arduino projects with lcd screen factory

Arduino shields allow you to quickly upgrade your projects with a wide array of useful features and tools that you can plug directly into your board. To show you how easy it is, we’ll walk through how to add a programmable LCD display to your Arduino project so you can display text, and provide input with a series of buttons.

We’ve talked a bit about Arduino shields before, but if you’re not familiar, a shield is an add-on for an Arduino project that can plug directly into your board to give it new features. Some are stackable, so you can add multiple modules to a single project. They often come with their own library of software that you can import into your sketches to control them just as easily as you do with other components you connect.

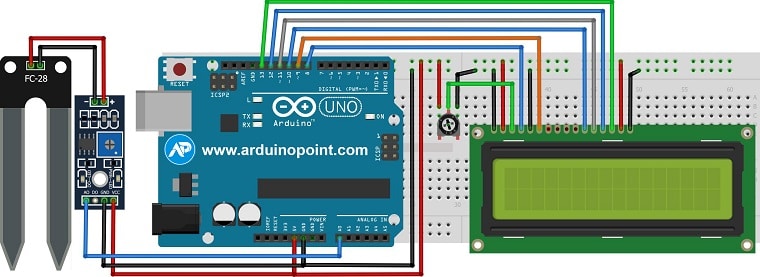

For this guide, we’ll be using an LCD display shield. There are several variations of this kind of shield out there, but the one we’ll be using isthe 1602 keypad shield, which can display up to 16 characters across 2 rows (hence 1602) for up to 32 characters at a time. It also comes with six buttons: four directional buttons (left, right, up, and down) and a select and reset button.

This shield has 28 pins that align with the pins on the Arduino Uno. Shields are generally designed to snap directly onto their corresponding boards, so if you have a shield that doesn’t match the pins on your board, you might need a different shield. In this case, if you have an Arduino Uno and the correct shield, you can insert the shield directly onto the board itself (we’ll talk more about this in the wiring section below).

However, the LCD display doesn’t need to use every pin on the board. This is where some pass-through pins come in handy. You can connect wires to the LCD display board where there are open contacts, and this will connect to the Arduino. This is handy because it means you don’t lose any open pins just because you’re using a shield.

The final piece that makes this work is the LiquidCrystal library. This library provides simple commands to display text, scroll text, control a cursor position, and more. As long as your LCD display shield is compatible with this library (and most popular shields are), then you can include this library and control your display with very simple commands.

Since shields plug directly into Arduino boards, you won’t need a ton for this project. That’s what makes Arduino shields great; they can dramatically simplify your projects. However, you still need a couple of things before we get started:

The Arduino IDE comes with a few sketches in the example book underFile > Examples > Liquid Crystal. For our purposes, we’ll use the HelloWorld sketch. You can load this up in your IDE, but we’ll include the full code below:

Next, these two lines will initialize variables for the six pins that are needed to control the LCD display in 4-bit mode: rs, enable, d4, d5, d6, and d7. The Arduino documentation has more information on the pins required to control the LCD display in 8-bit mode, but we won’t need that here.

The second line will assign those pins (via the variables you just created) to a new type of variable called LiquidCrystal, in this case named lcd. This lets you address the LCD display as a whole entity, rather than having to control each individual pin. This lets you use the other commands in the LiquidCrystal library with simple lines of code.

In the setup() section, there are only two commands: the first, lcd.begin()—which calls thebegin() command on the lcd variable we created earlier—initializes the LCD display. The second prints the phrase “hello, world!”

This print() command is different from the one you’ve used in the past. While the other, Serial.print(), prints data to the serial port, this one is part of the LiquidCrystal library and will print text to an LCD display. It can be called on any LCD object you create using the above method.

If you’re only using the shield, you won’t need any special wiring at all for this project. Simply align the pins on the bottom of your LCD shield with the pins on your Arduino Uno board. It’s recommended to start with the pins that align with A0 and RX0 on the far end of the Arduino board.

On the LCD shield itself, you’ll see many pins have empty contacts next to the solder points where the pins connect to the shield. If you want to add additional wires or components, this is where you can do so.

One of the most widely used information display elements in the Arduino world is the 16×2 LCD (Liquid Crystal Display). When manufacturing an electronic system, it can be interesting to have it give us some information about its status without having to connect it to a computer or to another system such as a smartphone. The 16×02 LCD screen is supplied with a large number of Arduino kits and is very sufficient for a large number of applications.

The 16×2 LCD screen can be found mounted on a shield with the bonus of a few buttons to create simple programmable interfaces to display values and control your Arduino project. All this while making the installation much easier.

Liquid crystal displays make use of the light modulation property of liquid crystals. Liquid crystal displays consist of two layers of polarizers, with perpendicular polarization directions, sandwiching two glass plates between which the liquid crystals are placed. On the glass plates is a matrix of electrodes for each pixel. A voltage applied between the electrodes of a pixel causes a change in the orientation of the molecules and thus the transparency of the pixel, which may or may not allow the light of the backlight to pass through.

It is exciting to see how the maker movement has taken off which encourages people to learn how to create things from scratch. Arduino is one of the most popular microcontrollers in the maker and hacker community because of its accessibility and flexibility. Because Arduino was designed to be beginner-friendly, people who are new to programming and electronics can create functional or artistic projects quickly. From wearable Arduino devices to home automation, this simple and versatile board allows for a wide spectrum of possibilities.

Arduino is an open-source electronics platform that consists of an easy-to-use microcontroller board and software IDE. There are different models of Arduino boards, such as the Arduino Uno, Arduino Nano, and Arduino Micro – all have similar functionalities with a few different types of sensors and components. We discussed more in detail the features of the popular Arduino Uno board in this blog post. There are also Arduino development kits available such as this Arduino Starter Kit that are perfect for beginners who want to tinker with electronics. In this article, we’ve listed five Arduino projects with step-by-step instructions that will spark your imagination.

This magical magnetic levitating lamp is a practical household device that can also act as a cool decoration. The project is beginner-friendly and can be built using an Arduino Nano Every and a 3D printer.

A similar concept to the magnetic levitating lamp, this Arduino air bonsai project uses magnetic levitation to keep a small plant afloat. The project uses an Arduino Pro Mini, magnets, and levitation coils. Try it out with any small plant you have at home!

For a beginner, this simple Arduino LCD game is the perfect starter project since it does not require a lot of materials. Simply use an Arduino Uno and an LCD screen to create this one-button video game that anyone can enjoy.

This Arduino Lie Detector is a really fun and interactive project that is beginner-friendly. You only need an Arduino Nano and a few other components to build this device. Learn about how lie detectors work and learn how to use an Arduino to monitor people’s electrodermal activity.

If you are up for an ambitious challenge, this Arduino Wall-E robot replica would be a rewarding DIY project to build. The robot features an Arduino Uno, and it involves painting the 3D-printed parts, wiring the electronics, and programming the software. Check out this guide if you are looking for a longer-term project that involves learning how to build a fully functional robot.

Arduino’s simplicity and popularity have resulted in innumerable variations to the board, as well as open-source libraries available to help people use it. Even though Arduino is intended for beginners, its capability is far from limited if you consider the number of projects you can build using this simple board. Try out these interesting DIY Arduino projects and let us know how it went!

If you want to start experimenting with Arduino but don’t have all the parts yet, sign up for our virtual prototyping platform that lets you interact with virtual Arduinos and components like LEDs and LCD screens.

TFT LCD screens combined with Human Machine Interface (HMI) technology result in exciting project ideas applicable to a wide variety of industries. STONE HMI TFT LCD Arduino project ideas. After all, HMI is a smart technology that uses touch to draw out information from both the human user and the display machine.

And when high-quality display screen modules such as STONE Tech’s TFT LCD products are laden with HMI technology, the result is outstanding machine performance capable of bringing out the best in every customer and business.

Now, this article will feature STONE HMI. Furthermore, we will also present some exciting project development initiatives carried out by the company using its vast range of TFT LCD modules paired with HMI technology, and the TFT LCD Arduino project.

Human Machine Interface (HMI) is an interface or dashboard that lets human users interact with a machine. HMI allows users to monitor and control a machine through the use of different touch technologies.

The interface with which HMI works consists of both hardware and software. These two work together to let users input signals using direct or indirect touch (such as by using a special screen stylus) on the machine display. Once the touch signals have been inputted, the machine recognizes them and sends them to the software to begin interpretation. The machine then responds by showing the desired information to the human user.

Information that a user can get from an HMI machine greatly varies depending on the setting with which the machine is used. Here are some examples of common HMI machines and the data it presents to its daily users:

An HMI in the form of a bank ATM can provide a user with financial information such as his bank account balance, withdrawals, deposits, bills payments, phone credit loading, and similar data.

Medical equipment in hospital settings uses HMI to display pertinent information regarding a patient. For instance, a ventilator machine can display data such as vital signs and a selection of possible breathing patterns for the patient. It can also alert medical practitioners when there is a problem with the patient or the machine through alarms and sounds.

Another HMI machine used in daily life is the car dashboard. An on-board car control panel using an intelligent touch screen can be used to display important car information like speed, gas levels, and time. The screen dashboard can also be used to toggle many functions like turning the AC and beam on or off using a single touch.

HMIs are user-friendly by nature. Graphics and colors can easily be added to the display to communicate with the end-users. Any problems arising from the HMI screen can also be detected easily using color codes, alarms, and sounds. Furthermore, you’ll need only a few touches to fix any issues detected by an HMI device.

HMI greatly improves productivity when used in industrial settings. These interactive screens and machines help automate several tasks. While these tasks could be carried out by a human worker, using an HMI machine gets the job done in less time, translating to more work finished by the day’s end.

Several HMI machines have the innate ability to record data. This is especially useful in adjusting machine settings or troubleshooting any mechanical issues. Automatic data gathering can be programmed into the HMI software, allowing the machine’s screen and hardware to capture data through a series of commands.

Using HMI machines in workplaces such as factories and corporate offices increases worker satisfaction. This is because the HMI technology allows workers to interact easily with the machine, automating some of their work and providing them more efficiency.

What makes HMI a good choice for industrial use is that it is fully flexible and customizable to fit several industrial needs. The TFT LCD screen sizes can be tailor-made to suit the HMI’s application. Furthermore, the software that comes with the machines can be adjusted as well.

Another exciting opportunity for HMIs is their ability to connect with the Internet, much like an Internet of Things (IoT) device. This allows greater opportunities for productivity such as remote controlling and network monitoring.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

STONE TFT LCD modules come with a microcontroller unit that has a cortex-m4 32-bit CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to it.

Each customizable TFT-LCD HMI display module comes with free access to STONE’s dedicated design software. STONE TOOLBox software is an easy-to-use program that allows you to set up graphical user interface functions such as:

STONE TOOLBox features a drag-and-drop mechanism and comes with simple instructions. Hence, even beginning engineers can quickly and seamlessly create an impressive user interface within minutes.

Intricate and intuitive interfaces will require a bit more steps. Nevertheless, using the TOOLBox program allows you to save time on developing HMI projects due to its ease of use.

HMI projects can quickly be done with Stone’s HMI-ready display modules. As previously mentioned, STONEprovides complete modules that include hardware and a free downloadable GUI design software – everything you need to get started on your HMI concept.

With faster project timelines comes greater production savings. Stone’s modules are cost-effective and since they have superior quality, you’re assured of a quick return on investment (ROI) with fewer costs on maintenance and repairs in the long run.

Also, STONE manufactures several TFT LCD touch screen sizes that range from 3.5 to 15.1 inches. Customized options are also available depending on your needs. There are also plenty of options and models for each screen size.

Indeed, STONE produces a plethora of HMI-ready TFT LCD screens. You won’t have a hard time finding the right display module compatible with your microcontroller projects.

Over the years, Stone’s modules have been used to create numerous projects featuring its reputable HMI technology. These project ideas cater to a wide variety of fields and industries.

STONE developed an oxygen monitor for an Italian customer. The monitor uses Stone’s 7-inch TFT LCD screen and was connected to an oxygen tank for medical use.

The end-product featured a touch screen display where fan functions such as speed, dose, and RF are controlled. Moreover, the resulting fan control board can operate at temperatures ranging from -20°C to 70°C, making it a simple yet heavy-duty device.

STONE’s display screen was connected to the Arduino development board through UART. But this required a level conversion achieved by the MAX3232. Meanwhile, the same Arduino board was wired to the MAX30100 module through an IIC interface.

Some modifications to the MAX30100 module were made, specifically to the IIC pull-up resistor. The remainder of the project was finished using Arduino codes to finally create a responsive display for heart rate and blood oxygen monitoring.

This project aims to create a fingerprint door lock that can enter, scan, compare, and delete fingerprints. It utilized an STM32 development board, fingerprint identification module, and Stone’s STVC050WT-01 LCD display.

STONE LCD screen’s role here is to display the fingerprint module’s status. As with all other projects, STONE TOOLBox software was used to generate the user interface flashed on the screen. Meanwhile, Stone’s LCD screen was connected to the development board and fingerprint identification module with MCU through UART-TTL signals.

The idea for this project is a real-time display of pictures collected by the camera on the LCD display screen. The TFT LCD STONE module used for this project is a 7-inch serial display module with 800×480 resolution. A camera module, development board, and some wires are needed to complete the project.

The user interface was designed using STONE TOOLBox and Adobe Photoshop. Then, the hardware parts were wired together; some parts needed welding. After that, a simple program was written following MCU to the command control TFT-LCD module.

This particular project used a STONE serial LCD touch display screen. This functions as the main display for the coffee machine. With the screen installed, you can:

RGB lamps that can be controlled through a touch display – this is the aim of this project idea. STONE’s 7-inch TFT LCD display module in STVC070WT-01 was used to connect and control an RGB lamp.

Last but not least is a basic appliance controller made using STONE’s 7-inch TFT LCD touch screen and an STM32 development board. The touch screen controls lights for various parts of the house. The finished product also collects data about humidity, temperature (indoor and outdoor), and air quality.

This project resulted in a simple electronic scale made by connecting STONE’s 5-inch touch screen to a development board, an ADC conversion module, and a pressure acquisition module. The finished product can:

STONE’s TFT LCD intelligent touch modules can be paired with Arduino technology to automate a variety of processes. This project clearly demonstrates this.

Here, a sensor directly connected to Arduino Uno is monitored by the display screen in real-time. Moreover, two light bulbs connected to Arduino are directly controlled by the display screen as well.

This project is all about making a car display dashboard using a 10.1-inch STONE LCD touch screen. The on-board display interface for a used car contains the following:

We presented an overview of what HMI technology is, how it works, and which applications use it. Also, we covered Stone’s range of HMI-capable TFT LCD display modules. Furthermore, we discussed a lengthy list of exciting project ideas made using Stone’s superior quality HMI displays.

STONE Technologies is truly your best bet for powering your HMI-driven development ideas(projects based on TFT LCD Arduino, STM32, ESP, etc.). Take inspiration from the actual examples we’ve shown you and build your very own HMI display device today.

Arduino Powered Binary Clock: We can design a binary clock by using Arduino. This project needs simple electronic elements like LEDs. The LEDs are arranged in a sequence to display the analog clock.

Arduino Powered Lucky Cat As Physical Webcounter: This project is used to make indicate us when person visits our web page or web site. The lucky cat idol will make us to know this by connecting this to the web server by using Arduino. This project uses the simple hardware components like LED and servo motors.

Arduino Powered Mobile Phone: The cell phone can charge the Arduino by using its Li ion battery. This Arduino powered mobile phone project will be useful for charging applications, by using simple elements like diodes and resisters.

Arduino Room Temperature Monitor: This project will help us to monitor the temperature of a room by using a thermostat and Arduino. We can monitor the temperature by using a http server api and can send text messages about the temperature and room conditions.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey