oled vs lcd touch screen design free sample

If you’re designing a display application or deciding what type of TV to get, you’ll probably have to choose between an OLED or LCD as your display type.

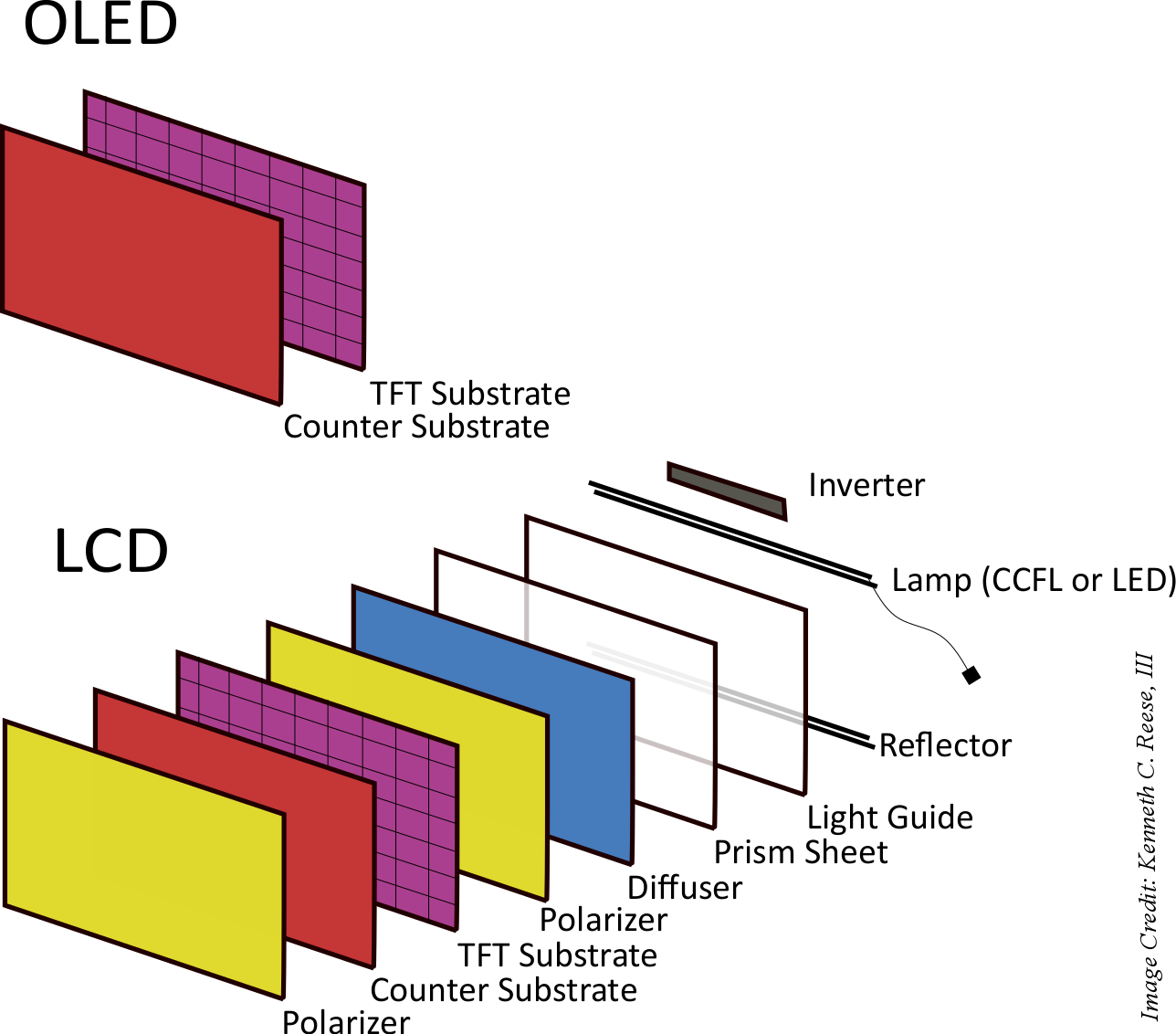

LCDs utilize liquid crystals that produce an image when light is passed through the display. OLED displays generate images by applying electricity to organic materials inside the display.OLED and LCD Main Difference:

graphics and images visible. This is the reason you’re still able to see light coming through on images that are meant to be dark on an LCD monitor, display, or television.

OLEDs by comparison, deliver a drastically higher contrast by dynamically managing their individual pixels. When an image on an OLED display uses the color black, the pixel shuts off completely and renders a much higher contrast than that of LCDs.OLED vs LCD - Who is better at contrast?

Having a high brightness level is important if your display is going to be used in direct sunlight or somewhere with high ambient brightness. The display"s brightness level isn"t as important if it’s going to be used indoors or in a low light setting.OLED vs LCD - Who is better at Brightness?

Have you ever looked at a screen from an angle and noticed that the images became washed out or shadowy? The further away you get from the “front and center” view, the worse the image appears to be. This is an example of viewing angles in action – the wider the viewing angle, the better the images on screen will appear as you view them from different vantage points.

This means the display is much thinner than LCD displays and their pixels are much closer to the surface of the display, giving them an inherently wider viewing angle.

You’ll often notice images becoming distorted or losing their colors when tilting an LCD or when you view it from different angles. However, many LCDs now include technology to compensate for this – specifically In-Plane Switching (IPS).

LCDs with IPS are significantly brighter than standard LCDs and offer viewing angles that are on-par with OLEDs.OLED vs LCD - Who is better at Viewing Angles?

LCDs have been on the market much longer than OLEDs, so there is more data to support their longevity. On average LCDs have proven to perform for around 60,000 hours (2,500) days of operation.

With most LCDs you can expect about 7 years of consistent performance. Some dimming of the backlight has been observed but it is not significant to the quality of the display.

OLEDs are a newer technology in the display market, which makes them harder to fully review. Not only does OLED technology continue to improve at a rapid pace, but there also hasn’t been enough time to thoroughly observe their performance.

You must also consider OLED’s vulnerability to image burn-in. The organic material in these displays can leave a permanent afterimage on the display if a static image is displayed for too long.

So depending on how your OLED is used, this can greatly affect its lifespan. An OLED being used to show static images for long periods of time will not have the same longevity as one displaying dynamic, constantly moving images.OLED vs LCD - Which one last longer?

There is not yet a clear winner when it comes to lifespans between LCD and OLED displays. Each have their advantages depending on their use-cases. It’s a tie!

For a display application requiring the best colors, contrast, and viewing angles – especially for small and lightweight wearable devices – we would suggest an OLED display.

Shopping for a new TV sounds like it could be fun and exciting — the prospect of a gleaming new panel adorning your living room wall is enough to give you goosebumps. But with all the brands to choose from, and different smart capabilities (we can explain what a smart TV is) to weigh, as well as the latest picture tech to consider, it can be daunting. Is this article, we compare OLED vs. LED technology to see which is better for today’s modern TVs. Once you determine which panel type is best for you, make sure you check out our list of the best TVs to get our editor’s recommendations.

If you’re in the market for a TV, you’ve likely heard the hype regarding OLED models. They’re thin, light, and offer incredible contrast and color that’s second to none. OLED is only one letter apart from the more common display type, LED, so what gives? Can they really be that different? In a word: Yes. That extra “O” makes a big difference, but it doesn’t automatically mean an OLED TV will beat an LED TV in every use case. Some TV manufacturers like Samsung use their own technology, called QLED to confuse consumers even more. Make sure that you spend some time looking at our comparison piece: QLED vs. OLED technology before you make your purchase decision.

When OLED TVs first arrived in 2013, they were lauded for their perfect black levels and excellent color, but they took a bit of a hit due to brightness levels that couldn’t compete with LED TVs. There was also a huge price gap between OLED TVs (not to be confused with QLED) and their premium LED counterparts. In fact, legend has it that OLED used to mean “only lawyers, executives, and doctors” could afford them. Thankfully, that’s no longer the case.

OLED TVs are much brighter than they used to be, and the prices have come down, especially with brands like Sony introducing competitive options in 2021. The LED market is due for a bit of a shake-up, too. For now, however, it’s time to take a look at how these two technologies differ and explore the strengths and weaknesses of each.

Non-OLED TVs are made of two main parts: An LCD panel and a backlight. The LCD panel contains the pixels, the little colored dots that make up a TV’s image. On their own, pixels cannot be seen; they require a backlight. When light from the backlight shines through an LCD pixel, you can see its color.

The “LED” in LED TV simply refers to how the backlight is made. In the past, a thicker and less-efficient technology called CCFL (cold-cathode fluorescent light) was used. But these days, virtually every flat-screen TV uses LEDs as its source of backlighting. Thus, when you see the term “LED TV,” it simply refers to an LED-backlit LCD TV.

That said, not all LED TVs are created equal. There can be differences in the number and quality of the LEDs used, which leads to differences in things like brightness and black levels. You may also have seen something called “QLED TV.” This is a type of LED TV that uses quantum dots to achieve better brightness and color. We’ll discuss QLED more below, but here’s a great overview of the differences between QLED and OLED TVs.

The “OLED” in OLED TV stands for “organic light-emitting diode.” OLEDs have the unusual property of being able to produce both light and color from a single diode when they’re fed electricity. Because of this, OLED TVs don’t need a separate backlight. Each pixel you see is a self-contained source of color and light.

Some of the inherent benefits of OLED screens are that they can be extremely thin, flexible, and even rollable. But the biggest benefit when we compare them to LED TVs is that each individual pixel receives its own luminance and power (as opposed to LED TVs, which have persistent pixels that require an external source of light to see). When it’s on, you can see it. When it’s off, it emits no light at all — it’s completely black. We’ll discuss how this affects black levels in a moment.

Currently, LG Display is the only manufacturer of OLED panels for TVs, famed for top-line models like the CX. Sony and LG have an agreement that allows Sony to put LG OLED panels into Sony televisions — like the bright X95OH — but otherwise, you won’t find OLED in many other TV displays sold in the U.S.

The differences in performance between LG’s OLED TVs and Sony’s result from different picture processors at work. Sony and LG have impressive processors that are also unique to each brand, which is why two TVs with the same panel can look drastically different. A good processor can greatly reduce issues like banding and artifacting and produce more accurate colors as well.

Samsung does make OLED smartphone panels, and the company recently announced it would start building new TV panels based on a hybrid of QLED and OLED known as QD-OLED, but it will be a few more years before we see the first TVs that use this technology.

Though they don really similar acronyms, an OLED TV is not the same as a QLED TV. The latter is actually based on LED tech, but it uses a technique that overlays self-emissive quantum dots over the pixels that help produce better brightness, vividness, and color accuracy. QLED is more of an iterative step than a generational leap, and though we’d certainly recommend buying one if OLED is out of reach, expect its eventual deprecation as technologies like quantum dot OLED (QD-OLED) and microLED take hold.

Despite the name, microLED has more in common with OLED than LED. Created and championed by Samsung, this technology creates super-tiny, modular LED panels that combine light emission and color like OLED screens do, minus the “organic” part. For now, the technology is primarily being used for extra-large wall TVs, where colors, blacks, and off-angle viewing are excellent but with more potential for greater brightness and durability than OLED TVs.

For the average consumer, microLED isn’t anything to consider yet. It remains difficult to scale down to less-than-gigantic TVs, and it’s unlikely to hit homes for another couple of years when it will still be exceedingly expensive. Of course, that was once true of OLED, which is why this tech is worth keeping an eye on for a future TV replacement.

Editor’s note: Since OLED TVs are still a premium display, we have compared OLED only to equally-premium LED TVs armed with similar performance potential (except, of course, in the price section).

A display’s ability to produce deep, dark blacks is arguably the most important factor in achieving excellent picture quality. Deeper blacks allow for higher contrast and richer colors (among other things) and thus a more realistic and dazzling image. When it comes to black levels, OLED reigns as the undisputed champion.

LED TVs rely on LED backlights shining behind an LCD panel. Even with advanced dimming technology, which selectively dims LEDs that don’t need to be on at full blast, LED TVs have historically struggled to produce dark blacks and can suffer from an effect called “light bleed,” where lighter sections of the screen create a haze or bloom in adjacent darker areas.

OLED TVs suffer from none of the black-level problems of traditional LED TVs. If an OLED pixel isn’t getting electricity, it doesn’t produce any light and is, therefore, totally black. Sounds like an obvious choice to us.

When it comes to brightness, LED TVs have a considerable advantage. Their backlights can be made from large and powerful LEDs. With the addition of quantum dots, that brightness can be preserved even as the size of the individual LEDs get smaller. OLED TVs can get pretty bright, too, and with such dark black levels, the contrast between the brightest and darkest spots on screen is all the more exaggerated. But cranking OLED pixels to their maximum brightness for extended periods reduces their lifespan, and the pixel takes slightly longer to return to total black.

With those considerations in mind, it’s important to note that all modern TVs — whether OLED, LED, or QLED — produce more than adequate brightness. The consideration then becomes where the TV will be used. In a dark room, an OLED TV is going to perform best, while LED TVs will outshine them (quite literally) in more brightly lit environments.

It should also be noted that there have been big gains recently in OLED brightness, making them perfectly suitable for nearly any situation, save direct sunlight beaming onto the screen. Still, when compared directly, LED TVs have the edge.

OLED used to rule this category, but by improving the purity of the backlight, quantum dots have allowed LED TVs to surge forward in color accuracy, color brightness, and color volume, putting them on par with OLED TVs. Those looking for TVs with Wide Color Gamut or HDR will find both OLED and LED TV models that support these features. OLED’s better contrast ratio is going to give it a slight edge in terms of HDR when viewed in dark rooms, but HDR on a premium LED TV screen has an edge because it can produce well-saturated colors at extreme brightness levels that OLED can’t quite match.

Because OLED pixels combine the light source and the color in a single diode, they can change states incredibly fast. By contrast, LED TVs use LEDs to produce brightness and tiny LCD “shutters” to create color. While the LED’s brightness can be changed in an instant, LCD shutters are by their nature slower to respond to state changes.

Refresh rate is how often the entire image on-screen changes. The faster the rate, the smoother things look, and the easier it is to pick out details in fast-moving content like sports. Most new TVs are capable of refresh rates of 120Hz, which means the entire image is updated 120 times every second. Some go as high as 240Hz.

If refresh rate were simply a matter of Hz, we’d call OLED TV the winner, simply because it can achieve rates of up to 1,000 times higher than LED TVs. But absolute speed isn’t the only consideration. Unlike movies and TV shows, which use a single refresh rate, video games often employ something called variable refresh rates, which simply means that the rate changes during different parts of a game. If a TV can’t match these rate changes, you end up with image tearing — a visible jerkiness that comes from the disparity between the rate the game is using and the rate the TV wants to use.

That’s why gamers, in particular, want TVs that can handle VRR or Variable Refresh Rate. It’s a rare feature on both OLED and LED TVs, but you can expect to see it show up on more models in both types of TVs. Right now, you can find VRR in certain Samsung, LG, and TCL TVs. But neither OLED nor LED TVs have a real advantage when it comes to VRR; some models have the feature, and some don’t. Your gaming system also has to support VRR, though that shouldn’t be much of an issue if you own a new Xbox Series X, PS5, or even a PS4/One X.

Finally, input lag is the gap in time between when you press a button on a game controller and the corresponding action shows up on-screen. Input lag can be a problem when TVs introduce a lot of picture processing that causes a slow-down in the signal they receive. But most modern TVs have a game mode, which eliminates the processing and reduces input lag to barely discernible levels. In the future, all TVs will be able to sense the presence of a video game and switch to this mode automatically, returning to the processed mode when gaming stops.

OLED, again, is the winner here. With LED TVs, the best viewing angle is dead center, and the picture quality diminishes in both color and contrast the further you move to either side. While the severity differs between models, it’s always noticeable. For its LED TVs, LG uses a type of LCD panel known as IPS, which has slightly better off-angle performance than VA-type LCD panels (which Sony uses), but it suffers in the black-level department in contrast to rival VA panels, and it’s no competition for OLED. Samsung’s priciest QLED TVs feature updated panel design and anti-reflective coating, which make off-angle viewing much less of an issue. While OLED still beats these models out in the end, the gap is closing quickly.

That said, OLED TVs can be viewed with no luminance degradation at drastic viewing angles — up to 84 degrees. Compared to most LED TVs, which have been tested to allow for a max viewing angle of 54 degrees at best, OLED has a clear advantage.

OLEDs have come a long way in this category. When the tech was still nascent, OLED screens were often dwarfed by LED/LCD displays. As OLED manufacturing has improved, the number of respectably large OLED displays has increased — now pushing 88 inches — but they’re still dwarfed by the largest LED TVs, which can easily hit 100 inches in size, and with new technologies, well beyond.

LG says you’d have to watch its OLED TVs five hours a day for 54 years before they’d fall to 50% brightness. Whether that’s true remains to be seen, as OLED TVs have only been out in the wild since 2013. For that reason and that reason only, we’ll award this category to LED TVs. It pays to have a proven track record.

Can one kind of TV be healthier for you than another? If you believe that we need to be careful about our exposure to blue light, especially toward the evening, then the answer could be yes. Both OLED and LED TVs produce blue light, but OLED TVs produce considerably less of it. LG claims its OLED panels only generate 34% blue light versus LED TV’s 64%. That stat has been independently verified, and LG’s OLED panels have been given an Eye Comfort Display certification by TUV Rheinland, a standards organization based out of Germany.

Will it make a difference to your overall health? We think the jury is still out, but if blue light is a concern, you should take a serious look at OLED TVs.

The effect we’ve come to know as burn-in stems from the days of the boxy CRT TV when the prolonged display of a static image would cause an image to appear to “burn” into the screen. What was actually happening was the phosphors that coated the back of the TV screen would glow for extended periods of time without any rest, causing them to wear out and create the appearance of a burned-in image. We think this should be called “burn out,” but we’ll set that one aside.

The same issue is at play with plasma and OLED TVs because the compounds that light up can degrade over time. If you burn a pixel long and hard enough, it will dim prematurely ahead of the rest of the pixels, creating a dark impression. In reality, this is not very likely to cause a problem for most people — you’d have to abuse the TV intentionally to get it to happen. Even the “bug” (logographic) that certain channels use disappears often enough or is made clear to avoid causing burn-in issues. You’d have to watch ESPN all day, every day for a long, long time at the brightest possible setting to cause a problem, and even then, it still isn’t very likely.

That said, the potential is there, and it should be noted. (This is also a contributing factor in the dearth of OLED computer monitors on the market, as computer screens are far more likely to display a static image for hours on end.) Since LED TVs aren’t susceptible to burn-in, they win this fight by a technicality.

OLED panels require no backlight, and each individual pixel is extremely energy-efficient. LED TVs need a backlight to produce brightness. Since LEDs are less energy-efficient than OLEDs, and their light must pass through the LCD shutters before it reaches your eyes, these panels must consume more power for the same level of brightness.

OLED TVs are premium TVs and almost always likely to be more expensive than an LED version of the same size. However, we have seen prices starting to drop down to manageable levels recently, especially if there are any discounts running. MSRPs can go as low as $1,300 to $1,500, but you probably won’t find many lower than that.

Conversely, LED TVs can range in price from a few hundred dollars — even for a quality big-screen model — to several thousand dollars, making them overall more accessible than OLEDs. While prices of the highest-quality LED TVs hover at nearly the same range as the price of OLEDs, when judged by price and price alone, LED TVs can still be acquired for a pittance in comparison.

In terms of picture quality, OLED TVs still beat LED TVs, even though the latter technology has seen many improvements of late. OLED is also lighter and thinner, uses less energy, offers the best viewing angle by far, and, though still a little more expensive, has come down in price considerably. OLED is the superior TV technology today. If this article were about value alone, LED TV would still win, but OLED has come a long way in a short time and deserves the crown for its achievements. Regardless of which technology you ultimately decide on, that’s not the only factor that you need to consider, so be sure to check our TV buying guide to make sure you’re buying the right TV to meet your needs.

When the touch technology is deposited on the cover glass using the sensor on lens approach, you end up with a separate touch module that can be sold to the LCD display assemblers. This would mean more revenues for the touch technology manufacturers who would supply these modules.

On the other hand, the on-cell alternative means that the LCD panel manufacturers can add these touch layers onto their own panels. The display assemblers would then just have to purchase a simple cover glass to complete the display. The touch module makers would be cut out of the process.

For now, it appears that the sensor on lens approach has an advantage over on-cell solutions. The on-cell approach means that LCD makers would have to make two separate models of each panel: one with touch and one without. This could add cost to an industry that is already running on razor-thin margins. Also, on-cell touch is limited to the size of the LCD panel; sensor on glass modules can be larger than the LCD panel, providing room for the dedicated touch points that are part of many smartphone designs.

In case you"ve been wondering where OLED displays fit into all this: An OLED display stack is somewhat different from an LCD stack. It only requires one substrate (glass) layer as opposed to LCD"s two, and the OLED material layer is much thinner than the LCD layer. As a result, the finished display can be half as thick as an LCD panel, saving weight and thickness -- which is important in a smartphone design.

(A number of smartphones today use a form of active-matrix OLED display called Super AMOLED; these include several Samsung devices such as the and the Motorola Droid Razr M).

As a practical matter, glass is still used as the encapsulating layer, so OLEDs generally have two layers of glass. In addition, not all OLEDs are RGB -- some use white emitters instead to try to reduce the differential aging problem, and add a color filter layer to the stack.

In spite of all this, as far as touch screen technologies are concerned, OLEDs are more like LCDs than they are different: Both have active matrix TFT backplanes, and both tend to have a cover glass layer for protection. So essentially the same stack configurations are available to OLED panels.

No matter which solution wins out, it is clear that pro-cap technology is the best method for touch screens on mobile devices -- at least for the foreseeable future. Still, there are some changes already showing up in touch screen technology.

For example, some panel makers are creating "in-cell" touch panels, where one of the conductive layers actually shares the same layer as the thin film transistors (TFTs) used to switch the display"s sub-pixels on and off. (These transistors are fabricated directly on the semiconductor backplane of the display.) This approach not only reduces the electromagnetic noise in the system, but also uses a single integrated controller for both the display and the touch system. This reduces part counts and can make the display component thinner, lighter, more energy efficient and more reliable.

This approach only makes sense for very high volume products, such as a smartphone from a major vendor that is expected to sell millions of units, because the panel will have to be made specifically for that unique model. The first products using "in-cell" touch technology have already appeared on the market, such as the new , but it looks as though it will take years before this approach will become a widespread solution.Additional resources

Some device manufacturers are also adding stylus support to their products. The new higher-resolution displays make it useful for some users to have access to a pointing or writing device that has a finer tip than a finger. Some devices rely on an "active" stylus that can be sensed by the pro-cap system, such as the Samsung Galaxy Note. Others, such as the , are choosing single-point infrared optical sensing that can detect the position of any pointed object on the screen.

Meanwhile, system designers are developing new ways to interact with mobile devices via touch, such as and . Even as other modes of interaction -- such as speech recognition for voice input -- become more sophisticated, touch is likely to remain the primary way we control our devices.

Enhance your designs with a switch that runs video or image sequences. Ideal for control rooms with real-time data, audio and broadcast panels, mission-critical applications, and medical applications.

Programmable display graphics for alphanumeric characters and animated sequences. 64 colors of backlighting can be controlled dynamically. Pushbutton switch with LCD, RGB LED backlighting.

64 colors of backlighting can be controlled dynamically. Pushbutton switch with LCD, RGB LED backlighting. Low energy. Dust-tight construction. Viewing area: 17.0mm x 13.0mm (horizontal x vertical).

Broad and even light distribution. Consistent backlighting. Low energy consumption. Programmable LCD with a variety of LED backlighting colors. Rubber dome.

Low-energy-consumption programmable LCD with a variety of LED backlighting colors. Rubber dome. High reliability and long life of one million actuations minimum.

Part Number: IS-S04G1LC-S -- Human-Machine Interface with four programmable 64x32 LCD SmartDisplay pushbuttons that monitor and control four 7V-12V fans or lights over eight levels of speed/brightness

LCD History | LCD Introduction | Twisted Nematic LCD | Supertwisted Nematic LCD | Positive & Negative Mode | Temperature Range | LCD Pixel Terms & Resolution Guide | LCD & TP Glossary

LCD Diagonal Dimension Calculator | How to Improve LCD Viewing Angle | How to Increase LCD Contrast | How to Improve LCD Response Time | Temperature Compensation for LCD Contrast & Voltage | V10 V90, Von Voff, Vth Vsat, Vsel Vnsel | Vertical alignment display (VTN) | Bistable LCD | Character LCD | Embedded LCD | Demo Board

TFT LCD Basic Knowledge | TFT Wide Viewing Angle Technologies | Sunlight Readable TFT LCD | TFT vs. IPS Display | LCD Controller Datasheet | TFT Controller Sample Codes | Electro-Optical Characteristics

With how fast technology changes, constantly learning and staying open-minded helps us stay on top of our game especially when we’re striving to be the best in our field. Brush up on your LCD knowledge with us!

LCD History | LCD Introduction | Twisted Nematic LCD | Supertwisted Nematic LCD | Positive & Negative Mode | Temperature Range | LCD Pixel Terms & Resolution Guide | LCD & TP Glossary

LCD Diagonal Dimension Calculator | How to Improve LCD Viewing Angle | How to Increase LCD Contrast | How to Improve LCD Response Time | Temperature Compensation for LCD Contrast & Voltage | V10 V90, Von Voff, Vth Vsat, Vsel Vnsel | Vertical alignment display (VTN) | Bistable LCD | Character LCD | Embedded LCD | Demo Board

TFT LCD Basic Knowledge | TFT Wide Viewing Angle Technologies | Sunlight Readable TFT LCD | TFT vs. IPS Display | LCD Controller Datasheet | TFT Controller Sample Codes | Electro-Optical Characteristics

With how fast technology changes, constantly learning and staying open-minded helps us stay on top of our game especially when we’re striving to be the best in our field. Brush up on your LCD knowledge with us!

Recently, ‘Liquid crystal display (LCD) vs. organic light-emitting diode (OLED) display: who wins?’ has become a topic of heated debate. In this review, we perform a systematic and comparative study of these two flat panel display technologies. First, we review recent advances in LCDs and OLEDs, including material development, device configuration and system integration. Next we analyze and compare their performances by six key display metrics: response time, contrast ratio, color gamut, lifetime, power efficiency, and panel flexibility. In this section, we focus on two key parameters: motion picture response time (MPRT) and ambient contrast ratio (ACR), which dramatically affect image quality in practical application scenarios. MPRT determines the image blur of a moving picture, and ACR governs the perceived image contrast under ambient lighting conditions. It is intriguing that LCD can achieve comparable or even slightly better MPRT and ACR than OLED, although its response time and contrast ratio are generally perceived to be much inferior to those of OLED. Finally, three future trends are highlighted, including high dynamic range, virtual reality/augmented reality and smart displays with versatile functions.

In this review paper, we present recent progress on LCDs and OLEDs regarding materials, device structures to final panel performances. First, in Section II, we briefly describe the device configurations and operation principles of these two technologies. Then, in Section III, we choose six key metrics: response time, contrast ratio, color gamut, lifetime, power efficiency, and panel flexibility, to evaluate LCDs and OLEDs. Their future perspectives are discussed in Section IV, including high dynamic range (HDR), virtual reality/augmented reality (VR/AR) and smart displays with versatile functions.

Liquid crystal (LC) materials do not emit light; therefore, a backlight unit is usually needed (except in reflective displays) to illuminate the display panel. Figure 1 depicts an edge-lit TFT-LCD. The incident LED passes through the light-guide plate and multiple films and is then modulated by the LC layer sandwiched between two crossed polarizers

VA was first invented in 1971 by Schiekel and Fahrenschonε<0 is used and the electric field is in the longitudinal direction. In the initial state (V=0), the LC directors are aligned in the vertical direction (Figure 2b). As the voltage exceeds a threshold, the LC directors are gradually tilted so that the incident light transmits through the crossed polarizers. Film-compensated MVA mode has a high on-axis contrast ratio (CR; >5000:1), wide viewing angle and fairly fast response time (5 ms). Thus it is widely used in large TVs

IPS mode was first proposed in 1973 by SorefFigure 2c). As the voltage increases, the strong in-plane fringing electric fields between the interdigital electrodes reorient the LC directors. Such a unique mechanism makes IPS a favorable candidate for touch panels because no ripple effect occurs upon touching the panel. However, the peak transmittance of IPS is relatively low (~75%) because the LC molecules above the electrodes cannot be effectively reoriented. This low transmittance region is called a dead zone

As summarized in Table 1, these four LCD modes have their own unique features and are used for different applications. For example, TN has the advantages of low cost and high optical efficiency; thus, it is mostly used in wristwatches, signage and laptop computers, for which a wide view is not absolutely necessary. MVA mode is particularly attractive for large TVs because a fast response time, high CR and wide viewing angle are required to display motion pictures. On the other hand, IPS and FFS modes are used in mobile displays, where low power consumption for a long battery life and pressure resistance for touch screens are critical.

Abbreviations: FFS, fringe-field switching; IPS, in-plane switching; LCD, liquid crystal display; MVA, multi-domain vertical alignment; TN, twisted nematic; TV, television.

The basic structure of an OLED display, proposed by Tang and VanSlykeFigure 3a. Electrons and holes are injected from electrodes to organic layers for recombination and light emission; hence, an OLED display is an emissive display, unlike an LCD. Currently, multi-layer structures in OLEDs with different functional materials are commonly used, as shown in Figure 3b. The emitting layer (EML), which is used for light emission, consists of dopant and host materials with high quantum efficiency and high carrier mobility. Hole-transporting layer (HTL) and electron-transporting layer (ETL) between the EML and electrodes bring carriers into the EML for recombination. Hole- and electron-injection layers (HIL and EIL) are inserted between the electrodes and the HTL and ETL interface to facilitate carrier injection from the conductors to the organic layers. When applying voltage to the OLED, electrons and holes supplied from the cathode and anode, respectively, transport to the EML for recombination to give light.

Schematic diagram of an OLED. (a) Basic structure proposed by Tang and VanSlyke in 1987. (b) Multi-layer structure employed in current OLED products. EIL, electron-injection layer; ETL, electron-transporting layer; EML, emitting layer; HTL, hole-transporting layer; HIL, hole-injection layer.

Generally, each layer in an OLED is quite thin, and the total thickness of the whole device is <1 μm (substrates are not included). Thus the OLED is a perfect candidate for flexible displays. For an intrinsic organic material, its carrier mobility (<0.1 cm2 Vs−1) and free carrier concentration (1010 cm−3) are fairly low, limiting the device efficiency. Thus doping technology is commonly used

The EML is the core of an OLED. Based on the emitters inside, OLED devices can be categorized into four types: fluorescence, triplet-triplet fluorescence (TTF), phosphorescence, and thermally activated delayed fluorescence (TADF)

First, upon electrical excitation, 25% singlets and 75% triplets are formed with higher and lower energy, respectively. In a fluorescent OLED, only singlets decay radiatively through fluorescence with an ~ns exciton lifetime, which sets the theoretical limit of the internal quantum efficiency (IQE) to 25%, as shown in Figure 4a.

Illustration of the emission mechanisms of OLEDs: (a) fluorescence, (b) TTF, (c) phosphorescence, and (d) TADF. ISC, intersystem crossing; RISC, reverse intersystem crossing; TF, triplet fusion.

With the introduction of heavy metal atoms (such as Ir and Pt) into the emitters, strong spin-orbital coupling greatly reduces the triplet lifetime to ~μs, which results in efficient phosphorescent emission. The singlet exciton experiences intersystem crossing to the triplet state for light emission, achieving a 100% IQE, as shown in Figure 4c. Owing to the long radiative lifetime (~μs) in a phosphorescent OLED, the triplet may interact with another triplet and polaron (triplet-triplet annihilation and triplet-polaron annihilation, respectively), which results in efficiency roll-off under high current driving

The energy between the singlet and triplet can be reduced (<0.1 eV) by minimizing the exchange energyFigure 4d. Achieving a 100% IQE is possible for TADF emission without a heavy atom in the organic material, which reduces the material cost and is more flexible for organic molecular design.

In practical applications, red and green phosphorescent emitters are the mainstream for active matrix (AM) OLEDs due to their high IQE. While, for blue emitters, TTF is mostly used because of its longer operation lifetime

It is worth mentioning that, although IQE could be as high as 100% in theory, due to the refractive index difference the emission generated inside the OLED experiences total internal reflection, which reduces the extraction efficiency. Taking a bottom emission OLED with a glass substrate (n~1.5) and an indium-tin-oxide anode (n~1.8) as an example, the final extraction efficiency is only ~20%

To evaluate the performance of display devices, several metrics are commonly used, such as response time, CR, color gamut, panel flexibility, viewing angle, resolution density, peak brightness, lifetime, among others. Here we compare LCD and OLED devices based on these metrics one by one.

From Figure 5, we can gain several important physical insights: (1) Increasing the frame rate is a simple approach to suppress image motion blur, but its improvement gradually saturates. For example, if the LC response time is 10 ms, then increasing the frame rate from 30 to 60 fps would significantly reduce the MPRT. However, as the TFT frame rate continues to increase to 120 and 240 fps, then the improvement gradually saturates. (2) At a given frame rate, say 120 fps, as the LC response time decreases, the MPRT decreases almost linearly and then saturates. This means that the MPRT is mainly determined by the TFT frame rate once the LC response time is fast enough, i.e., τ≪Tf. Under such conditions, Equation (1) is reduced to MPRT≈0.8Tf. (3) When the LC response is <2 ms, its MPRT is comparable to that of an OLED at the same frame rate, e.g., 120 fps. Here we assume the OLED’s response time is 0.

The last finding is somehow counter to the intuition that a LCD should have a more severe motion picture image blur, as its response time is approximately 1000 × slower than that of an OLED (ms vs. μs). To validate this prediction, Chen et al.

If we want to further suppress image blur to an unnoticeable level (MPRT<2 ms), decreasing the duty ratio (for LCDs, this is the on-time ratio of the backlight, called scanning backlight or blinking backlight) is mostly adopted

High CR is a critical requirement for achieving supreme image quality. OLEDs are emissive, so, in theory, their CR could approach infinity to one. However, this is true only under dark ambient conditions. In most cases, ambient light is inevitable. Therefore, for practical applications, a more meaningful parameter, called the ACR, should be considered

To investigate the ACR, we have to clarify the reflectance first. A large TV is often operated by remote control, so touchscreen functionality is not required. As a result, an anti-reflection coating is commonly adopted. Let us assume that the reflectance is 1.2% for both LCD and OLED TVs. For the peak brightness and CR, different TV makers have their own specifications. Here, without losing generality, let us use the following brands as examples for comparison: LCD peak brightness=1200 nits, LCD CR=5000:1 (Sony 75″ X940E LCD TV); OLED peak brightness=600 nits, and OLED CR=infinity (Sony 77″ A1E OLED TV). The obtained ACR for both LCD and OLED TVs is plotted in Figure 7a. As expected, OLEDs have a much higher ACR in the low illuminance region (dark room) but drop sharply as ambient light gets brighter. At 63 lux, OLEDs have the same ACR as LCDs. Beyond 63 lux, LCDs take over. In many countries, 60 lux is the typical lighting condition in a family living room. This implies that LCDs have a higher ACR when the ambient light is brighter than 60 lux, such as in office lighting (320–500 lux) and a living room with the window shades or curtain open. Please note that, in our simulation, we used the real peak brightness of LCDs (1200 nits) and OLEDs (600 nits). In most cases, the displayed contents could vary from black to white. If we consider a typical 50% average picture level (i.e., 600 nits for LCDs vs. 300 nits for OLEDs), then the crossover point drops to 31 lux (not shown here), and LCDs are even more favorable. This is because the on-state brightness plays an important role to the ACR, as Equation (2) shows.

Calculated ACR as a function of different ambient light conditions for LCD and OLED TVs. Here we assume that the LCD peak brightness is 1200 nits and OLED peak brightness is 600 nits, with a surface reflectance of 1.2% for both the LCD and OLED. (a) LCD CR: 5000:1, OLED CR: infinity; (b) LCD CR: 20 000:1, OLED CR: infinity.

Recently, an LCD panel with an in-cell polarizer was proposed to decouple the depolarization effect of the LC layer and color filtersFigure 7b. Now, the crossover point takes place at 16 lux, which continues to favor LCDs.

For mobile displays, such as smartphones, touch functionality is required. Thus the outer surface is often subject to fingerprints, grease and other contaminants. Therefore, only a simple grade AR coating is used, and the total surface reflectance amounts to ~4.4%. Let us use the FFS LCD as an example for comparison with an OLED. The following parameters are used in our simulations: the LCD peak brightness is 600 nits and CR is 2000:1, while the OLED peak brightness is 500 nits and CR is infinity. Figure 8a depicts the calculated results, where the intersection occurs at 107 lux, which corresponds to a very dark overcast day. If the newly proposed structure with an in-cell polarizer is used, the FFS LCD could attain a 3000:1 CRFigure 8b), corresponding to an office building hallway or restroom lighting. For reference, a typical office light is in the range of 320–500 luxFigure 8 depicts, OLEDs have a superior ACR under dark ambient conditions, but this advantage gradually diminishes as the ambient light increases. This was indeed experimentally confirmed by LG Display

Calculated ACR as a function of different ambient light conditions for LCD and OLED smartphones. Reflectance is assumed to be 4.4% for both LCD and OLED. (a) LCD CR: 2000:1, OLED CR: infinity; (b) LCD CR: 3000:1, OLED CR: infinity. (LCD peak brightness: 600 nits; OLED peak brightness: 500 nits).

For conventional LCDs employing a WLED backlight, the yellow spectrum generated by YAG (yttrium aluminum garnet) phosphor is too broad to become highly saturated RGB primary colors, as shown in Figure 9aTable 2. The first choice is the RG-phosphor-converted WLEDFigure 9b, the red and green emission spectra are well separated; still, the green spectrum (generated by β-sialon:Eu2+ phosphor) is fairly broad and red spectrum (generated by K2SiF6:Mn4+ (potassium silicofluoride, KSF) phosphor) is not deep enough, leading to 70%–80% Rec. 2020, depending on the color filters used.

Recently, a new LED technology, called the Vivid Color LED, was demonstratedFigure 9d), which leads to an unprecedented color gamut (~98% Rec. 2020) together with specially designed color filters. Such a color gamut is comparable to that of laser-lit displays but without laser speckles. Moreover, the Vivid Color LED is heavy-metal free and shows good thermal stability. If the efficiency and cost can be further improved, it would be a perfect candidate for an LCD backlight.

A color filter array is another effective approach to enhance the color gamut of an OLED. For example, in 2017, AUO demonstrated a 5-inch top-emission OLED panel with 95% Rec. 2020. In this design, so-called symmetric panel stacking with a color filter is employed to generate purer RGB primary colors

As mentioned earlier, TFT LCDs are a fairly mature technology. They can be operated for >10 years without noticeable performance degradation. However, OLEDs are more sensitive to moisture and oxygen than LCDs. Thus their lifetime, especially for blue OLEDs, is still an issue. For mobile displays, this is not a critical issue because the expected usage of a smartphone is approximately 2–3 years. However, for large TVs, a lifetime of >30 000 h (>10 years) has become the normal expectation for consumers.

Here we focus on two types of lifetime: storage and operational. To enable a 10-year storage lifetime, according to the analysis−6 g (m2-day)−1 and 1 × 10−5 cm3 (m2-day)−1, respectively. To achieve these values, organic and/or inorganic thin films have been developed to effectively protect the OLED and lengthen its storage lifetime. Meanwhile, it is compatible to flexible substrates and favors a thinner display profile

The next type of lifetime is operational lifetime. Owing to material degradation, OLED luminance will decrease and voltage will increase after long-term drivingT50) can be as long as >80 000 h with a 1000 cd m−2 luminanceT50, half lifetime) with an initial luminance of 1000 nits. However, this is still ~20 × shorter than that of red and green phosphorescent OLEDs

To further enhance the lifetime of the blue OLED, the NTU group has developed new ETL and TTF-EML materials together with an optimized layer structure and double EML structureFigure 10a shows the luminance decay curves of such a blue OLED under different initial luminance values (5000, 10 000, and 15 000 nits). From Figure 10b, the estimated T50 at 1000 nits of this blue OLED is ~56 000 h (~6–7 years)

Power consumption is equally important as other metrics. For LCDs, power consumption consists of two parts: the backlight and driving electronics. The ratio between these two depends on the display size and resolution density. For a 55″ 4K LCD TV, the backlight occupies approximately 90% of the total power consumption. To make full use of the backlight, a dual brightness enhancement film is commonly embedded to recycle mismatched polarized light

The power efficiency of an OLED is generally limited by the extraction efficiency (ηext~20%). To improve the power efficiency, multiple approaches can be used, such as a microlens array, a corrugated structure with a high refractive index substrateFigure 11 shows the power efficiencies of white, green, red and blue phosphorescent as well as blue fluorescent/TTF OLEDs over time. For OLEDs with fluorescent emitters in the 1980s and 1990s, the power efficiency was limited by the IQE, typically <10 lm W−1(Refs. 41, 114, 115, 116, 117, 118). With the incorporation of phosphorescent emitters in the ~2000 s, the power efficiency was significantly improved owing to the materials and device engineering−1 was demonstrated in 2011 (Ref. 127), which showed a >100 × improvement compared with that of the basic two-layer device proposed in 1987 (1.5 lm W−1 in Ref. 41). A white OLED with a power efficiency >100 lm W−1 was also demonstrated, which was comparable to the power efficiency of a LCD backlight. For red and blue OLEDs, their power efficiencies are generally lower than that of the green OLED due to their lower photopic sensitivity function, and there is a tradeoff between color saturation and power efficiency. Note, we separated the performances of blue phosphorescent and fluorescent/TTF OLEDs. For the blue phosphorescent OLEDs, although the power efficiency can be as high as ~80 lm W−1, the operation lifetime is short and color is sky-blue. For display applications, the blue TTF OLED is the favored choice, with an acceptable lifetime and color but a much lower power efficiency (16 lm W−1) than its phosphorescent counterpartFigure 11 shows.

Power efficiency of white, red, green and phosphorescent blue and fluorescent/TTF blue OLEDs over time. Data are compiled from Refs. 41, 45, 114, 115, 116, 117, 118, 119, 120, 121, 122, 123, 124, 125, 126, 127, 128, 129, 130, 131, 132, 133.

To compare the power consumption of LCDs and OLEDs with the same resolution density, the displayed contents should be considered as well. In general, OLEDs are more efficient than LCDs for displaying dark images because black pixels consume little power for an emissive display, while LCDs are more efficient than OLEDs at displaying bright images. Currently, a ~65% average picture level is the intersection point between RGB OLEDs and LCDs

In addition to the aforementioned six display metrics, other parameters are equally important. For example, high-resolution density has become a standard for all high-end display devices. Currently, LCD is taking the lead in consumer electronic products. Eight-hundred ppi or even >1000 ppi LCDs have already been demonstrated and commercialized, such as in the Sony 5.5″ 4k Smartphone Xperia Z5 Premium. The resolution of RGB OLEDs is limited by the physical dimension of the fine-pitch shadow mask. To compete with LCDs, most OLED displays use the PenTile RGB subpixel matrix scheme

The viewing angle is another important property that defines the viewing experience at large oblique angles, which is quite critical for multi-viewer applications. OLEDs are self-emissive and have an angular distribution that is much broader than that of LCDs. For instance, at a 30° viewing angle, the OLED brightness only decreases by 30%, whereas the LCD brightness decrease exceeds 50%. To widen an LCD’s viewing angle, three options can be used. (1) Remove the brightness-enhancement film in the backlight system. The tradeoff is decreased on-axis brightness

In addition to brightness, color, grayscale and the CR also vary with the viewing angle, known as color shift and gamma shift. In these aspects, LCDs and OLEDs have different mechanisms. For LCDs, they are induced by the anisotropic property of the LC material, which could be compensated for with uniaxial or biaxial films

Cost is another key factor for consumers. LCDs have been the topic of extensive investigation and investment, whereas OLED technology is emerging and its fabrication yield and capability are still far behind LCDs. As a result, the price of OLEDs is about twice as high as that of LCDs, especially for large displays. As more investment is made in OLEDs and more advanced fabrication technology is developed, such as ink-jet printing

Currently, both LCDs and OLEDs are commercialized and compete with each other in almost every display segment. They are basically two different technologies (non-emissive vs. emissive), but as a display, they share quite similar perspectives in the near future. Here we will focus on three aspects: HDR, VR/AR and smart displays with versatile functions.

Both LCD and OLED are HDR-compatible. Currently, the best HDR LCDs can produce brighter highlights than OLEDs, but OLEDs have better overall CRs thanks to their superior black level. To enhance an LCD’s CR, a local dimming backlight is commonly used, but its dimming accuracy is limited by the number of LED segmentations

The peak brightness of LCDs could be boosted to 2000 nits or even higher by simply using a high-power backlight. OLEDs are self-emissive, so their peak brightness would trade with lifetime. As a result, more advanced OLED materials and novel structural designs are highly desirable in the future. Another reason to boost peak brightness is to increase sunlight readability. Especially for some outdoor applications, such as public displays, peak brightness is critical to ensure good readability under strong ambient light. As discussed in the section of ‘CR and ACR’, high brightness leads to a high ACR, except that the power consumption will increase.

Immersive VR/AR are two emerging wearable display technologies with great potential in entertainment, education, training, design, advertisement and medical diagnostics. However, new opportunities arise along with new challenges. VR head-mounted displays require a resolution density as high as >2000 ppi to eliminate the so-called screen door effect and generate more realistic immersive experiences.

An LCD’s resolution density is determined by the TFTs and color filter arrays. In SID 2017, Samsung demonstrated an LCD panel with a resolution of 2250 ppi for VR applications. The pitches of the sub-pixel and pixel are 3.76 and 11.28 μm, respectively. Meanwhile, field sequential color provides another promising option to triple the LCD resolution density

Currently, displays are no longer limited to traditional usages, such as TVs, pads or smartphones. Instead, they have become more diversified and are used in smart windows, smart mirrors, smart fridges, smart vending machines and so on. They have entered all aspects of our daily lives.

As these new applications are emerging, LCDs and OLEDs have new opportunities as well as new challenges. Let us take a vehicle display as an example: high brightness, good sunlight readability, and a wide working temperature range are required

We have briefly reviewed the recent progress of LCD and OLED technologies. Each technology has its own pros and cons. For example, LCDs are leading in lifetime, cost, resolution density and peak brightness; are comparable to OLEDs in ACR, viewing angle, power consumption and color gamut (with QD-based backlights); and are inferior to OLED in black state, panel flexibility and response time. Two concepts are elucidated in detail: the motion picture response time and ACR. It has been demonstrated that LCDs can achieve comparable image motion blur to OLEDs, although their response time is 1000 × slower than that of OLEDs (ms vs. μs). In terms of the ACR, our study shows that LCDs have a comparable or even better ACR than OLEDs if the ambient illuminance is >50 lux, even if its static CR is only 5000:1. The main reason is the higher brightness of LCDs. New trends for LCDs and OLEDs are also highlighted, including ultra-high peak brightness for HDR, ultra-high-resolution density for VR, ultra-low power consumption for AR and ultra-versatile functionality for vehicle display, transparent display and mirror display applications. The competition between LCDs and OLEDs is still ongoing. We believe these two TFT-based display technologies will coexist for a long time.

Chen J, Hardev V, Hartlove J, Hofler J, Lee E. A high-efficiency wide-color-gamut solid-state backlight system for LCDs using quantum dot enhancement film. SID Symp Dig Tech Pap

Takeda A, Kataoka S, Sasaki T, Chida H, Tsuda H et al. A super-high image quality multi-domain vertical alignment LCD by new rubbing-less technology. SID Symp Dig Tech Pap

Kim SS, You BH, Cho JH, Kim DG, Berkeley BH et al. An 82-in. ultra-definition 120-Hz LCD TV using new driving scheme and advanced Super PVA technology. J Soc Inf Display

Hsiao K, Tang GF, Yu G, Zhang ZW, Xu XJ et al. Development and analysis of technical challenges in the world"s largest (110-in.) curved LCD. SID Symp Dig Tech Pap

Li WJ, Yao L, Liu HC, Wang ZM, Zhang ST et al. Highly efficient deep-blue OLED with an extraordinarily narrow FHWM of 35 nm and a y coordinate<0.05 based on a fully twisting donor-acceptor molecule. J Mater Chem C

Hosoumi S, Yamaguchi T, Inoue H, Nomura S, Yamaoka R et al. Ultra-wide color gamut OLED display?using a deep-red phosphorescent device with high efficiency, long life, thermal stability, and absolute BT.2020 red chromaticity. SID Symp Dig Tech Pap

Lee MT, Wang CL, Chan CS, Fu CC, Shih CY et al. Achieving a foldable and durable OLED display with BT.2020 color space using innovative color filter structure. J Soc Inf Display

Lin BY, Lee MZ, Tseng PC, Lee JH, Chiu TL et al. 16.1-times elongation of operation lifetime in a blue TTA-OLED by using new ETL and EML materials. SID Symp Dig Tech Pap

Lee C, Kim JJ. Enhanced light out-coupling of OLEDs with low haze by inserting randomly dispersed nanopillar arrays formed by lateral phase separation of polymer blends. Small

Shin H, Lee JH, Moon CK, Huh JS, Sim B et al. Sky-blue phosphorescent OLEDs with 34.1% external quantum efficiency using a low refractive index electron transporting layer. Adv Mater

Greinert N, Schoenefeld C, Suess P, Klasen-Memmer M, Bremer M et al. Opening the door to new LCD applications via polymer walls. SID Symp Dig Tech Pap

Käläntär K. A directional backlight with narrow angular luminance distribution for widening the viewing angle for an LCD with a front-surface light-scattering film. J Soc Inf Display

Kim HJ, Shin MH, Lee JY, Kim JH, Kim YJ. Realization of 95% of the Rec. 2020 color gamut in a highly efficient LCD using a patterned quantum dot film. Opt Express

Chen HF, Sung J, Ha T, Park Y, Hong CW. Backlight Local Dimming Algorithm for High Contrast LCD-TV. New Delhi, India: Proceedings of ASID; 2006, pp168–pp171.

Yoo O, Nam S, Choi J, Yoo S, Kim KJ et al. Contrast enhancement based on advanced local dimming system for high dynamic range LCDs. SID Symp Dig Tech Pap

Chen CH, Lin FC, Hsu YT, Huang YP, Shieh HP. A field sequential color LCD based on color fields arrangement for color breakup and flicker reduction. J Display Technol

Lin FC, Huang YP, Wei CM, Shieh HPD. Color-breakup suppression and low-power consumption by using the Stencil-FSC method in field-sequential LCDs. J Soc Inf Display

Ghosh A, Donoghue EP, Khayrullin I, Ali T, Wacyk I et al. Directly patterened 2645 Ppi full color OLED microdisplay for head mounted wearables. SID Symp Dig Tech Pap

Kimura K, Onoyama Y, Tanaka T, Toyomura N, Kitagawa H. New pixel driving circuit using self-discharging compensation method for high- resolution OLED micro displays on a silicon backplane. J Soc Inf Display

Reinert-Weiss CJ, Baur H, Al Nusayer SA, Duhme D, Frühauf N. Development of active matrix LCD for use in high-resolution adaptive headlights. J Soc Inf Display

Okuyama K, Nakahara T, Numata Y, Nakamura T, Mizuno M et al. Highly transparent LCD using new scattering-type liquid crystal with field sequential color edge light. SID Symp Dig Tech Pap

The AMOLED display requires ELVDD, ELVSS, and AVDD voltages. ELVDD and ELVSS are the positive and negative driving voltage to the electroluminescent (EL). ELVDD is implemented using a boost converter, whereas ELVSS is an inverting buck boost converter. AVDD is the output to the DDI (display driver IC), which is implemented in boost converter topology as well.

Both OLED and LED TVs use thin panels with millions of pixels to deliver crystal-clear picture quality, and there are excellent sets in both categories. The major difference lies in how they light the image.

Looking strictly at picture quality, it’s hard to beat an OLED TV. But there are loads of reasons you might opt for an LED TV instead. One undeniable factor is price. LED TVs start under $500, while even a small OLED will set you back $1,200. LEDs also come in a wider variety of sizes and models, though the options for OLEDs are growing.

LED TVs (left) shine a backlight through layers of filters, diffusors, and polarizers to create a picture. An OLED TV (right) doesn"t need a backlight because its pixels are self-lighting, so the panel design is more simple.

LED TVs are a type of LCD TV. They require many layers to create the picture you see. One of the most important is the backlight, which is made up of small, bright LEDs or light-emitting diodes. This LED backlight shines through a liquid crystal layer, and each liquid crystal pixel acts like a shutter, either blocking the light or allowing it to pass through.

Direct-lit backlights use a grid with a small number of LEDs across the entire back of the screen. These LEDs can"t be independently dimmed, so contrast isn’t as good as more advanced backlights.

Edge-lit TVs use strings of LEDs along either the sides of the screen, the top and bottom, or just the bottom. "Light guides" redirect and scatter the light evenly to produce a more uniform picture. They are thinner than direct-lit TVs. Some use frame dimming to adjust picture brightness frame by frame, while others use local dimming to darken zones as needed.

Higher-end sets use a more advanced type of backlight called full-array with local dimming — FALD for short. Like direct-lit TVs, the backlight covers the whole back of the screen, but FALD sets use a lot more LEDs. They also offer many dimmable zones for wider contrast and more realistic shadow detail than direct- or edge-lit sets.

An exciting development for 2021 is the implementation of mini LEDs. These TVs take the FALD technology a big step further by using LEDs that are significantly smaller than those used in traditional backlighting. That means they can pack a lot more of them in, allowing much more precise light control than the already-excellent standard FALD sets. You"ll find this cool feature on LG"s QNED and Samsung"s Neo QLED TVs.

If you"re confused by where QLED TVs fit in, you"re not alone. These Samsung sets are actually a type of LED TV that uses a special quantum dot layer to deliver vibrant color. The new "Neo QLEDs" mentioned above, pair this special quantum dot layer with the dense array of mini LEDs for rich color and excellent contrast.

OLED stands for “organic light-emitting diode.” Unlike the transmissive liquid crystal pixels in an LED TV, an OLED’s pixels are emissive. That means they don’t need a separate light source, like the backlight in an LED TV. It also means that when an OLED pixel is not activated, it emits no light at all. This is what gives 4K OLED TVs the incredible black levels they are known for.

Black levels and brightness are key factors in picture quality, and they are especially important when displaying the expanded contrast range of HDR content. OLED and LED TVs can both do a great job with this, but they have different strengths.

Brightness is one area where high-quality LED TVs have outperformed OLEDs. This year’s OLEDs are brighter than ever before, but they still can’t match the brightness that an LED backlight can deliver.

But if you are mostly interested in nighttime viewing, you’ll be stunned by the absolute black of an OLED display. And with the ability to turn off each pixel individually, you get no “blooming” — or those pesky halos you sometimes see around bright objects on dark backgrounds.

OLED and premium LED TVs with FALD backlights offer more precise light control for incredible contrast. Edge-lit sets with local dimming or frame dimming struggle in this area.

Verdict: Both OLED and LED TVs can look amazing. OLED cannot be beat for contrast, and the picture will knock your socks off in a darkened room. But if you’re going to be watching TV during the day, it’s worth considering an LED set.

Viewing angle is another area where OLED has a big advantage over LED TVs. When you sit directly in front of an LED set, the picture looks bright and colorful, but once you move to the sides the picture can become distorted or washed out. This is caused by the backlight and the shutter effect of the screen"s pixels.

OLED"s self-lighting pixels completely eliminate this issue, so picture quality is perfect from every angle. That"s a major advantage if your couch is often full of family or friends.

Verdict: When it comes to viewing angles, OLEDs can’t be beat. Some LED TVs use IPS panels that offer wider viewing angles, but the trade-off is that contrast suffers.

LED TVs have been around for many years and have proven to be extremely reliable, typically providing many years of trouble-free service. OLED TVs haven"t been around as long, but their expected lifespan is around 100,000 hours (similar to LED TVs).

One potentialissue you might hear about with OLED TVs is the risk of burn-in. This can happen if you spend hours every day watching programming that displays a very bright st

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey