lcd panel ribbon repair factory

Try using lcd ribbon cable repair found on Alibaba.com to make many types of production jobs faster and easier. Each model can be filled with different types of liquid and quickly dispensed into containers. Use lcd ribbon cable repair to fill paint cans with speed and precision. Other compatible fluids include resin or glue, making such devices suitable for manufacturing all kinds of helpful products.

All lcd ribbon cable repair are built to be easy to operate, reducing labor and training times needed. Some versions can pour food-grade liquids such as beer or milk into bottles for future sealing. Most units work automatically so workers can program them and stay back as they work on their own. When installed on a factory floor, they offer greater efficiency to help save time and costs.

Shop for lcd ribbon cable repair at Alibaba.com to find many helpful suppliers with a wide range of options that can be ordered. Choose just the right size to fit the intended workspace. Pick a wattage level that promises good speed and power without using too much electricity and driving up costs. Certain designs can dispense products in the form of powder or granules into nearby containers. Use these to package particular powdered food and pharmaceutical ingredients.

Search for lcd ribbon cable repair on Alibaba.com and enjoy lower costs when working with various liquids or powders. Whether for use in food manufacturing or building materials, there are plenty of options to browse. Find a satisfactory brand that will improve efficiency for better overall quality in each final product.

At the same time I done two of these devices, with the exact same parts, one works, so I tried swapping the ribbon cables + LCD/Screen from the working into this device, and the working one remained working and the other remained touchless, still. This to me confirms that both the new screen and existing ribbon cables are fine (since they all work on that one device).

I"m not totally sure the next direction to look at for the device with touch issues regardless of LCD/Screen+Ribbon cable, at a guess motherboard issues? I had a bit of a look and there are no shorts or missing components easily visible from the front side, and I"ve also done a factory reset to try and rule out software issues.

All our BMW Non Bond Ribbon cables are made in house at AK speedo using high quality plastic sheeting with high quality print and are all cut and checked by hand.This ribbon gives you a perfect connection between the PCB and LCD Display and can be fitted more than once if you make a mistake during fitting. Non Bond pressureribbons give a much better and more reliable join between the LCD and PCB connection pads.

Replacement Non Bonding Ribbon Flat Cable.Full ribbon cable fitting instructions.Requires No Bonding, Simply stick down. Good Mechanical skill required for fitting. Made in the UK by AK speedo

Replacement Non Bonding Ribbon Flat Cable.Full ribbon cable fitting instructions.Requires No Bonding, Simply stick down. Good Mechanical skill required for fitting. Made in the UK by AK speedo

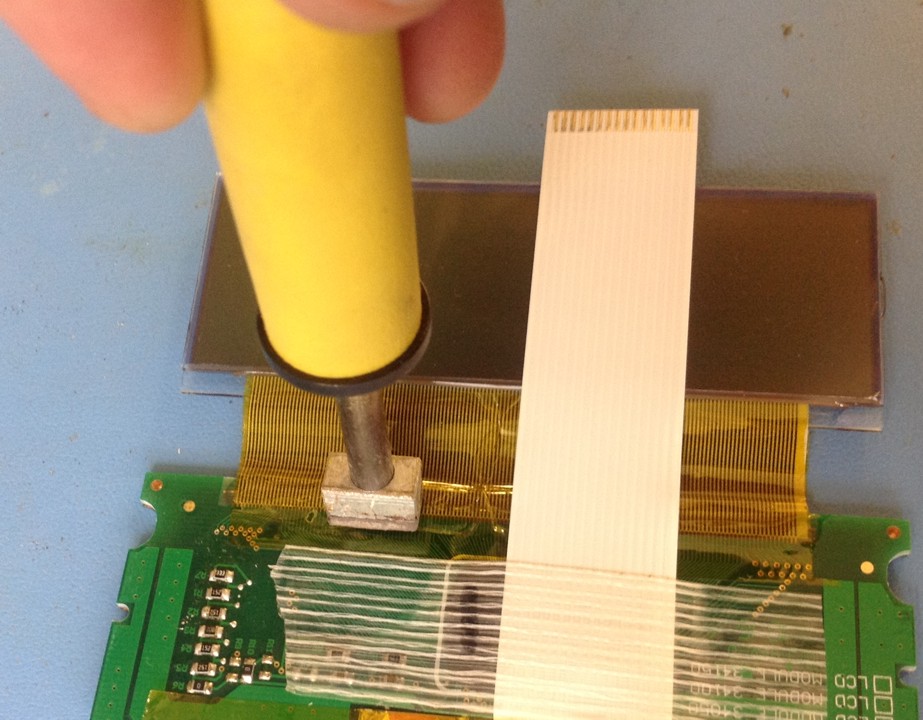

Once done, the next step is to prepare tools and materials in the picture in advance for removing the problem flex cables and laminating the new flex cables on the LCD.

That’s all. Don’t you think that it is easy for you to operate? We think that this machine would be one of your excellent helpers for the mobile phone repair.

The use of lcd ribbon cable repair in organizing multiple wires in many modern devices has increased. To meet the high demand for low-cost apparatus for organizing and streaming multi-wire systems, Tradechina.com offers premium lcd ribbon cable repair made of durable electrical tape, rubber, or vinyl materials. The lcd ribbon cable repair on offer on our site effectively protects your wires from the effects of abrasions and vibrations while keeping the equipment at its peak working condition.

Our high-quality and affordable lcd ribbon cable repair available for sale include premium materials and features such as wires, connectors, and terminators. Different types and sizes of lcd ribbon cable repair use different types of terminals and connectors, and so the wire harnessing capability and reliability vary from product to product. We have a great range of top quality lcd ribbon cable repair for many different applications, including electronics, automobiles, chassis, engines, electrical devices, and many more.

Our lcd ribbon cable repair are available as heat-shrink wrapped, with a woven outer jacket or simple zip tie, and come in designs and styles you would love. The quality and durable coatings on our lcd ribbon cable repair make them strong enough to stand moisture, harsh temperatures, UV rays, and extreme dirt. Buyers can choose from a wide variety of lcd ribbon cable repair that are flexible, lightweight, and small in size installed in areas with limited spacing.

Check out Tradechina.com to find the best lcd ribbon cable repair that fits your budget and purposes. Our products are designed to be of high-quality and affordable enough to match the budgetary needs of wholesalers and retailers.

Vertical lines appearing on LCD screen is very common. Whether the screen belongs to a laptop computer or desktop PC, mobile phone, or even a television, the fault is usually due to the ribbon cable and its connections.

A faulty ribbon cable can cause all sorts of havoc manifesting in bright vertical lines. Sometimes they can be coloured lines such as blue, green, grey, black, and red. The lines can appear thick or thin and on just one-half of the screen. Sometimes the fault will manifest as two vertical white lines. You can even get horizontal lines as well.

If you have lines appearing on the LCD screen, then the first simple thing to check is the seating of the ribbon cable that connects the display panel to the motherboard. Most of the time, the fault is with the poor connection made by the ribbon cable.

One of the most common problems with ribbon cables is oxidation of the contacts. It can happen either on the ribbon cable contacts or on the socket contacts. Manufacturers often use a mix of gold and copper for the electrical contacts, however, if they have not used enough gold, then oxidation occurs over time. This results in a working television or laptop screen suddenly exhibiting lines.

The solution is of course very simple, one needs to clean the contacts with a high quality electrical contact cleaner. It is best to clean the socket and the ribbon cable contacts, which will solve the fault.

One of the most common faults with laptops is that the ribbon cable connecting to the LCD panel cracks. It typically fails near the hinge area due to flexing in that region, and over time, some of the tracks on the plastic cable breaks. I have seen these types of faults on many laptops. It does not matter whether it is a Lenovo, IBM, Acer, Samsung, Toshiba, or even a MacBook Pro!

It is also possible to have a dislodged cable, which typically occurs on mishandled laptops. The plastic clip that holds the ribbon cable is very small and delicate and if the laptop receives an impact, the ribbon cable can dislodge.

This type of fault can also occur on LCD televisions; however, it tends to be on new units, where the box has received an impact during transit from the factory.

In this situation, the repair can be easy, as the cable will simply require reseating. However, there is still the labour time to consider as it can take the best part of the day to gain access to the ribbon cable.

I used this same method of troubleshooting to repair an LCD television recently. Modern televisions have a video out socket, and if you feed the signal from that to another monitor, you can check for the quality of the video display. If the external monitor does not show lines, then you know for sure that it is a connection issue. Hence, this method of troubleshooting works for some of the modern televisions as well.

When half of the vertical interlace is missing showing a picture that is broken up vertically, the display appears with vertical lines. This is usually due to a cracked ribbon cable.

Generally, for laptops a replacement cable is always required due to it breaking near the hinge. I had this Dell laptop and replacing the LCD ribbon cable solved the problem. I managed to buy a replacement from Dell for a modest price £6.00. The laptop was just outside the warranty period; however, they still shipped out the cable free of charge. This is the reason why people buy Dell. In my experience Dell tend to stand by their customers and products, and their prices for replacement parts are realistic and down to earth.

Replacing a laptop ribbon cable is simple, and the top-half of the laptop, and keyboard needs removing to gain access to the socket on the motherboard side. As you can see, it flexes near the hinge area and breaks where the ribbon cable wraps around the hinge.

Degradation of the fine ribbon cable in older TI graphing calculators is a familiar problem, manifesting as missing rows and columns in the LCD. Otherwise perfectly functional calculators are put to waste over two relatively short-lived ribbon cables, one of which is unreplaceable, with long-term repair methods elusive.

As the LCD is integral to the very purpose of the calculator, I was interested in correcting this common issue for the sake of correcting it. Something as trivial as "exercising" missing lines in the display would often reinvigorate them for about a day, which prompted me to investigate a more reliable repair.

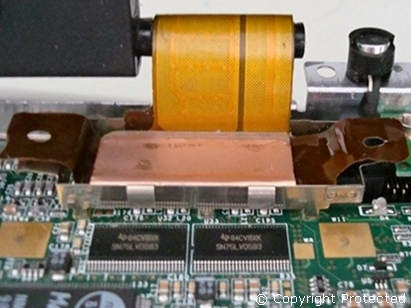

Though TI does not specify the assembly method actually used, many similar ribbon cables are applied by hot press. While this entails expensive, specialized equipment, I learned to imitate the hot press process using inexpensive, readily-available components through a video on automobile instrument panel repair. Note that I modified the method since we are not able to install a new cable.

I have applied the method to seven graphing calculators exhibiting fine ribbon cable failure. In the 20 days between the repair and this writing, I observed a high degree of success across the calculators repaired.

Before continuing, check whether the fine ribbon cable is culprit. Missing or intermittently functioning lines are prime indicators of fine ribbon cable degradation. If the contents of the screen are garbled or corrupted, the coarse ribbon cable will need to be repaired first:

These are available on eBay for about US $7. The point of this is to distribute heat and pressure along the ribbon cable connection in a similar manner to a hot press. If given a choice between a tip for 30W, 45W, 60W, etc. choose 30W unless using a larger unregulated iron.

Remove the circuit board from the calculator. Locate where the fine ribbon cable connects to the edge of the LCD glass. If there is foam padding attached, gently peel it off and set it aside. Be sure NOT to tear the ribbon cable off either end, which will ruin the chances of a successful repair.

Locate where the fine ribbon cable connects to the board. Set the LCD face down on a flat, non-abrasive surface and place the iron flat on the connection as such:

Make two passes across the connection as before. The edge of the LCD may change color as heat is applied, but if it is turning a dark or purplish blue, move the iron faster to prevent overheating.

Now reassemble the calculator and test if the display looks good. If any defects remain, do another pass over the cable connections. There is the possibility, however, that some lines do not resolve even on the second or third attempts. These, unfortunately, will remain unrepairable.

Note: From my testing, the silicone pad is necessary to distribute heat and pressure along the cable. It will also wear out when used multiple times. Replace it when it no longer slides smoothly over the ribbon cable connection.

The TI-85 and 86 feature two ribbon cables, one on top responsible for vertical columns and one on the side for horizontal rows. Determine which one needs repair and move the side ribbon cable out of the way if necessary. I have yet to attempt a repair on the side ribbon cable, which appears more challenging to access than the top cable.

One TI-82 has one column that will start working once something is displayed on it. Despite two repair attempts, this column would not stay put when the calculator was powered off for a longer period of time.

Ideally, an economical, readily-available replacement LCD assembly without such a flawed ribbon cable would be available to prolong the useful life of TI graphing calculators. This is currently in the works as we see with KermMartian"s Surget. In the absence of a finished replacement LCD, this currently is the most effective method I have found to breathe new life into aging calculators, restoring the majority of, though not all, missing LCD lines.

Across a sample of seven calculators over 20 days, each LCD line that was repairable and repaired remained functional. The long-term viability of this repair method remains to be discovered, though it is one that vaguely emulates a common method of LCD ribbon cable assembly at the factory. In the meantime, I will take note of and post any significant changes that I notice on the calculators I have repaired using this method.

No further repairs were attempted. Hopefully the repairs on the TI-82s and the TI-85 will continue to last a while more. I"d say this was a rather fun experiment and I will continue posting any significant developments.

- If the bulbs are out behind the display, then all the rows and colunms do work on the SAAB SID display, but the background light of the SID display is uneven, or some cases the display is completely dark. This case no need to repair the pixels, you do not need a silver ribbon cable, nor a new SID display. This case you just need to buy the lightbulbs that provide light behind the SAAB SID display.

- If the SAAB SID display has really pixel problems, then typically lines or colunms of the display are missing. Several cases the characters are broken, numbers and letters shown on the SAAB SID LCD display are unreadable - the backlight is even. In case of a real pixel problem, when one or more pixels are missing from the SAAB LCD display, you need to buy a silver ribbon cable, a carbon ribbon cable, or some cases a complete SAAB LCD display. It really depends on that if it is a BMW, a Mercedes and Audi, VW, Saab or other make, and of course if it a MID display, a speedometer, a board computer or other LCD dipslay. Most cases, when you have a pixel failure, and you decide to repair it, it"s really worth to buy a set of bulbs too, as bulbs tend to go out during repair - this is due to the massive mechanical shocks experienced during the pixel repair procedure.

Well, most of the SAAB SID LCD display pixel repair kits we sell are designed to be simple and easy to use. The word easy should now be the subject of further discussion. An average SAAB SID pixel repair is far more difficult then replacing a lightbulb. You definitely have to have good mechnical skills, and some household tools, too, such as nippers, screewdrivers, household tape, and other goodies to fix things around the house.

If you have to ask one of these questions, then you definitly should NOT do a SAAB SID LCD display pixel repair at home (we were asked these questions before, this is not a joke):

Well, Pixelfix is an internationally registered trademark. Pixelfix only sells the highest quality SAAB SID cables, that are capable of lifetime operation. We sell most of our repairs with lifetime warranty, and you will find the exact same SAAB SID displays, cables, and other spare parts that we use for professional repairs. Them SAAB SID cables we use for LCD display pixel repair are real silver, which is a very expensive base material, that is why the price is much higher compared to carbon SID cables.

No worries, we do provide technical support, and help repairing your SAAB SID display. However there is an advice you ought to consider before starting the work. If you have not done this before, this is mandatory. PLEASE read the manual, and if available watch the video BEFORE starting the work on your SAAB SID display. This will definitely save a lot of time and will help to do a hassle free work.

- the contacts of the SAAB SID display or the SID panel are not perfectly clean - this case there is no contact between the SAAB SID display and the panel

- the alignment of the silver ribbon cable is no good, so the pads of the silver ribbon cable do not match the pads of the SAAB SID LCD display or the SID panel.

Let"s talk about the worst case scenario, you started the repair, but you do not seem to deal with the repair of the SAAB SID display. This case we have a backup solution. We always stand behind our customers, so you may send the SAAB SID LCD display unit to us for repair, and no matter what the condition of the unit is, we can help. More precisely, up to this point we always succeeded, meaning none of our customers managed to do such a damage in the unit that we could not fix. The repair does not cost a fortune, in a lucky case it is 20-30 Euro plus return delivery cost only.

In Union Repair store, we grade our iPhone screen into 5 different types of quality on the basis of different material assembled. The following is the full details of each condition.

It is with widely accept major complaint replacements for original parts, which keeps a right balance between price and quality. It has sustainable supplying chain in China, and all the components of the screen are copy quality. Typically, the LCD screen is from several different factories, the most popular 4 on China market are JK,AUO, LongTeng, and ShenChao. By comparing the brightness and sharpness of the LCD, we found JK is the best quality among them and the second best is AUO. No doubt, the other components on the screen are all copy.

It is better than After Market Basic cause it comes with original laminated flexes and the LCD panel. Other components like touch panel, frame(hot pressed), backlight, polarize lens, and OCA is all copy from different factories.

The core components (like LCD and flexes) is 100% original pulled from used iPhone while the frame and touch panel is copy. The touch panel and frame come together with cold pressed glue and assembled together with the LCD by the capable third-party factory which keeps its excellent quality.

It is 100% original from Apple-authorized factories like Toshiba, Sharp, and LG. We get this kind of screen from the first level dealer. The touch panel of the screen is oleophobic coated which prevents from fingerprints when using your iPhone. And starting with iPhone 7g, the backlight from different authorized factories comes with a different code. Backlight from Sharp has the code begins with DKH/CON, from Toshiba begins with C11/F7C/FZQ, from LG begins with DTP/C3F.

The first question is, is there enough slack in the ribbon cable to allow the broken end of the main part to be fully inserted in the connector, without straining any existing sharp bends at the back of the display or pulling it round any sharp corners?

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey