arduino projects with lcd screen manufacturer

Adding a display to your Arduino can serve many purposes. Since a common use for microcontrollers is reading data from sensors, a display allows you to see this data in real-time without needing to use the serial monitor within the Arduino IDE. It also allows you to give your projects a personal touch with text, images, or even interactivity through a touch screen.

Transparent Organic Light Emitting Diode (TOLED) is a type of LED that, as you can guess, has a transparent screen. It builds on the now common OLED screens found in smartphones and TVs, but with a transparent display, offers up some new possibilities for Arduino screens.

Take for example this brilliant project that makes use of TOLED displays. By stacking 10 transparent OLED screens in parallel, creator Sean Hodgins has converted a handful of 2D screens into a solid-state volumetric display. This kind of display creates an image that has 3-dimensional depth, taking us one step closer to the neon, holographic screens we imagine in the future.

Crystalfontz has a tiny monochrome (light blue) 1.51" TOLED that has 128x56 pixels. As the technology is more recent than the following displays in this list, the cost is higher too. One of these screens can be purchased for around $26, but for certain applications, it might just be worth it.

The liquid crystal display (LCD) is the most common display to find in DIY projects and home appliances alike. This is no surprise as they are simple to operate, low-powered, and incredibly cheap.

This type of display can vary in design. Some are larger, with more character spaces and rows; some come with a backlight. Most attach directly to the board through 8 or 12 connections to the Arduino pins, making them incompatible with boards with fewer pins available. In this instance, buy a screen with an I2C adapter, allowing control using only four pins.

Available for only a few dollars (or as little as a couple of dollars on AliExpress with included I2C adapter), these simple displays can be used to give real-time feedback to any project.

The screens are capable of a large variety of preset characters which cover most use cases in a variety of languages. You can control your LCD using the Liquid Crystal Library provided by Arduino. The display() and noDisplay() methods write to the LCD, as shown in the official tutorial on the Arduino website.

Are you looking for something simple to display numbers and a few basic characters? Maybe you are looking for something with that old-school arcade feel? A seven-segment display might suit your needs.

These simple boards are made up of 7 LEDs (8 if you include the dot), and work much like normal LEDs with a common Anode or Cathode connection. This allows them to take one connection to V+ (or GND for common cathode) and be controlled from the pins of your Arduino. By combining these pins in code, you can create numbers and several letters, along with more abstract designs—anything you can dream up using the segments available!

These tiny LCD screens are monochrome and have a screen size of 84 x 48 pixels, but don"t let that fool you. Coming in at around $2 on AliExpress, these displays are incredibly cheap and usually come with a backlight as standard.

Depending on which library you use, the screen can display multiple lines of text in various fonts. It"s also capable of displaying images, and there is free software designed to help get your creations on screen. While the refresh rate is too slow for detailed animations, these screens are hardy enough to be included in long-term, always-on projects.

For a step up in resolution and functionality, an OLED display might be what you are looking for. At first glance, these screens look similar to the 5110 screens, but they are a significant upgrade. The standard 0.96" screens are 128 x 64 monochrome, and come with a backlight as standard.

They connect to your Arduino using I2C, meaning that alongside the V+ and GND pins, only two further pins are required to communicate with the screen. With various sizes and full color options available, these displays are incredibly versatile.

For a project to get you started with OLED displays, our Electronic D20 build will teach you everything you need to know -- and you"ll end up with the ultimate geeky digital dice for your gaming sessions!

These displays can be used in the same way as the others we have mentioned so far, but their refresh rate allows for much more ambitious projects. The basic monochrome screen is available on Amazon.

Thin-film-transistor liquid-crystal displays (TFT LCDs) are in many ways another step up in quality when it comes to options for adding a screen to your Arduino. Available with or without touchscreen functionality, they also add the ability to load bitmap files from an on-board microSD card slot.

Arduino have an official guide for setting up their non-touchscreen TFT LCD screen. For a video tutorial teaching you the basics of setting up the touchscreen version, YouTuber educ8s.tv has you covered:

With the touchscreen editions of these screens costing less than $10 on AliExpress, these displays are another great choice for when you need a nice-looking display for your project.

Looking for something a little different? An E-paper (or E-ink depending on who you ask) display might be right for you. These screens differ from the others giving a much more natural reading experience, it is no surprise that this technology is the cornerstone of almost every e-reader available.

The reason these displays look so good is down to the way they function. Each "pixel" contains charged particles between two electrodes. By switching the charge of each electrode, you can influence the negatively charged black particles to swap places with the positively charged white particles.

This article has covered most options available for Arduino displays, though there are definitely more weird and wonderful ways to add feedback to your DIY devices.

Now that you have an idea of what is out there, why not incorporate a screen into your DIY smart home setup? If retro gaming is more your thing, why not create some retro games on Arduino?

In this Arduino tutorial we will learn how to connect and use an LCD (Liquid Crystal Display)with Arduino. LCD displays like these are very popular and broadly used in many electronics projects because they are great for displaying simple information, like sensors data, while being very affordable.

You can watch the following video or read the written tutorial below. It includes everything you need to know about using an LCD character display with Arduino, such as, LCD pinout, wiring diagram and several example codes.

An LCD character display is a unique type of display that can only output individual ASCII characters with fixed size. Using these individual characters then we can form a text.

If we take a closer look at the display we can notice that there are small rectangular areas composed of 5×8 pixels grid. Each pixel can light up individually, and so we can generate characters within each grid.

The number of the rectangular areas define the size of the LCD. The most popular LCD is the 16×2 LCD, which has two rows with 16 rectangular areas or characters. Of course, there are other sizes like 16×1, 16×4, 20×4 and so on, but they all work on the same principle. Also, these LCDs can have different background and text color.

It has 16 pins and the first one from left to right is the Groundpin. The second pin is the VCCwhich we connect the 5 volts pin on the Arduino Board. Next is the Vo pin on which we can attach a potentiometer for controlling the contrast of the display.

Next, The RSpin or register select pin is used for selecting whether we will send commands or data to the LCD. For example if the RS pin is set on low state or zero volts, then we are sending commands to the LCD like: set the cursor to a specific location, clear the display, turn off the display and so on. And when RS pin is set on High state or 5 volts we are sending data or characters to the LCD.

Next comes the R/W pin which selects the mode whether we will read or write to the LCD. Here the write mode is obvious and it is used for writing or sending commands and data to the LCD. The read mode is used by the LCD itself when executing the program which we don’t have a need to discuss about it in this tutorial.

After all we don’t have to worry much about how the LCD works, as the Liquid Crystal Library takes care for almost everything. From the Arduino’s official website you can find and see the functions of the library which enable easy use of the LCD. We can use the Library in 4 or 8 bit mode. In this tutorial we will use it in 4 bit mode, or we will just use 4 of the 8 data pins.

We will use just 6 digital input pins from the Arduino Board. The LCD’s registers from D4 to D7 will be connected to Arduino’s digital pins from 4 to 7. The Enable pin will be connected to pin number 2 and the RS pin will be connected to pin number 1. The R/W pin will be connected to Ground and theVo pin will be connected to the potentiometer middle pin.

We can adjust the contrast of the LCD by adjusting the voltage input at the Vo pin. We are using a potentiometer because in that way we can easily fine tune the contrast, by adjusting input voltage from 0 to 5V.

Yes, in case we don’t have a potentiometer, we can still adjust the LCD contrast by using a voltage divider made out of two resistors. Using the voltage divider we need to set the voltage value between 0 and 5V in order to get a good contrast on the display. I found that voltage of around 1V worked worked great for my LCD. I used 1K and 220 ohm resistor to get a good contrast.

There’s also another way of adjusting the LCD contrast, and that’s by supplying a PWM signal from the Arduino to the Vo pin of the LCD. We can connect the Vo pin to any Arduino PWM capable pin, and in the setup section, we can use the following line of code:

It will generate PWM signal at pin D11, with value of 100 out of 255, which translated into voltage from 0 to 5V, it will be around 2V input at the Vo LCD pin.

First thing we need to do is it insert the Liquid Crystal Library. We can do that like this: Sketch > Include Library > Liquid Crystal. Then we have to create an LC object. The parameters of this object should be the numbers of the Digital Input pins of the Arduino Board respectively to the LCD’s pins as follow: (RS, Enable, D4, D5, D6, D7). In the setup we have to initialize the interface to the LCD and specify the dimensions of the display using the begin()function.

The cursor() function is used for displaying underscore cursor and the noCursor() function for turning off. Using the clear() function we can clear the LCD screen.

In case we have a text with length greater than 16 characters, we can scroll the text using the scrollDisplayLeft() orscrollDisplayRight() function from the LiquidCrystal library.

We can choose whether the text will scroll left or right, using the scrollDisplayLeft() orscrollDisplayRight() functions. With the delay() function we can set the scrolling speed.

So, we have covered pretty much everything we need to know about using an LCD with Arduino. These LCD Character displays are really handy for displaying information for many electronics project. In the examples above I used 16×2 LCD, but the same working principle applies for any other size of these character displays.

I hope you enjoyed this tutorial and learned something new. Feel free to ask any question in the comments section below and don’t forget to check out my full collection of 30+ Arduino Projects.

The Arduino board has a wide variety of compatible displays that you can use in your electronic projects. In most projects, it’s very useful to give the user some sort of feedback from the Arduino.

With the TFT display you can display colorful images or graphics. This module has a resolution of 480 x 320. This module includes the SD card socket and SPI FLASH circuit.

This is a tiny display with just 1 x 0.96 Inch. This display has a black background, and displays characters in white. There are other similar displays that can show the characters in other colors.

Liquid Crystal displays or LCDs have been used in electronics equipment since the late 1970s. LCD displays have the advantage of consuming very little current And they are ideal for your Arduino projects.

In this article and in the accompanying video I’ll show you how easy it is to add an LCD display to your next Arduino design. I’ll also show you a very popular Arduino Shield that has a keypad which you can use in your projects as well.

Today LCD displays are used in a variety of items from test equipment to televisions. They’re inexpensive and versatile, this makes them ideal for all sorts of designs.

LCD displays do not emit light. Instead they block the passage of light, like little windows which open and shut the let light through. The liquid crystals used inside LCD displays are sandwiched between two layers of polarized material. By changing the orientation of the liquid crystals they allow light to pass or they block the light entirely.

Because transmissive LCD displays (the type we will be using) work by blocking light they require a backlight. Several methods have been used to create back lights including electroluminescent panels and fluorescent tubes. these days the most common form of backlight is an LED, in fact so-called LED televisions are usually just LCD screens with an LED backlight system.

Another type of LCD display, the passive-matrix display, does not require a backlight, it works using reflected light. This type of display is often found in digital watches.

The principles of liquid crystals were discovered in the late 1880s but work on Modern LCD displays did not begin until the mid-1960s. a number of patents were filed in the early 1970s and in 1973 the Sharp Corporation introduced LCD displays for calculators.

The first color LCD displays were developed in the early 1980s but production units were not commonly available until the mid-1990s. By the late 1990s LCD displays were quite common.

A number of LCD displays are available for experimenters. These low-cost monochrome displays are ideal for use with microcontrollers like the Arduino and micro computers like the Raspberry Pi.

The LCD1602 display module is a very popular and inexpensive LCD display. It is available in a number of different colors such as blue yellow and green and can easily be connected to an Arduino or Raspberry Pi.

Because the LCD module uses a parallel data input it requires 8 connections to the host microcontroller for the data alone. Add that to the other control pins and it consumes a lot of connections. On an Arduino Uno half of the I/O pins would be taken up by the display, which can be problematic if you want to use the I/O pins for other input or output devices.

We will begin our experiments by hooking up the LCD1602 to an Arduino Uno and running a few of the example sketches included with the Arduino IDE. This will allow you to get familiar with the display without needing to write any code.

We need to hookup our LCD display to our Arduino. The display can use any of the Arduino digital I/O pins as it has no special requirements, but if you hook it up as I’ve illustrated here you can run the example sketches without needing to make any modifications.

In addition to the LCD1602 display ands the Arduino Uno you will need a 10K trimpot ot potentiometer, this is used a s a brightness control for the display. You’ll also need a 220 ohm resistor to drop the voltage for the displays LED backlight.

The Arduino IDE includestheLiquidCrystallibraryand this library has a number of example sketches. I’ll go over three of them here but you can also try the other ones.

The sketch starts with a number of credits and a description of the required hardware hookup. You’ll note that this is the same hookup you just performed on your Arduino and LCD module.

We then initialize an object that we call “lcd” using the pinouts of the LCD display. If you decide to hook up your display to different pins then you’ll need to modify this section.

In the beginning of the loop we set our cursor to the first position in the second row. Note that the row numbers start with zero so the second row is row 1.

That ends the loop, so we start back at the top of the loop and repeat. The result will be a counter on the second line that counts seconds from the htime the Arduino was last reset.

Load the sketch up to your Arduino and observe your display. If you don’t see anything try adjusting the brightness control that you wired to the display.

The second example we will try isthe Scroll sketch. Scrolling is a useful technique when you can’t get your text to fit on one line of the LCD display.

A character on the display is formed in a 5 x 8 matrix of blocks so you need to define your custom character within that matrix. To define the character you’ll use thecreateCharfunctionof the LiquidCrystal library. You are limited to defining a maximum of eight characters.

To usecreateCharyou first set up an array of bytes with 8 elements. Each element in the array defines one row of the character in the 5 x 8 matrix. You then use createCharto assign a number from 0 to 7 to that array.

The Custom Character demonstration requires one additional component to be wired to the Arduino, a potentiometer (10K or greater) wired up to deliver a variable voltage to analog input pin A0.

As with the previous sketches we examined this one starts by loading theLiquidCrystallibrary and defining an object calledlcdwith the connection information for the display. It then moves on to define the custom characters.

Each character is defined as an array with 8 elements, the zeros and ones in the array indicate which elements in the character should be on and which ones should be off. Five arrays are defined, although the sketch actually only used four of them.

Finally the setup routine ends by printing a line to the first row of the LCD display. The line makes use of two of the custom characters, the “heart” and the “smiley”.

We begin by reading the value of the voltage on pin A0 using the ArduinoanalogReadfunction. As the Arduino has a 10-bit analog to digital converter this will result in a reading ranging from 0 to 1023.

We then use an Arduinomapfunction to convert this reading into a range from 200 to 1000. This value is then assigned to an integer calleddelayTime, which as its name implies represents a time delay period.

One thing you may have noticed about using the LCD display module with the Arduino is that it consumes a lot of connections. Even in 4-wire mode there are still a total of seven connections made to the Arduino digital I/O pins. As an Arduino Uno has only 14 digital I/O pins that’s half of them used up for the display.

In other cases you would need to resort to using some of the analog pins as digital pins or even moving up to an Arduino Mega which has many more I/O pins.

But there is another solution. Use the I2C bus adapter for the LCD display and connect using I2C. This only consumes two I/O pins and they aren’t even part of the set of digital I/O pins.

The bus has evolved to be used as an ideal method of communicating between microcontrollers, integrated circuits, sensors and micro computers. You can use it to allow multiple Arduinos to talk to each other, to interface numerous sensors and output devices or to facilitate communications between a Raspberry Pi and one or more Arduinos.

In I2C communications there is the concept of Master and Slave devices. There can be multiples of each but there can only be one Master at any given moment. In most Arduino applications one Arduino is designated Master permanently while the other Arduinos and peripherals are the Slaves.

The Master transmits the clock signal which determines how fast the data on the bus is transferred. There are several clock speeds used with the I2C bus. The original design used 100 KHz and 400 KHz clocks. Faster rates of 3.4 MHz and higher are available on some I2C configurations.

Every device on the I2C bus has a unique address. When the Master wants to communicate with a Slave device it calls the Slaves address to initiate communications.

The I2C Adapter for the LCD display is a tiny circuit board with 16 male header pins soldered to it. These pins are meant to be connected directly to the 16-pin connection on the LCD1602 display (or onto other displays that use the same connection scheme).

The device also has a 4-pin connector for connection to the I2C bus. In addition there is a small trimpot on the board, this is the LCD display brightness control.

Most of these devices have three jumpers or solder pads to set the I2C address. This may need to be changed if you are using multiple devices on the same I2C bus or if the device conflicts with another I2C device.

Most Arduino Unos also have some dedicated pins for I2C, these are internally connected to A4 and A5 and are usually located above the 14 digital I/O pins. Some models of the Uno have additional I2C connectors as well.

Note how much easier it is to use the I2C connection, which does not consume any of the Arduino Unos 14 digital I/O pins. Since A4 and A5 are being used for the I2C bus they can’t be used as analog inputs in this configuration.

Nick has written a simple I2C scanner sketch that he’s put into the public domain. It scans your I2C bus and gives you back the address of every I2C device it finds. I’ve repeated Nick’s sketch here, it’s also in the ZIP file that you can download with all of the code for this article.

Load this sketch into your Arduino then open your serial monitor. You’ll see the I2C address of your I2C LCD display adapter. You can then make note of this address and use it in the sketches we’ll be looking at now.

In order to run the subsequent sketches you’ll need to install another library. This is theNewLiquidCrystallibrarywhich, as its name implies, is an improved version of the LiquidCrystal library packaged with your Arduino IDE.

The sketch starts by loading the ArduinoWirelibrary. This is the Arduino library that facilitates communications over I2C and it’s part of your Arduino IDE installation.

On the next line we define the connections to the LCD display module from the I2C Adapter,. Note that these are NOT the connections from the Arduino, they are the connections used by the chip on the adapter itself.

Load the sketch and run it on your Arduino. If you can’t get it to work check out the address and connection information to be sure you have it right.

We need to make a minor wiring adjustment to the hookup with our I2C adapter, specifically we will need to add a DHT22 temperature and humidity sensor into the circuit. The wiring is shown here:

As you can see the DHT22 is connected with its output tied to pin 7 of the Arduino. The other two connections are 5 volts and ground. Note that pin 3 of the DHT22 is not used.

This sketch also makes use of theDHTlibrary from Adafruit. We used this library in a previous article, “Using the HC-SR04 Ultrasonic Distance Sensor with Arduino” so you may want to take a look at that one in order to get it installed.

The key thing to note is that this library is dependant upon another Adafruit library, theirUnified Sensorlibrary. Both can be installed using the Library Manager in your Arduino IDE.

The sketch is similar to our demo sketch in that it creates an “lcd” object with the I2C and display connection information. It also defines a couple of parameters for the DHT22 sensor, as well as some floating variables to hold the temperature and humidity values.

So far we have used the LCD1602 display module for all of our experiments. For our final demonstration we’ll switch to a popular Arduino shield that contains a LCD1602 along with some push buttons.

The LCD Keypad Shield is available from several different manufacturers. The device fits onto an Arduino Uno or an Arduino Mega and simplifies adding an LCD display to your project.

The Reset button is simply connected to the Arduino Reset pin and works just like the Reset button on the Arduino itself. This is common on many shields as the shields physically cover the Reset button.

Instead the buttons are connected to a resistor array that acts as a voltage divider. The entire array is connected to the Arduino’s analog A0 pin. One pin for five push buttons.

Note that the LCD is being used in 4-wire mode. The LCD itself is the same one used on the LCD1602 module, so all of the code for that module will work with the LCD Keypad Shield as well.

Now that you know how the LCD Keypad module works and which Arduino pins it uses all that remains is to install it onto your Arduino and load the demo sketch.

One thing – once the shield is installed on the Arduino you won’t have easy access to the unused I/O pins to connect any sensors or output devices you may want to use (although the demo sketch doesn’t need anything else connected). There are a couple of ways to get around this:

Use a shield that exposes the pins for prototyping before you install the LCD Keypad shield. In the video associated with this article I use a “Screw Shield” that brings all of the Arduino I/O pins out to a series of screw connectors. There are other similar shields. Using one of these shields is the easiest way to work with the LCD Keypad shield, as well as other Arduino shields.

The sketch begins by including theLiquidCrystallibrary. You can use the original one or the one includes with theNewLiquidCrystallibrary. We then set up an object with the LCD connections, note that these are just hard-coded as they won’t change.

Next we define a number of constants, one for each of the push buttons. Note that nothing is defined for the Reset button as it simply mimics the Arduino Reset button, however a constant is defined for the “none” condition.

After that we define a function calledread_LCD_buttons(). This function reads the value on analog port A0 and returns an integer corresponding to the button integers we defined earlier. Note that the function adds approximately 50 to each of the manufacturers specified values to account for intolerances in the resistors in the voltage divider.

We start the loop by placing the cursor 9 spaces over on the second line. We then use themillisfunction to display a counter that counts the time since the Arduino was reset. This is to test the Reset button.

We then call ourread_LCD_buttons()function and use it to display the value of the push button, right before the counter. Then we end the loop and do it again.

Load the code onto the Arduino and run it. You should see the value of each button as you press it, along with a counter that increments each second. If you press Reset the counter should reset itself back to zero.

As you can see LCD displays are pretty simple to use thanks to the availability of some excellent libraries for the Arduino. As these displays are also very inexpensive they will make an ideal addition to many of your Arduino projects.

And finally the LCD Keypad Shield is a convenient method of adding both a display and a simple keypad to your project, no wiring or soldering required.

Welcome to my collection of Arduino projects. As a maker, techie and mechatronics engineer I’ve been using Arduino for more then 8 years. Arduino is an incredibly versatile microcontroller with limitless possibilities for developing electronics applications and prototypes.

We can use Arduino for simple tasks such as controlling LEDs and DC motors, to controlling real CNC machines and robots. That’s right, in the following list I will share my Arduino experience with you. You will find Arduino projects for beginners and more advanced projects for Arduino enthusiast.

Even if you are just getting started with Arduino, you don’t have to worry about that. Each of the following DIY Arduino projects is covered with detailed step by step tutorial on how to do it yourself and includes circuit schematics, source codes and videos.

Using the comments section below, you can also suggest your ideas, as well as discuss anything related to these Arduino projects. I will continuously update this article with all new stuff that I make. Last update: February 2022.

As an Arduino enthusiast, I found making robots with Arduino to be most fun for me. There is so much to learn from them as a maker and an engineer. So, here are my Arduino projects related to robotics so you can learn too.

When it comes to automated manufacturing, robot arms play big role with so many applications. They are often used for welding, assembling, packing, painting, pick and place tasks and much more. This Arduino project is actually a robotic arm made out of 3D printed parts, servo motors joints and controlled using an Arduino Nano. What’s even cooler we can control the robot arm wirelessly via a smartphone and a custom build Android application.

The robot arm has 5 degrees of freedom, so we need 5 servo motors, plus an additional servo for the gripper mechanism. For the communication with the smartphone we use the HC-05 Bluetooth module.

The following project is one of the coolest Arduino project in this list. It’s an Arduino robot car which instead of normal wheels, it employs omnidirectional wheels or mecanum wheels which enable to robot to move in any direction.

The wheels are attached on four stepper motors which are individually control. By rotating the wheels in certain pattern, they exert diagonal forces due the diagonally positioned rollers on the circumference of the wheels, and so they can move in any direction. The robot car can be remotely controlled either vie Bluetooth communication and an custom build Android application. Also, we can control it using an DIY RC transmitter with the help of the NRF24L01 transceiver module.

Here’s an upgraded version of the previous mecanum wheels robot project. On top of the platform I added the DIY Arduino Robot Arm project mentioned above and now they can work together.

Of course, as for any of my Arduino projects, the Arduino code, the custom build Android application, as well as the 3D model files can be found and downloaded from the particular project article.

This Arduino based SCARA robot is a step-up big compared to the previous projects in every aspect. It has a better and more robust design with precisely controlled stepper motors and custom build GUI for controlling it.

As a controller it has an Arduino UNO board, combined with a CNC shield and four A4988 stepper drivers. It has 4 DOF, driven by four NEMA 17 stepper motors.

For controlling the robot we are using an Arduino Mega board in combination with a RAMPs board. This a popular combination used for 3D printing and it can be used for laser engraving machines as well. As for a firmware, we are using the Marlin 3D Printer firmware and the Repetier control software.

The rover features a rocker-bogie suspension which allows the rover to run smoothly on uneven terrain, just like the real rover. It has six independently controlled DC motors for driving and four servos for steering, and it’s controlled using an Arduino MEGA board. There’s also an FPV camera located in the cameras unit of the rover which can by used for controlling the rover remotely. The remote control is done with the help of a cheap commercial RC transmitter and receiver.

Making biologically inspired robots is very popular among engineering students. This Arduino project is all about it, we will build a hexapod robot which features six legs, a tail or abdomen, a head, antennas, mandibles and even functional eyes. All of this makes the robot look like an ant.

Each leg have three joints, and for each joint we need a servo motor. That means that we need total of 18 servos for this project, and additionally 3 servos for the head movements and 1 servo for the tail. The brain of the robot is an Arduino Mega. We need MEGA because it’s the only board that can control more than 12 servos using the Servo library.

I also designed a custom PCB which acts as an Arduino Mega Shield so we can easily attach all servo connects. We can control the ant robot via Bluetooth and a smartphone, or radio communication. The ant also has built-in ultrasonic sensor in the head. With that it can detect objects in front, and it can even strike if the object is present if front of it.

The following projects show how capable Arduino is. A CNC or Computer Numerical Control is an automated control of machines, like mills, lathes, plasma cutters, 3D printers and etc. So, using the Arduino as a controller we are actually able to build any of these CNC machines.

For the project my goal was to build the simplest CNC machine with minimum parts possible and by using just a single power tool. On top of that, I wanted to use common materials or avoid 3D printers so I used MDF board for building the base frame.

The CNC machine is composed of just two linear rails which are secured to a base frame made of 8mm MDF board. For controlling it we are using an Arduino UNO board in combination with a CNC shield and two DRV8825 stepper drivers. As a tool it has an laser module attached so this machine is actually a CNC laser engraver.

The idea for this Arduino project was similar to the previous one, to build a CNC machine using minimum parts possible. Here I used 3D several printed parts, and just two MGN15H linear rails for the main construction of the machine.

Building your own CNC machine might seem like a big challenge for many of you, but the following Arduino CNC Machine project shows that building a CNC machine is actually not that hard.

Controlling stepper motors using Arduino is without a doubt one of most satisfying thing for an Arduino enthusiast. There so many machines based on this motors, like CNC machines, 3D printers, various automation machines etc. This Arduino project is all about that. It describes how you can build such a machine. It’s a machine for bending wire, where with the help of stepper motors we can precisely bend wire and make various shapes and forms out of it.

The machine features three stepper motors. With the first stepper we feed the wire to the bending mechanism. Here we have another stepper motor used for the bending the wire at the right angle. There’s also another stepper, for controlling the Z-axis. This stepper enables the machine to create three dimensional shapes. With this project we can also see how useful 3D printers are for Arduino projects of this type or for prototyping.

Many Arduino projects that I make require wireless control and that’s why I build this Arduino based wireless radio controller. With this RC transmitter I can wirelessly control pretty much with a range up to 700m in open space. It features 14 channels, 6 of which are analog and 8 digital inputs.

The brain of this Arduino project is an Arduino Pro Mini board which is the smallest Arduino board. The radio communication is based on the NRF24L01 module, it has 2 joysticks, 2 potentiometers and 4 momentary push buttons. Also an accelerometer and gyro module which can be used for controlling things with just moving around or tilting the controller. I mounted all electronic components on a custom design PCB and made a cover out of transparent acrylic.

This is a follow up project of the above one. Just like DIY RC Transmitter, this DIY Arduino RC Receiver can be used for many application. We can easily pair the two projects together and control anything wirelessly. Among others, I made an example of controlling a commercial RC car model using these DIY transmitter and receiver.

The custom PCB that I made uses the same NRF24L01 module for the radio communication. The controller is an Arduino Pro Mini and it features input/ output 9 channels.

The following Arduino project is a great example of utilizing the DIY RC transmitter from above. It’s a 3D printed hovercraft which I entirely designed on my own, and of course, the 3D printing files are available for downloading. The hovercraft uses two brushless motors, one for creating an air cushion for the lift, and the other for generating thrust or moving forward.

For the wireless control we are using the NRF24L01 module, which accepts the data coming from the RC transmitter. Then using the Arduino and two ESCs (Electronic Speed Controler) we control the BLDC motors speed. On the back side of the hovercraft there is also a servo for controlling the rudders, or for controlling the steering. I must say that driving this DIY hovercraft is so fun.

Anyone who had a chance of playing around with some RC airplanes knows how cool and fun it is. It’s even cooler and more satisfying if you build the RC airplane on your own. The following project steps the satisfaction up even further, because here I will show you how to build your own RC airplane which is 100% DIY build. Also, we have a 100% DIY radio control system based on the Arduino.

The airplane is entirely made out of Styrofoam and what’s cooler, the shapes are made with the help of my DIY Arduino CNC Foam Cutting Machine, a project already mention above. The radio communication is based on the NRF24L01 transceiver modules. For that purpose, I used my DIY Arduino RC Transmitter and DIY Arduino RC Receiver.

You can choose one of the three different methods of wireless control explained in this project, or that’s the HC-05 Blueooth module, the NRF24L01 transceiver module and theHC-12 long range wireless module. Additionally you can learn how to make your own Android app for controlling the Arduino robot car.

This Arduino project idea is rather practical because it features indoor and outdoor temperature and humidity measurement. It is based on the DHT11/ DHT22 sensor, the NRF24L01 transceiver module for the wireless communication and theDS3231 RTC. For the display we can either use 16×2 character LCD or a 3.2 inches TFT touch screen.

The outdoor unit can be powered with batteries and the indoor unit with an AC adapter. The outdoor unit measures the temperature and the humidity and sends the values to the main indoor unit. Here these values are printed on the LCD along with the data and time values from the DS3231 RTC module.

The slider has three NEMA 17 stepper motors controlled via the A4988 stepper drivers and the Arduino Nano board. Using a joystick we can control the pan and tilt movements and using a potentiometer we can control the sliding movement. With this DIY camera slider we can use the Set button to set two different IN and OUT points. Then the camera can automatically move from one to the other point.

If you are interested in building something more complex with Arduino then this project is the one for you. Although complex, you could easily recreate it as there is a detailed step by step explanation on how everything works, including circuit schematics and source codes.

The following Arduino project is a simple gimbal or a self-stabilizing platform. It can be used for keeping objects or the top platform level. The project is rather simple with just several electronic components.

The combination of DC motors and Arduino is always fun, and so is this project. Here we will build our own robot car from scratch. The car will be powered with Li-ion batteries and two 12V DC motors, and controlled using the L298N driver and an analog Joystick.

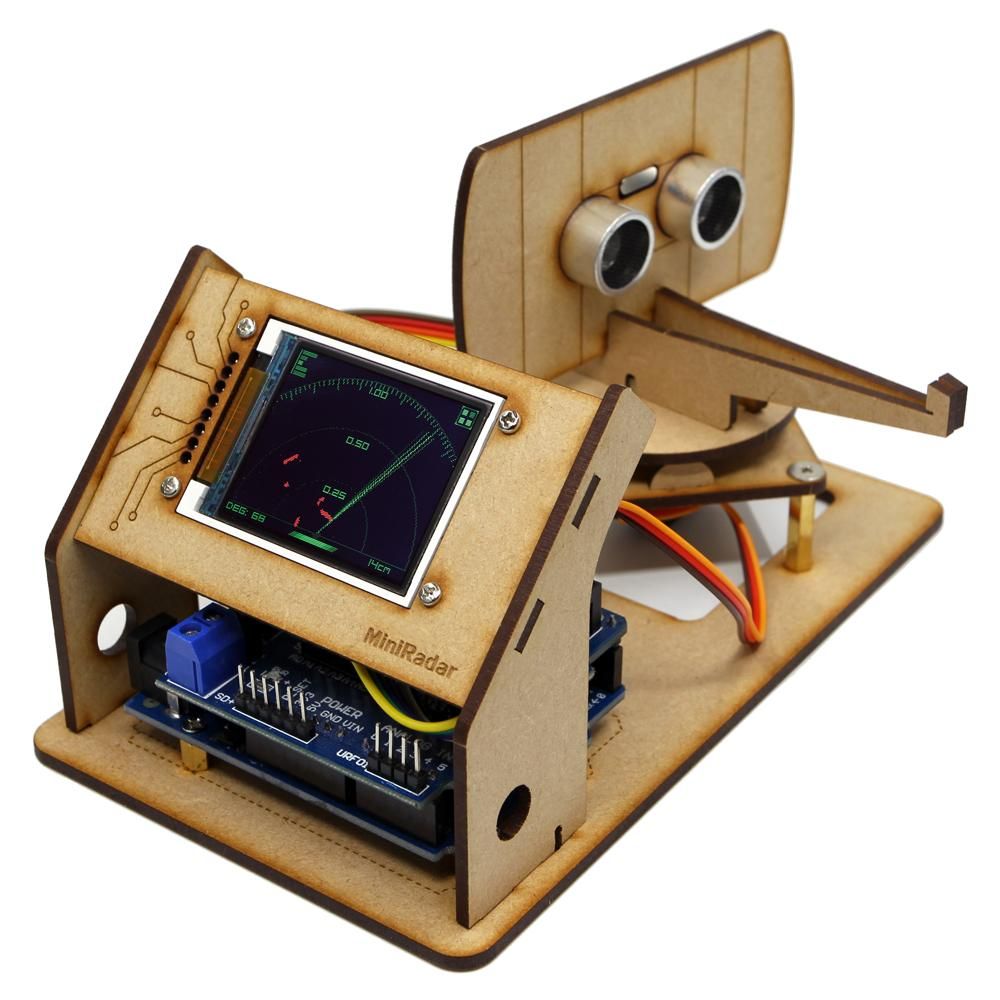

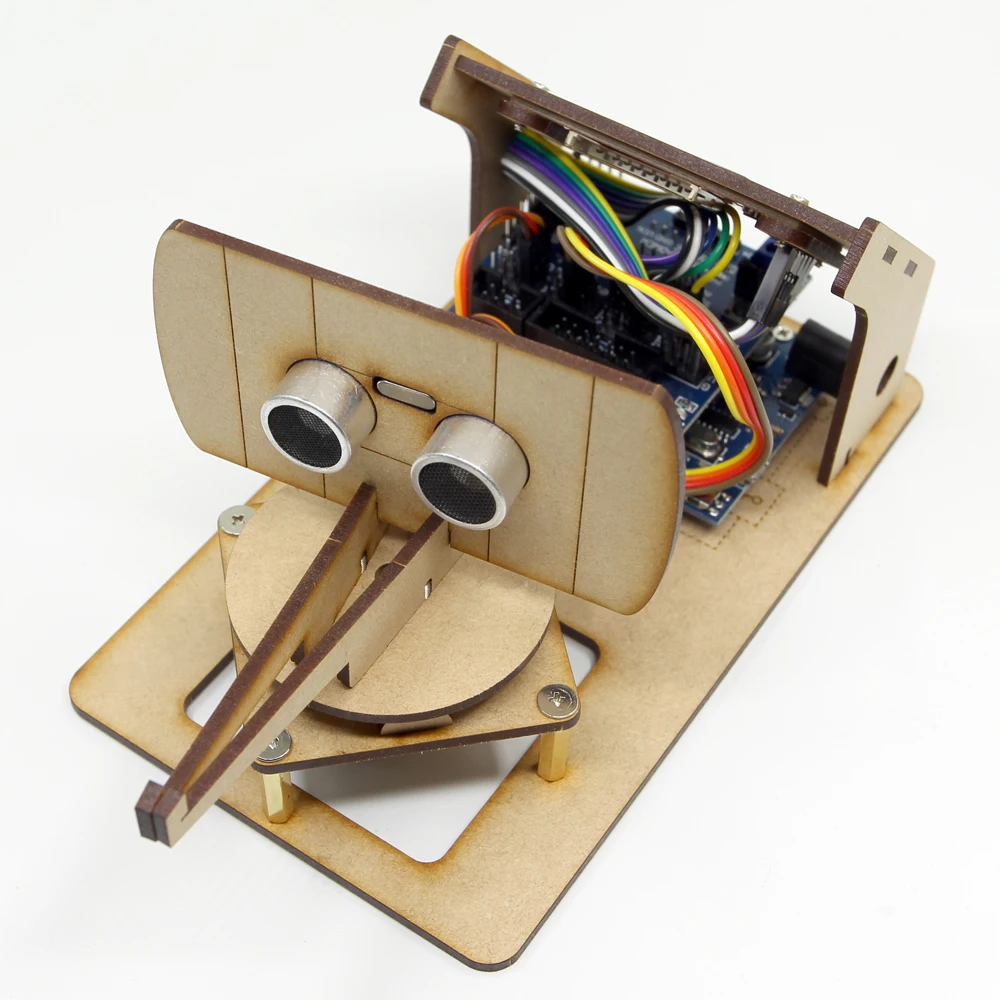

This is one of my most popular project and it’s really fun to build. The radar can detect objects in front of it and map them on PC screen using the Processing IDE.

For this project you just need two components along with an Arduino board, and that’s an ultrasonic sensor and small servo motor. The range of the radar can be adjusted to up to 4 meters with 180 degrees rotation.

The project also includes and accelerometer which is used for the digital spirit level function or for measuring angle. The results are displayed on 16×2 LCD and all components are attached on a custom design PCB.

In this project we will learn how to use a color detecting sensor along with the Arduino. We are going to be sorting out colored skittles but you can use the same sensor and method for sorting out anything else.

In this project we will learn how to use the Arduino to make an RFID controlled door lock. The system consists of an MFRC522 RFID reader and RFID tags/ cards that are based on the MIFARE protocol.

This game project is based on the popular Flappy Bird game for smartphones. Using the touch screen we control the bird while trying to avoid the pillars.

For this project we need a 3.2 inches TFT Touch screen, an TFT Mega shield adapter and an Arduino Mega board. The code is a bit longer but everything is explained in details.

The code behind this project is a bit more complex with around 550 lines but everything is explained in details with comments for each lines. There is also a detailed video explanation for it.

The heart of the table is an Arduino which controls the 45 WS2812B Addressable LEDs. The objects on top of the table are detected using infrared proximity sensors. What’s even cooler it has built-in Bluetooth module which enables interaction with a smartphone for selecting the LEDs colors.

In this Arduino project we are building an Air Quality Monitor which can measure several important air quality parameters such as PM2.5, CO2, VOC, Ozone, as well as temperature and humidity. I designed a custom PCB on which we can easily attach the sensors we need and show the results on a 2.8 inches touch display. The device can also keep track of the sensors values from the last 24 hours.

The following section of this article contains Arduino projects ideas based on my detailed tutorials on various sensors and modules, as well as your suggestions from the comments section below.

We can use NEMA 17 or 23 stepper motors in combination with these drivers which provide high speed reduction ratios. As for controller we could use an Arduino Uno or Arduino MEGA board.

Controlling your home power outlets via a smartphone is the first step in home automation. You can easily make your own Arduino controlled power outlets utilizing the knowledge you can get from my Arduino tutorials.

For this project you just need two components along with the Arduino board. An HC-05 Bluetooth module and a5V Relay module for which I already have detailed tutorials. For powering the Arduino and the relay you can use 220/ 110V AC to 5V DC converter.

Using your smartphone you can connect and control your power outlet via Bluetooth. You can either use some already made apps for controlling Arduino from the Play Store or create your own custom made app. In this way we can also control the power outlets through voice control commands.

Home automation is one of the most popular Arduino projects nowadays. The goal of this project is to remotely control anything in your house like lights, appliances, temperature, security devices and so on, with a single device or your smartphone.

In order to make such a project we need decent amount of knowledge in Arduino. The following home automation concept that I suggest is based on my detailed Arduino tutorials for various sensors and modules.

Of course, there are endless possibilities and combinations for building a home automation system using the Arduino board. You can always change and add more devices. You can also make a Bluetooth communication so you can control all of this using your smartphone etc.

The idea for this project is to remotely control an Arduino project using hand gestures. Let’s say we want to control the Arduino Robot Car that we mentioned above. So instead of the joystick we will use an MEMS module for the control.

The lcd.begin(16,2) command set up the LCD number of columns and rows. For example, if you have an LCD with 20 columns and 4 rows (20x4) you will have to change this to lcd.begin(20x4).

The lcd.print("--message--") command print a message to first column and row of lcd display. The "message" must have maximum length equal to lcd columns number. For example, for 16 columns display max length is equal with 16 and for 20 columns display max length is equal with 20.

Thelcd.setCursor(0,1) command will set cursor to first column of second row. If you have an LCD 20x4 and you want to print a message to column five and third row you have to use: lcd.setCursor(4,2).

Try downloading the codebender plugin and clicking on the Run on Arduino button to program your Arduino with this sketch. And that"s it, you"ve programmed your Arduino board!

You can keep playing with that by clicking the "Edit" button and start making your own modifications to the code. For example, try to change message on first and second row.

Arduino shields allow you to quickly upgrade your projects with a wide array of useful features and tools that you can plug directly into your board. To show you how easy it is, we’ll walk through how to add a programmable LCD display to your Arduino project so you can display text, and provide input with a series of buttons.

We’ve talked a bit about Arduino shields before, but if you’re not familiar, a shield is an add-on for an Arduino project that can plug directly into your board to give it new features. Some are stackable, so you can add multiple modules to a single project. They often come with their own library of software that you can import into your sketches to control them just as easily as you do with other components you connect.

For this guide, we’ll be using an LCD display shield. There are several variations of this kind of shield out there, but the one we’ll be using isthe 1602 keypad shield, which can display up to 16 characters across 2 rows (hence 1602) for up to 32 characters at a time. It also comes with six buttons: four directional buttons (left, right, up, and down) and a select and reset button.

This shield has 28 pins that align with the pins on the Arduino Uno. Shields are generally designed to snap directly onto their corresponding boards, so if you have a shield that doesn’t match the pins on your board, you might need a different shield. In this case, if you have an Arduino Uno and the correct shield, you can insert the shield directly onto the board itself (we’ll talk more about this in the wiring section below).

However, the LCD display doesn’t need to use every pin on the board. This is where some pass-through pins come in handy. You can connect wires to the LCD display board where there are open contacts, and this will connect to the Arduino. This is handy because it means you don’t lose any open pins just because you’re using a shield.

The final piece that makes this work is the LiquidCrystal library. This library provides simple commands to display text, scroll text, control a cursor position, and more. As long as your LCD display shield is compatible with this library (and most popular shields are), then you can include this library and control your display with very simple commands.

Since shields plug directly into Arduino boards, you won’t need a ton for this project. That’s what makes Arduino shields great; they can dramatically simplify your projects. However, you still need a couple of things before we get started:

The Arduino IDE comes with a few sketches in the example book underFile > Examples > Liquid Crystal. For our purposes, we’ll use the HelloWorld sketch. You can load this up in your IDE, but we’ll include the full code below:

Next, these two lines will initialize variables for the six pins that are needed to control the LCD display in 4-bit mode: rs, enable, d4, d5, d6, and d7. The Arduino documentation has more information on the pins required to control the LCD display in 8-bit mode, but we won’t need that here.

The second line will assign those pins (via the variables you just created) to a new type of variable called LiquidCrystal, in this case named lcd. This lets you address the LCD display as a whole entity, rather than having to control each individual pin. This lets you use the other commands in the LiquidCrystal library with simple lines of code.

In the setup() section, there are only two commands: the first, lcd.begin()—which calls thebegin() command on the lcd variable we created earlier—initializes the LCD display. The second prints the phrase “hello, world!”

This print() command is different from the one you’ve used in the past. While the other, Serial.print(), prints data to the serial port, this one is part of the LiquidCrystal library and will print text to an LCD display. It can be called on any LCD object you create using the above method.

If you’re only using the shield, you won’t need any special wiring at all for this project. Simply align the pins on the bottom of your LCD shield with the pins on your Arduino Uno board. It’s recommended to start with the pins that align with A0 and RX0 on the far end of the Arduino board.

On the LCD shield itself, you’ll see many pins have empty contacts next to the solder points where the pins connect to the shield. If you want to add additional wires or components, this is where you can do so.

TFT LCD screens combined with Human Machine Interface (HMI) technology result in exciting project ideas applicable to a wide variety of industries. STONE HMI TFT LCD Arduino project ideas. After all, HMI is a smart technology that uses touch to draw out information from both the human user and the display machine.

And when high-quality display screen modules such as STONE Tech’s TFT LCD products are laden with HMI technology, the result is outstanding machine performance capable of bringing out the best in every customer and business.

Now, this article will feature STONE HMI. Furthermore, we will also present some exciting project development initiatives carried out by the company using its vast range of TFT LCD modules paired with HMI technology, and the TFT LCD Arduino project.

Human Machine Interface (HMI) is an interface or dashboard that lets human users interact with a machine. HMI allows users to monitor and control a machine through the use of different touch technologies.

The interface with which HMI works consists of both hardware and software. These two work together to let users input signals using direct or indirect touch (such as by using a special screen stylus) on the machine display. Once the touch signals have been inputted, the machine recognizes them and sends them to the software to begin interpretation. The machine then responds by showing the desired information to the human user.

Information that a user can get from an HMI machine greatly varies depending on the setting with which the machine is used. Here are some examples of common HMI machines and the data it presents to its daily users:

An HMI in the form of a bank ATM can provide a user with financial information such as his bank account balance, withdrawals, deposits, bills payments, phone credit loading, and similar data.

Medical equipment in hospital settings uses HMI to display pertinent information regarding a patient. For instance, a ventilator machine can display data such as vital signs and a selection of possible breathing patterns for the patient. It can also alert medical practitioners when there is a problem with the patient or the machine through alarms and sounds.

Another HMI machine used in daily life is the car dashboard. An on-board car control panel using an intelligent touch screen can be used to display important car information like speed, gas levels, and time. The screen dashboard can also be used to toggle many functions like turning the AC and beam on or off using a single touch.

HMIs are user-friendly by nature. Graphics and colors can easily be added to the display to communicate with the end-users. Any problems arising from the HMI screen can also be detected easily using color codes, alarms, and sounds. Furthermore, you’ll need only a few touches to fix any issues detected by an HMI device.

HMI greatly improves productivity when used in industrial settings. These interactive screens and machines help automate several tasks. While these tasks could be carried out by a human worker, using an HMI machine gets the job done in less time, translating to more work finished by the day’s end.

Several HMI machines have the innate ability to record data. This is especially useful in adjusting machine settings or troubleshooting any mechanical issues. Automatic data gathering can be programmed into the HMI software, allowing the machine’s screen and hardware to capture data through a series of commands.

Using HMI machines in workplaces such as factories and corporate offices increases worker satisfaction. This is because the HMI technology allows workers to interact easily with the machine, automating some of their work and providing them more efficiency.

What makes HMI a good choice for industrial use is that it is fully flexible and customizable to fit several industrial needs. The TFT LCD screen sizes can be tailor-made to suit the HMI’s application. Furthermore, the software that comes with the machines can be adjusted as well.

Another exciting opportunity for HMIs is their ability to connect with the Internet, much like an Internet of Things (IoT) device. This allows greater opportunities for productivity such as remote controlling and network monitoring.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

STONE TFT LCD modules come with a microcontroller unit that has a cortex-m4 32-bit CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to it.

Each customizable TFT-LCD HMI display module comes with free access to STONE’s dedicated design software. STONE TOOLBox software is an easy-to-use program that allows you to set up graphical user interface functions such as:

STONE TOOLBox features a drag-and-drop mechanism and comes with simple instructions. Hence, even beginning engineers can quickly and seamlessly create an impressive user interface within minutes.

Intricate and intuitive interfaces will require a bit more steps. Nevertheless, using the TOOLBox program allows you to save time on developing HMI projects due to its ease of use.

HMI projects can quickly be done with Stone’s HMI-ready display modules. As previously mentioned, STONEprovides complete modules that include hardware and a free downloadable GUI design software – everything you need to get started on your HMI concept.

With faster project timelines comes greater production savings. Stone’s modules are cost-effective and since they have superior quality, you’re assured of a quick return on investment (ROI) with fewer costs on maintenance and repairs in the long run.

Also, STONE manufactures several TFT LCD touch screen sizes that range from 3.5 to 15.1 inches. Customized options are also available depending on your needs. There are also plenty of options and models for each screen size.

Indeed, STONE produces a plethora of HMI-ready TFT LCD screens. You won’t have a hard time finding the right display module compatible with your microcontroller projects.

Over the years, Stone’s modules have been used to create numerous projects featuring its reputable HMI technology. These project ideas cater to a wide variety of fields and industries.

STONE developed an oxygen monitor for an Italian customer. The monitor uses Stone’s 7-inch TFT LCD screen and was connected to an oxygen tank for medical use.

The end-product featured a touch screen display where fan functions such as speed, dose, and RF are controlled. Moreover, the resulting fan control board can operate at temperatures ranging from -20°C to 70°C, making it a simple yet heavy-duty device.

STONE’s display screen was connected to the Arduino development board through UART. But this required a level conversion achieved by the MAX3232. Meanwhile, the same Arduino board was wired to the MAX30100 module through an IIC interface.

Some modifications to the MAX30100 module were made, specifically to the IIC pull-up resistor. The remainder of the project was finished using Arduino codes to finally create a responsive display for heart rate and blood oxygen monitoring.

This project aims to create a fingerprint door lock that can enter, scan, compare, and delete fingerprints. It utilized an STM32 development board, fingerprint identification module, and Stone’s STVC050WT-01 LCD display.

STONE LCD screen’s role here is to display the fingerprint module’s status. As with all other projects, STONE TOOLBox software was used to generate the user interface flashed on the screen. Meanwhile, Stone’s LCD screen was connected to the development board and fingerprint identification module with MCU through UART-TTL signals.

The idea for this project is a real-time display of pictures collected by the camera on the LCD display screen. The TFT LCD STONE module used for this project is a 7-inch serial display module with 800×480 resolution. A camera module, development board, and some wires are needed to complete the project.

The user interface was designed using STONE TOOLBox and Adobe Photoshop. Then, the hardware parts were wired together; some parts needed welding. After that, a simple program was written following MCU to the command control TFT-LCD module.

This particular project used a STONE serial LCD touch display screen. This functions as the main display for the coffee machine. With the screen installed, you can:

RGB lamps that can be controlled through a touch display – this is the aim of this project idea. STONE’s 7-inch TFT LCD display module in STVC070WT-01 was used to connect and control an RGB lamp.

Last but not least is a basic appliance controller made using STONE’s 7-inch TFT LCD touch screen and an STM32 development board. The touch screen controls lights for various parts of the house. The finished product also collects data about humidity, temperature (indoor and outdoor), and air quality.

This project resulted in a simple electronic scale made by connecting STONE’s 5-inch touch screen to a development board, an ADC conversion module, and a pressure acquisition module. The finished product can:

STONE’s TFT LCD intelligent touch modules can be paired with Arduino technology to automate a variety of processes. This project clearly demonstrates this.

Here, a sensor directly connected to Arduino Uno is monitored by the display screen in real-time. Moreover, two light bulbs connected to Arduino are directly controlled by the display screen as well.

This project is all about making a car display dashboard using a 10.1-inch STONE LCD touch screen. The on-board display interface for a used car contains the following:

We presented an overview of what HMI technology is, how it works, and which applications use it. Also, we covered Stone’s range of HMI-capable TFT LCD display modules. Furthermore, we discussed a lengthy list of exciting project ideas made using Stone’s superior quality HMI displays.

STONE Technologies is truly your best bet for powering your HMI-driven development ideas(projects based on TFT LCD Arduino, STM32, ESP, etc.). Take inspiration from the actual examples we’ve shown you and build your very own HMI display device today.

Your Image on an Arduino! - TFT LCD Screen Guide: Have you ever heard of TFT LCD screens? They are great ways to display information from your Arduino, or display pictures. The…

Arduino Powered Binary Clock: We can design a binary clock by using Arduino. This project needs simple electronic elements like LEDs. The LEDs are arranged in a sequence to display the analog clock.

Arduino Powered Lucky Cat As Physical Webcounter: This project is used to make indicate us when person visits our web page or web site. The lucky cat idol will make us to know this by connecting this to the web server by using Arduino. This project uses the simple hardware components like LED and servo motors.

Arduino Powered Mobile Phone: The cell phone can charge the Arduino by using its Li ion battery. This Arduino powered mobile phone project will be useful for charging applications, by using simple elements like diodes and resisters.

Arduino Room Temperature Monitor: This project will help us to monitor the temperature of a room by using a thermostat and Arduino. We can monitor the temperature by using a http server api and can send text messages about the temperature and room conditions.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey