-glass) source driver. With the aid of emission microscope (EMMI), Energy Dispersive Analysis X-Ray (EDAX), and Chip Probing (CP) tester, the root cause of the failure is well explained. The formation mechanism of metal slice from the outer rings is thoroughly studied. A solution to completely eliminate the source of metal slices from the outer rings during wafer processing is also proposed.

Pulse Width Modulation is something you will hear talked about quite a lot nowadays. We have a full detailed article about PWM which is worth reading through. In simple terms, PWM is a method used for dimming a monitors backlight whereby the backlight is turned off and on rapidly to simulate lower brightness levels. As you decrease the brightness setting of the screen the “off” periods are increased in length progressively and this in turn leads to a lower luminance output for the display (darker image). The problem with PWM is that on modern LED backlights the rapid turning of the backlight off and on can lead to flickering. Sometimes when the frequency of the PWM is low this might even be visible to some users. In other cases, while it might not be visible the user may still experience unwanted side-effects of its use including eye-strain, headaches, eye fatigue and even nausea.

To overcome this, many manufacturers now actively promote their use of flicker-free backlights and have done away with PWM completely. If you are sensitive to the use of PWM or are just worried about your eye health, we would certainly recommend trying to avoid displays where PWM is used.

Dithering and Frame Rate Control (FRC) relate to the colour depth of a monitor panel and are technologies used to boost the colours which the matrix can display. For instance TN Film screens are traditionally more economical than other technologies when it comes to colour depth. In fact, they only display 64 red, 64 blue and 64 true green shades by default through pixel rotations. The maximum amount of colours achievable from liquid crystal rotation alone is 262,144. In order to reach 16 million colours and above, panel manufacturers commonly use two technologies: Dithering and Frame Rate Control (FRC). These terms are often interchanged, but strictly can mean different things.

Spatial Dithering – This dithering method involves assigning appropriate colour values from the available colour palette to close-by pixels in such a way that it gives the impression of a new colour tone which otherwise could not have been created at all. In doing so, there complex mappings according to which the ground colours are mutually assigned, otherwise it could result in colour noise / dithering noise. Dithering can be used to allow 6-Bit panels, like TN Film, to show 16.2 million perceived colours. This can however sometimes be detectable to the user, and can result in chessboard like patterns being visible in some cases. Spatial dithering is rarely used in the modern market and instead Frame Rate Control is more widely utilised.

Frame Rate Control / Temporal Dithering– The other method is Frame-Rate-Control (FRC), also referred to sometimes as temporal dithering. This works by combining four colour frames as a sequence in time, resulting in perceived mixture. In basic terms, it involves flashing between two colour tones rapidly to give the impression of a third tone, not normally available in the palette. This allows a total of 16.2 reproducible million colours in 6-bit TN Film matrices. FRC is also used to enhance the colour depth of 8-bit panels, boosting them from their standard 16.7 million colours to 1.07 billion in the case of “10-bit” panels (8-bit + FRC). There are a number of FRC algorithms which vary in their effectiveness. Sometimes, a twinkling artefact can be seen, particularly in darker shades, which is a side affect of such technologies.

While TFT screens are best run at their native resolutions, it is possible to run them at lower resolutions if need be. In doing so the screen must interpolate the image from below the native resolution, leading commonly to some loss in image clarity and sharpness as the image is stretched across pixels. In office use this can be a problem and can look quite poor, but in gaming, it is generally not so much of a problem. The ability of a TFT to interpolate the image depends on the particular panel and scaler used, and some manufacturers have been able to improve the ability of their panels to run outside the native resolution. Generally though it is not recommended to run outside the native resolution on a TFT if you can help it. Where resolutions are very high (e.g. Ultra HD / 4K) then you will still want to run the display at the full native resolution, but enabled operating system scaling to make everything easier to see.

Where screens are having to handle lower resolutions, the image will normally be interpolated and stretched to fill the screen completely. This can cause problems if your source content does not match the aspect ratio of the screen. One way manufacturers can get round this is with the use of aspect ratio retention methods including what is commonly referred to as 1:1 pixel mapping. This aspect ratio retention can be carried out by the screen in some cases where the options are available, or if not, you can normally achieve it via your graphics card control panel.

This feature refers to the screens ability to maintain an aspect ratio of a source image at the hardware level. For instance, if you tried to play a 4:3 aspect game on a 16:10 format display, the image would normally be stretched to fill the screen, stretching the aspect ratio horizontally. However, if the hardware is capable of maintaining the aspect ratio, the screen can display the source in it’s normal 4:3 ratio, and will add black borders along each side.

This aspect ratio retention can be achieved in two ways. The most reliable and easy to use is through the hardware (monitor) itself and normally involves the availability of preset modes in the OSD. There are often differing options available for aspect ratio control, including:

“fill” the screen ignoring any aspect ratio differences between source and display. A 4:3 source would be stretched to fill the screen regardless for example.

“aspect” or “auto” is used to maintain whatever aspect ratio is sent by the source, but interpolate the image to fill as much of the screen as possible. This would result in black borders along the right and left hand sides on a WS format screen displaying a 4:3 source for example.

4:3, 5:4, 16:9 and 16:10 – often modes are provided to specially control and maintain a defined source aspect ratio such as these. Keep in mind the native aspect ratio of the screen as well.

“1:1 pixel mapping” – this is used to literally map the exact number of pixels specified in the source resolution to pixels on the screen. For instance a 1024 x 768 source resolution would be displayed on a 1920 x 1200 resolution monitor, only using the pixels required and would not be interpolated or stretched. This would result in black borders on all sides of the image. This would be like using a smaller screen within the larger screen and is handy for those wanting to run games at lower resolutions but without losing image quality through interpolation.

The other option for aspect ratio retention is through software. NVIDIA and AMD display drivers for instance can achieve similar settings to above quite easily. However, results can be a little more variable and difficult to achieve. They are of course no use if you are using an external device such as a DVD/Blu-ray player or games console as they are not normally able to control the aspect ratio themselves and would need to rely on the screen to support it at a hardware level.

Backlight leakage refers to the problem some screens exhibit where in a darkly lit room, and with a dark image on the screen, you can clearly see areas particularly around the edges where the backlight shines through. This is a problem with the manufacturing stage and quality of the monitor build and can also sometimes be influenced by transportation and storage. A lot of panels will show slightly uneven backlighting, with perhaps a little light noticeable at the edges of the screen or in the corners. Where it is minor, and only visible on very specific (and unrealistic) test situations it is probably not worth worrying about. Also consider that a screen might need some “bedding in” time to settle in your office before you test this kind of thing. Panel uniformity can vary from one screen to the next and from sample to sample, it is very hard to predict. Where backlight bleed is severe or very distracting, a return to the retailer or manufacturer is suggested.

Note: if you want to test your own screen for backlight bleed and uniformity problems at any point you need to ensure you have suitable testing conditions. Set the monitor to a sensible day to day brightness level, preferably as close to 120 cd/m2 as you can get it (our tests are once the screen is calibrated to this luminance). Don’t just take a photo at the default brightness which is almost always far too high and not a realistic usage condition. You need to take the photo from about 1.5 – 2m back to avoid capturing viewing angle characteristics, especially on IPS-type panels where off-angle glow can come in to play easily. Photos should be taken in a darkened room at a shutter speed which captures what you see reliably and doesn’t over-expose the image. A shutter speed of 1/8 second will probably be suitable for this.

On modern IPS panels when viewing a black image there is typically a characteristic white glow when viewed from an angle, commonly referred to as “IPS-glow”. This is common on most modern IPS-type panels and can be distracting to some users. The level of glow shown here is pretty typical of a modern IPS-type panel. If you view dark content from a normal head-on viewing position, you can actually see this glow slightly as your eyes look towards the edges of the screen if it is of a large size. The wider the screen and the bigger it is, the more likely you are to see some glow from your normal viewing position as you glance towards the edges. A curve to the screen can help reduce this a little as the angle between your eyes and the edges is reduced a little. Some people may find this IPS-glow problematic if they are working with a lot of dark content or solid colour patterns. In normal day to day uses, office work, movies and games you probably wouldn’t really notice this unless you were viewing darker content. If you move your viewing position back, which is probably likely for movies and games, the effect reduces as you do not have such an angle from your eye position to the screen edges.

This is one area where TN Film panel technology is actually better than IPS-type for viewing angles, as there is far less pale glow from an angle on dark content. For dark room conditions, and a lot of dark content some people might prefer to live with the more restrictive viewing angles and less glow of the TN Film panel. Others might want to use the screen for more all-round uses and prefer the IPS panel. It’s down to preference really and your individual uses.

We want to make a point at this stage relating to IPS glow. The above image shows the corners of the screen as observed from a central viewing position, at a normal viewing distance of a couple of feet from the screen. As you look towards the corners of the screen you can see a glow and pale areas on the dark content. This is not backlight bleed! We see many reports of users who mistake IPS glow which is a panel characteristic, for backlight bleed which is a build quality issue. This glow in the corners is caused by your angle of vision when viewing the screen and is because of the pixel structure on the IPS panel. If you view the screen from even wider angles (like the image shown above it) the glow becomes more white and pale. This IPS glow is a “feature” of nearly every IPS-type panel on the market, so as a buyer you should be expecting it. It’s not grounds for a return of the screen as a fault when it is just a feature of the panel technology. The bigger the screen, and the wider the field of view, the more obvious this glowing from the corners will be. On a 34″ ultra-wide screen for instance there are very wide fields of view and so you will notice it when sat up close to the screen and viewing dark content.

If you move your viewing position back a metre or so and view that side of the screen head on as shown above, the glow has disappeared. You can tell there’s barely any clouding or bleed from the backlight in these corners. So what was previously thought of as bleed, actually isn’t at all.

Banding is an issue which you can sometimes spot on a monitor, and involves blocking and gradation of colours to a considerable level. This is most evident when viewing colour gradients, and rather than the colours showing a gradual change in shade as they should, the image appears as blocks with clearly defined steps. A certain degree of gradation in a gradient image can be expected from many monitors, despite the fact that in an ideal world, the gradient would be smooth and all transitions would be transparent. However, it is in the cases where the gradation is more noticeable that it results in what is popularly referred to as “banding”.

Some users think that striped gradients are due to the use of 6-bit matrixes instead of 8-bit ones, but this is not exactly true. The lower colour depth of the matrix may indeed lead to stripes in gradients if the Frame Rate Control is poorly implemented (this is the technology that emulates 16 million colours while the matrix itself is only capable of displaying ~262,000), but the real reason is usually different. Before outputting the image on the screen, the monitor performs a series of calculations and transformations: colour temperature correction, gamma compensation, contrast correction, etc. If the accuracy of those calculations is low, you see striped gradients. The matrix’s colour depth has nothing to do with it. Even an “honest” 8-bit matrix cannot guarantee that the monitor will correctly process the data before sending them to the matrix. Some models will offer technologies which have higher bit internal processing (commonly 10-bit or 12-bit for example) along with higher bit LUT to help provide wider colour palettes and better processing. This can help minimise and avoid banding issues on gradients.

Some monitors have made banding rather infamous and so many potential buyers now cite this as an important test of a screen, and something which can really separate the good from the bad. A lot of this is quite exaggerated however, with far too much concern about even slight gradation across colour gradients. The early releases of the Dell 2xx7 series were a classic example of where colour banding became a concern. The early releases did show some pretty bad banding, which was promptly fixed by Dell with firmware upgrades. However, it has resulted in many users criticising displays for even slight gradation, and not really considering whether it is really an issue in real use. For the majority of users, it would probably not be an issue in practice, and you’d probably be hard pressed to see any adverse affects of this issue in anything other than colour gradient tests. I would advise caution about the talk of banding on displays, and consider whether there is really as much of an issue as some people make out.

The Screen Door effect is so called because sometimes it is possible to clearly see the individual pixels in a panel and the gaps between them. This is quite rare, but can be distracting if you are using a TFT up close. It may be more apparent where pixel pitch is large (e.g. a large screen with a relatively low native resolution / number of pixels in the matrix).

Input lag is described as the lag between the output from a graphics card and the image which is displayed on the screen you are using. For LCD screens this should not be confused with pixel response time which describes the speed at which a pixel can change from one orientation to another. Pixel response times impact aspects such as motion blur and ghosting in moving images. On the other hand input lag is a delay between what is sent to the monitor, and what you actually see. This can have impacts particularly in gaming where if the screen is lagging at all, it can have adverse affects on first person shooter games and the likes where every millisecond counts. Lag is more about the ‘feel’ of delay.

Input lag is sometimes categorised in two ways which can make things a little confusing. One way to describe input lag is to talk about the raw signal processing delay introduced by the electronics of the screen. In some cases this can be measured accurately using an oscilloscope system. However while that might strictly be the “input lag” of the screen it doesn’t account for the overall lag of the display experienced by the user. It is the overall “display lag” which is also important to users and is really the number most regularly referred to as “input lag”. The display lag would be a combination of the signal processing lag and an element of the pixel response times. This overall display lag would then be that seen by the user when comparing against a CRT for instance.

The level of lag really depends on the TFT display, and is controlled by many signal processing factors including, but not limited to the internal electronics and scaling chips. Some manufacturers even take measures to help reduce this, providing modes which bypass scaler chips and options which reduce the input lag. These are often reserved for gamer-orientated screens but the results can be quite noticeable in some cases. Where NVIDIA G-sync modules are used you will tend to see very low levels of lag as well, as the screen does not have a scaler present.

In practice, input lag is unlikely to affect too many general users. There is quite a lot of fuss made about it on forums, but in reality I would doubt many people will see any real issues on the majority of displays. Some professional gamers who rely on being able to match their key presses and mouse movements with what is shown on the screen might suffer in some cases, so it is something to be wary of. Generally though, we would avoid worrying too much about this issue for most average uses.

If you want a full understanding of what a Look Up Table is I’d recommend reading here on Wikipedia. For the sake of keeping this more simple, in the context of monitors we commonly talk about two types of LUT which ultimately communicate with one another to produce the image seen on your screen.

A graphics card LUT– This is the LUT relating only to the graphics card driving your monitor. In crude terms, it controls the colours, and output of the graphics card. During processes such as calibration, this LUT can be adjusted and this can help improve colour accuracy and other settings such as colour temperature and gamma. These corrections and settings can be saved and profiled to ensure lasting results.

A monitor LUT – All monitors will have a LUT which translates the data sent from the graphics card to it and controls the display of the image. Some higher end monitors allow you to adjust the settings in the screen itself, and this is often referred to as a hardware calibrated LUT. Again calibration can adjust the settings of the screen, but this time they are saved within the screen itself for improved accuracy and stability. Hardware calibration is usually reserved for high end professional-grade screens due to its cost to implement.

Whereas a typical 1D LUT adjusts colour on separate tables for each red, green, and blue, a 3D LUT accomplishes this on a single, mixed-colour cubic table. A 3D LUT improves the monitor’s additive colour mixture (combination of RGB), a key factor in its ability to display neutral grey tones.

Cleartype was introduced by Microsoft for use with LCD displays to make fonts more rounded and less jagged. This is effectively a filter used to blur the fonts a little which some people prefer the look of. This can vary from one TFT to another, and it is easy enough to turn on and off to allow you to decide which you prefer. Microsoft’s article about the Cleartype filter can be found here:

Image burn in was traditionally a problem with CRT displays, where prolonged images on the screen could leave a ghost image behind after it has changed. This was a problem with older CRT displays and was the reason for the introduction of screen savers. With TFT’s this is not really a major problem as the image cannot be burnt into the screen by the cathode ray gun, as the pixels all operate individually. Some screens can very occasionally show some lasting imprint of an image if the same picture is left on the screen for long periods of time, but it is generally not permanent. This can often be easily solved by looking at some fast moving scenes or gaming. For the sake of electricity more than anything else though, it is probably easiest to use the power settings on your PC to turn the screen off when not in use.

One of the main concerns people have when buying a TFT relates to the problem of dead pixels. Pixels can sometimes be ‘dead’ (stuck on black or white). Sometimes the sub pixels which make up the pixel can be dead which leaves the pixel looking red, green or blue. Sometimes the sub pixels can be ‘lazy’ and with a bit of luck can come back to life.

Dead pixels / sub pixels defects are normally caused during the manufacturing stage, and it is very rare for a panel to generate a pixel fault at a later stage unless you have a tendency to prod the screen. Nowadays, manufacturing levels are very good and it is quite rare for a pixel to be ‘dead’, and you will see some manufacturers like Samsung and ViewSonic for instance, offering zero dead pixel policies. Dead sub pixels are still a problem, and the policy will not cover these in most cases. Dead pixels are not really considered a fault with a TFT monitor and you will need to consider this before purchasing. Refer to the manufacturer to find out what their dead pixel policy is.

The OSD refers to the “On Screen Display” available on nearly all TFT monitors. This allows the user to change settings ranging from brightness, contrast and colour levels (typically RGB) to more advanced features like aspect ratio and monitor preset modes instance. One thing to note is that some features like contrast, phase and pixel clock are only available when using the VGA (analogue) interface and become greyed out when using the DVI (digital interface) as they are no longer required. Proper configuration of a monitor requires RGB levels to be altered and brightness and contrast to be set correctly. More advanced features are often accessible and modern OSD often offer a wealth of selections. Some OSD also offer factory menus and information about the screen or panel being used which can be particularly useful for the enthusiast.

High-bandwidth Digital Content Protection (HDCP) is a form of Digital Rights Management (DRM) developed by Intel Corporation to control digital audio and video content as it travels across Digital Visual Interface (DVI) or High-Definition Multimedia Interface (HDMI) connections. The specification is proprietary, and creating an implementation of HDCP requires a license.

HDCP’s main target is to prevent transmission of non-encrypted high definition content. In basic terms source material (HD-DVD, BluRay, Next Gen Video Games etc) will be encrypted with HDCP protection. In order to view / use these sources you will need each step in the ‘chain’ to have support for this protection technique. This includes graphics cards in PC’s, DVD players and ultimately (and where we are interested in), the monitor / display device. If all these steps do not have support for HDCP, any encrypted material will have problems playing, typically being reduced to a much lower resolution, showing “not supported” type messages, or not showing any image at all.

HDCP functions over digital interfaces only; and so DVI and HDMI ports are those most affected at present. For a monitor or TV to be truly HD compliant, it must offer HDCP compatibility. Many modern displays do offer this support, but bare in mind they would need digital interfaces to offer this. You may want to consider whether a monitor has HDCP support or not when making your decision, since it may well have an impact on your use in the future. While it was thought that HDCP would not be implemented for many years, it seems it may well be sooner than we had expected. See the below links for further information.

Many screens today have the added functionality of height, pivot, rotate or tilt functions, or sometimes more than one of these. These are provided depending on the stand used and often dependent on the size of the screen. To provide a versatile stand with a wide range of adjustments can add additional cost to the screen and so on some models they are left off.

Tilt – allows the screen to tilt backwards and forwards to achieve a comfortable angle for viewing. Tilt is provided on nearly all monitors, even on the most basic stands

Height – allows for an adjustment of the screen up and down and is useful to achieve a comfortable position for different users, desk positions etc. Height adjustment is not always provided by stands as it usually results in a higher production costs

Rotate – is a function allowing you to flip the screen between landscape and portrait modes. This might be left off some larger screens as it loses its practical uses. Where provided the screen often comes coupled with software which automatically rotates your desktop on demand. This can also easily be achieved with most graphics card software. This can be handy for office and photo work in particular.

Be careful of screens with limited tilt and height adjustments, as they might be restrictive when it comes to aligning them to your line of sight. The use of some features, particularly rotate, becomes a little questionable on the larger screens such as >24″ models, but some may still find them useful and an attractive buying point.

It is possible to detach the stand from some TFT models and instead mount them to a swinging arm on a wall or desk. If this is something you might wish to do, look for TFT’s which specify compatibility with VESA mounts. These can provide improved alignment of a monitor and easier use depending on your needs.

One of the requirements for a Windows Vista when it was released (and kept in later operating systems) was that a compatible monitor is DDC/CI (Display Data Channel Command Interface) compliant. This provides full bidirectional communication between host (PC) and display. Through DDC/CI support, user can use appropriate software to adjust the monitor instead of using the monitor control keys.

These terms are used where a monitor will support displaying multiple inputs on the screen at the same time. For instance you may be able to display the DVI input as well as the HDMI input at the same time. The method for showing two different inputs at the same time can commonly be achieved using PiP or PbP as demonstrated in the image above. You can normally resize and re-position the different images to suit.

Colour reproduction is related to the ability of a panel to produce the colours desired. Typically, the colour reproduction is measured by reviewers using a hardware colorimeter device and a top end software package. They are recorded on graphs similar to this example (on the right):

This graph on the right shows the difference between the desired color shade and the one actually displayed. Basically, the lower these bars down the Y-axis, the better, in terms of colour accuracy. For reference, LaCie (who produce this specific software) describe the DeltaE readings as:

See our reviews for further information about colour accuracy, but it is worth noting that colour accuracy will vary from one screen to another, often varies between different panel technologies, and will vary between default factory settings and a calibrated profile. As a note, the example shown above has very poor colour reproduction accuracy.

This curve indicates the contrast value measured at a given brightness adjustment on the OSD. In theory, brightness and contrast are two independent parameters, and good contrast is a requirement regardless of the brightness adjustment. Unfortunately, such is not the case in practice. The brightness adjustment is shown on the X-axis, contrast on the Y-axis, and in theory this should be fairly even across the OSD brightness adjustment range (but isn’t always!)

Again, some reviewers like ourselves measure the uniformity of a screen. This is useful for considering the uniformity of the panels lighting, and relates to backlight bleeding sometimes when uniformity is particularly bad. Measurements are taken across the screen and compared with a given reference value as measured in the centre of the screen. The deviance from this reference point is then provided as a percentage, showing how the luminance varies across the screen.

I would just turn down the brightness (for less power consumption and monitor longevity, the backlight has nothing to do with the "burn in") and leave a screen saver on overnight. On my monitor, once the screen is back to normal, it doesn"t come back for a while.

It’s important to have accurate and reliable information. Our learning hub is built for you and provides the content that helps you understand how to improve your operations and the lives of the firefighters on your crew.

We work closely with our production facilities to ensure all products follow consistent quality and design guidelines. Being ISO 9001:2015 certified is a fundamental part of how we work. These certifications set the standard for all our daily processes.

We’re proud to uphold our ISO certification status and work with a mindset for growth and improvement. From manufacturing and assembly to customer service and design, we continue to provide the best quality to our customers, on time and without errors. Quality control is performed in-house on all display designs. Our production facilities are also TS-16949 and ISO-14001 certified to ensure consistent quality from start to finish.

“Newhaven Display is committed to providing the highest quality display products and design services to our customers in a timely manner that satisfies all requirements, promotes growth, and increases customer satisfaction. To do this, we implement and improve quality processes beyond industry standards to meet the needs of every customer.”

Quality is important to us and we take our inspections seriously. All products arriving at our Illinois warehouse must pass an inbound quality inspection before they’re accepted, and an outbound inspection prior to release.

We created this guide to provide a detailed explanation of requirements that Newhaven Display products and services must meet. Customers can expect every product they receive from us to meet or exceed these standards.

From designing the end-customer product to special guidance for medical devices or water sensitivity, we want to make sure you experience our products at their full potential, so we created guidelines detailing proper usage and care procedures.

These recommendations for proper handling and cleaning will help prevent accidental damages and answer common questions related to display maintenance.

We explain the difference between permanent image burn-in and temporary image retention, and provide some tips for maintaining your display screens to help avoid burn-in.

For over 20 years, Newhaven Display International has been providing custom display solutions to customers worldwide across different industries. Get in touch today and let us design, develop and manufacture a custom display solution for your application.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey