lcd panel ratings quotation

If you"re considering implementing industrial displays or digital signage you may be concerned about your assets being accidentally damaged or vandalised. Here is a quick guide about IK impact protection ratings to understand the durability of the displays you"re considering to purchase in order to safeguard your investment.

Industrial displays in open-frame, panel-mount and chassis-mount format can be configured with toughened glass to improve the level of IK protection and protect the asset from damage. This damage isn"t necessarily from vandalism but the harsh environments they"re deployed in. These displays aren"t limited to installation in factories but carry through to installations in public areas, for example any ATM or vending machine will typically have a toughened open-frame display mounted behind a custom chassis.

Typically a 6mm or 8mm layer of toughened glass is applied to the display to increase scratch resistance and impact rating. Another option to increase a displays protection is to optically bond the screen. Optical bonding is a process where a layer of resin is applied between the glass or touchscreen and LCD display, bonding them to make a solid laminate with no gaps or pockets of air. More can be read about optical bonding here.

If you"re looking for ~500-1000 display panels with the intent to buy, I would strongly suggest speaking with an account manager, sales rep, and/or applications engineer at a distributor. Such an order will likely generate enough revenue for them to give you a whole lot more than the time of day. I know the local account managers and FAE"s for a few large component distributors in my area (Future Electronics and Allied Electronics), and they are usually helpful, though not always prompt.

Looking at Future, they do seem to have a few LCDs quoted on their site, however it is certainly not a comprehensive list. If you contact a sales rep (there or anywhere) and provide them your requirements, they may come back with additional parts that their manufacturers produce that better fit your need.

Unless your volumes are going to be in the millions, let me dispel any thoughts you have of "Why not just talk to (LCD mfc) directly?". Said manufacturers will not care about you, and the premium they will charge to deal with you (if they bother at all) will be higher than what a typical distributor would, because, frankly, they do not want your direct business. Use the middlemen. They will make specifying, finding, and sourcing LCD panels vastly easier and cheaper.

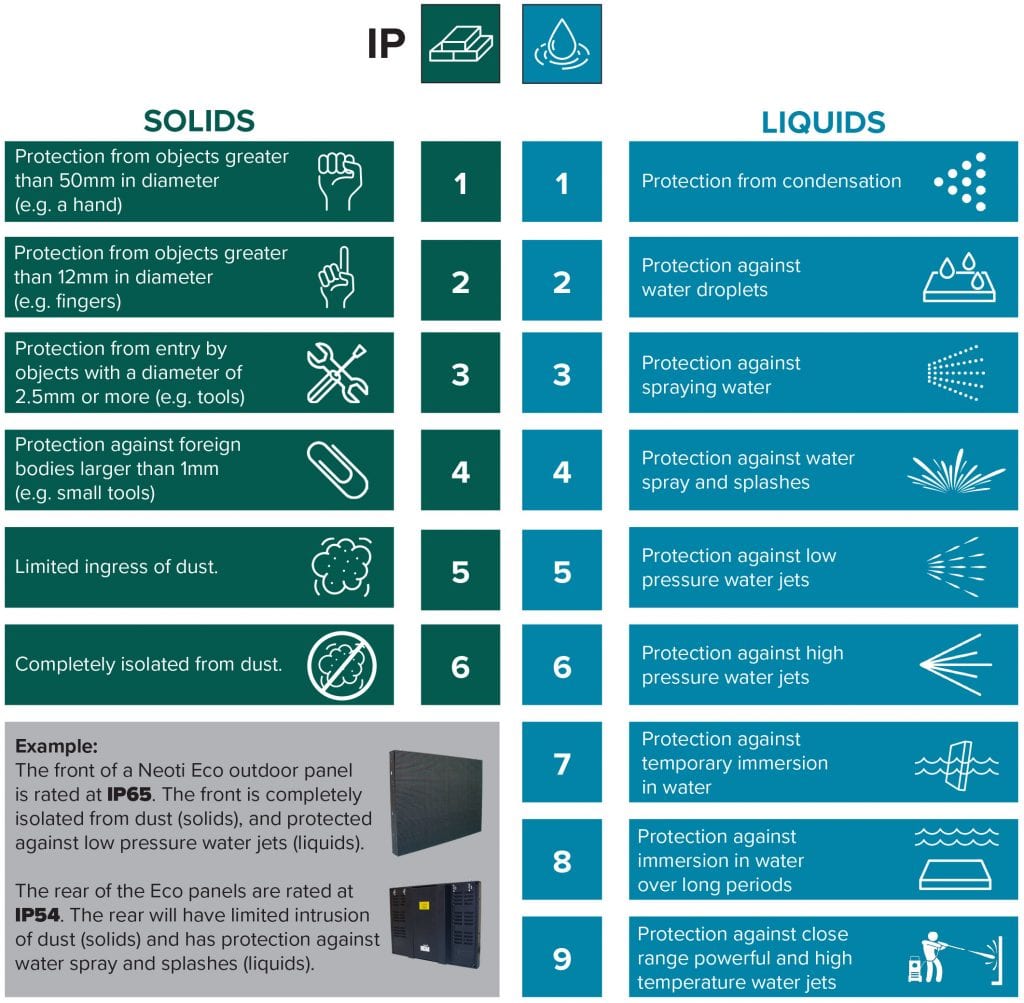

IP stands for International Protection Rating, commonly called Ingress Protection Rating. It is defined in the international standard IEC 60529 as the degree of protection against the intrusion of solid objects, dust, accidental contact, and water in electrical enclosures. IP ratings are used as a reference point for electronic enclosure designs to help users determine what’s required for a certain environment and application.

IP ratings on LED displays are important to ensure the right product is selected for the application and environment. Selecting an LED panel with the correct IP rating will ensure the display is protected from the environmental elements and will perform as expected. The danger of selecting a product with an inadequate rating is completing an install and then experiencing operation issues and permanent damage.

Now that you understand the difference in ratings, you can be better informed when asking questions related to which LED product to purchase for your application. For even more assistance, contact one of our team members, and we will be happy to assist finding your perfect product match.

Liquid Crystal Display (LCD) screens are a staple in the digital display marketplace and are used in display applications across every industry. With every display application presenting a unique set of requirements, the selection of specialized LCDs has grown to meet these demands.

LCD screens can be grouped into three categories: TN (twisted nematic), IPS (in-plane switching), and VA (Vertical Alignment). Each of these screen types has its own unique qualities, almost all of them having to do with how images appear across the various screen types.

This technology consists of nematic liquid crystal sandwiched between two plates of glass. When power is applied to the electrodes, the liquid crystals twist 90°. TN (Twisted Nematic) LCDs are the most common LCD screen type. They offer full-color images, and moderate viewing angles.

TN LCDs maintain a dedicated user base despite other screen types growing in popularity due to some unique key features that TN display offer. For one,

Displays with VA screens deliver wide viewing angles, high contrast, and good color reproduction. They maintain high response rates similar to TN TFTs but may not reach the same sunlight readable brightness levels as comparable TN or IPS LCDs. VA displays are generally best for applications that need to be viewed from multiple angles, like digital signage in a commercial setting.

Based on current trends, IPS and TN screen types will be expected to remain the dominant formats for some time. As human interface display technology advances and new product designs are developed, customers will likely choose IPS LCDs to replace the similarly priced TN LCDs for their new projects.

To edit a line item that is already included on the quote, hover over the line item and click the Actions dropdown menu, then select Edit. Make any changes in the right panel, then click Save.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey