tft lcd polarisation free sample

During high sunlight situations, people may wear sunglasses, including polarized sunglasses, while viewing a traditional head-up display (HUD). Such people may see ghost images on the traditional HUD, which are caused by reflections as a result of lighting interacting with the multiple internal surfaces of the components of the traditional HUD, specifically a thin-film transistor (TFT) liquid crystal display (LCD), an active polarization modulator such as a twisted nematic (TN) cell, and a hot mirror. When the TN cell and the hot mirror are placed in front of the TFT-LCD, four additional optical surfaces are introduced and ghost images are induced by these surfaces. Such ghost images and reflections can make it difficult for a user to clearly view the images on the traditional HUD. For example, ghost images reduce the contrast of the display content.

Disclosed herein are example implementations of a head-up display (HUD). One example HUD includes a thin-film transistor liquid crystal display (TFT-LCD), an active polarization modulator, and a wavelength filter. The active polarization modulator and the wavelength filter are optically bonded to the TFT-LCD.

Also disclosed herein are example implementations of a system for a HUD. One example system includes an active polarization modulator front plate and a coating. The coating is adjacent to the active polarization modulator front plate. The system also includes an active polarization modulator rear plate, and an LCD front plate. The system further includes a first reflective polarizer and an LCD rear plate. The first reflective polarizer is adjacent to the active polarization modulator rear plate and the LCD front plate. The system further includes a second reflective polarizer. The second reflective polarizer is adjacent to the LCD rear plate.

A head-up display (HUD) panel that offers both improved viewing by a user wearing polarized sunglasses and improved viewing in high sunlight situations is desirable. Certain embodiments of the present disclosure may, for example, relate to a HUD panel that offers improved viewing by a user wearing polarized sunglasses and improved viewing in high sunlight situations. Certain embodiments may combine the internal surfaces of components of the HUD panel, eliminating the reflections and ghost images. For example, one or more embodiments may describe stacking discrete components in a picture generation unit (PGU) of the HUD to provide a compact PGU design. One or more embodiments may describe reducing or eliminating extra optical surfaces, which traditionally result from stacking discrete components, like a TFT-LCD, an active polarization modulator, such as a TN cell, and a hot mirror. Reducing or eliminating the extra optical surfaces may reduce or eliminate ghosting.

Light passing through the HUD panel 200 may be reflected or polarized. For example, light that is P-polarized is polarized parallel to a plane of incidence which in a HUD is the plane formed by gut rays 108 and 110. Light that is S-polarized is polarized perpendicular to a plane of incidence. A TFT-LCD polarizes light in either P-polarization or S-polarization.

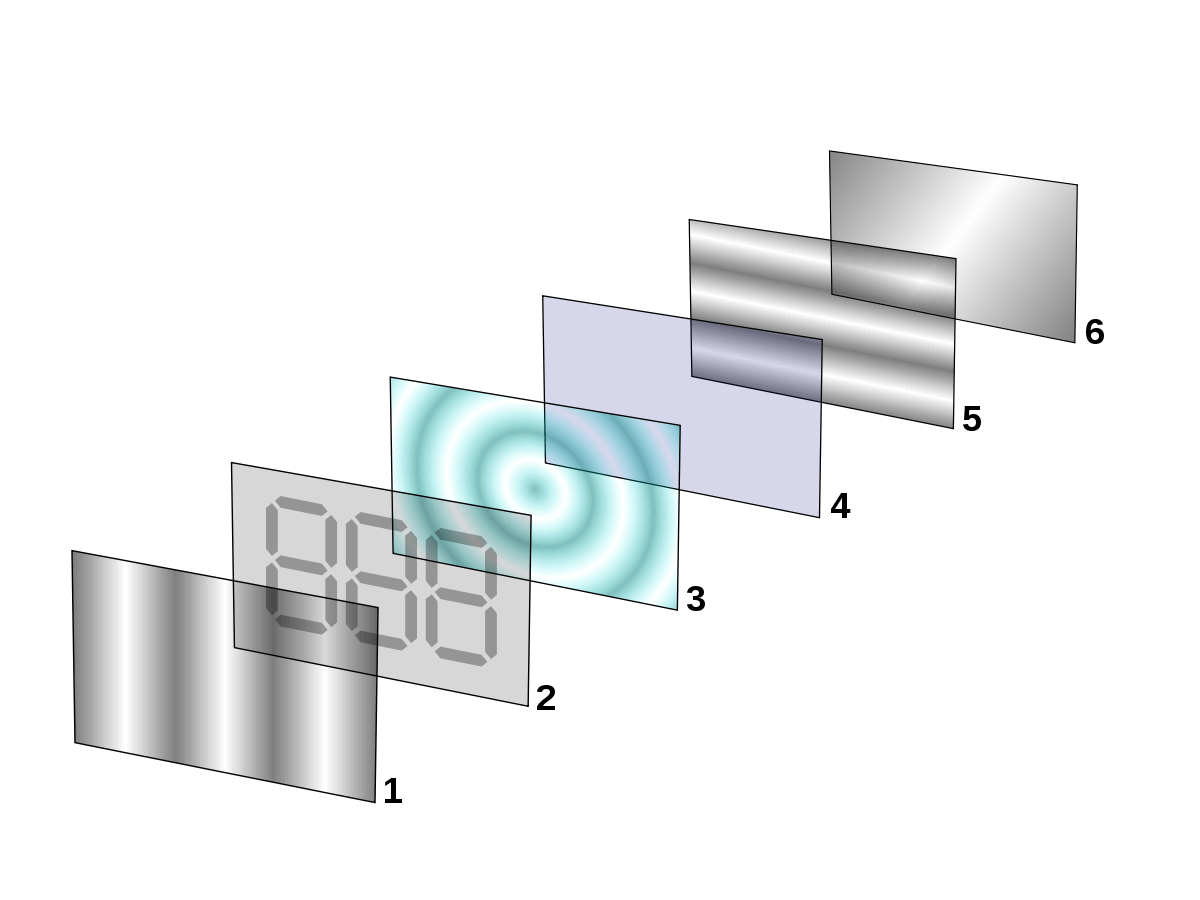

FIG. 2A illustrates a stacked HUD panel 200 in accordance with aspects of the present disclosure. The HUD panel 200, in this example, includes an anti-reflection and infrared cut-off coating 202, an active polarization modulator front plate 204, a first liquid crystal (LC) 206, an active polarization modulator rear plate 208, a first reflective polarizer 210, an LCD front plate 212, a second LC 214, an LCD rear plate 216, and a second reflective polarizer 218. The TN cell 220 (stack of 204, 206, 208, and 210) is used both as the substrate of the TFT-LCD 222 to provide polarization control (for polarized sunglasses) and as a hot mirror 224 (stack of 202 and 204) (for sunlight/infrared resistance), eliminating two internal surfaces. The now-integrated TN cell 220 and hot mirror 224 are optically bonded to the TFT-LCD 222 (stack of 210, 212, 214, 216, and 218) by sharing reflective polarizer 210 to eliminate the remaining two internal surfaces. The now-integrated TN cell 220 and hot mirror 224 may be optically bonded to the TFT-LCD 222 by using a liquid adhesive or any other desirable adhesive or bond. The resulting stacked HUD panel 200 contains only the original two surfaces of the TFT-LCD 222. The TFT-LCD 222 includes its own polarizer that is the reflective type to reflect any excessive amount of solar radiation entering the stacked HUD panel 200 as well as to reflect unusable light energy from within.

In one example embodiment, the stacked HUD TFT-LCD can be configured as follows: 1) the anti-reflection and infrared cut-off coating 202 is positioned adjacent the active polarization modulator front plate 204; 2) the first LC 206 is positioned between the active polarization modulator front plate 204 and the active polarization modulator rear plate 208; 3) the first reflective polarizer 210 is positioned adjacent the LCD front plate 212; 4) the second LC 214 is positioned between the LCD front plate 212 and the LCD rear plate 216; and 5) the second reflective polarizer 218 is positioned adjacent the LCD rear plate 216. The HUD panel 200 can include additional and/or fewer components and configurations and is not limited to those illustrated in FIG. 2A.

The HUD panel 200 can be incorporated into a windshield of a vehicle. For a windshield HUD (WHUD) to be compatible with polarized sunglasses, the HUD panel 200 includes an electro-optical element, such as the TN cell 220 to modulate the polarization from the TFT-LCD 222. The HUD panel 200 may include a wavelength filter, such as the hot mirror 224, to increase the sunlight resistance of the TFT-LCD 222. In a traditional HUD panel 200, adding these two extra elements in front of the TFT-LCD 222 introduces four additional optical surfaces, which can induce ghost images. These ghost images reduce the contrast of the WHUD content. To eliminate the ghosting, the HUD panel 200 is stacked in such a configuration to eliminate the additional optical surfaces. For example, by properly stacking various elements, such as the TFT-LCD 222, the TN cell 220, and the hot mirror 224, the additional optical surfaces are eliminated. As described in one or more embodiments, properly stacking various elements of the HUD panel 200 may include stacking the hot mirror 224 in front of the TN cell 220, which is stacked in front of the LCD 222. In this configuration, a PGU of the WHUD system can maintain its polarized sunglasses compatibility and sunlight resistance requirements.

FIG. 2B illustrates a stacked HUD panel 201 with an air gap in accordance with aspects of the present disclosure. The stacked HUD panel 201 can be configured as follows: 1) the anti-reflection and infrared cut-off coating 202 is positioned adjacent the active polarization modulator front plate 204; 2) the first LC 206 is positioned between the active polarization modulator front plate 204 and the active polarization modulator rear plate 208; 3) a first linear polarizer 226 is positioned adjacent the active polarization modulator rear plate 208; 4) an air gap 230 is positioned between the first linear polarizer 226 and a second linear polarizer 228; 5) the LCD front plate 212 is positioned between the second linear polarizer 228 and the second LC 214; 6) the second LC 214 is positioned between the LCD front plate 212 and the LCD rear plate 216; and 5) the second reflective polarizer 218 is positioned adjacent the LCD rear plate 216. The stacked HUD panel 201 can include additional and/or fewer components and configurations and is not limited to those illustrated in FIG. 2B.

In this embodiment, the TN cell 220 can be separated from TFT-LCD 222. The TN cell 220 and the TFT-LCD 222 do not share the same linear polarizer. TFT-LCD 222 can have a front linear polarizer (e.g., the second linear polarizer 228) and the TN cell 220 can have its own linear polarizer (e.g., the first linear polarizer 226) on a surface toward the TFT-LCD 222. The linear polarizers 226, 228 can be absorptive to reduce ghost image visibility. There is an air gap 230 in between these two linear polarizers 226, 228. Air flow can be forced to pass through the air gap 230 in order to take heat away from both linear polarizers 226, 228.

As shown in Table 1, a PGU with the active TN cell 220 is more efficient than an S-polarized TFT-LCD PGU, a 45° linear polarized TFT-LCD PGU, and a 42° linear polarized TFT-LCD PGU. The WHUD system with the active TN cell 220 is therefore more efficient. The WHUD system with the active TN cell 220 has lower light energy absorption on an LCD in an ON condition for the V-polarized brightness and an OFF condition for the total brightness. In this example, V-polarized refers to the light that is vertically polarized to the ground. There can be some power in V-polarization while the output from the PGU are all S-polarization due to the windshield azimuth angle. Furthermore, using the active TN cell 220 in the HUD panel 200 results in a lower temperature rise on the LCD and a lower current demand for a light-emitting diode (LED).

The TN cell 220 can be positioned or sandwiched between two plates made of glass. The hot mirror 224 is an optical mirror reflecting infrared (IR) and allowing visible light to pass through. The hot mirror 224 may need a substrate to carry a thin film coating. Usually the thin film is designed to be low reflection in the visible light spectrum and high reflection in the infrared spectrum. Thus, the TN cell 220 can be the substrate of the thin film coating to provide both polarization control and hot mirror 224 functions simultaneously. This stacked configuration of the HUD panel 200 eliminates two surfaces. The TN cell 220 and hot mirror 224 are integrated in the HUD panel 200 and can be optically bonded to the TFT-LCD 222 to eliminate another two surfaces. After this integration, the HUD panel 200 has only two optical surfaces, which is the same amount of optical surfaces as a traditional TFT-LCD 222.

A first polarizer, such as the first reflective polarizer 210 can be located on a front plate, such as the LCD front plate 212 of the TFT-LCD 222. The first reflective polarizer 210 can be a reflective type to reflect the excess amount of solar radiation from heating the entire stack. A second polarizer, such as the second reflective polarizer 218, can be located on a rear TFT-LCD plate, such as the LCD rear plate 216. The second reflective polarizer 218 can also be a reflective type to reflect the unusable portion of the flux from backlight from heating the entire stack. Such example configurations can prevent or reduce ghosting and stray light.

FIG. 7 is a diagram of an electrical polarization rotator 700 of the HELD panel 200, which can include stacked components 705, such as a display panel 703 and an electro-optical half-wave plate 704, in accordance with aspects of the present disclosure. The display device 702 is compatible with polarized sunglasses 716. The polarization of sunglasses is disclosed in U.S. patent application Ser. No. 15/602,997, which is hereby incorporated by reference in its entirety. The display device 702 includes a display, such as a linear polarized display panel 703, for displaying information. The display device 702 includes components that may be stacked to reduce internal surfaces. The components may include the TFT-LCD 222, the TN cell 220, and the hot mirror 224 as described in FIGS. 2A and 2B. The stacked components 705, including the display panel 703 and the electro-optical half-wave plate 704 can be configured to reduce a ghost image on the display 703. The stacked components 705 can include additional and/or fewer components and configurations and is not limited to those illustrated in FIGS. 2A, 2B, and 7.

FIG. 9 is a diagram 900 showing reflective and transmitted light in accordance with aspects of the present disclosure. In one embodiment, a combination of at least two optical filters can be used to prevent excessive radiation energy heating the TFT-LCD 222. The optical filters can include at least one of a reflective polarizer 904, a TN cell 220, and a hot mirror 224. In this configuration, most of the IR light can be rejected and approximately half of the visible light can be rejected. For example, the reflective polarizer 904 can be used to transmit approximately half or 50% of the visible light and a hot mirror 914 can be used to reflect most or all of the IR light.

Diagram 902 includes the reflective polarizer 904. The reflective polarizer 904 can be on the TN cell 220 or on the TFT-LCD 222. In this configuration, sunlight 906 passes through the reflective polarizer 904 in a direction 908. Approximately 50% of the visible light from sunlight 906 is transmitted in the direction 908 and 50% of the visible light from sunlight 906 is reflected in a direction 910.

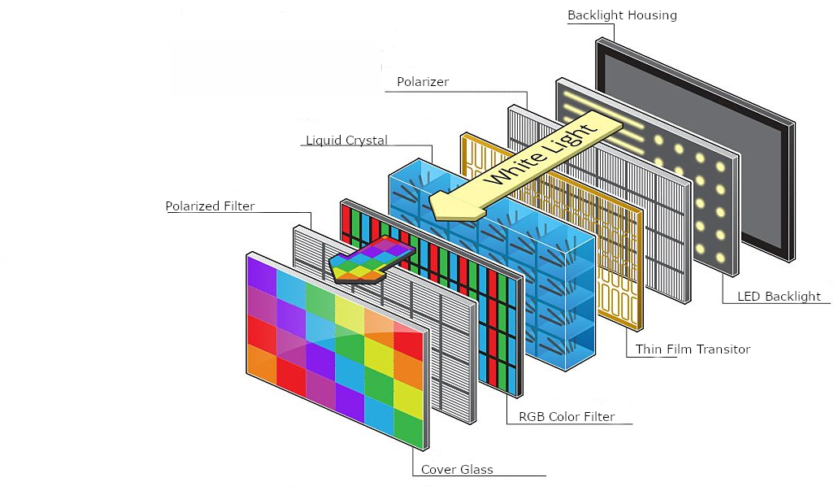

A TFT LCD, or a thin film transistor liquid crystal display, is one of the fastest growing forms of display technology today. The thin film transistor (TFT) is a type of semiconductor device used in display technology to enhance efficiency, compactness, and cost of the product. In conjunction with its semiconductor properties, the TFT LCD is an active matrix display, controlling pixels individually and actively rather than passively, furthering the benefits of this semiconductor device.

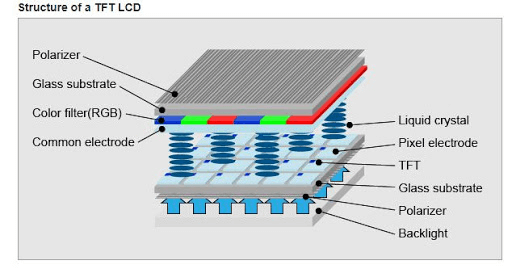

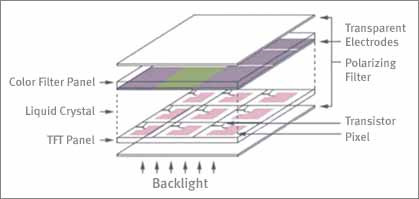

The TFT LCD is built with three key layers. Two sandwiching layers consist of glass substrates, though one includes TFTs while the other has an RGB, or red green blue, color filter. The layer between the glass layers is a liquid crystal layer.

The Architecture of a TFT Pixelbelow) from the other substrate layer of the device and control the amount of voltage applied to their respective sub-pixels. This layer also has pixel electrodes between the substrate and the liquid crystal layer. Electrodes are conductors that channel electricity into or out of something, in this case, pixels.

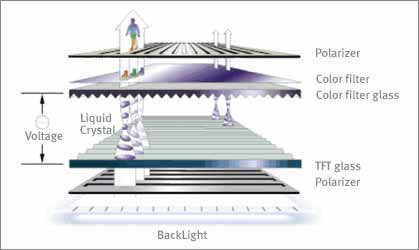

The outer sides of the glass substrates (closest to the surface or closest to the back) have filter layers called polarizers. These filters allow only certain beams of light to pass through if they are polarized in a specific manner, meaning that the geometric waves of the light are appropriate for the filter. If not polarized correctly, the light does not pass through the polarizer which creates an opaque LCD screen.

The twisted nematic effect is one of the cheapest options for LCD technology, and it also allows for fast pixel response time. There are still some limits, though; color reproduction quality may not be great, and viewing angles, or the direction at which the screen is looked at, are more limited.

The light that passes through the device is sourced from the backlight which can shine light from the back or the side of the display. Because the LCD does not produce its own light, it needs to use the backlight in the OLED) have come into use as well. Typically white, this light, if polarized correctly, will pass through the RGB color filter of the surface substrate layer, displaying the color signaled for by the TFT device.

Within an LCD, each pixel can be characterized by its three sub-pixels. These three sub-pixels create the RGB colorization of that overall pixel. These sub-pixels act as capacitors, or electrical storage units within a device, each with their own independent structural and functional layers as described earlier. With the three sub-pixels per pixel, colors of almost any kind can be mixed from the light passing through the filters and polarizer at different brightness based on the liquid crystal alignment.

TFT displays are also known as an “Active Matrix TFT LCD module” and have an array of thin film transistors fabricated on the glass that makes the LCD. There is one of these transistors for each pixel on the LCD.

LCDs use voltage applied to a field of microscopic liquid crystals to change the crystal’s orientation, which in turn changes the polarization of the liquid crystal which creates light or dark pixels on the display.

Beautiful, complex images: All of our TFT modules are full-color graphic displays. Unlike standard monochrome character displays, you can create complex images for an imaginative user experience.

Single Supply: Most of the TFTs use an integrated controller with built-in voltage generation so only a single 3.3v supply is needed for both the panel power and logic voltage.

Many of our character LCD modules use a standard HD44780 controller, so they can be quickly integrated into a new product or used as a replacement in your existing products.

Many of the LCD controllers on board our graphic LCD display modules also include a CGROM (character generator ROM) which allows for easy character information as well as full bit-mapped graphic information to be shown.

Some of the graphic LCD displays have the ability to render graphics in grayscale, enabling you to show images and elements of your UI (user interface) with more depth and definition.

The video you show is of a liquid crystal display (LCD) monitor, also known as "TFT". The "trick" depends on the specific design characteristics of these monitors (described below) and will not generally work with other types of displays such as LED and PLASMA displays.

All liquid crystal displays (LCD) operate on the principle of being able to "twist" polarized light as it passes through a "nematic" liquid crystal. The orientation of each liquid crystal in a display is governed by an electric field applied to a transparent electrode, through an array of thin-film transistors (TFT). The liquid crystal is normally "sandwiched" between two polarizing filters at 90 degrees to each other. Polarized light enters the back of the liquid crystal from the back-lit LED. When the nematic crystal is not energised, it "twists" the polarized light by 90 degrees so that it passes through the second polarizing filter. Wnen an electric field is applied to the liquid crystal, the light does not get twisted so gets blocked by the second polarizing filter.

For more detail on the internal workings, including a"tear down" of an LCD-TFT monitor see this video: http://www.engineerguy.com/videos/video-lcd.htm

By taking out the second polarizing filter and placing them on a pair of glasses, the display appears "invisible" (white) to the naked eye because ALL the from the LED backlight that passes through the first polarizing filter gets through the TFT section to the naked eye, regardless of it"s orientation (polarization) so the naked eye sees it as "white". It"s not until the second polarizing filter is applied to "filter" the light from specific pixels which have "twisted" their light (with respect to the other pixels) that we can distinguish between the pixels.

The video you show is of a liquid crystal display (LCD) monitor, also known as "TFT". The "trick" depends on the specific design characteristics of these monitors (described below) and will not generally work with other types of displays such as LED and PLASMA displays.

All liquid crystal displays (LCD) operate on the principle of being able to "twist" polarized light as it passes through a "nematic" liquid crystal. The orientation of each liquid crystal in a display is governed by an electric field applied to a transparent electrode, through an array of thin-film transistors (TFT). The liquid crystal is normally "sandwiched" between two polarizing filters at 90 degrees to each other. Polarized light enters the back of the liquid crystal from the back-lit LED. When the nematic crystal is not energised, it "twists" the polarized light by 90 degrees so that it passes through the second polarizing filter. Wnen an electric field is applied to the liquid crystal, the light does not get twisted so gets blocked by the second polarizing filter.

For more detail on the internal workings, including a"tear down" of an LCD-TFT monitor see this video: http://www.engineerguy.com/videos/video-lcd.htm

By taking out the second polarizing filter and placing them on a pair of glasses, the display appears "invisible" (white) to the naked eye because ALL the from the LED backlight that passes through the first polarizing filter gets through the TFT section to the naked eye, regardless of it"s orientation (polarization) so the naked eye sees it as "white". It"s not until the second polarizing filter is applied to "filter" the light from specific pixels which have "twisted" their light (with respect to the other pixels) that we can distinguish between the pixels.

I basically know how TFT" displays work. They have on both sides a polarizing foil, in 90 degrees with the crystals in the middle modifying which light particles should pass through or not. The light is emitted by a backlight in the display. So far so good.

What I try to find out or understand is, whether it would be possible somehow - by modification of the TFT / the 2 polarising foils / or by adding a new polarizing foil / or by any other means or filters that the backlight can be removed and replaced by a mirror.

Basically what I am trying to find out if its possible to build - in theory - a TFT display that is not backlight but gets the light from the front (from the direction where the viewer is).

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

polarizability, transmittance and tone, and other indicators include uv resistance and transmittance, total reflectance and diffuse reflectance of semi-transmittance polarizer.In the general use of LCD products, the requirement of polarization and transmittance of the higher the better.The higher the polarizability and transmittance, the higher the display efficiency of LCD display device, and the lower the relative energy consumption.But for the conventional iodine dyeing polarizing products, polarizing and transmittance is a pair of contradictions, the higher the polarizing degree, transmittance will be lower, but also subject to the constraints of color, so the general type of polarizing products are between 90% - 99%, transmittance between 41% - 44%.Tonal indicators mainly to satisfy people"s visual habit, also requires polaroid product color deviation is smaller, to ensure the consistency of the end product appearance color LCD, it mainly by the polaroid products chromaticity coordinate parameters of L, a, b value and their control to identify the tolerance range, generally the scope of its control tolerance as small as possible.

The durability technical indexes of LCD polarizer include high temperature resistance, heat and humidity resistance, low temperature resistance and heat and cold impact resistance.High temperature resistance refers to the temperature resistance working condition of polarizer under constant baking temperature. At present, according to the technical level of polarizer, it is usually divided into general types: working temperature is 70℃×500HR;Medium endurance type: working temperature is 80℃×500HR;High endurance type: operating temperature above 90℃×500H these three grades.

Heat and humidity resistance technical index refers to the heat and humidity resistance performance of LCD polarizer under constant temperature and humidity conditions. It is usually divided into three technical grades, namely, general type: heat and humidity working condition: 40℃×90%RH×500HR;Medium endurance type: hot and humid working condition: 60℃×90%RH×500HR;High endurance type: hot and humid working conditions: 70℃×95%RH×500HR or above.

Due to constitute the basic materials of polarizing film containing PVA membrane and iodine and iodide are easy to hydrolysis of materials, and at the same time because the LCD polarizing piece by using pressure sensitive adhesive under high temperature and high humidity conditions also easy degradation, therefore, the durability of the LCD polarizing piece the most important technique index is resistant to high temperature and damp and hot, if resistance to heat and humid indexes through, other type durability index usually won"t be a problem.

including: pressure sensitive adhesive and glass substrate, pressure sensitive adhesive and peel film, polaroid protective film and peel film, and bonding durability of pressure sensitive adhesive.Pressure sensitive adhesive and glass substrate between the peeling force is also known as adhesive bonding strength, which is the most important bonding characteristics of LCD polaroid products.This technical index is usually measured by the standard of eiaj-ed-2521a of the specification of Japan electronics and machinery industry association. It is expressed in unit of g/25mm. Generally, the stripping force of pressure sensitive adhesive of LCD polarizing plate on glass substrate is stipulated to be above 500g/25mm, while the upper limit in actual use is generally below 1000g/25mm.There are practical examples that show that when the adhesive to the glass substrate peeling force of 500g/25mm or less, will occur in the glass screen surface after the polaroid adhesive automatic peeling and warping phenomenon.

The technical indicators of the appearance performance of the LCD polarizer mainly refer to the surface flatness of the polarizer products and the number of appearance defects. These technical indicators mainly affect the utilization ratio of the polarizer products in the patch.These technical indicators usually have relatively consistent technical provisions in the polarizing disc industry, usually for each polarizing disc product (500×1000 mm) less than 15 points less than 150 microns.

Because LCD polaroid product final inspection are using artificial visual inspection, therefore in the process of the batch production of polaroid, appearance owe point will have certain discrete distribution, the distribution of the every polaroid production enterprise is to use a certain internal control specifications and delivery specifications difference to ensure delivery of quality standards.It should be noted, however, that as 150ms is already near the minimum limit of visual resolution for the human eye, especially in industrial mass production where inspectors experience visual fatigue over long periods of time, the 150ms off-point inspection standard is reasonable and reliable.

In a broad sense, optical films are film products with optical properties. The two common types of optical films are backlight module and polarizing. The prominent applications of these films are OLED (Organic Light Emitting Diode) panels and TFT (Thin Film Transistor) LCD liquid crystal panels. Based on the material used to make films, the optical films can be bifurcated into functional thin films and selective separation membrane.

The functional thin film is mainly used for optical technology and selective separation membrane plays a crucial role in the waste water management system. The demand for optical films has increased due to the large sizes of LCD panels. This factor creates opportunities for the polarizing films. According to a report published by Research Dive, the optical films market is anticipated to garner revenue of $30.1 billion by 2024 with a healthy growth rate of 7.1% in the forecast period.

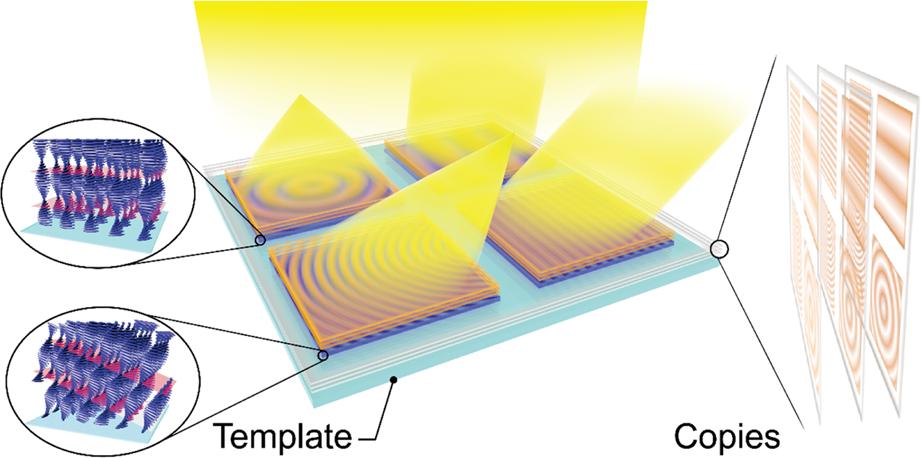

A Japanese company called as DuPoint Teijin Films Ltd has managed to create liquid polarizer that is used in LCD (Liquid Crystal Display). This is a combination of multilayer film technology and polymer that aids in recycling of the rejected polarized light back to the viewer; thus augmenting the output. Reflective polarizer film is used in STN (Super Twisted Nematic) display and reflection mode TN (Twisted Nematic).Indium Tin Oxide (ITO) Film:

This is made by using micro replication film structure technique in which the prism structure is created by acrylic resin. According to the geometric optics principle, the emitted light is passed via circulation of the prism film and the backlight film. This is converged at the front to generate a high brightening effect. Normal prism film is mainly used at LCD backlight units that aids in luminance by directing the light from the source of light.Multifunctional Prism Film:

This blocks the light and allows the light to pass through liquid crystals in the LCD panel. Polarizing film is the core element of the LCD panel that facilitates image display on the screen. Some of the vital benefits of polarizing films are as follows:High luminescence

Micro-lens array structure is utilized for combining prism and diffusion functions. The conventional prism sheets are replaced by micro-lens films in the LCD TV panels. This enhances the light efficiency of the LCD and is also cost effective in nature. Micro-lens films are manufactured by using IC (Integrated Circuit) technologies such as photo-resist processing, photolithography, and reactive ion etching. Some of the applications of micro-lens are as follows:Fiber couplers

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey