css lcd display supplier

Custom Silicon Solutions (CSS) is a Semiconductor Company specializing in custom “Mixed Signal” technology that can combine both Analog and Digital functions in a single chip. CSS’s talents and expertise excel in adding Nonvolatile Memory (EEPROM) functions to the same chip. This combined technology capability makes possible a single chip that can replace most of your existing electronic system. CSS is a “fabless” semiconductor company, which allows us to choose the best foundry to meet your needs. Packaging is also subcontracted for improved flexibility and lower cost. Unlike most, CSS typically test both prototype and production units in-house. This optimum approach significantly lowers testing costs (both development and recurring) and provides more timely test data for further cost reductions.

CSS has been successful in this business since 1996, providing Measurement and Control ASICs to the Industrial, Medical, Security, Sensors and Automotive markets. The CSS history with the executive staff at Spirit Electronics provides a winning combination to see your project through with high quality program management, engineering and attention to detail to deliver “as designed” ASIC with minimum re-spin.

Crystalfontz America is the leading supplier of LCD, TFT, OLED and ePaper display modules and accessories. We specialize in providing our customers the very best in display products, cables and connectors.

In addition to our large catalog of displays, we offer LCD development kits, breakout boards, cables, ZIF connectors and all of the LCD software and drivers you need to develop your product or project. We are located in the U.S. so we can get product to you fast!

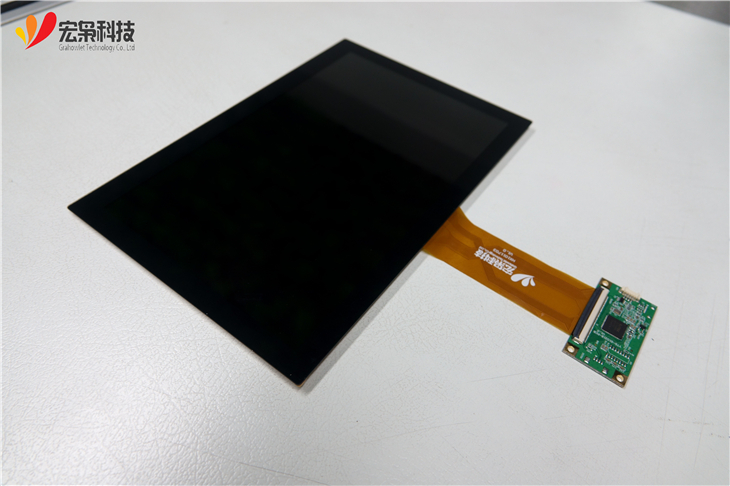

New Vision Display is a custom LCD display manufacturer serving OEMs across diverse markets. One of the things that sets us apart from other LCD screen manufacturers is the diversity of products and customizations we offer. Our LCD portfolio ranges from low-cost monochrome LCDs to high-resolution, high-brightness color TFT LCDs – and pretty much everything in between. We also have extensive experience integrating LCD screen displays into complete assemblies with touch and cover lens.

Sunlight readable, ultra-low power, bistable (“paper-like”) LCDs. Automotive grade, wide operating/storage temperatures, and wide viewing angles. Low tooling costs.

Among the many advantages of working with NVD as your LCD screen manufacturer is the extensive technical expertise of our engineering team. From concept to product, our sales and technical staff provide expert recommendations and attentive support to ensure the right solution for your project.

In addition, our extensive technology portfolio and manufacturing capabilities enable us to deliver high-quality products that meet the unique specifications of any application. To learn more about what makes us the display manufacturer for your needs, get in touch with us today.

As a leading LCD panel manufacturer, NVD manufactures custom LCD display solutions for a variety of end-user applications: Medical devices, industrial equipment, household appliances, consumer electronics, and many others. Our state-of-the-art LCD factories are equipped to build custom LCDs for optimal performance in even the most challenging environments. Whether your product will be used in the great outdoors or a hospital operating room, we can build the right custom LCD solution for your needs. Learn more about the markets we serve below.

After months of price cuts, manufacturers of large-size liquid-crystal displays (LCDs) are under pressure to reduce panel prices further, following a major build-up of inventory. A recent report from US business analyst iSuppli revealed that the second quarter of 2010 saw the manufacture of 52 million large (ten inches and above) LCD television panel shipments, but the sale of only 38.7 million LCD television sets. The resulting imbalance between supply and demand is having a strong impact on the sector.

“This gap is higher than anything seen in 2009. Over-supply persisted in the first two months of the third quarter as buyers cut orders in July and August,” says iSuppli analyst Sweta Dash. “LCD television brands are expected to lower prices more aggressively to reduce their inventory levels, thus putting mounting pressure on panel suppliers to reduce prices further.”

Dash points out that manufacturers of monitor and notebook panels have been reducing supply to mitigate excessive inventory levels, and that panel prices are now stabilizing as a result. In contrast, high depreciation costs at relatively new LCD television panel fabrication plants mean suppliers have been less willing to reduce production.

However, Dash predicts that the potentially strong sales of LCD television sets in China could reduce inventory levels and help to steady panel prices by the end of the fourth quarter of 2010.

At the same time, rapidly rising sales of smart phones and tablet PCs are predicted to see the global market for small- and medium-size thin-film transistor (TFT) LCDs expanding at its fastest pace for three years. According to analyst Vinita Jakhanwal, also from iSuppli, global shipments of TFT LCD panels are set to rise by 28.1% in 2010, from 1.8 billion to 2.3 billion units.

“Sales of smart phones and tablets are booming thanks to the iPhone, iPad and other competing products,” explains Jakhanwal. “Smart phone manufacturers are now adopting TFT LCDs that use in-plane switching technology, which supports a wider viewing angle and better picture quality than a conventional LCD.” But the fast-paced market expansion probably won"t last, predicts Jakhanwal. “Growth in TFT LCD shipments will slow in 2011 and beyond as the expansion of smart phone and tablet markets cools to more normal levels.”

The adoption of touch-screen technology in the mobile phone industry is fuelling the demand for active-matrix organic light-emitting diode (AMOLED) displays, reports US market research firm DisplaySearch. AMOLED displays have been the only technology in the mobile phone display market to increase revenues every quarter this year, as both unit shipments and average prices have risen. “With an average worldwide market penetration of mobile phones at 70%, manufacturers are eager to introduce new features such as touch-screens to ensure continued growth this year,” says Calvin Hsieh, research director at DisplaySearch. “The success that AMOLED displays are finding in high-end smart phones reflects these trends.”

AMOLED technology rose in popularity after its integration into mobile phones manufactured by Samsung and HTC. In the first quarter of 2010, the average screen size for an AMOLED display exceeded three inches, which is larger than that of competing TFT LCDs. Taiwan-based display manufacturers AUO and Chimei Innolux are scheduled to start mass-producing AMOLED displays in 2011. Hsieh believes AMOLED technology will now see increased year-on-year growth, although TFT LCDs will still ship more units.

US-based quantum-dot and materials developer Nanosys has opened a new facility in Gyeonggi-do, Korea, to support its recent expansion into the Asian market. Led by former LG Electronics vice president Jong-Uk Bu, Nanosys Korea will develop "architected materials" for Asian electronics manufacturers, including high-performance LED backlights for displays and silicon composite anode materials for use in lithium–ion batteries. Earlier this year, Nanosys unveiled QuantumRail, quantum-dot-based LED backlighting units that improve LED backlit display colour gamut and efficiency. Nanosys says that its quantum dot LED technology makes it possible to deliver saturated red, green and blue colours that exceed the NTSC 1953 guidelines for displays. This latest announcement follows collaborations with Korea-based electronics manufacturers LG Innotek and Samsung Electronics to develop display products based on quantum-dot crystals.

![]()

Dark spots or patches may occasionally appear on some liquid crystal display (LCD) panels. This clouding phenomenon is recognized in the industry as YOGORE or "Mura", a Japanese term for "unevenness." This term is used to describe a low-contrast, irregular pattern or region that causes uneven screen uniformity under certain conditions. Mura is a result of the deterioration of the liquid crystal (LC) alignment layer; most commonly caused by long-term operation under high ambient temperatures. It is an industry-wide phenomenon and Mura is not repairable.

Elo Mura specificationsMura-like image retention is not covered by the Elo TouchSystems product warranty.The visual performance of liquid crystal displays (LCDs) has usually been evaluated by visual inspection. One of the visual problems hardest to recognize are regions of low contrast and non-uniform brightness or Mura. The accurate and consistent detection of Mura is extremely difficult as it can appear in various shapes and sizes and the inspection results tend to be subjective and based on opinion. As Mura does not lend itself to quantitative measurement, no specification for Mura is available.KB#000002625

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey