assembly code for lcd display quotation

In this tutorial, I’ll explain how to set up an LCD on an Arduino and show you all the different ways you can program it. I’ll show you how to print text, scroll text, make custom characters, blink text, and position text. They’re great for any project that outputs data, and they can make your project a lot more interesting and interactive.

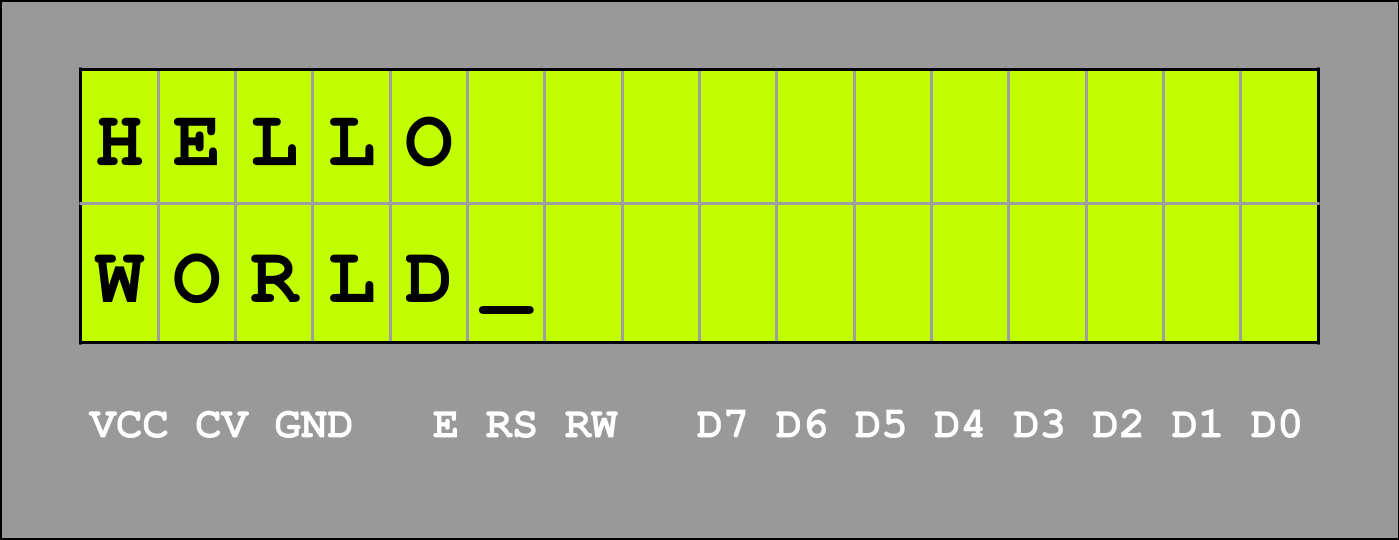

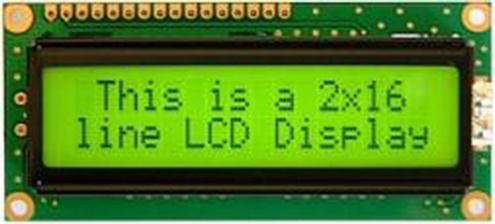

The display I’m using is a 16×2 LCD display that I bought for about $5. You may be wondering why it’s called a 16×2 LCD. The part 16×2 means that the LCD has 2 lines, and can display 16 characters per line. Therefore, a 16×2 LCD screen can display up to 32 characters at once. It is possible to display more than 32 characters with scrolling though.

The code in this article is written for LCD’s that use the standard Hitachi HD44780 driver. If your LCD has 16 pins, then it probably has the Hitachi HD44780 driver. These displays can be wired in either 4 bit mode or 8 bit mode. Wiring the LCD in 4 bit mode is usually preferred since it uses four less wires than 8 bit mode. In practice, there isn’t a noticeable difference in performance between the two modes. In this tutorial, I’ll connect the LCD in 4 bit mode.

BONUS: I made a quick start guide for this tutorial that you can download and go back to later if you can’t set this up right now. It covers all of the steps, diagrams, and code you need to get started.

Here’s a diagram of the pins on the LCD I’m using. The connections from each pin to the Arduino will be the same, but your pins might be arranged differently on the LCD. Be sure to check the datasheet or look for labels on your particular LCD:

Also, you might need to solder a 16 pin header to your LCD before connecting it to a breadboard. Follow the diagram below to wire the LCD to your Arduino:

All of the code below uses the LiquidCrystal library that comes pre-installed with the Arduino IDE. A library is a set of functions that can be easily added to a program in an abbreviated format.

In order to use a library, it needs be included in the program. Line 1 in the code below does this with the command #include

Now we’re ready to get into the programming! I’ll go over more interesting things you can do in a moment, but for now lets just run a simple test program. This program will print “hello, world!” to the screen. Enter this code into the Arduino IDE and upload it to the board:

There are 19 different functions in the LiquidCrystal library available for us to use. These functions do things like change the position of the text, move text across the screen, or make the display turn on or off. What follows is a short description of each function, and how to use it in a program.

TheLiquidCrystal() function sets the pins the Arduino uses to connect to the LCD. You can use any of the Arduino’s digital pins to control the LCD. Just put the Arduino pin numbers inside the parentheses in this order:

This function sets the dimensions of the LCD. It needs to be placed before any other LiquidCrystal function in the void setup() section of the program. The number of rows and columns are specified as lcd.begin(columns, rows). For a 16×2 LCD, you would use lcd.begin(16, 2), and for a 20×4 LCD you would use lcd.begin(20, 4).

This function clears any text or data already displayed on the LCD. If you use lcd.clear() with lcd.print() and the delay() function in the void loop() section, you can make a simple blinking text program:

This function places the cursor in the upper left hand corner of the screen, and prints any subsequent text from that position. For example, this code replaces the first three letters of “hello world!” with X’s:

Similar, but more useful than lcd.home() is lcd.setCursor(). This function places the cursor (and any printed text) at any position on the screen. It can be used in the void setup() or void loop() section of your program.

The cursor position is defined with lcd.setCursor(column, row). The column and row coordinates start from zero (0-15 and 0-1 respectively). For example, using lcd.setCursor(2, 1) in the void setup() section of the “hello, world!” program above prints “hello, world!” to the lower line and shifts it to the right two spaces:

You can use this function to write different types of data to the LCD, for example the reading from a temperature sensor, or the coordinates from a GPS module. You can also use it to print custom characters that you create yourself (more on this below). Use lcd.write() in the void setup() or void loop() section of your program.

The function lcd.noCursor() turns the cursor off. lcd.cursor() and lcd.noCursor() can be used together in the void loop() section to make a blinking cursor similar to what you see in many text input fields:

Cursors can be placed anywhere on the screen with the lcd.setCursor() function. This code places a blinking cursor directly below the exclamation point in “hello, world!”:

This function creates a block style cursor that blinks on and off at approximately 500 milliseconds per cycle. Use it in the void loop() section. The function lcd.noBlink() disables the blinking block cursor.

This function turns on any text or cursors that have been printed to the LCD screen. The function lcd.noDisplay() turns off any text or cursors printed to the LCD, without clearing it from the LCD’s memory.

These two functions can be used together in the void loop() section to create a blinking text effect. This code will make the “hello, world!” text blink on and off:

This function takes anything printed to the LCD and moves it to the left. It should be used in the void loop() section with a delay command following it. The function will move the text 40 spaces to the left before it loops back to the first character. This code moves the “hello, world!” text to the left, at a rate of one second per character:

This function takes a string of text and scrolls it from right to left in increments of the character count of the string. For example, if you have a string of text that is 3 characters long, it will shift the text 3 spaces to the left with each step:

Like the lcd.scrollDisplay() functions, the text can be up to 40 characters in length before repeating. At first glance, this function seems less useful than the lcd.scrollDisplay() functions, but it can be very useful for creating animations with custom characters.

lcd.noAutoscroll() turns the lcd.autoscroll() function off. Use this function before or after lcd.autoscroll() in the void loop() section to create sequences of scrolling text or animations.

This function sets the direction that text is printed to the screen. The default mode is from left to right using the command lcd.leftToRight(), but you may find some cases where it’s useful to output text in the reverse direction:

This code prints the “hello, world!” text as “!dlrow ,olleh”. Unless you specify the placement of the cursor with lcd.setCursor(), the text will print from the (0, 1) position and only the first character of the string will be visible.

This command allows you to create your own custom characters. Each character of a 16×2 LCD has a 5 pixel width and an 8 pixel height. Up to 8 different custom characters can be defined in a single program. To design your own characters, you’ll need to make a binary matrix of your custom character from an LCD character generator or map it yourself. This code creates a degree symbol (°):

LCD connected to this controller will adjust itself to the memory map of this DDRAM controller; each location on the LCD will take 1 DDRAM address on the controller. Because we use 2 × 16 type LCD, the first line of the LCD will take the location of the 00H-0FH addresses and the second line will take the 40H-4FH addresses of the controller DDRAM; so neither the addresses of the 10H-27H on the first line or the addresses of the 50H-67H on the second line on DDRAM is used.

To be able to display a character on the first line of the LCD, we must provide written instructions (80h + DDRAM address where our character is to be displayed on the first line) in the Instruction Register-IR and then followed by writing the ASCII code of the character or address of the character stored on the CGROM or CGRAM on the LCD controller data register, as well as to display characters in the second row we must provide written instructions (C0H + DDRAM address where our character to be displayed on the second line) in the Instructions Register-IR and then followed by writing the ASCII code or address of the character on CGROM or CGRAM on the LCD controller data register.

As mentioned above, to display a character (ASCII) you want to show on the LCD, you need to send the ASCII code to the LCD controller data register-DR. For characters from CGROM and CGRAM we only need to send the address of the character where the character is stored; unlike the character of the ASCII code, we must write the ASCII code of the character we want to display on the LCD controller data register to display it. For special characters stored on CGRAM, one must first save the special character at the CGRAM address (prepared 64 addresses, namely addresses 0–63); A special character with a size of 5 × 8 (5 columns × 8 lines) requires eight consecutive addresses to store it, so the total special characters that can be saved or stored on the CGRAM addresses are only eight (8) characters. To be able to save a special character at the first CGRAM address we must send or write 40H instruction to the Instruction Register-IR followed by writing eight consecutive bytes of the data in the Data Register-DR to save the pattern/image of a special character that you want to display on the LCD [9, 10].

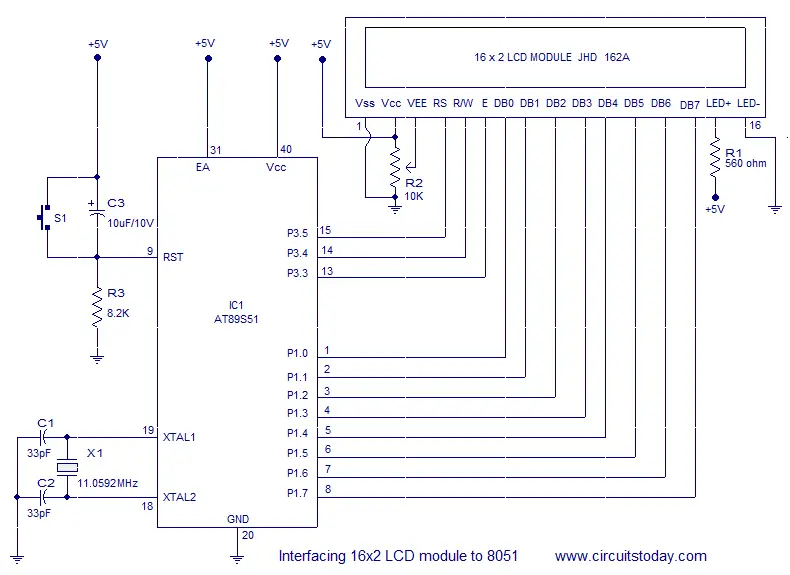

We can easily connect this LCD module (LCD + controller) with MCS51, and we do not need any additional electronic equipment as the interface between MCS51 and it; This is because this LCD works with the TTL logic level voltage—Transistor-Transistor Logic.

The voltage source of this display is +5 V connected to Pin 2 (VCC) and GND power supply connected to Pin 1 (VSS) and Pin 16 (GND); Pin 1 (VSS) and Pin 16 (GND) are combined together and connected to the GND of the power supply.

Pins 7–14 (8 Pins) of the display function as a channel to transmit either data or instruction with a channel width of 1 byte (D0-D7) between the display and MCS51. In Figure 6, it can be seen that each Pin connected to the data bus (D0-D7) of MCS51 in this case P0 (80h); P0.0-P0.7 MCS-51 connected to D0-D7 of the LCD.

Pins 4–6 are used to control the performance of the display. Pin 4 (Register Select-RS) is in charge of selecting one of the 2 display registers. If RS is given logic 0 then the selected register is the Instruction Register-IR, otherwise, if RS is given logic 1 then the selected register is the Data Register-DR. The implication of this selection is the meaning of the signal sent down through the data bus (D0-D7), if RS = 0, then the signal sent from the MCS-51 to the LCD is an instruction; usually used to configure the LCD, otherwise if RS = 1 then the data sent from the MCS-51 to the LCD (D0-D7) is the data (object or character) you want to display on the LCD. From Figure 6 Pin 4 (RS) is connected to Pin 16 (P3.6/W¯) of MCS-51 with the address (B6H).

Pin 5 (R/W¯)) of the LCD does not appear in Figure 6 is used for read/write operations. If Pin 5 is given logic 1, the operation is a read operation; reading the data from the LCD. Data will be copied from the LCD data register to MCS-51 via the data bus (D0-D7), namely Pins 7–14 of the LCD. Conversely, if Pin 5 is given a voltage with logical 0 then the operation is a write operation; the signal will be sent from the MCS51 to LCD through the LCD Pins (Pins 7–14); The signal sent can be in the form of data or instructions depending on the logic level input to the Register Select-RS Pin, as described above before if RS = 0 then the signal sent is an instruction, vice versa if the RS = 1 then the signal sent/written is the data you want to display. Usually, Pin 5 of the LCD is connected with the power supply GND, because we will never read data from the LCD data register, but only send instructions for the LCD work configuration or the data you want to display on the LCD.

Pin 6 of the LCD (EN¯) is a Pin used to enable the LCD. The LCD will be enabled with the entry of changes in the signal level from high (1) to low (0) on Pin 6. If Pin 6 gets the voltage of logic level either 1 or 0 then the LCD will be disabled; it will only be enabled when there is a change of the voltage level in Pin 6 from high logic level to low logic level for more than 1000 microseconds (1 millisecond), and we can send either instruction or data to processed during that enable time of Pin 6.

Pin 3 and Pin 15 are used to regulate the brightness of the BPL (Back Plane Light). As mentioned above before the LCD operates on the principle of continuing or inhibiting the light passing through it; instead of producing light by itself. The light source comes from LED behind this LCD called BPL. Light brightness from BPL can be set by using a potentiometer or a trimpot. From Figure 6 Pin 3 (VEE) is used to regulate the brightness of BPL (by changing the current that enters BPL by using a potentiometers/a trimpot). While Pin 15 (BPL) is a Pin used for the sink of BPL LED.

4RSRegister selector on the LCD, if RS = 0 then the selected register is an instruction register (the operation to be performed is a write operation/LCD configuration if Pin 5 (R/W¯) is given a logic 0), if RS = 1 then the selected register is a data register; if (R/W¯) = 0 then the operation performed is a data write operation to the LCD, otherwise if (R/W¯) = 1 then the operation performed is a read operation (data will be sent from the LCD to μC (microcontroller); it is usually used to read the busy bit/Busy Flag- BF of the LCD (bit 7/D7).

5(R/W¯)Sets the operating mode, logic 1 for reading operations and logic 0 for write operations, the information read from the LCD to μC is data, while information written to the LCD from μC can be data to be displayed or instructions used to configure the LCD. Usually, this Pin is connected to the GND of the power supply because we will never read data from the LCD but only write instructions to configure it or write data to the LCD register to be displayed.

6Enable¯The LCD is not active when Enable Pin is either 1 or 0 logic. The LCD will be active if there is a change from logic 1 to logic 0; information can be read or written at the time the change occurs.

I decided to design this project on my Father"s birthday. I searched around, and learned how to print text onto a display. I then designed a system to print the text on each line, and if it gets too long to print an ellipsis. After that, I streamlined it to just under 60 lines of code (including visual breaks). For my project, I used an Arduino Nano, because that"s what I had laying around, but you can use any Arduino you wish, and it should work the same.

As I’m now delving into the world of computer engineering, I thought I’d take you along in a series of tutorials on programming the 8051 microcontroller using Assembly.

You can view my complete compilation of tutorials in this Github repository, and the code for this tutorial in this folder. Since I’m on break from university and don’t have access to the cool electronics from our lab, I’ll be using MultiSim to construct and program the microcontroller circuits. (You can download MultiSim on Windows with a free 7-day evaluation, extended to 45 days upon request.)

In this tutorial, we’ll interface the 8051 microcontroller with an LCD and display a blinking “Hello World” message. LCDs are widely used in electronics for displaying messages and data, so hopefully you can apply what you learn here to your other projects!

8051 microcontroller (MCU). Built with 40 pins, 4KB of ROM storage, 128 bytes of RAM storage, and 2 16-bit timers. It consists of four 8-bit input/output (I/O) ports, each with bidirectional ability, i.e., the ability to receive data as input or send data as output. We will use these ports to interface with the LCD, and primarily configure the ports to output data to the LCD.

LCD (Liquid Crystal Display). Electronic display module. Here we use a 16x2 LCD, which means there are two lines and each can display 16 characters. In this LCD, each character is displayed in a 5x7 pixel matrix.

Crystal. Generates clock pulses required for the synchronization of all internal operations. We connect it to pins XTAL1 and XTAL2 of the MCU. Here we use a frequency of 11MHz.

Bussed three-line resistor R1. Serves as pull-up resistor for port 0 pins (port 0 always requires external pull-up resistors). Here we use a resistance of 10K.

Now let’s dive a bit deeper and take a look inside the LCD to see what’s going on. Below is a block diagram of the 16x2 LCD, adapted from this source and the HD44780U (LCD-II) datasheet. It may be a bit overwhelming, but we’ll break it down.

Let’s start with a high-level overview of the 16 pins of LCD module. When looking at a 16x2 LCD, you’ll see something similar to the figures below. The first is a representation of an LCD in MultiSim, and the second is an actual HD44780 LCD. You’ll only see 14 pins on the MultiSim representation since the backlight pins aren’t necessary.

Command register. Stores command codes, such as those to clear the display, set the cursor, and read/write data. Some common commands are shown below, where the codes are given by the values of RS, RW, and D0-D7.

Display Data RAM (DDRAM). Stores display data represented in 8-bit character codes. Each address in DDRAM corresponds to a position on the LCD, shown in the figure below.

Character Generator ROM (CGROM). Stores all permanent character patterns, e.g., letters of the alphabet. It generates 5 × 7 dot (pixel) character patterns from the 8-bit character codes in DDRAM. (If you’re not using the cursor, it’s 5 x 8.) Note that the patterns are stored such that their memory address is equivalent to the ASCII code for that pattern.

Step 1: Define custom characterSend address of CGRAM as a command to LCD to store custom character in that location. The (hex) address of the first character you define would be 40, the second would be 48, etc.

Step 2: Display custom characterSet the LCD cursor where you want to display your custom character. E.g., if it’s the beginning of the first line, send command 80 (hex).

DDRAM stores the ASCII code of custom character. (In this case, since the ASCII code is in the range mapped to CGRAM, it uses the patterns stored there to generate the character display.)

Display controller matches ASCII code of custom character in DDRAM with the CGRAM address and displays it on the LCD according to the character pattern in CGRAM.

Busy flag (BF). Checks the internal status of the LCD. When the busy flag is 1, the LCD is still executing previously-received commands and the next instruction will not be accepted. When the busy flag is 0, the LCD is ready to accept new information and the next instruction can be written.

LCD driver. Receives low-level instructions and turns them into waveforms for controlling commons (COM) and segments (SEG), i.e., sub-units of the display. (For a good explanation of this, see this pdf).

Now that we have some background on the LCD structure, let’s discuss the control pins a bit more. Recall from the section on LCD pins that there are three signals that the microprocessor uses to control the data transfer with the LCD module. A summary of these pins and their functions is given in the table below.

RW (read/write). This pin switches between writing data to the LCD and reading data from the LCD by setting RW = 0 or RS = 1, respectively. (RW is usually set to 0 since only the “Get status” instruction requires it.)

E (enable). This pun functions as the command/data latching signal for the LCD. When E=0, the LCD does not care what is happening with RW, RS, and the data bus lines. When E = 1, the LCD is processing the incoming data. However, it is really an edge-triggered pin, in particular negative edge-triggered. This means the LCD will latch in whatever is on the Data Bits and process it on the falling edge of the E signal, i.e., transitioning from high (1) to low (0).

The diagram below shows the timing for the LCD write cycle, demonstrating the interactions between the RS, RW, E, and data (D0-D7) signals. All 8 data signals are grouped together in the bottom row as their individual values don’t matter in terms of influencing the events of the cycle.

At event 1, the RW signal is set low to indicate the LCD is ready to accept data, i.e., the MCU can write data. RS is set as high or low depending on whether the MCU is writing data or commands, respectively. The data signals are ignored during this period.

When the MCU has information to send to the LCD, it loads data to the Data Bits and then asserts the E signal high at event 2 to indicate the data is available to read.

At some point in the interval between events 2 and 4 (i.e., while E is high), the data byte is sent to the data lines and the LCD reads the data bus (event 3). The next region is labeled “valid data,” as this is the actual data that will be written to the LCD.

On the falling edge of the E signal at event 4, the LCD latches the data and the data is no longer available on the data bus. The data must not actually change until data hold time is met at event 5. The RS, RW, and data lines are all free to change to other values after event 5. The only thing that you can’t do is bring E high again too soon, as a certain time buffer is required between writes to the device.

If we put all that we’ve learned together about the LCD structure and programming the control pins, we end up with a diagram that looks as follows. (Note that this represents “write mode,” i.e., RW = 0, and only considers CGROM for simplicity.)

In Assembly, any sort of conditional jump instruction (e.g.,JNC, JNZ, DJNZ) can be used for implementing for loops, but most often we use DJNZ (decrement and jump if not zero). In this directive, the register is decremented; if not zero, it jumps to the target address referred to by the label.

The structure of a for loop in Assembly is shown in the code below. Prior to the start of the loop a register is loaded with the number of iterations you desire. Once we arrive at the end of the loop, we use theDJNZ directive, which combines the register decrement and the jump back to the beginning of the loop.

Similar to functions in high-level programming, subroutines are “self-contained” pieces of code in a program that accomplish specific sub-tasks. In a given program, we often need to perform a particular sub-task many times on different data values. Rather than repeat the same block of instructions every time, we can package the instructions in a subroutine to call upon when needed.

A subroutine is called by transferring control to its entry point, so when the subroutine completes its execution, it needs to return control back to the calling routine. Therefore, whenever we create a subroutine, we end it with aRET (return) instruction.

In assembly code, theEQU directive gives a symbolic name (label) to a numeric constant, a register-relative value or a PC-relative value. It is essentially the same as setting a variable in higher-level programming languages.

Since we will use the RS, RW, and E pins a lot, we’ll assign symbolic names to the corresponding pins we’ve chosen (which depend on the wiring of the MCU to the LCD). In the circuit schematic above, you can see that bits 0, 1, and 2 of port 0 on the MCU have been wired to the RS, RW, and E pins, respectively.

We’ll also letDATA_PORT correspond to port 2, as bits 0–7 of port 2 are connected to pins D0-D7 of the LCD. We’ll discuss the labels defined in lines 6–7 in the section on the byte-looping subroutine.

Let’s say that rather than using the symbolic namesRS, RW, and E, we used P0.0, P0.1, and P0.2 everywhere. The first disadvantage of this is that if you changed the wiring such that the LCD control pins were connected to port 2 instead of port 0, you would have to replace every instance of P0 with P2. In the case of using variables, you would only have to change the defined ports and bits in the EQU statements.

The second disadvantage is readability. Looking through the code, you might forget, for example, thatP0.0 corresponds to RS. Using (well-named) variables eliminates this problem.

In Assembly, theDB (define byte) directive defines a byte-size variable, which can be in decimal, binary, hex, or ASCII format. In the code below, hex format is indicated by appending an “H” to the numerical value, and ASCII format is indicated by placing characters in quotation marks. (The assembler will assign the ASCII code for the characters automatically.) DB followed by multiple operands simply defines a succession of bytes. Note that if the operand is a string, it is already a succession of bytes, as each character takes one byte in memory.

We can access the data we’ve defined by assigning labels before the directives. In other words, we create variables storing the data. Later, we’ll use these variables to load the data in the main program.

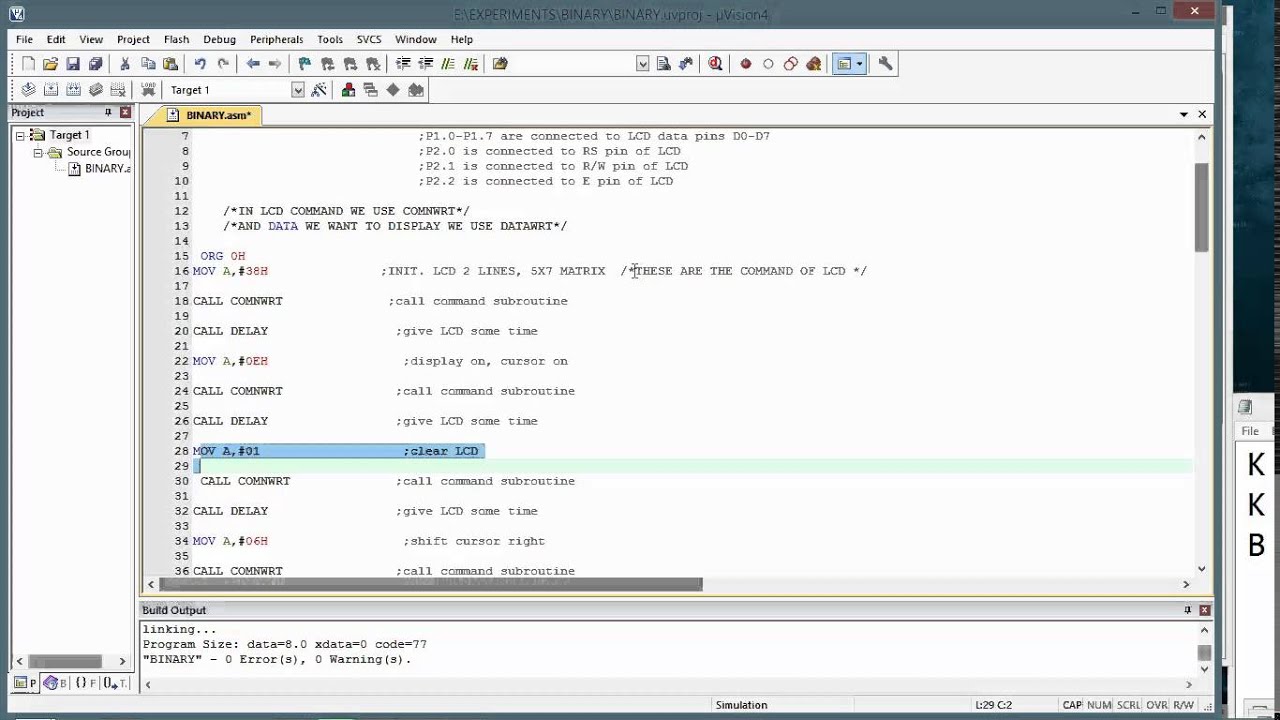

This, in effect, creates a lookup table at theINIT_CMND address. We can think of each command as an entry in a table, with 38H being the first entry, 0EH being the 2nd, and 06H being the 3rd. The value of each entry can be accessed via its index in the table, which we will see come into play when we write both commands and data to the LCD one byte at a time.

We define variablesLINE1 and LINE2, containing the commands to bring the cursor to lines 1 and 2 in a similar fashion. Finally, we define variables DATA1 and DATA2, containing the data to display on lines 1 and 2 of the LCD.

Proper delays between actions in embedded systems are important so that the system has time to execute instructions. In our system, there are two ways we can ensure the LCD staggers its internal operations:Using just delays

In practice, it is recommended to use the second method, as the delay produced is almost exactly the amount of time the LCD needs for processing. However, for our purposes, we’ll stick with the first method, which is simpler but serves the same purpose as long as the delay is appropriate. (For an example of method two, see this article.)

One classic way to make a delay is to use nested decrement loops. Every time the inner loop counts down to 0, then the next decrements, and so on. The code for the delay subroutine we’ll use is shown below.

We can calculate the length of the delay our subroutine produces by analyzing the number of machine cycles (MC) taken for each instruction and taking into account the number of repetitions. We’ll break down our calculations by the inner and outer loops.

Now, we can find the delay in microseconds (us). The machine cycle for a system of 11.0592 MHz is 1.085 us, so the total delay of our delay subroutine is:

As you can see in the excerpts of code above, setting each pin low or high is relatively straightforward. TheCLR directive is used for the former and the SETB directive is used for the latter.

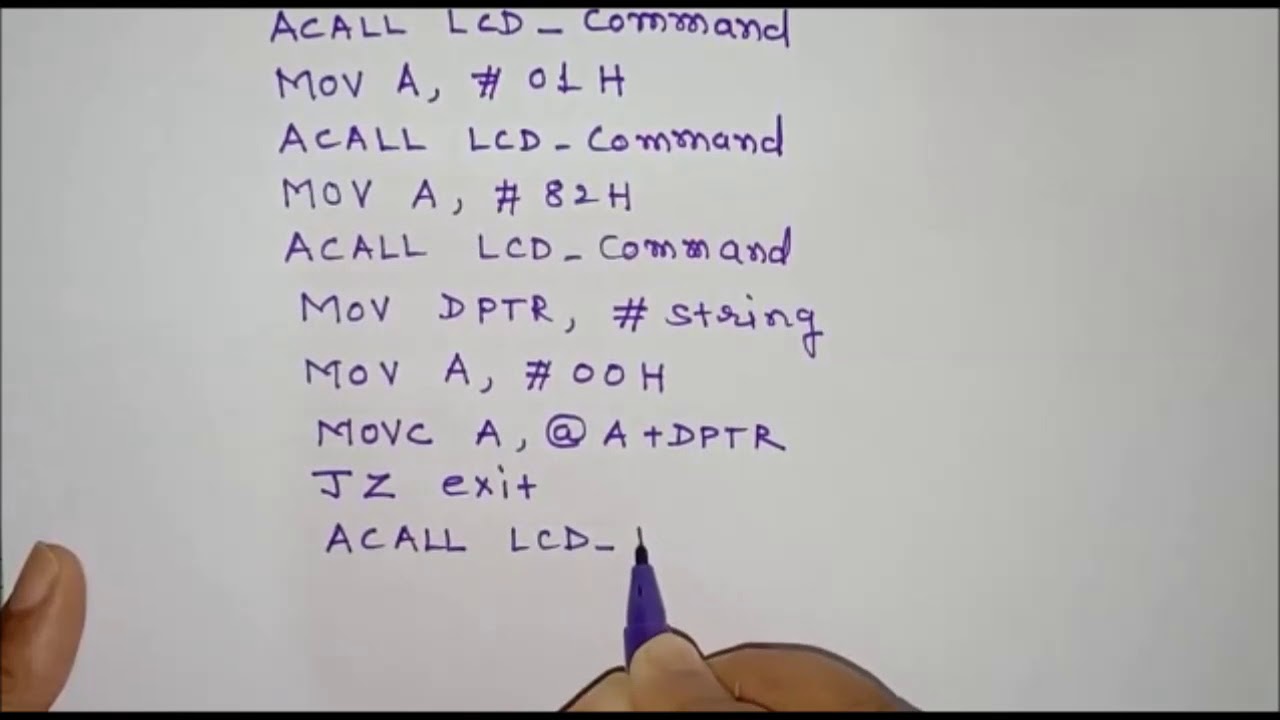

Understanding the first step, loading the data port, was more difficult for me, so let’s dive a bit deeper. In both excerpts, lines 3–4 correspond to step 1. The values of A (the accumulator register) and the DPTR (data pointer) function as parameters passed to the subroutine, together addressing the desired byte of data or command in code space. Here’s how it works:The DPTR points to the start of the lookup table.

The GIF below shows a visual of this process. Here, DPTR points toDATA1 and A iterates through each character of the data. (As a side note, a great way to debug your code is to check the values of registers at various “checkpoints.”)

Since we write data and commands one byte at a time, we now define a subroutine that loops through each entry in a given lookup table (pointed to by DPTR) and sends it to the LCD.

Since Assembly is a low-level programming language, and thus cannot be object-oriented, we go about this using the following method:A for loop iterates for a number of times equal to the number of entries (bytes) in the table.

Going back to the section on assigning symbolic names, you’ll see that we assign register 0 (R0) the symbolic nameNBYTES, and use it for storing the number of bytes in a table of data or commands. We also assign register 1 (R1) the symbolic name BYTE_IDX, and use it for tracking the current iteration we’re at when looping through the bytes.

You’ll notice from the code excerpt below that we increment A indirectly via the value ofBYTE_IDX. We do this because the WRT_DATA and WRT_CMND subroutines make use A for storing table entries, and simply incrementing A would make the index have a large offset.

Now that we’ve defined all of our subroutines, we can create the main body of our program. We begin by initializing the LCD with the commands in theINIT_CMND table. We first point the DPTR to the table and then specify the number of bytes the table has — 3 since there are 3 commands. After these “parameters” are set, we can call the SEND_CMND_BYTES subroutine.

As described for the initialization process, every time we prepare to send commands or data to the LCD, we point the DPTR to the appropriate table and specify the number of entries.

Congratulations, we made it to the end! We can finally put everything together. Remember to check out my Github for the program and MultiSim files, as well as other 8051 projects!

This repository contains all the code for interfacing with a 16x2 character I2C liquid-crystal display (LCD). This accompanies my Youtube tutorial: Raspberry Pi - Mini LCD Display Tutorial.

During the installation, pay attention to any messages about python and python3 usage, as they inform which version you should use to interface with the LCD driver. For example:

It is possible to define in CG RAM memory up to 8 custom characters. These characters can be prompted on LCD the same way as any characters from the characters table. Codes for the custom characters are unique and as follows:

This is demo showcases how extended strings could be used. Extended strings can contain special placeholders of form {0xFF}, that is, a hex code of the symbol wrapped within curly brackets. Hex codes of various symbols can be found in the following characters table:

For example, the hex code of the symbol ö is 0xEF, and so this symbol could be printed on the second row of the display by using the {0xEF} placeholder, as follows:

If you want to combine placeholder to write a symbol {0xFF} with the native Python placeholder {0} for inserting dome data into text, escape the non-native placeholders. Here is an example:

This is a demo of a graphical progress bar created with custom characters. This bar could be used, for example, for showing the current level of battery charge.

This is a script that shows a famous quote, a currency conversion pair of your choice and the weather of a city. It also shows the last three characters from your ip address, the date in DDMM format and the hour in HH:MM format

In order to use the script, you need to get API key tokens for both exchange rate services and the weather api. Once you"ve done that, edit the script to put your tokens in the USER VARIABLES section.

A city/country string is also needed to show weather info for such city. Search for your city on openweathermap.org and take note of the City,country string and put it in the script.London,gb is given as an example.

Thank you for you interest in learning how to contribute to this repository. We welcome contributions from novices to experts alike, so do not be afraid to give it a try if you are new to git and GitHub. First, however, take a few minutes to read our CONTRIBUTING.md guide to learn how to open Issues and the various sorts of Pull Requests (PRs) that are currently accepted.

If you haven"t bought the LCD display yet you can start with Serial.print and when that is running as you want you can then easily transfer everything to the LCD display.

If you haven"t bought the LCD display yet you can start with Serial.print and when that is running as you want you can then easily transfer everything to the LCD display

I have already run the "hello world" and it showed up on screen but I can"t do the same with my own code so I want to know how to run my code, I mean timers of pin9,pin8, pin7, pin6, pin5. Also when it will finished I want to show up "end of process" phrase on screen.

As we don"t know if you are using an LCD with I2C or SPI or "direct" wiring - we can"t hepl you with the constructor. But you told us, that the "Hello World" showed up in the display.

Define the output pins and give them "readable" names, such as LED_RED = 5, LED_BLUE = 6 etc.; this makes a code better readable and "debuggable" - maybe not needed here, but it"s a good habit, especially when you start with bigger codes or if you are expanding existing ones.

and then i press button Start, was written "Start" on the LCD...then I want to display a timer, such as: [ top LED - 1(led-2; led-3; led-4; led-5) and below the appropriate time (Timer) (seconds) ]... and finally write "process completed" ))) it will be perfect for me... Of course if it is possible, if not, then the timer to appear !... in advance thank you very much ...

Could I use these libraries in my assembly code using mplab ide + c18 ? or I still have to write an assembly driver for the display (lot of time lost)?

http://ww1.microchip.com/downloads/en/DeviceDoc/39629c.pdf and the PIC-LCD"s schematic: https://www.olimex.com/Products/PIC/Development/PIC-LCD/resources/PIC-LCD-SCH-REV-D.pdf and finally the example to run in MPLAB: https://www.olimex.com/Products/PIC/Development/PIC-LCD/resources/PIC-LCD_LCD.zip. Now you open the datasheet and go to page 257, PART22: LIQUID CRYSTAL DISPLAY (LCD) DRIVER MODULE. There are a lot of good tables and registers you might want to check but we will head for the table on page 279 (table 22-6). Now you have also to open the schematic of the PIC-LCD and zoom at the LCD part and also have the schematic of the display open. The rows of display table are pins of the processor with names S45 to S0 (and some extra names), that is why you need to check which pin is exactly representing your chosen symbol in the board"s schematic(they are not shown in display"s datasheet since you might use other video controller - not the mentioned PIC). After that you should see which of the four COMs it represents - depending on the row(being in second row means COM2, being in third row means COM3, etc). Then in PIC18F8490"s datasheet (Table 22-6) you find the box which contains the Sxx (the number from the schematic for example S45 or S32) concatenated with Cx (COM number) - this will give you the register and the bit you need to set.

Please also check page 278 (22.11 Configuring the LCD Module). These are things to consider before setting any part of the module. Remember the above is true only for PIC18F8490, if you use MSP processor you have to do approximately the same but using the respective processor datasheet.

I don"t know if I explained it very well but this is the best explanation I can pull on the subject. The single page about the display is sufficient enough for the display, the rest depends on the video controller"s datasheet.

This tutorial includes everything you need to know about controlling a character LCD with Arduino. I have included a wiring diagram and many example codes. These displays are great for displaying sensor data or text and they are also fairly cheap.

The first part of this article covers the basics of displaying text and numbers. In the second half, I will go into more detail on how to display custom characters and how you can use the other functions of the LiquidCrystal Arduino library.

As you will see, you need quite a lot of connections to control these displays. I therefore like to use them with an I2C interface module mounted on the back. With this I2C module, you only need two connections to control the LCD. Check out the tutorial below if you want to use an I2C module as well:

Makerguides.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to products on Amazon.com.

These LCDs are available in many different sizes (16×2 1602, 20×4 2004, 16×1 etc.), but they all use the same HD44780 parallel interface LCD controller chip from Hitachi. This means you can easily swap them. You will only need to change the size specifications in your Arduino code.

For more information, you can check out the datasheets below. The 16×2 and 20×4 datasheets include the dimensions of the LCD and in the HD44780 datasheet you can find more information about the Hitachi LCD driver.

Most LCDs have a built-in series resistor for the LED backlight. You should find it on the back of the LCD connected to pin 15 (Anode). If your display doesn’t include a resistor, you will need to add one between 5 V and pin 15. It should be safe to use a 220Ω resistor, but this value might make your display a bit dim. You can check the datasheet for the maximum current rating of the backlight and use this to select an appropriate resistor value.

After you have wired up the LCD, you will need to adjust the contrast of the display. This is done by turning the 10 kΩ potentiometer clockwise or counterclockwise.

Plug in the USB connector of the Arduino to power the LCD. You should see the backlight light up. Now rotate the potentiometer until one (16×2 LCD) or 2 rows (20×4 LCD) of rectangles appear.

In order to control the LCD and display characters, you will need to add a few extra connections. Check the wiring diagram below and the pinout table from the introduction of this article.

We will be using the LCD in 4-bit mode, this means you don’t need to connect anything to D0-D3. The R/W pin is connected to ground, this will pull the pin LOW and set the LCD to WRITE mode.

To control the LCD we will be using the LiquidCrystal library. This library should come pre-installed with the Arduino IDE. You can find it by going to Sketch > Include Library > LiquidCrystal.

The example code below shows you how to display a message on the LCD. Next, I will show you how the code works and how you can use the other functions of the LiquidCrystal library.

After including the library, the next step is to create a new instance of the LiquidCrystal class. The is done with the function LiquidCrystal(rs, enable, d4, d5, d6, d7). As parameters we use the Arduino pins to which we connected the display. Note that we have called the display ‘lcd’. You can give it a different name if you want like ‘menu_display’. You will need to change ‘lcd’ to the new name in the rest of the sketch.

In the loop() the cursor is set to the third column and first row of the LCD with lcd.setCursor(2,0). Note that counting starts at 0, and the first argument specifies the column. If you do not specify the cursor position, the text will be printed at the default home position (0,0) if the display is empty, or behind the last printed character.

Next, the string ‘Hello World!’ is printed with lcd.print("Hello World!"). Note that you need to place quotation marks (” “) around the text. When you want to print numbers or variables, no quotation marks are necessary.

The LiquidCrystal Arduino library has many other built-in functions which you might find useful. You can find an overview of them below with explanation and some code snippets.

Clears the LCD screen and positions the cursor in the upper-left corner (first row and first column) of the display. You can use this function to display different words in a loop.

This function turns off any text or cursors printed to the LCD. The text/data is not cleared from the LCD memory. This means it will be shown again when the function display() is called.

Scrolls the contents of the display (text and cursor) one space to the left. You can use this function in the loop section of the code in combination with delay(500), to create a scrolling text animation.

This function turns on automatic scrolling of the LCD. This causes each character output to the display to push previous characters over by one space. If the current text direction is left-to-right (the default), the display scrolls to the left; if the current direction is right-to-left, the display scrolls to the right. This has the effect of outputting each new character to the same location on the LCD.

The following example sketch enables automatic scrolling and prints the character 0 to 9 at the position (16,0) of the LCD. Change this to (20,0) for a 20×4 LCD.

With the function createChar() it is possible to create and display custom characters on the LCD. This is especially useful if you want to display a character that is not part of the standard ASCII character set.

Technical info: LCDs that are based on the Hitachi HD44780 LCD controller have two types of memories: CGROM and CGRAM (Character Generator ROM and RAM). CGROM generates all the 5 x 8 dot character patterns from the standard 8-bit character codes. CGRAM can generate user-defined character patterns.

/* Example sketch to create and display custom characters on character LCD with Arduino and LiquidCrystal library. For more info see www.www.makerguides.com */

After including the library and creating the LCD object, the custom character arrays are defined. Each array consists of 8 bytes, 1 byte for each row. In this example 8 custom characters are created.

In this article I have shown you how to use an alphanumeric LCD with Arduino. I hope you found it useful and informative. If you did, please share it with a friend that also likes electronics and making things!

I would love to know what projects you plan on building (or have already built) with these LCDs. If you have any questions, suggestions, or if you think that things are missing in this tutorial, please leave a comment down below.

I decided to design this project on my Father"s birthday. I searched around, and learned how to print text onto a display. I then designed a system to print the text on each line, and if it gets too long to print an ellipsis. After that, I streamlined it to just under 60 lines of code (including visual breaks). For my project, I used an Arduino Nano, because that"s what I had laying around, but you can use any Arduino you wish, and it should work the same.

Using scripting interface directly is recommended for simple tasks not requiring any control structures. For complex tasks, using WinSCP .NET assembly is preferred.

For automation, commands can be read from a script file specified by /script switch, passed from the command-line using the /command switch, or read from standard input of winscp.com.

When running commands specified using /script or /command, batch mode is used implicitly and overwrite confirmations are turned off. In an interactive scripting mode, the user is prompted in the same way as in GUI mode. To force batch mode (all prompts are automatically answered negatively) use the command overwrite confirmation prompt would be answered negatively, making overwrites impossible).

WinSCP executables return exit code 1 when any command is interrupted due to an error or any prompt is answered Abort (even automatically in batch mode). Otherwise it returns the exit code 0.

WinSCP automatically resolves %TIMESTAMP[rel]#format% to a real time (optionally to a past or future time) with the given format. The format may include yyyy for year, mm for month, dd for day, hh for hour, nn for minute and ss for second. For example, the %TIMESTAMP#yyyy-mm-dd% resolves to 2016-06-22 on 22 June 2016. See other formats you can use.

The optional rel part, with syntax [-+]time[YDHNS], produces past (-) or future (+) timestamps. One of the following units must be used: Y (years), D (days), H (hours), N (minutes) or S (seconds). For example, the %TIMESTAMP-1D#yyyy-mm-dd% (the -1D meaning one day in the past) resolves to 2016-06-21 on 22 June 2016.

You can find the key fingerprint on Server and Protocol Information Dialog. You can also copy the key fingerprint to clipboard from the confirmation prompt on the first (interactive) connection using Copy key fingerprints to clipboard command (in the script, use SHA-256 fingerprint of the host key only).

If you are going to run the script under a different account (for example using the Windows Task Scheduler), make sure the script does not rely on a configuration settings that might differ on the other account. When using registry as configuration storage, the settings are accessible only for your Windows account. Ideally, make sure the script does not rely on any external configuration, to make it completely portable. Note that the configuration also includes verified SSH host keys and FTPS/WebDAVS TLS/SSL certificates.

The best way to do that is to configure all the options you need using script commands only (session URL), or if no such command is available, using raw site settings and raw configuration. Finally force scripting mode to start with the default configuration using

Dr Pan: Hello, Greg. STN is the abbreviation for Super Twisted Nematic. The main difference between TN, HTN, STN and FSTN LCD is the view angle. From the definition, the maximum view angle of STN LCD is 210~255 degree. Take this STN positive LCD for example. The view angle is 12 o’clock direction and it can be seen very clearly in the full view angle: 12 o’clock direction, 3 o’clock direction, 6 o’clock direction, 9 o’clock direction and the front side.

When it is a positive and reflective display, it can display without LED backlight; when it is a positive and transmissive/ transflective display, it can’t display without LED backlight, we have two options for the background color: grey background and blue letters, yellow-green background and black/blue letters.

When it is a negative and transmissive/ transflective display, it can’t display without LED backlight, the background is blue and the color of the letters is the color of LED backlight.

By the way, no matter it is a positive or negative display, the background color is affected by the color of LED backlight on some level. That is why the color of LED backlight is usually white.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey