tft lcd polarisation factory

Application: TV Laptop Mobile phone LCD Polarizer, polarized sunglasses, polarized fishing glasses, polarizing microscope, polarizing camera filter, photography, light control windows, polariscope, rotating filter with using two polarizers, photoelastic stress analysis, glare reduction, motion illusion, polarized dental photography.

Do you want to purchase eco-friendly, energy saving and high quality tft-lcd polarizer film made by professional manufacturers? With hundreds of professional staff in our factor…

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

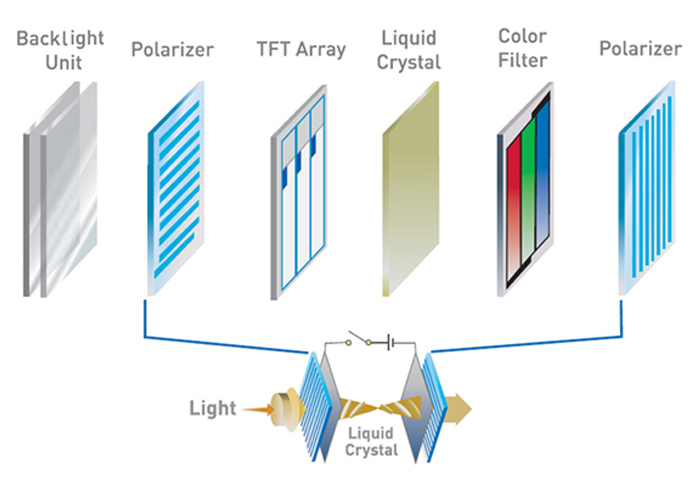

A liquid crystal display (LCD) has liquid crystal material sandwiched between two sheets of glass. Without any voltage applied between transparent electrodes, liquid crystal molecules are aligned in parallel with the glass surface. When voltage is applied, they change their direction and they turn vertical to the glass surface. They vary in optical characteristics, depending on their orientation. Therefore, the quantity of light transmission can be controlled by combining the motion of liquid crystal molecules and the direction of polarization of two polarizing plates attached to the both outer sides of the glass sheets. LCDs utilize these characteristics to display images.

An LCD consists of many pixels. A pixel consists of three sub-pixels (Red/Green/Blue, RGB). In the case of Full-HD resolution, which is widely used for smartphones, there are more than six million (1,080 x 1,920 x 3 = 6,220,800) sub-pixels. To activate these millions of sub-pixels a TFT is required in each sub-pixel. TFT is an abbreviation for "Thin Film Transistor". A TFT is a kind of semiconductor device. It serves as a control valve to provide an appropriate voltage onto liquid crystals for individual sub-pixels. A TFT LCD has a liquid crystal layer between a glass substrate formed with TFTs and transparent pixel electrodes and another glass substrate with a color filter (RGB) and transparent counter electrodes. In addition, polarizers are placed on the outer side of each glass substrate and a backlight source on the back side. A change in voltage applied to liquid crystals changes the transmittance of the panel including the two polarizing plates, and thus changes the quantity of light that passes from the backlight to the front surface of the display. This principle allows the TFT LCD to produce full-color images.

A liquid crystal display (LCD) has liquid crystal material sandwiched between two sheets of glass. Without any voltage applied between transparent electrodes, liquid crystal molecules are aligned in parallel with the glass surface. When voltage is applied, they change their direction and they turn vertical to the glass surface. They vary in optical characteristics, depending on their orientation. Therefore, the quantity of light transmission can be controlled by combining the motion of liquid crystal molecules and the direction of polarization of two polarizing plates attached to the both outer sides of the glass sheets. LCDs utilize these characteristics to display images.

An LCD consists of many pixels. A pixel consists of three sub-pixels (Red/Green/Blue, RGB). In the case of Full-HD resolution, which is widely used for smartphones, there are more than six million (1,080 x 1,920 x 3 = 6,220,800) sub-pixels. To activate these millions of sub-pixels a TFT is required in each sub-pixel. TFT is an abbreviation for "Thin Film Transistor". A TFT is a kind of semiconductor device. It serves as a control valve to provide an appropriate voltage onto liquid crystals for individual sub-pixels. A TFT LCD has a liquid crystal layer between a glass substrate formed with TFTs and transparent pixel electrodes and another glass substrate with a color filter (RGB) and transparent counter electrodes. In addition, polarizers are placed on the outer side of each glass substrate and a backlight source on the back side. A change in voltage applied to liquid crystals changes the transmittance of the panel including the two polarizing plates, and thus changes the quantity of light that passes from the backlight to the front surface of the display. This principle allows the TFT LCD to produce full-color images.

[1] The present invention relates to a cutting method of a large size TFT-LCD panel and a liquid crystal display unit to enhance a simplicity of process facility and a speediness through solving a problem of an increase of facilities due to manufacturing TFT-LCD panels of respective sizes and reducing a subsequently increased cost by enabling a mass production of a various size of TFT-LCD panels in one manufacturing line through using a TFT-LCD panel cut in a desired size that is manufactured in large size. Background Art

[5] Most of all as an outline, one pixel (composed of R. G. B. three sub-pixels) in the thin film transistor (TFT) - LCD is approximately as fine as 0.3 mm wide.

[6] Of course, the TFT included in the pixel is smaller than the pixel. Moreover, in order to meet a resolution of 1600x1200, 1,920,000 pixels are required and 5,760,000 TFTs are necessary if the sub-pixels are considered. Therefore, an overall process is very precise and demands a level of semiconductor process.

TFT process, a color filter (CF) process, a cell process and a module process. The cell process makes one panel with two glasses undergone the TFT process and the CF process. Then, the module process completes the manufacturing process by mounting the one TFT-LCD panel undergone the cell process in a real monitor or TV.

[8] First, the TFT process is the most basic core process for forming the most basic electrodes that provides an electrode for each cell. The process includes five process steps in order of forming a gate electrode, an insulating film, a semiconductor film, a data electrode, a protective film, and a pixel electrode that requires one or more pattern processes for each process step. Not only this pattern process that may be called a core

process in the processes of manufacturing the TFT-LCD panel is necessary in the TFT process but also a similar pattern process is necessary in the CF process.

TFT-LCD panel formed as hereinabove, the TFT-LCD panel is completed by providing a polarized plate on a surface of the TFT substrate and the CF substrate.

[11] The TFT-LCD panel of size demanded by a user may be produced in a large amount but the other TFT-LCD panel of less demand may be produced in only a limited amount since various sizes of the TFT-LCD panels completed as hereinabove require a difference in production line and in each process of the production line dependent on the sizes of the TFT-LCD panels. Disclosure of Invention Technical Problem

[13] The cutting method of a large size TFT-LCD panel of the present invention, provided to solve the hereinabove problems, has an object of enhancing a simplicity of process facility and speediness through solving a problem of an increase of facilities due to manufacturing TFT-LCD panels of different sizes and reducing a subsequently increased cost by enabling a mass production of a various size of TFT-LCD panels in one manufacturing line through using a TFT-LCD panel cut in a desired size that is manufactured in large size.

[14] The cutting method of a large size TFT-LCD panel formed as hereinabove can devise a simplicity in process and a profitability through solving a spatial enlargement and other costs increase due to an increase of facilities by equipping a facility"s process dependent on a size according to a production of TFT-LCD panels in various sizes, having an advantage of possibly producing a various size of the TFT-LCD panel asked by a user purpose or a user taste in a simple and convenient way, and solving an abandonment and reduction of the facilities due to a change in consumption dependent

[18] FIG. 4 illustrates a state of a scribe line set into a mid-depth of a color filter substrate and a thin film transistor substrate by diamond wheel in the cutting method of a large size TFT-LCD panel of the present invention.

[20] FIG. 6 illustrates a state completed after processing sealing a cut portion in the cutting method of a large size TFT-LCD panel of the present invention.

[27] In a completed large size TFT-LCD panel formed in a sequentially coupled configuration of a polarized plate, a color filter (CF) substrate, a liquid crystal layer, a thin film transistor (TFT) substrate and a polarized plate below the TFT substrate, a polarized plate stripping step that removes a portion of a predetermined width to be cut from the each polarized plate provided on a surface and an opposite surface of the large size TFT-LCD panel, a cutting location setting step that sets a portion not damaging a gate line and a data line of the TFT substrate through investigating a portion stripped in the polarized plate stripping step by microscope, a scribe line setting step that sets a first scribe line cutting the CF substrate into its mid-depth along the portion set in the cutting location setting step using a diamond wheel, a turning

over step that turns over the large size TFT-LCD panel to a side opposite from a side where a portion of the first scribe line is set after chucking one end of the large size TFT-LCD panel, a scribe line setting step that sets a second scribe line cutting the TFT substrate into its mid-depth in the stripped polarized plate portion along the portion set in the cutting location setting step which precisely corresponds with the set first scribe line using a diamond wheel after turning over the large size TFT-LCD panel, a tempering step that tempers for 30 minutes to form a natural crack in the scribe lines formed on the CF substrate and the TFT substrate of the large size TFT-LCD panel, a cutting step that cuts the CF substrate and the TFT substrate naturally cracked after the 30 minutes tempering step, and a sealing process step that sealing a cut portion formed in the cutting step, and

[28] In a completed large size TFT-LCD panel formed in a sequentially coupled configuration of a polarized plate, a color filter (CF) substrate, a liquid crystal layer, a thin film transistor (TFT) substrate and a polarized plate, a cutting location setting step that sets a portion to be cut, a scribe line setting step that sets a first scribe line cutting the CF substrate into its mid-depth along the portion set in the cutting location setting step using a diamond wheel, a turning over step that turns over the large size TFT-LCD panel to a side opposite from a side where a portion of the first scribe line is set after chucking one end of the large size TFT-LCD panel, a scribe line setting step that sets a second scribe line cutting the TFT substrate into its mid-depth along the portion set in the cutting line setting step which precisely corresponds with the set first scribe line, using a diamond wheel after turning over the large size TFT-LCD panel, a tempering step that tempers for 30 minutes to form a natural crack in the scribe lines formed on the CF substrate and the TFT substrate of the large size TFT-LCD panel, a cutting step that cuts the CF substrate and the TFT substrate naturally cracked after the 30 minutes tempering step, and a sealing process step that sealing a cut portion formed in the cutting step may accomplish the present invention object.

[29] Further, the present invention comprises a scribe line setting step that sets scribe lines simultaneously cutting the CF substrate and the TFT substrate into their mid-depths along the portions set in the cutting location setting step using a diamond wheel.

[30] The cutting method of a large size TFT-LCD panel further comprises a blocking off a light illuminated from a backlight through attaching a light blocking tape along a cut portion selected between the CF substrate and the TFT substrate or the both substrates or between the polarized plates located above the CF substrate and below the TFT substrate or the both polarized plates.

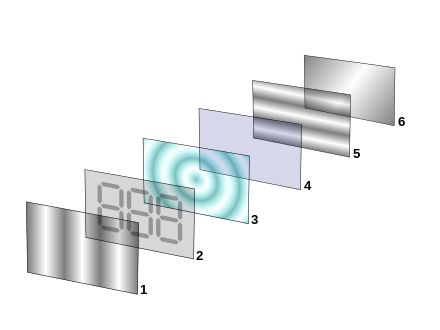

LCD panel 100 is formed in structure sequentially coupled of, a polarized plate 10, a color filter (CF) substrate 11, a liquid crystal layer 12, a thin film transistor (TFT) substrate 13 and a polarized plate 14.

[36] In order to cut the large size TFT-LCD panel 100 completed as hereinabove, a polarized plate stripping step is initially performed that removes a portion of a predetermined width to be cut from the each polarized plate 10 provided on a surface above the CF substrate 11 and an opposite surface below the TFT substrate 13.

[38] The TFT substrate 13 is exposed if the polarized plates 10 and 14 around the cutting portion are removed by its lengthwise direction. Since gate lines transferring a scanning signal and data line transferring a screen image signal are configured by innumerably crossing with each other and difficult to perceive by naked eyes, a cutting location setting step sets a portion not damaging the gate line and the data line of the TFT substrate through investigating a portion stripped on the polarized plate stripping step by microscope.

[43] To process a side opposite from a side where a portion of the first scribe line is set, the present step turns over the large size TFT-LCD panel 100 after chucking one end of the large size TFT-LCD panel 100.

[45] The present step sets a 2nd scribe line setting step cutting the TFT substrate 13 into its mid-depth in the portion of the stripped polarized plate 14 bonded with the TFT substrate 13 below along the portion set in the cutting location setting step which

precisely corresponds with the set first scribe line, using a diamond wheel after turning over the large size TFT-LCD panel 100. This step is also difficult and requires a skill of high precision to correspond with the set first scribe line.

[48] A natural crack is made if tempered for 30 minutes to form a natural crack in the scribe lines formed on the CF substrate 11 and the TFT substrate 13 of the large size TFT-LCD panel 100. Then, the air flows into a liquid crystal layer 12. If there is the air flow into the liquid crystal layer 12, the liquid crystal layer 12 is temporarily restricted from flowing out by the flowed in air.

[50] After the 30 minutes tempering step, the CF substrate 11 and the TFT substrate 13 are naturally cracked along the first scribe line and the second scribe line and the present step externally applies a certain amount of force in order to cut the large size TFT-LCD panel 100 along the scribe lines.

[52] The present step is the last step that applies a sealant 30 on a cut portion in the large size TFT-LCD panel 100 and the present invention is completed by applying the sealant 30.

[53] Through undergoing the process hereinabove, the large size TFT-LCD panel 100 is possible to be cut into a plural or multiple numbers without a many numbers of equipment and to meet a desired size of a demander or an operator.

[56] That is, in a large size TFT-LCD panel 100 completed of forming sequentially coupled, a polarized plate 10, a color filter (CF) substrate 11, a liquid crystal layer 12, a thin film transistor (TFT) substrate 13 and a polarized plate 14 below the TFT substrate 13, a cutting location setting step that sets a portion to be cut, a scribe line setting step that sets a first scribe line cutting the CF substrate 11 into its mid-depth along the portion set in the cutting location setting step using a diamond wheel, a turning over step that turns over the large size TFT-LCD panel 100 to a side opposite from a side where a portion of the first scribe line is set after chucking one end of the large size TFT-LCD panel 100, a scribe line setting step that sets a second scribe line cutting the TFT substrate 13 into its mid-depth along the portion set in the cutting location setting step corresponds with the set first scribe line, using a diamond wheel after turning over the large size TFT-LCD panel 100, a tempering step that tempers for

30 minutes to form a natural crack in the scribe lines formed on the CF substrate 11 and the TFT substrate 13 of the large size TFT-LCD panel 100, a cutting step that cuts the CF substrate 11 and the TFT 13 substrate naturally cracked after the 30 minutes tempering step, and a sealing process step that sealing a cut portion formed in the cutting step may configure the present invention.

[59] For example, after undergoing the sequentially processed cutting location setting steps of the first or the second exemplary embodiments through the polarized plate stripping step that removes a corresponding portion of a predetermined width to be cut from the polarized plates 10 and 14 provided on a surface of the CF substrate 11 and an opposite surface of the TFT substrate 13 like the first exemplary embodiment or without the polarized plate stripping step like the second exemplary embodiment, a scribe line setting step sets scribe lines simultaneously cutting the CF substrate 11 and the TFT substrate 13 into their mid-depths along the portion set in the cutting location setting step using a diamond wheel.

TFT substrate 13 by applying the same scribe line depth and the like enables not only an abridgement of the operation process but also a precise setting job.

[61] The present exemplary embodiment may or may not include the polarized plate stripping step like the first or second exemplary embodiment, and the subsequent steps may proceed in the same sequence as tempering step for the natural crack, cutting step cutting the CF substrate 11 and the TFT substrate 13 and sealing process step .

[62] Meanwhile, when a light from the backlight unit through the TFT-LCD panel 100 processed by the respective exemplary embodiments is illuminated to display a corresponding image, the image may be displayed with an image quality relatively unclear at a portion corresponding to the cutting portion.

[64] Here, the light blocking tape 20 may be attached in a range covering any cut portions of the CF substrate 11 and the TFT substrate 13 or the both substrates 11 and 13 as shown in FIG. 7.

10 bonded above with the CF substrate 11 or at a periphery of the polarized plate 14 bonded below with the TFT substrate 14 which are removed with the set cutting portion, may maximize a clearness of the screen quality when the light from the back light unit is illuminated on the cut portion of the TFT-LCD panel 100 completed by cutting into a desirable size.

[67] Meanwhile, as shown in FIG. 9 of other exemplary embodiment, a transparent tape is used to cover an outer peripheral edge of the CF substrate 11 and the TFT substrate 13 after sealing the outer peripheral edge with an ultraviolet sealant 31 while the CF substrate 11 and the TFT substrate 13 are in bonded state.

[68] Further, though not shown in the drawings, the peripheries of the CF substrate 11 and the TFT substrate 13 may be covered by tape-processing or may be fixed by clipping and the like.

[70] Further, FIG. 10 and FIG. 11 illustrate an application of the TFT-LCD panel according to the cutting method provided by the present invention. FIG. 10 is a brief exploded perspective view of a liquid crystal display unit. FIG. 11 is a brief cross sectional view of FIG. 10.

[71] As shown in FIG. 10 and FIG. 11, the cut processed TFT-LCD panel 100 equipped with the backlight unit (not shown in drawing) below undergoes a series of course coupling a top sash 2 corresponding to an upper frame with an accommodating frame 3 accommodating the TFT-LCD panel 100 and the backlight unit to be used for the liquid crystal display unit.

[72] Here, when the TFT-LCD panel 100 cut processed in a desired size according to the present invention is received in the top sash 2 and the accommodating frame 3, a realization of a clear screen may be difficult since a slight difference may be produced, not accurately fixing the TFT-LCD panel 100, and producing a flowing phenomena because of the internal difference.

[74] Accordingly, in order to prevent the flowing phenomena, that is the flowing phenomena of the received TFT-LCD panel 100, attaching a plurality of both-faces tape 4 at the outer peripheral edge on the top sash 2 surface and attaching a plurality of both-faces tape 4 at the outer peripheral edge on the accommodating frame 3 surface as well is preferable to completely prevent the flowing phenomena.

[76] Therefore, since a large size TFT-LCD panel may be miniaturized for an application to various video games, monitors or cell phone liquid crystal displays through cut processing the large size TFT-LCD panel without a separate manufacturing line for manufacturing process according to present invention, an industrial applicability expecting an effective reduction of manufacturing facility and its value may be recognized.

TFT-LCD was invented in 1960 and successfully commercialized as a notebook computer panel in 1991 after continuous improvement, thus entering the TFT-LCD generation.

Simply put, the basic structure of the TFT-LCD panel is a layer of liquid crystal sandwiched between two glass substrates. The front TFT display panel is coated with a color filter, and the back TFT display panel is coated with a thin film transistor (TFT). When a voltage is applied to the transistor, the liquid crystal turns and light passes through the liquid crystal to create a pixel on the front panel. The backlight module is responsible for providing the light source after the TFT-Array panel. Color filters give each pigment a specific color. The combination of each different color pixel gives you an image of the front of the panel.

The TFT panel is composed of millions of TFT devices and ITO (In TI Oxide, a transparent conductive metal) regions arranged like a matrix, and the so-called Array refers to the region of millions of TFT devices arranged neatly, which is the panel display area. The figure below shows the structure of a TFT pixel.

No matter how the design of TFT display board changes or how the manufacturing process is simplified, its structure must have a TFT device and control liquid crystal region (if the light source is penetration-type LCD, the control liquid crystal region is ITO; but for reflective LCD, the metal with high reflection rate is used, such as Al).

The TFT device is a switch, whose function is to control the number of electrons flowing into the ITO region. When the number of electrons flowing into the ITO region reaches the desired value, the TFT device is turned off. At this time, the entire electrons are kept in the ITO region.

The figure above shows the time changes specified at each pixel point. G1 is continuously selected to be turned on by the driver IC from T1 to TN so that the source-driven IC charges TFT pixels on G1 in the order of D1, D2, and Dn. When TN +1, gATE-driven IC is selected G2 again, and source-driven IC is selected sequentially from D1.

Many people don’t understand the differences between generations of TFT-LCD plants, but the principle is quite simple. The main difference between generations of plants is in the size of glass substrates, which are products cut from large glass substrates. Newer plants have larger glass substrates that can be cut to increase productivity and reduce costs, or to produce larger panels (such as TFT display LCD TV panels).

The TFT-LCD industry first emerged in Japan in the 1990s, when a process was designed and built in the country. The first-generation glass substrate is about 30 X 40 cm in size, about the size of a full-size magazine, and can be made into a 15-inch panel. By the time Acer Technology (which was later merged with Unioptronics to become AU Optronics) entered the industry in 1996, the technology had advanced to A 3.5 generation plant (G3.5) with glass substrate size of about 60 X 72 cm.Au Optronics has evolved to a sixth-generation factory (G6) process where the G6 glass substrate measures 150 X 185 cm, the size of a double bed. One G6 glass substrate can cut 30 15-inch panels, compared with the G3.5 which can cut 4 panels and G1 which can only cut one 15-inch panel, the production capacity of the sixth generation factory is enlarged, and the relative cost is reduced. In addition, the large size of the G6 glass substrate can be cut into large-sized panels, which can produce eight 32-inch LCD TV panels, increasing the diversity of panel applications. Therefore, the global TFT LCD manufacturers are all invested in the new generation of plant manufacturing technology.

The TRANSISTor-LCD is an acronym for thin-film TFT Display. Simply put, TFT-LCD panels can be seen as two glass substrates sandwiched between a layer of liquid crystal. The upper glass substrate is connected to a Color Filter, while the lower glass has transistors embedded in it. When the electric field changes through the transistor, the liquid crystal molecules deflect, so as to change the polarization of the light, and the polarizing film is used to determine the light and shade state of the Pixel. In addition, the upper glass is fitted to the color filter, so that each Pixel contains three colors of red, blue and green, which make up the image on the panel.

The organic light display can be divided into Passive Matrix (PMOLED) and Active Matrix (AMOLED) according to the driving mode. The so-called active driven OLED(AMOLED) can be visualized in the Thin Film Transistor (TFT) as a capacitor that stores signals to provide the ability to visualize the light in a grayscale.

Although the production cost and technical barriers of passive OLED are low, it is limited by the driving mode and the resolution cannot be improved. Therefore, the application product size is limited to about 5″, and the product will be limited to the market of low resolution and small size. For high precision and large picture, the active drive is mainly used. The so-called active drive is capacitive to store the signal, so when the scanning line is swept, the pixel can still maintain its original brightness. In the case of passive drive, only the pixels selected by the scan line are lit. Therefore, in an active-drive mode, OLED does not need to be driven to very high brightness, thus achieving better life performance and high resolution.OLED combined with TFT technology can realize active driving OLED, which can meet the current display market for the smoothness of screen playback, as well as higher and higher resolution requirements, fully display the above superior characteristics of OLED.

The technology to grow The TFT on the glass substrate can be amorphous Silicon (A-SI) manufacturing process and Low-Temperature Poly-Silicon (LTPS). The biggest difference between LTPS TFT and A-SI TFT is the difference between its electrical properties and the complicated manufacturing process. LTPS TFT has a higher carrier mobility rate, which means that TFT can provide more current, but its process is complicated.A-si TFT, on the other hand, although a-Si’s carrier movement rate is not as good as LTPS’s, it has a better competitive advantage in cost due to its simple and mature process.Au Optronics is the only company in the world that has successfully combined OLED with LTPS and A-SI TFT at the same time, making it a leader in active OLED technology.

The LTPS membrane is much more complex than a-SI, yet the LTPS TFT is 100 times more mobile than A-SI TFT. And CMOS program can be carried out directly on a glass substrate. Here are some of the features that p-SI has over A-SI:

LCD screens are backlit to project images through color filters before they are reflected in our eye Windows. This mode of carrying backlit LCD screens, known as “penetrating” LCD screens, consumes most of the power through backlit devices. The brighter the backlight, the brighter it will appear in front of the screen, but the more power it will consume.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey