can i use isopropyl alcohol to clean lcd screen factory

Screens, especially touchscreens, collect a lot of dirt, grease and hair. This means that periodic cleaning is something we all have to and should do.

Now, plenty of people get away with wiping a smartphone screen against their t-shirt or pants or using a sleeve to clean a laptop display, but this is not the best way and can itself damage the display.

Do a quick search on the internet, and you"ll find that isopropyl alcohol is the weapon of choice in cleaning displays. This is true, but if used incorrectly, this chemical can also damage the display.

The big DON"T of using isopropyl alcohol is this -- don"t pour or even spray isopropyl alcohol on your display. If you put too much isopropyl alcohol on a screen, damage can occur in two ways:The isopropyl alcohol can seep between the layers of the display, completely ruining it and requiring the device to have a replacement screen fitted

Apple has, naturally, published detailed information on safely cleaning a whole range of products, from notebooks to tablets to smartphones. While this is aimed at Apple users, the information applies to other brands too.

If you have been wondering how to clean a monitor with isopropyl alcohol, then let me tell you that the answer is very simple. All you need is a lint-free cloth and a container filled with 99% pure isopropyl alcohol. To start, dip your cloth in the container of alcohol and wipe away grime from your screen without applying too much pressure. After cleaning, let the monitor dry completely before turning it on again.

Use a soft, lint-free cloth. Avoid paper towels or anything else that might contain fibers. If you"re concerned about your monitor"s finish, you should be especially careful when cleaning it with alcohol—so don"t use any kind of rag or cloth you"ve already used on something else. If you"re concerned about dust or other contaminants on the monitor itself, then go ahead and use a small piece of tape to pick up excess dust before cleaning the screen with isopropyl alcohol.

A damp cloth is best for cleaning the monitor"s screen. This will prevent you from scratching it with a dry cloth or paper towel, which could damage your screen and make it harder to see.

Use a lint-free cloth. You don"t want to leave behind any debris, so you want to avoid using paper towels or other cloths that have fibers that could stick to your screen.

Use only enough isopropyl alcohol to clean off the dust and dirt from your monitor. Overapplying the cleaning solution will cause it to evaporate too quickly and leave residue on your screen, as well as potentially damaging it if there"s too much moisture in the air.

If you"re using a circular motion with your cloth, wipe slowly and do not press down hard on any part of the surface of your display—you could cause permanent damage by scratching or marring it with too much pressure or speed! Instead, move lightly around each individual point until all traces of dust have been removed before moving onto another area (if needed).

The next step after this is drying off any excess liquid: if there is any left over after patting down with one dry portion of cloth material, use another clean section again but be careful not overdo it here so as not spill water into places where they should not go!

Let the alcohol dry completely before turning on the monitor. If you do not, it could damage your monitor and void your warranty. Allow at least five minutes for a regular monitor, and overnight for laptops—the liquid will evaporate faster in warmer weather than in colder.

If you are looking for a way to clean your monitor, then consider using isopropyl alcohol. Isopropyl alcohol is a common solvent used in the medical and pharmaceutical industries, as well as one of the most effective disinfectants around. You can find it at your local drug store or supermarket, usually labeled “rubbing alcohol” or “isopropyl rubbing alcohol”.

Isopropyl alcohol is also very safe to use on monitors because they do not contain any oil or other contaminants that can be removed by detergents such as soap. Another benefit of this cleaner is that it will remove fingerprints without leaving any residue behind (unlike commercial cleaners).

Cleaning your monitor with isopropyl alcohol is a simple way to keep it looking good. It’s also cheap and easy to do, so there’s no reason not to try it. The alcohol will remove dust and fingerprints from both LCD and CRT monitors, leaving them looking like new again!

Like the OP, I"ve always used a 50/50 mixture of isopropyl alcohol and distilled water. Just now, I seem to have damaged the screen of my (Late 2013) MacBook Pro Retina by cleaning it with this mixture and a microfibre cloth.

There is a coating on the screen that has rubbed off in a patch about a quarter inch wide and two inches long. It"s very noticeable, but luckily it"s on the bezel rather than the screen proper. I"ll probably live with it, as a repair would probably involve replacing the whole screen. ($$$$)

This was possibly the third or fourth time that I"ve used this mixture to clean this screen in the few months that I"ve owned this machine. It"s really annoying to find that the most expensive laptop I"ve ever bought has a screen that can be so easily damaged, using a cleaner that I"ve seen recommended lots of times on the web and which has worked well for me in the past.

Isopropyl Alcohol is commonly found as rubbing alcohol in the grocery store, usually in a 70% isopropyl alcohol 30% distilled water mix; there is no need to dilute it when it comes that way. Some stores may sell 100% isopropyl alcohol which should be diluted. Something about the 70/30 mix causes the alcohol to evaporate away in the most efficient manner, so it"s better to do that than a 50/50 mix.

Isopropyl alcohol should be used only when distilled water won"t do the job, because repeated applications can eventually damage more delicate finishes.

Solutions that eyeglasses stores sell to clean glasses should certainly be safe for monitors, for finishes on glasses can be even more delicate. They are a good place to find the microfiber cloths which really are the best material for the job.

Windex and other ammonia-based cleaners should never be used; they WILL ruin your monitor, staining the finish a yellow color that can"t ever be removed.

Responsible for performing installations and repairs (motors, starters, fuses, electrical power to machine etc.) for industrial equipment and machines in order to support the achievement of Nelson-Miller’s business goals and objectives:

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

• Provide electrical emergency/unscheduled diagnostics, repairs of production equipment during production and performs scheduled electrical maintenance repairs of production equipment during machine service.

A variety of chemicals can be found throughout the electronic assembly and repair process, but no solvent appears more commonly than isopropyl alcohol. It is universally used for cleaning and as a main constituent of fluxes, but how much do you really know about isopropyl alcohol?

Isopropyl alcohol (CAS #67-63-0) is also referred to as IPA, isopropanol, 2-propanol, and even rubbing alcohol (more on that later). It dissolves a wide range of both polar and nonpolar soils, and is often used to dissolve and remove light oils, fingerprints, cutting fluids, flux residues, carbon deposits, and mold release. It is also readily miscible in water, which makes it an effective drying agent.

For electronic printed circuit board (PCB) assembly, you will find isopropyl alcohol being used either to clean flux residues from recently soldered circuit boards, or in PCB repair and rework. IPA is also used to remove solder paste or adhesive from SMT stencils. Maintenance cleaning with isopropyl alcohol is common for removing caked-on and burnt-on flux from SMT reflow ovens, wave soldering fingers, selective soldering nozzles, pallets, and anywhere else flux tends to collect in automated soldering processes.

Isopropyl alcohol is generally compatible with most materials used in electronics. As with any chemical product used, component compatibility must be determined on a non-critical area prior to use. The following are a list of common materials used in PCB assembly and their respective compatibility ratings:

When a solvent is not compatible with a substrate, it may cause crazing (micro-cracks) or soften the material. In the case of seals or gaskets, this incompatibility will cause parts to swell, shrink, or become brittle. This video shows an extreme example of acetone on polycarbonate, which causes it to fog, soften, and even scratch from contact with the plastic dropper.

Isopropyl alcohol is available in a large number of varieties and grades, which are generally differentiated by the amount of water in the solution and trace amounts of other chemicals or nonvolatile materials.

Isopropyl alcohol is hydrophilic, so it readily accepts water into an azeotropic solution. When you see on the label “70% isopropyl alcohol”, it refers to amount of alcohol in relation to the amount of dissolved water – i.e. 70% alcohol to 30% water. Water can be removed to form purer grades of isopropyl alcohol, resulting in what is called “anhydrous” isopropyl alcohol.

Whether an IPA has 0.2% or 50% water has little effect on the look and smell of the material, but greatly impacts surface tension (its ability to wet) and the dry time. The more water isopropyl alcohol contains, the greater the surface tension. This causes the solvent to bead up more as it dries rather than wet or sheet, which can lead to spotting. “Water spots” are particularly problematic when cleaning mirrors, lenses, and other optics.

The dry time is greatly increased as the percentage of water in the alcohol solution is increased. This can be an advantage or disadvantage depending on the application. For example, isopropyl alcohol is often used as a flux remover to remove flux residues from around solder joints. Technicians tend to prefer a fast dry time so that they can clean the electronics and bring them back into service as quickly as possible. When breaking down and removing thick, gummy, or baked-on materials, more dwell or soak time is required. Slowing down the dry time often improves the cleaning effectiveness. That is one of the reasons 70% pure isopropyl alcohol is commonly used for degreasing and SMT stencil cleaning. In the case of electrical contact cleaning, the faster evaporation time helps ensure that the flammable solvent is gone before energizing the equipment.

ACS / reagent grade- meets or exceeds purity standards set by the American Chemical Society (ACS). This grade is specified for food, drug, or medicinal use and other applications that require strict quality specifications and purity over 95%.

USP grade- meets or exceeds requirements of the United States Pharmacopeia (USP). For food, drug, or medicinal use in addition to most laboratory purposes.

The general term “rubbing alcohol” is often used for isopropyl alcohol, but users looking to buy a specific grade of alcohol should avoid products labeled that way. Rubbing alcohol does not refer to a specific grade, and may even be a different type of alcohol, like ethanol (also called ethyl alcohol, CAS #67-17-5). Consumer rubbing alcohol can also contain other ingredients like denaturant, fragrances, and colorants that are potential contaminants. ASTM D770 (currently on revision 11(2019)) is the standard specification for isopropyl alcohol published by ASTM International.

As mentioned above, isopropyl alcohol is also available in different grades, or percentages of solvent to water, to fit a variety of specific applications. When deciding on the best isopropyl product for a particular manufacturing or repair process, first decide on the grade of solvent, then the packaging.

Bulk containers- Isopropyl alcohol is packaged in 1 gallon bottles, 5-gallon containers, 54-gallon drums, and even totes for automated dispensing. In most cases, a spigot can be attached to the 1 and 5 gallon containers for convenient dispensing in benchtop or workstation use. When transferring to another container, make sure the smaller bottle is properly marked with the chemical name and warning information.

Small bottles / spray bottles- To avoid the risk and hassle of pouring and labelling smaller containers, isopropyl alcohol is also available in smaller plastic containers like pints and quarts. Some have a trigger spray attachment for convenient cleaning.

Pump dispensers / dauber bottles- Empty bottles are available to make dispensing even more convenient. A wipe or swab can be saturated in the opening, which is filled with a valve when the user pushes down. This keeps the isopropyl alcohol sealed, which avoids cross contamination when a wipe is resaturated after use, causing it to draw in moisture from the ambient air. These bottles can come with a variety of features including ESD-safe materials and a selection of labels for standard chemicals like IPA.

Aerosol cans- An aerosol can is a sealed container, so it has some of the advantages of a pump dispenser. In addition, the propellant forces the solvent out of the can, creating agitation as it hits the substrate.

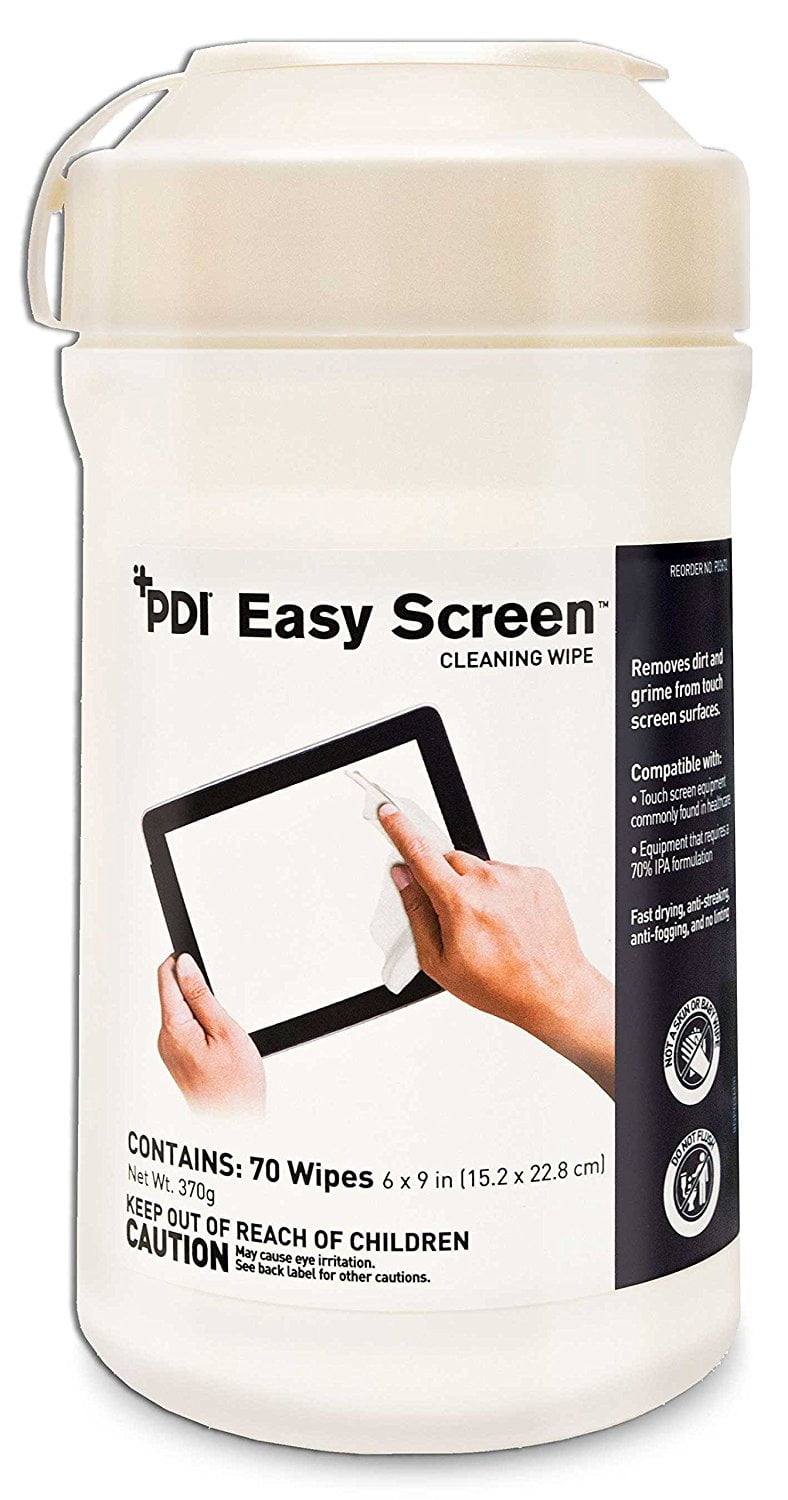

Presaturated wipes- For the ideal mix of form and function, wipes are available, and are already saturated with isopropyl alcohol. They can come in pop-up tubs where the wipes are pulled up from the top, plastic boxes or pouches that reduce linting caused by wipe perforations, and even individually wrapped packages. The individually wrapped wipes are perfect for field maintenance because they fit neatly in a tool box.

Although isopropyl alcohol is generally considered safe if handled properly, it is a flammable solvent, so precautions need to be taken to prevent a dangerous situation from developing.

Ventilation- the work area must be adequately ventilated to prevent an accumulation of vapors, which could combust. Ventilation should be explosion-proof.

Storage- because isopropyl alcohol is very flammable, it needs to be stored in a closed container in a cool, well-ventilated area away from ignition sources like heat, sparks and flames. It has an NFPA rating of 3, so it should be stored in a cabinet or room designed for that type of hazardous material. If solvent is transferred to another container, make sure it is marked with the chemical name and required warning information.

Personal protection equipment- isopropyl alcohol has a tendency to defatten the skin, which means it draws out the protective oils from the skin and can lead to dermatitis if improperly handled. Gloves made of nitrile or other solvent-resistant materials should be worn. Glasses or even a face shield should be worn if the user is spraying an IPA product, or if splashing could occur. Respirators can be used if ventilation is not adequate enough to avoid breathing in a high concentration of vapors.

Disposal- isopropyl alcohol needs to be disposed of as a hazardous liquid according to state and local requirements. It certainly cannot be flushed down the drain, and additional disposal requirements may need to be followed depending on the soils dissolved in the waste material.

Safety Data Sheets (SDS)- The central resource for all safety requirements is the SDS, which should be readily available wherever isopropyl alcohol is used.

Is it any wonder isopropyl alcohol can be found in all corners of electronic PCB assembly, rework and repair operations? It is effective, reasonably priced, and safe if handled properly. To buy isopropyl alcohol in the grade and packaging that is best for your application, go to www.techspray.com.

No matter where LCD screens are kept, they will always need cleaning from time to time. Cleaning an LCD may seem like a daunting task, but there are a few simple ways to clean it without damaging to scratching to surface.

There are many cleaning solutions available in shops. However these may seem a bit expensive and are sometimes quite unnecessary. PixelClean is one of the better and less expensive brands. It is highly recommended. Most products will come with instructions on how to use them.

It is recommended to use a simple alcohol solution to clean an LCD screen. This solution is made up of part distilled water and part 50% isopropyl alcohol. Be warned that isopropyl alcohol is flammable.

50% isopropyl alcohol is very common. If you find 70%, 91%, or 99% isopropyl alcohol, adjust the formula to use less alcohol and more distilled water.

The reason you want this mixture is because alcohol evaporates so quickly. More importantly, it doesn’t leave any residue behind, so the screen will be cleaned without there being any streaks or marks left. You can buy this at your local pharmacy–it’s used for cleaning wounds.

Do NOT use tissues/Kleenex to wipe your screen. That is ineffective, because they will leave little tissue particles all over your screen. You want a 100%-cotton cloth that is soft and absorbent. A t-shirt is a good cloth, but so is a sock or a Turkish towel, so long as it is 100% cotton.

Stay away from cloth that has polyester in it because this can contain stiff filaments. These filaments can scratch the screen while you are rubbing over it. Also stay away from paper towel and tissues. While it might feel soft, remember that it is paper and therefore, it comes from wood. This means that there might be microscopic wood fragments in the paper towel that will scratch your screen if you move it over it. Therefore, avoid anything paper and instead, focus on the cotton.

First dampen the cloth with the alcohol solution. You should never spray any sort of liquid directly onto the screen. You also don’t want to try and clean the screen without some sort of liquid because the dust particle, as it is moved across the screen, will scratch.

Wipe the screen gently from top to bottom or in a counter clockwise direction, and wait for it to dry. You’ll remove all of the dust and the liquid that is on the screen will evaporate quickly. Then, the screen will be clean and scratch free.

Be careful not to let the cleaning solution leak into the sides of the monitor. Also, be certain that you do not press hard on the LCD screen. You can permanently damage an LCD screen by pressing on it too hard.

If there is just dust on your screen, there is no need to fully clean it. To remove dust all that must be done is to wipe it away with a microfiber cloth. Simply wipe your screen from end to end gently with the cloth.

Over time, dirt, smudges, dust, and more can reduce the picture quality on an LCD, much like looking through a dirty pair of glasses. Cleaning an LCD screen is a simple and straightforward process.

3. Do not spray any cleaning fluid directly on the LCD screen to prevent liquid from dripping inside of it. (This also applies to touch screen monitors.)

4. A suitable cleaning solution for LCDs is a mixture of 50% Isopropyl alcohol and 50% distilled or otherwise purified water. For touch screens, 5-10% bleach may be used to clean the touch glass without harming it.

5. For purposes of disinfecting, benzyl alcohol and/or hydrogen peroxide can be used without harming the LCD screen and/or Touch Screen; please follow the same application directions as above to avoid damaging the touch screen and/or PC.

In manufacturing and for the everyday consumer, IPA 99% is especially useful to clean electronic parts, since electronic parts and devices can be highly sensitive during and after production.

IPA 99% is also completely miscible in water, which is efficient when cleaning consumer products that may require a water and IPA 99% mixture, such as laptop computers.

Most are aware of IPA 99% highly effective utilization for medical use and as a laboratory solvent, but Isopropyl Alcohol plays an important role in the everyday maintenance of electronics for businesses, manufacturers, and consumers.

Isopropyl Alcohol 99% is the best substance to use for this purpose. Isopropyl Rubbing Alcohol 91% may also be effective, but it is best to use the purest IPA available.

IPA 99% has flammable liquid and vapors, so be sure that the device is completely turned off and give IPA 99% time to evaporate before turning any hot components on.

A cloth, cotton swab, or cotton swab can be applied with Isopropyl Alcohol 99% to the electronic parts that need to be cleaned, but be sure not to leave any fibers on the device components.

IPA 99% should be sufficient to clean sensitive parts of electronic devices, but for personal computers an aerosol can of pressurized air may be enough for casual cleaning.

During these unprecedented times, it is crucial to stay up to date with any and all methods to stay healthy. Here at TRU-Vu, we value our customers’ health and safety. For this reason, we have put together some guidelines for cleaning and disinfecting TRU-Vu touch screen monitors. This can be achieved without causing any damage to the touch screen

To begin with, it is important to distinguish cleaning from disinfecting. Cleaning removes dirt, germs, and impurities. Cleaning does help to reduce germs that can lead to infection, it does not kill the germs or virus. Disinfecting utilizes chemicals to kill germs to reduce/eliminate the chance of infection.

The U.S. Centers for Disease Control and Prevention (CDC) states: “diluted housed bleach solutions, alcohol solutions with at least 70% alcohol, and most common EPA-registered household disinfectants should be effective” for disinfecting surfaces to prevent the spread of coronavirus (COVID-19).

Be sure to not get any liquids inside of the unit. To best avoid doing so, do not directly spray the monitor. Either use wet wipes, or spray/dampen a cloth with water or gentle cleaner and be sure to squeeze any excess moisture off.

Avoid using abrasive cloths, such as rags or paper towels, as they can spread lint and/or even damage the screen. Instead, use only non-abrasive cloths, such as soft lint-free cloth, in order to avoid scratching the monitor.

Dampen a new clean, non-abrasive cloth with a disinfectant recommended by the CDC: a household bleach solution (1/3 cup of bleach per gallon of water) or Isopropyl alcohol ( 71% to 85% alcohol). Be sure to squeeze any excess liquid off of the cloth. Do not spray the solution directly onto the touch screen.

More information about recommended disinfectants for COVID-19 from the EPA can be found at: https://www.epa.gov/pesticide-registration/list-n-disinfectants-use-against-sars-cov-2

Apply the solution to a soft cleaning cloth; do not spray directly onto the touch screen. Wear gloves during the cleaning process. Finally, discard both the gloves and the cleaning cloth following the cleaning process.

Certainly, If you have any questions, or require further assistance with cleaning your TRU-Vu touch screen monitor, please contact us at #847-259-2344.

With over 540 LCD monitors and touch screens on our site, selecting the ideal equipment, or touch screen solution may be a bit overwhelming.To help narrow-down the choices, check out ourAdvanced Search Tool.For example, this enables you filter by your own specific search requirements.

Whether it"s the monitor in your cubicle at work or a laptop on the standing desk in your home office, computer screens get grimy. Getting rid of dust is a major concern: As it silently and continuously builds up, it may distort the color or brightness of your screen. Greasy fingerprints are another offender. Even if you don"t have a touchscreen model, fingerprints happen and become especially visible when the screen is black. Finally, germs are always an issue — it"s just good practice to keep frequently used surfaces sanitary.

Cleaning a screen requires a delicate touch. Some cleaners or cloths are too abrasive. Using the wrong liquid can cause damage, and using too much liquid can cause your laptop or monitor to short out altogether. To find out what cleaning products and supplies are safest to use, we checked in with Carolyn Forté, the Executive Director of the Good Housekeeping Institute Cleaning Lab.

Forté says, "If there"s one thing you should avoid entirely, it"s regular glass cleaner that you"d find in the cleaning aisle.Windows are different surfaces from computer screens and with different cleaning needs." She explains that using a clean, dry microfiber cloth is the best and safest way to remove streaks or smudges and that just plain wiping also removes bacteria. But to actually disinfect, you"ll need a cleaning product.

A note on the various degrees of cleaning: Some products may only clean or sanitize a screen, which the CDC definesas "[lowering] the number of germs on surfaces or objects to a safe level," based on how they work, the ingredients they contain and the length of time they remain on the surface. Others disinfect, which actually "kills germs on surfaces or objects" and "further lowers the risk of spreading infection" overall. Disinfecting takes longer than cleaning or sanitizing.

The answer is complicated, as there are hundreds of laptop manufacturers and even more when it comes to monitors — and they all have their own safe cleaning recommendations. Always start by following your computer manufacturer"s cleaning advice, especially if your device is still under warranty. If that doesn"t totally take care of the problem, there may be other steps you can take depending on the type of screen you have, but proceed carefully.

What is safe for your laptop screen usually comes down to whether or not it has a glass covering. For Macs, this is usually the case. But PC models may not have glass over their LCD screens. When in doubt, refer to your user"s manual, or reach out to your laptop"s manufacturer online via email or on-site support chats to learn more.

That being said, Forté says most Apple laptops and monitors — or any laptop with a glass-protected screen —can be wiped down with either Lysol or Clorox disinfecting wipes.Since laptops are routinely handled, Forté says even if you disinfect your device, it won"t stay disinfected for long. If you still want to give disinfecting a go, surfaces cleaned with traditional disinfecting wipes usually need to remain wet for four minutes to kill viruses and bacteria, but check the label of the wipes you are using to be sure. Then, let your screen air dry and buff again with a microfiber cloth.

Remember: For any device, you never want to spray a cleaning agent directly onto the screen — it could seep into the cracks and crevices of your laptop, Forté says. "You want to make sure that no excess water, cleaner or liquid gets inside your laptop," she explains. "Always spray onto a cloth first if you are trying to use aerosols or sprays, and make sure any wipes you use are not overly wet."

How to clean and disinfect a non-LCD (glass-covered) laptop screen:Unplugyour laptop from its power source, and turn it off (do the same for monitors).

Wring out a disinfecting wipe to ensure it"s not oversaturated and gently wipe your laptop"s screen horizontally and vertically making sure it stays wet for the time required by the package instructions and taking care to not touch any openings (including ports or speakers).

If you have a PC laptop with an LCD screen, you should not use disinfecting wipes. Manufacturers, such as Hewlett-Packard, say that active ingredients found in both Clorox and Lysol wipes could damage your screen. This HP customer support web page alsocautions: "Do not use any of the following chemicals or any solutions that contain them: Acetone, ethyl alcohol, toluene, ethyl acid, ammonia or methyl chloride." It also states that "some commercial glass cleaners contain ammonia and are therefore unacceptable." It"s best and safest to wipe them with a dry cloth or for stubborn spots, use an LCD-safe cleaner sparingly applied first to the cloth and then to the screen. Never spray the screen directly.

Microfiber cloths are made with special fibers that have more surface area to trap dirt, grime and germs, Forté says, and with edges to lift bacteria off your screen. While a dry microfiber clothcan"t disinfect an LCD screen, using one to wipe down your screen won"t put it in danger of the permanent damage that cleaners could pose and can remove some germs.

Additional recommendations on HP"s support page read, "To clean smudges from the LCD screen, choose a nonabrasive cloth or towel. Turn off the computer and disconnect the power cable. Wipe the screen gently with a soft, dry cloth. If any marks remain, moisten the cloth with LCD cleaner, and then gently stroke the cloth across the display in one direction, moving from the top of the display to the bottom."

Forté confirms that you should not use soap and water to clean any computer screen. Some soap varieties may contain ingredients known to affect LCD screens and a sudsy mix is not only too wet, but won"t evaporate quickly enough to safely be used on a laptop screen.

Since your keyboard is the part of your laptop you"re touching most, you might be wondering if you should use disinfectants on this surface as well. Apple"s cleaning recommendations page indicates that 70% isopropyl alcohol wipes or Clorox Disinfecting Wipes can be used to gently wipe the hard, non-porous surfaces of Apple products, like displays, keyboards and exterior surfaces. PC laptop manufacturers all have various instructions (HP says cleaning the keycaps with dish soap is fine).

Forté says you shouldn"t be afraid to wipe down your keyboard with a wipe after you"ve taken time to clean your laptop"s screen. Despite official recommendations, keyboards are made with plastic keys that are non-porous, and Forté explains that they shouldn"t be affected,especially if you"re careful in ensuring excess liquid isn"t seeping between and beneath the keys. Just like when you clean your screen, you"ll want to make sure your computer is off.

Both Forté and Apple recommend holding your laptop at a 75° angle and using a can of compressed air to blow away debris that"s become lodged between keys before wiping it down. Lastly, you can also dip a clean microfiber cloth or a large cotton swab into rubbing alcohol and go over each of the keys to clean and sanitize them.

The bottom line:It"s clear that laptop manufacturers have various recommendations when it comes to cleaning so be sure to follow their guidelines first. While disinfectants may contain solvents or other cleaning agents potentially damaging to some surfaces, they"re formulated to actually kill germs. Regular screen cleaners or microfiber cloths don"t have the same killing power as disinfectants, but are viable cleaning alternatives if you"re concerned about the safety of your computer screen.

Zee Krstic is a health editor for Good Housekeeping, where he covers health and nutrition news, decodes diet and fitness trends and reviews the best products in the wellness aisle. Prior to joining GH in 2019, Zee fostered a nutrition background as an editor at Cooking Light and is continually developing his grasp of holistic health through collaboration with leading academic experts and clinical care providers. He has written about food and dining for Time, among other publications.

This content is imported from OpenWeb. You may be able to find the same content in another format, or you may be able to find more information, at their web site.

/how-to-clean-a-monitor-5323506-11-38be8b68456d4e93b42f06f48f03a3f6.jpg)

You’re on your computer A LOT. If you’re like most people, you’re on it anywhere from 3 to 7 hours a day. And the screen is REALLY close to your face, like 12 inches or so.

Which means all that coughing, sneezing, coffee sipping, and touching is inevitably leaving behind a trail of gunky, oily, germy messiness. Most visible when the screen goes black, sure, but sitting there, staring back at you the whole time. What to do?

The sleeve of your shirt won’t cut it this time. It’s time for a computer screen intervention (aka a helpful cleaning guide) to bring the dignity back to your monitor.

Don’t directly wet the screen. That means never spray it. If you’re going to use a cleaning solution, spray your cleaning towel, and then wipe the surface of the screen. When you spray it directly, you risk oversaturating the pixels, which can cause component failures, electrical problems, and even fire.

Don’t use regular cleaning supplies. Using multi-surface or glass cleaning products is a big no-no. The chemicals in these products are too strong for your monitor. Even regular soap and water is too harsh of a solution for your computer screen.

Don’t press too hard. Use a gentle circular motion to clean your screen and never apply too much pressure. Doing so can cause permanent damage, and is a major bummer when all you were trying to do was remove that coffee splatter.

Turn your computer off. A black screen makes spotting smudges and oil schmears easier, but merely putting your computer to sleep isn’t enough. Powering your computer down ensures you don’t damage its pixels while they’re still firing electricity and also eliminates the risk of electric shock or even fire.

Use a microfiber cloth. Never use a paper towel, old t-shirt, or napkins to clean your computer monitor. At worst, the fibers in these materials may scratch the surface of your screen and at best, they’ll leave a trail of lint. Instead, use a microfiber cloth, which is made up of a super soft synthetic material that won’t cause any damage to your screen, and will wipe away debris beautifully.

Wipe gently. Use a gentle, circular motion to wipe your screen clean. For any tough food particles or debris, a repeated circular motion may help do the trick. If not, skip to the next method which will show you how to make a homemade cleaning solution. It bears repeating, never spray your screen directly with cleaners, or soap and water.

Clean the frame and base. The only areas of your monitor that can withstand multi-purpose cleaners are the frame and base of your computer. Very carefully, lightly spray a paper towel with the cleaner (don’t soak it!) and run it along the frame and base. Never apply the paper towel to the actual screen of your computer.

Turn your computer off. For this method, the first step is to again power down your computer so that you can easily see all the debris on its screen AND so that you don’t inadvertently cause damage or burnout to the pixels.

Make a cleaning solution. The first and easiest cleaner you should try is distilled water, which doesn’t contain any chemicals. If your screen needs something stronger, mix ¼ cup distilled water and ¼ cup white vinegar in a spray bottle. If you don’t have white vinegar, a ¼ cup of distilled water and a ¼ of rubbing alcohol will do the trick, too. This simple solution can be used on many household items, from windows to shower doors .

Spray the microfiber cloth. Spray your cleaner onto a clean microfiber towel. Never spray the screen directly or you risk component failure or electrical shock.

Cleaning your computer screen will provide the much-needed physical (and mental!) cleansing you so desperately deserve. If you’re on a laptop, you can rest assured you won’t offend anyone at the coffee shop or in the conference room with splatters from last week’s roast beef sandwich. If you’re on a desktop computer, a clean screen could be just what you need to feel at home in your home office. And if that doesn’t do the trick, hey, maybe try washing the walls. Either way, cleaning your monitor is a win-win.

When a laboratory has an abundance of electronics that need to be kept in working order, eventually it’ll be necessary to find the right chemical to use for cleaning. For most laboratories, a solution comprised of distilled water and an alcohol is the right solution because of its low-cost and high-efficacy cleaning potential. But, especially for laboratories which may just be getting established for the first time, it may be unclear which alcohol is the appropriate choice to make the cleaning solution.

The question of ethyl alcohol vs. (IPA)for cleaning electronics has several ramifications for the laboratory supply chain as well as the longevity of laboratory hardware. To shed light on this issue, it’s necessary to briefly discuss why electronics need a special cleaning solution at all.

Cleaning electronics is a bit different than cleaning other pieces of laboratory hardware because electronics can be easily damaged when they are exposed to minerals or ionic compounds. The reason for this is that electronic components require the unimpeded flow of electrons to properly function; any disruption in the pre-engineered flow of electrons within a component will result in the component malfunctioning via a shorted circuit at the point of disruption.

In extreme cases, this malfunctioning can be permanent if the component’s electron-bearing pathways are disrupted by a substance that is difficult or impossible to remove, like residual minerals in non-distilled water.

However, not all electronic components are equally vulnerable to disruption. Electronics have several features which require special attention, including:

Of these components, it is typically sensors and exposed semiconductor materials which are the most vulnerable to damage by using the incorrect cleaning solution. If water bearing minute quantities of dissolved minerals splashes onto an exposed semiconductor, it will be nearly impossible to remove the trace minerals which will disrupt electron flow.

While sensors tend to be slightly more hardy because they are exposed to a partially uncontrolled environment to fulfill their core purpose, most pieces of laboratory hardware have sensors which are highly sensitive, making even minor disruptions to their functioning relatively hazardous to their output of clean data.

The printed circuit board plastics of electronic components are typically the hardiest part of any laboratory hardware. However, when exposed to the wrong cleaning solution, even the hard plastic of PCBs can corrode—and manufacturers are rarely willing to replacing a damaged PCB as cheaply as they might replace a sensor or semiconductor component.

Ethyl alcohol is a great choice for cleaning electronics in the laboratory because it’s inexpensive, mineral-free, and evaporates quickly.While ethanol isn’t a strong solvent, it is typically sufficiently powerful to clean sensitive electronics which may have accumulated light layers of corrosion or dirt. It’s also a useful chemical for a plethora of laboratory tasks ranging from basic sterilization to removing labels from old pieces of hardware.

Cleaning electronics with ethanol requires a different reagent grade than for the ethanol intended for routine laboratory use, however, so the ethanol purchased for cleaning electronics will probably be a different item in the lab’s inventory regardless of what else is on hand.

Whereas standard laboratory task-grade ethanolis inexpensive and most laboratories will have a vast reservoir prepared to tackle whatever is needed, standard grade ethanol is not pure enough to be used to safely clean electronics. Despite having minimal mineral content, the trace minerals leftover from the manufacturing process in standard grade ethanol will have a deleterious effect on lab electronics, though the damage will be nowhere near the damage caused by water exposure. Instead, cleaning electronics with ethanol requires the use of ultra-pure ethanol, which has been purged of all extraneous mineral content. Alternatively, ethanol-soaked laboratory wipes can be an appealing way to clean electronics.

Ethanol’s drawback is that it can sometimes leave oil traces on the surface it evaporates from. These traces of oil can subsequently cause malfunctions in highly sensitive electronics. This drawback is highly minimized when using the purest form of ethanol, but the most sensitive electronic components may still have problems when cleaned with ethanol as a result.

is the more common choice for cleaning electronics because it evaporates more rapidly than ethanol and also because it does not leave any traces of oils upon evaporation. Similarly to ethanol, most laboratories have ample quantities of isopropyl alcohol (IPA) around for general purpose use.

However, unlike ethanol, the most common sources of laboratory isopropyl alcohol are ready to use for cleaning electronics. Lab wipes and reagent-grade bottles of isopropyl alcohol are each pure enough to clean sensitive electronic components without hazard.

Not all electronic components are compatible with isopropyl alcohol cleaning, however. In particular, polycarbonate electronic components, typically in PCBs, seals and gaskets, are extremely harmed by exposure to an isopropyl alcohol cleaning solution. While it may be possible to mitigate the impact of the cracking which occurs when isopropyl alcohol seeps into the polycarbonate by using a more dilute cleaning solution, a better strategy is to avoid using isopropyl alcohol on these components entirely.

Notably, isopropyl alcohol also combusts more readily than ethanol. While the difference is negligible in most lab situations as both will alight when exposed to an open flame, laboratories which routinely operate sensitive experiments at high heat may find that isopropanol is too volatile to be safely used for cleaning components which may still be warm from use. Importantly the residual oils from ethanol may be problematic in this context as well, so the advantage of ethanol is not assured.

Anticipating a laboratory’s utilization of key cleaning chemicals like isopropyl alcohol is significantly easier when a laboratory works with a knowledgeable supplier who understands the lab’s typical needs. By working with the right supplier, labs can ensure that they have consistent access to the chemicals they need, when they need them.

For over 40 years, Lab Pro has been committed to providing critical electronics cleaning supplies for cleanrooms like isopropanol and ethanol in California and worldwide. Come visit the biggestLab Supply showroomin California, orcontact us onlineor at 888-452-2776.

Fingerprints on your screen? Dirt and dust hidden in between your keyboard keys? All areas that need to be cleaned, but make sure you are cleaning these areas properly, so you don’t cause immediate or long-term damage! Below are our tips to properly clean and sanitize your workspace.

These materials are harmful on a microscopic level. They could be holding onto tiny specs of dust, sand, metal, etc. and could ruin your screen with just a single wipe!

Spraying directly onto your screen results in the excess liquid seeping into any weak spots or tiny openings on your screen. The liquid wreaks havoc on the inside and can cause potentially irreversible damage.

We Recommend: Spray directly onto your microfiber cloth and make wide swipes from top to bottom or side to side. Avoid circular motions or focusing on a single spot too much, and this can cause damage.

ALWAYS make sure your electronics are unplugged and turned-off before you start cleaning. Your keyboard and mouse are less sensitive than your monitor, but gentle care should still be used when cleaning.

We Recommend: Unplug and turn off all devices. If you are using a wireless mouse or keyboard, also remove the batteries. You can use compressed air, tape, slime, clean & unused brushes or simply shake your keyboard upside-down to get the debris out. Then, grab your Lysol wipe (or disinfectant of your choosing) and wipe down your keyboard and mouse. Make sure that your wipes aren’t overly wet to avoid getting excess moisture into any openings.

A good rule of thumb when it comes to any electronics – make sure they are COMPLETELY dry before putting the batteries back in and/or turning them back on. Doing so before they are dry can result in damage.

Don"t forget your about cell phone! Many of the same rules from above apply here. Spray a microfiber cloth with your disinfectant of choice and wipe your screen with a microfiber cloth. If you are using disinfectant wipes, make sure to avoid excess moisture and wipe the phone dry with your microfiber cloth. If you use a phone case, make sure you are cleaning that regularly as well.

Be gentle and patient when cleaning your computer, laptop, phone, screens, etc. Many times, your technology is provided by the company you work for or is under a warranty. Avoid disassembling any products, as this could make the warranty void, cause damage, or worse.

If you are unsure about the best practices for cleaning, reach out to your current IT provider or call our office at 802-655-0880 - we are happy to offer free advice or guidance!

Everyone is spending more time staring at their laptop, tablet, or computer screens these days—which means more chances for finger smudges, accidental coffee drips, or even a wayward sneeze. All things considered, we could all be cleaning our laptop screens more frequently.

Fortunately, cleaning a laptop screen takes only a few minutes and a few basic supplies. The key to successful screen cleaning is that less is more. It"s important to use the least amount of cleaning products and the gentlest pressure possible to prevent damage to the screen.

There are two basic types of laptop screens: glass-covered LCD (liquid crystal display) screens and nonglass-covered LCD screens. Glass-covered screens, featured on many Apple products, are more durable and can withstand more moisture and stronger cleaning products like disinfecting wipes when cleaning. LCD screens that are not protected by glass can be permanently damaged by many cleaning products.

Before you attempt to clean your laptop screen or any electronic device, take the time to read the manufacturer"s guidelines on cleaning and maintenance. If you"ve lost or tossed the owner"s manual, you can find them online.

How frequently you clean your laptop and the screen will depend on how often you use it. If you use it daily, cleaning the laptop screen, keyboard, and external parts, should be done at least weekly. Laptops that travel around with you to places outside the home should be cleaned more often. Plan a deep clean every three to six months on the entire laptop.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

You can email the site owner to let them know you were blocked. Please include what you were doing when this page came up and the Cloudflare Ray ID found at the bottom of this page.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey