are we moving towards tft lcd made in china

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

![]()

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

In this article, we are looking at the benefits of looking for Chinese TFT LCD manufacturers. Instead of resorting to other manufacturing means, opting for the Chinese is a much wiser and lucrative choice. If you are looking for Chinese LCD manufacturers, you should start with STONE Tech.

There is no doubt that China has taken the mass manufacturing business by storm. There are few products that we can encounter in our lives that don’t have the words ‘Made in China’ scribbled underneath. There is a glut of products that are mass-manufactured by the Chinese and then shipped out internationally to be sold.

Handbags, wallets, phone cases, and other similar items have become the favorites of wholesalers and bulk buyers. These products are directly sold to end consumers. However, the fascinating thing about the Chinese production and manufacturing business is that it does not only cover the end-consumer products. Rather, you can also acquire raw and basic materials needed for the further manufacturing of goods and products. One such product is LCD displays.

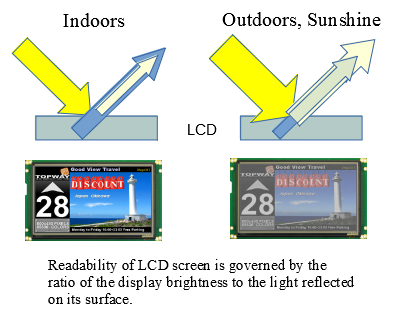

LCD displays have become something of a necessity in today’s world of tech advancement. Many things in our daily life have been automated, and are operated using an interactive user interface. For these kinds of machines and gadgets, LCD displays are typically necessary.

In this article, we are looking at the benefits of looking for Chinese LCD manufacturers. Instead of resorting to other manufacturing means, opting for the Chinese is a much wiser and lucrative choice. If you are looking for Chinese LCD manufacturers, you should start with Stoneitech.com.

STONE Tech is an LCD manufacturer located in Beijing, China. It was founded back in 2010, and it has been developing TFT LCD display modules ever since. These modules can be used for a variety of different machines including electric equipment, precision instruments, and civil electronics etcetera.

One of the main benefits that you get with Stoneitech.com is that there is a wide range of diverse products that you can purchase. For example, there are three different application types that you can choose from which include the Industrial Type, Advanced Type, and Civil Type. Similarly, there is a range of different sizes that you can choose from. There are 11 different sizes that you can buy, ranging from the smallest 3.5-inch display to the large 15.1-inch one. The same goes for the Android series which where you can choose between 4.5-inch and 31.5-inch displays.

When you are going to be ordering in bulk, you need to save up on costs as much as you can. The more you save up, the more profit you can make when reselling. Furthermore, lower costs can allow you to set lower prices when selling. This can attract more customers and your sales can increase.

In the initial period of your business, you want to build trust with your customers and give them more value than they expect. The best way you can achieve this is by making your products available for less than the average price. And this can only be done if you are saving up on costs yourself.

The same applies to LCD displays. When you save up on costs when buying LCD displays, you can set a lower price for the whole machine or gadget that you are producing.

This is a very useful benefit for small start-up companies. Generally, manufacturers in the USA are not going to be very willing to work with you unless you are a big company or unless you have a large recognition and following. Due to this, smaller companies can have trouble getting their demands heard. However, the refusal of suppliers to do so is not unjustified. Smaller companies are going to start off with smaller orders. Small orders are not very lucrative and beneficial for suppliers. The larger the order, the more convenient it will be for the manufacturer.

However, with Chinese manufacturers, this problem is minimized. The Chinese often don’t care how big a brand you are and what recognition your company has. As long as you meet the minimum order requirements, you can get your products easily. This is highly advantageous for smaller companies. Due to this, smaller firms can get started and kick off their business.

When it comes to LCD modules, the orders are not received by the hundreds or thousands as is the case with other smaller products such as handbags and wallets etcetera. One module can cost around $250, and it is for this reason that the dynamics are a little different with this business. That is why STONE offers single pieces for sale as well as multiple pieces. This encourages smaller businesses to make their purchases since they can easily purchase as many modules as they like. As long as you meet the limit stated by the supplier, you are good to go.

Typically, when you are paying less, you can have the expectation that the quality might not be good or the time taken may be too long. However, when you are buying from the Chinese, you don’t have to face any of these problems. While you are paying less, you can get satisfactory quality and even the production time is cut down.

The factories in China have more machines and workers working simultaneously. This means that you can get bigger orders more quickly. For example, if you are getting 10 units from a domestic supplier in 4 days, you will be able to get 12 units from a Chinese supplier in just 3 days. That means that the production rate is increased, and the time taken is also cut short. This is merely an example to show that both aspects of production are enhanced when you do business with the Chinese.

Another great benefit of getting production done in China is the option for expansion. What that means is that while you can transport your merchandise to your home country, you also have the option of making them available in China. Instead of only bringing the goods back home to resell, you can set up a business that makes your merchandise available for sale in China as well.

In the case of LCD modules, this benefit relates to a reselling business. For example, if you are planning on buying some modules to use in your machines etcetera, then there is not a very suitable opportunity for you to expand. If you want to start a business in another country, you will have to open a manufacturing unit there so that your products can be produced and then get sold. Or, you will have to transport your final products to the other country in order to run your business.

However, if you are buying the LCD modules to resale at a profit, you can use the Chinese markets to grow your business. You can buy the modules at a reduced price and then sell them at a profit in a different area or city where the people will be willing to pay more.

Now that we have seen the benefits of choosing Chinese manufacturers for LCD modules, let us narrow it down a bit and look at why you should choose STONE specifically.

STONE offers its customers ease when it comes to making a purchase. Generally, wholesalers and suppliers sell their merchandise in bundles of 10, 50, 100, etc. However, the STONE store gives you the option of buying single pieces so that you can buy as much as you presently need.

One of the main things that you have to look at in any supplier is the level of reliability and trust. This is usually determined by the level of experience and the time that the supplier has spent in the market. STONE was founded in 2010 and has been producing LCD modules for the past 10 years.

If you are looking to buy LCD modules in bulk, look no further than the Middle Kingdom. China has become the hub of mass manufacturing and is the favorite spot for wholesalers and business owners.

In case you need some convincing about buying from the Chinese, we have compiled a list of benefits that you can enjoy when looking for TFT LCD manufacturers in China.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

There is also a downloadable design software called STONE Designer. This is a completely free GUI design software you can use to create responsive digital module-ready user interfaces.

STONE TFT LCD modules come with a microcontroller unit that has a 1GHz Cortex-A8 CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to them.

The famous china LCD display manufacturers. It is the world’s leading semiconductor display technology, products, and services provider. Products are widely used in mobile phones, tablets, laptops, monitors, televisions, cars, digital information displays, and other display fields.

Focus on the development and production of china HMI (Intelligent TFT LCD Module) LCD display manufacturers, production, and sales of LCD display modules for 16 years. The company master TFT LCD technology and software system. The main products are industrial electronic series, advanced series, and civil and commercial series. Application scenarios include automation systems, medical beauty equipment, vending machines, smart lockers, energy, and power equipment (refueling machines, charging piles), elevators, smart homes, and offices, measuring instruments, public transportation, etc.

The company serves the consumer display market of the mobile terminal and professional display market. Its products are widely used in many fields such as smartphone, tablet computer, smart wear, car display, medical display, industrial control, aviation display, and smart home, and provide the best product experience for customers through TIANMA and NLT brands.

Mainly committed to the r&d, production, and sales of TFT-LCD/stn-LCD /OLED display modules, it is a modern high-tech enterprise that provides a full range of product LCD module technology and manufacturing support services for TCL group member enterprises and international electronic enterprises.

Set an LCD display module (LCM), capacitive touch screen (CTP), fully integrated touch display module (TDM), LCD thin technology development, production, and service in one national high-tech company.

Domestic size of the top four small and medium-sized flat panel display manufacturers. The products cover medium and small-size TFT-LCD display modules and high-precision miniature cameras, which have been widely used in the fields of smartphones, medical treatment, and industrial display.

The LCD business division is specialized in the r&d, production, and sales of the LCD display (LCD) and LCD module (LCM) series of products. It has ten semi-automatic COG production lines, 1.5KK of monthly COG products, covering COG, TAB, COB, and other LCD module products, TFT, CSTN, and other color LCD display products, and OLED display products. touch screen manufacturers.

Byd IT products and business mainly include the establishment of rechargeable batteries, plastic parts, metal parts, hardware, and electronic products, mobile phone keys, microelectronics, LCD display module, optoelectronic products, flexible circuit board, chargers, connectors, uninterruptible power supply, dc power supply, solar energy products, mobile phone decoration, mobile phones ODM, mobile phone test, assembly operations, laptop, ODM, manufacturing, testing and assembly operations, etc.

Star source products cover backlight, LCD, optical diaphragm, etc., widely used in LCD modules, photo frames, tablets, portable, instruments, and meters.

The company has long invested in the research and development of the TFT-lcm LCD module, focusing on consumer products and industrial control products. Currently, 3.5-11.6 inch modules are available, among which 4.0, 4.3, 5, 6, and 10.1-inch products have reached the leading level in the industry. Products are mainly used in vehicles, mobile TV, PMP, DVD, EPC, security, and industrial control products.

Professional development, design, production, and sales of LCD display module (LCM), products cover COB, TAB, COG, and other LCD module products, TFT, CSTN, and other color LCD display products, as well as OLED display products. Products are widely used in mobile phones, communications, digital products, household appliances, industrial control, instrumentation, vehicle display, color screen display, and other fields.

Mainly engaged in research and development, manufacturing, and sales of the LCD display and LCD display module. Products are widely used in all kinds of electronic products and equipment HMI interface, such as medical equipment, instruments and meters, audio, household appliances, telephone and clocks, game machines, and other different types and use.

Focusing on the LCD module industry, is a collection of research and development, manufacturing, sales as one of the high-tech enterprises. TFT module size from 1.44 to 7 inches, product specifications cover QVGA, WVGA, qHD, HD, etc., the market prospects are broad.

The display manufacturers company mainly researches and develops the LCD display, charger, battery, and other products of mobile communication mobile phone, telephone, MP3, and other high-tech products.

The company integrates research and development, design, production, sales, and service into one, and provides comprehensive touch and display integrated solutions for the complete machine touch screen manufacturer of smartphones, specializing in the development and manufacture of Sensor sensors, capacitive touch screens (GFF/OGS/GG), small and medium-sized LCD (TN/HTN/STN/CSTN/TFT) and corresponding modules and glass cover plate products. The company’s products are widely used in communication terminals (smartphone, tablet computer, etc.), household appliances, car electronics, digital products, and other industries, exported to Europe and America, Japan and South Korea, Singapore, and other countries.

Mainly produces medium and small-size LCD display module (LCM), multi-point capacitive touch screen (CTP), and other high-tech products. At present, more than 1000 models of 1.2-12.1 inch products have been developed. Products are widely used in mobile phones, GPS, mobile TV, tablet computers, digital photo frames, e-books, and other consumer electronics.

It is a professional development and production of small and medium-sized flat panel display upstream materials manufacturers. The company’s main products include LCD display panels, color filter, ITO conductive glass (CF), TFT LCD panel, and capacitive touch screen with multi-touch control functions (sensor and the final module), can provide complete medium and small size flat-panel display device using the solution of raw materials, product specifications varieties complete, widely used in 10.4 inches below the smartphone, tablet, PMP, digital camera, digital camera, GPS and other products of the display panel.

Now it is divided into mobile phone business division: the main products are (2.8-6) inch and the LCD screen and capacitive screen all fit together.MID tablet computer and ultrabook computer division: the main production product size is (7-15) inch capacitive touch screen.

It set TP lamination, assembly lamination r & d, production, sales as one of the production and processing enterprises. Its products are dedicated to mobile phones, tablets, industrial control equipment, and other fields.

Committed to 3.5~4.3 inches, 5 inches, 5.88 inches, 6.2 inches, 7.0 inches, 8.0 inches, 9.7 inches, 10.1 inches, 12.1 inches medium size FOG, backlight process production, products should be widely used in high-end communication phones, tablets, notebook computers, car TV, navigator, and other display products. automotive LCD display touch screen manufacturers.

The company has an injection molding business division, SMT business division, FPC business division, backlight business division, irrigation crystal business division, TFT module business division, SIN module business division, products involving touch screen, LCD display module, backlight, black and white screen, flexible circuit board.

Engaged in the laptop, tablet, smartphone, computer high-performance board card, LCD module, and other electronic products research and development, production, and sales of high-tech private enterprises.

Is a professional engaged in LCD display module, electronic components, production, design, research and development, sales as one of the high-tech enterprises. Products are widely used in mobile phones, game consoles, PDA, portable DVDs, video phones, intercom doorbells, car video, industrial control medical, and other fields.

STONE provides a full range of 3.5 inches to 15.1 inches of small and medium-size standard quasi TFT LCD module, LCD display, TFT display module, display industry, industrial LCD screen, under the sunlight visually highlight TFT LCD display, industrial custom TFT screen, TFT LCD screen-wide temperature, industrial TFT LCD screen, touch screen industry. The TFT LCD module is very suitable for industrial control equipment, medical instruments, POS system, electronic consumer products, vehicles, and other products.

Samsung Display, one of the leading amorphous silicon (a-Si) TFT LCD manufacturers for the past 20 years, is shutting down its first G7 line, Line 7-1, from as early as the end of July and there are rumors of a few more fab closures to come. Its a-Si TFT LCD footprint is expected to shrink dramatically over the next few years with potentially just one a-Si fab in operation in 2018 to serve its market-leading TV business.

Panasonic LCD is also rumored to be shutting down most or all of its G8.5 line. Based on the near term decline in a-Si TFT LCD capacity, Credit Suisse upgraded AUO and Innolux on this news and their shares surged.

Samsung’s Line 7-1, which began operation in October 2004 and production in May 2005, is rumored to be shutting down from the 30th July through the end of the year. It has a unique glass size (1,870 x 2,200mm), which was the largest in the world at the time of its introduction and is optimized for both 40” and 46” LCD TV panel production. It was also the site of the Samsung-Sony joint venture, S-LCD, established in April 2004. This line enabled Samsung and Sony to rapidly take share from smaller G6 fabs optimized for 32” and 37” panels. During that time, the two companies competed aggressively in retail while establishing 40” and 46” as mainstream sizes. The JV with Sony ended in 2011. S-LCD also built an 8th gen fab that began production in Q3’07, and Samsung built a second G7 line (L7-2) on its own, with even more capacity at over 170,000 substrates per month. L7-2 began production in Q3’08.

Displays are already a weak spot in Samsung’s financial performance. The category caused the device solutions division to be the only one to suffer a loss among all major divisions within Samsung in Q1’16, and its revenues of KRW6 trillion ($5.2 billion) were the lowest in two years. The display division alone posted an operating loss of KRW270 billion ($233 million) in Q1’16 resulting in an operating margin of -4.4%. While Samsung has a number of technology and capacity advantages in OLEDs for mobile displays, its a-Si TFT LCD business has matured and is increasingly becoming commoditized, as new entrants from China with government support are taking share. In addition, most of the a-Si TFT LCD market segments have become stagnant or are in decline, which points to more losses given the growing Chinese competition. On the other hand, OLEDs and flexible OLEDs are poised for rapid growth as they take share. As a result, it makes good business sense for Samsung to exit much of the a-Si TFT LCD market.

Line 7-2, newer and larger than 7-1, is also rumored to be for sale and is expected to be shut down in 2017, but probably depends on profitability. Line 7-2 has been producing 3-4 million 40” panels and 300,000 75” panels annually, as well as monitor panels. Twinstar is also a potential customer for the manufacturing equipment and this line may also be utilized for OLED production in the future.

Samsung is expected to begin shipping for the first OLED iPhone in volume from Q3’17, with input capacity from the modified Line 7 ramping up to between 90,000 and 120,000 substrates per month. Apple is expected to purchase 70 million OLED panels in 2017, according to sources.

That is not all, however. Line 6, Samsung"s last 5th gen line with 1,100 x 1,300mm substrates and around 190,000 substrate per month capacity, is also expected to be shut down, according to industry insiders. That line, which features a-Si and oxide TFT LCD production, has been producing tablet, notebook PC and LCD monitor panels. Those markets have also been hit by stagnant demand, growing competition from China, commoditization and declining margins. This line is expected to be shut down between the end of 2016 and 2017. Line 6 is predicted to be converted to a semiconductor facility, making application processors for smartphones and tablets.

If Samsung closes down Line 6 and Lines 7-1 and 7-2, its a-Si production will be down to just two G8.5 fabs: one in Suzhou, China and one in Tangjong, Korea. The Suzhou fab, ramping to over 100,000 substrates per month, is also rumored to be a candidate for sale with Chinese and Indian TFT LCD suppliers as potential customers. If Samsung licenses its latest a-Si TFT LCD or oxide TFT LCD technology, that would certainly make the sale more attractive. This means Samsung would have just one a-Si TFT LCD fab: Line 8.

I believe Line 8 will be sufficient for Samsung to support its internal TV brand with leading edge panels for the TV market as it has a monthly capacity of 400,000 2,200 x 2,500mm (G8.5) substrates. Samsung’s TV business would likely continue to outsource its low-end panels for its TVs to other LCD manufacturers and focus this fab on higher margin products such as 8k, HDR, QD WCG, etc. I cannot see Samsung abandoning LCD TV panel production until it believes OLEDs are cost effective enough to takeover the mid-range high end of the TV market. This likely means not until OLED materials can be inkjet printed, Samsung is still likely to focus all of its TV panel production on LCDs.

If this occurs as described, Samsung Display"s output of 42" and larger panels would be LCD, and sub-42" would be OLED, although it may not have much production between 15" and 40". This would be an amazing, but expected, transformation given the supply/demand and profitability outlook for the a-Si market.

Panasonic is also following Samsung’s lead. It is expected to reduce the glass input of its G8.5 line from around 50,000 per month to just 10,000 per month by September. Given the limited scale and cost effectiveness of this Japanese factory and the loss of share of Panasonic"s TV brand in many regional TV markets, the company is better off purchasing panels from LG and lower cost Chinese suppliers. Otherwise it would be trying to run a high cost fab in Japan, in a market where commoditization is becoming increasingly common and a large wave of new, lower cost capacity from China is on its way. The company may keep 10,000 of capacity for some period for Panasonic-branded products, but it is hard to imagine operating a fab at just 10,000 per month for long, as the lack of volume will further increase costs relative to other higher volume players.

Interestingly, with both Samsung and Panasonic reducing their a-Si capacity in the near term, Credit Suisse has upgraded its outlook for AUO and Innolux to outperform, and both companies have seen significant share price increases as a result. Credit Suisse indicated that the closure of L7-1 will reduce supply by 12 million 40” panels - or 1/3 of the 40” market - which will tighten supply in the 40”-43” market and produce a better pricing environment. AUO’s earnings per share (EPS) was raised from NT$10.20 to NT$13 ($0.32 - $0.40), while Innolux’s EPS was raised from NT$10.10 to NT$14 ($0.31 - $0.43). Both companies" stock prices have taken off, with AUO’s stock price rising by 22% in the US in three days.

As Japanese and Korean players take more a-Si capacity offline, it will create a better environment for the Taiwanese and Chinese suppliers, enabling the market to better digest all the new capacity being brought online in China. However, there is a tremendous amount of capacity coming and much of this older capacity from Samsung and Panasonic may get sold and reintroduced. As pointed out at SID 2016, by 2019 China is expected to have:

2016 and 2017 are expected to be back-to-back years of over $12 billion in LCD/OLED equipment spending. Unless these fabs struggle with their ramp and their yields, the a-Si market will continue to be oversupplied although conditions should improve in the 40”-43” market in the second half of 2016.

Rather than battle it out with government-subsidized Chinese players, Samsung appears to be accelerating its exit of the increasingly commoditized a-Si TFT LCD market. This should please its shareholders, especially if it can sell all its old equipment and license its a-Si technology for a royalty, but will be harmful to some of its suppliers. It is also likely to protect its TV business by holding onto its most competitive fab, but will increasingly become an OLED company. Interesting questions as a result of these moves include:

A couple of days after this article was originally posted, it was claimed - and later denied by a company official - that Samsung will move its a-Si TFT LCD operations out of Samsung Display and into Samsung Electronics. Such a move aligns perfectly with its intention, indicated above, to close its a-Si fabs as in a couple of years its a-Si TFT LCD operations may be limited to providing panels to its TV business. - Ross Young

Ross Young is the CEO and Founder of Display Supply Chain Consultants. He also serves on the Board of Directors of publicly traded touch sensor manufacturer UniPixel and diamond semiconductor developer Akhan Technologies. He previously founded DisplaySearch and served as its CEO from 1996 - 2007 where he launched most of their categories of coverage. He has also held executive positions at Samsung LCD and IMS Research.

China"s first 8.5-generation TFT-LCD production line was launched in Bengbu, East China"s Anhui province, on June 18, 2019, representing a breakthrough in the production of high-definition LCD screen, Science and Technology Daily reported.

TFT-LCD, or Thin Film Transistor Liquid Crystal Display, is key strategic material of the electronic information display industry. The Gen 8.5 TFT-LCD production line, launched by the Bengbu Glass Industry Design and Research Institute of the China National Building Material Group, will produce high-definition LCD screens of 55 inches, the report said.

According to the Liquid Crystal Branch of the China Optics and Optoelectronics Manufactures Association, the demand for TFT-LCD in the Chinese mainland was about 260 million square meters in 2018, including 233 million square meters" Gen 8.5 TFT-LCD. However, the annual supply of domestically made TFT-LCD is less than 40 million square meters, with all of them Gen 6 or below, which cannot meet the demand in scale and quantity.

The association predicted that China"s market demand for Gen 8.5 TFT-LCD or above will exceed 300 million square meters by 2020, accounting for 49.6 percent of the total global demand.

The production and control precision of Gen 8.5 TFT-LCD is comparable to that of the semiconductor industry, representing a higher level of large-scale manufacturing of modern glass industry.

The institute in Bengbu, with 60 years of expertise in glass, has finally made a breakthrough in the production of Gen 8.5 TFT-LCD, and will provide key raw material guarantee for China"s LCD panel industry after it goes into mass production in September, the report said.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

China is the leader in producing LCD display panels, with a forecast capacity share of 56 percent in 2020. China"s share is expected to increase in the coming years, stabilizing at 69 percent from 2023 onwards.Read moreLCD panel production capacity share from 2016 to 2025, by countryCharacteristicChinaJapanSouth KoreaTaiwan-----

DSCC. (June 8, 2020). LCD panel production capacity share from 2016 to 2025, by country [Graph]. In Statista. Retrieved December 25, 2022, from https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. "LCD panel production capacity share from 2016 to 2025, by country." Chart. June 8, 2020. Statista. Accessed December 25, 2022. https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. (2020). LCD panel production capacity share from 2016 to 2025, by country. Statista. Statista Inc.. Accessed: December 25, 2022. https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. "Lcd Panel Production Capacity Share from 2016 to 2025, by Country." Statista, Statista Inc., 8 Jun 2020, https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC, LCD panel production capacity share from 2016 to 2025, by country Statista, https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/ (last visited December 25, 2022)

We"ve been committed to offering easy,time-saving and money-saving one-stop purchasing service of consumer for Tft Lcd Panel, Tft Information Display, Round Lcd Display, Led Tft Display,Lcd Counter Module. Honesty is our principle, skilled procedure is our perform, service is our target, and customers" satisfaction is our long term! The product will supply to all over the world, such as Europe, America, Australia,Wellington, Tunisia,New York, Mauritius.It using the world"s leading system for reliable operation, a low failure rate, it suitable for Argentina customers choice. Our company is situated within the national civilized cities, the traffic is very convenient, unique geographical and economic conditions. We pursue a people-oriented, meticulous manufacturing, brainstorm, build brilliant" business philosophy. Strict quality management, perfect service, reasonable price in Argentina is our stand on the premise of competition. If necessary, welcome to contact us by our website or phone consultation, we will be happy to serve you.

Corning began shipping production samples from the Wuhan plant in January of 2020 and achieved finishing line mass production by mid-2020, despite pandemic-related challenges. The Wuhan manufacturing facility is Corning’s sixth LCD glass plant on the Chinese mainland and its second Gen 10.5 facility along with the company’s Hefei plant in the Anhui Province, which opened in 2018.

John Zhang, senior vice president and general manager, Corning Display, said, “Our Wuhan plant is the most recent demonstration of Corning’s commitment to China’s display industry. We appreciate the support we have received from the Dongxihu District, Wuhan municipal, and Hubei provincial governments. With our advanced glass technology and skilled local talent base, we are poised to make even greater contributions to growth in the region.”

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey