msp430 lcd display code manufacturer

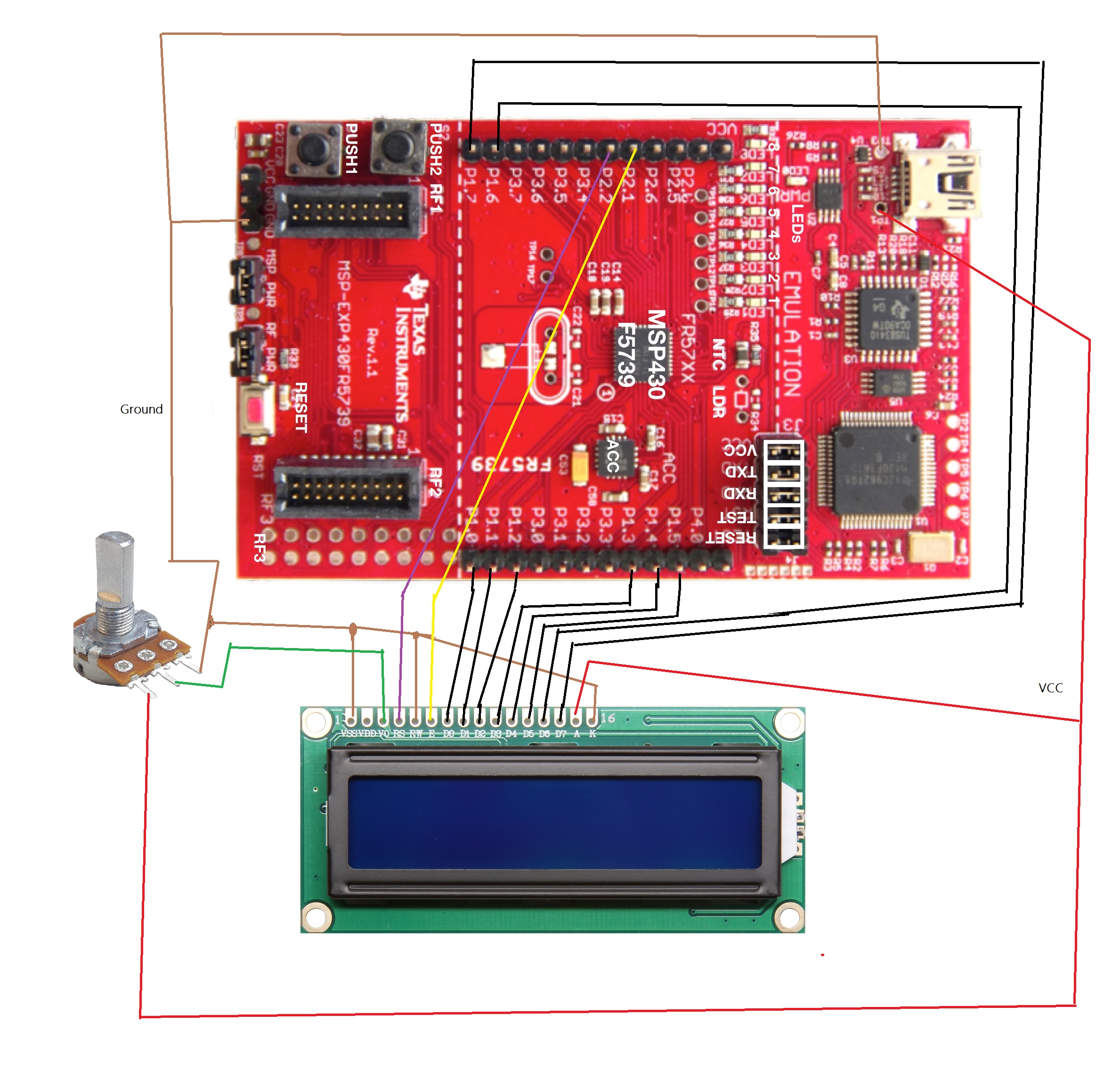

This article is the continuation of our tutorial series on programming MSP430 using Code Composer Studio. Last tutorial was based on GPIO pins. This tutorial is about interfacing a display with MSP430, when it comes to display the 16*2 LCD Display,it is the first choice for any electronic hobbyist. Previously we have also interfaced LCD with MSP430 using Arduino IDE, in this tutorial, we will use the native Code Composer studio platform instead of using the Arduino IDE, this way as a designer, we get more flexibility.

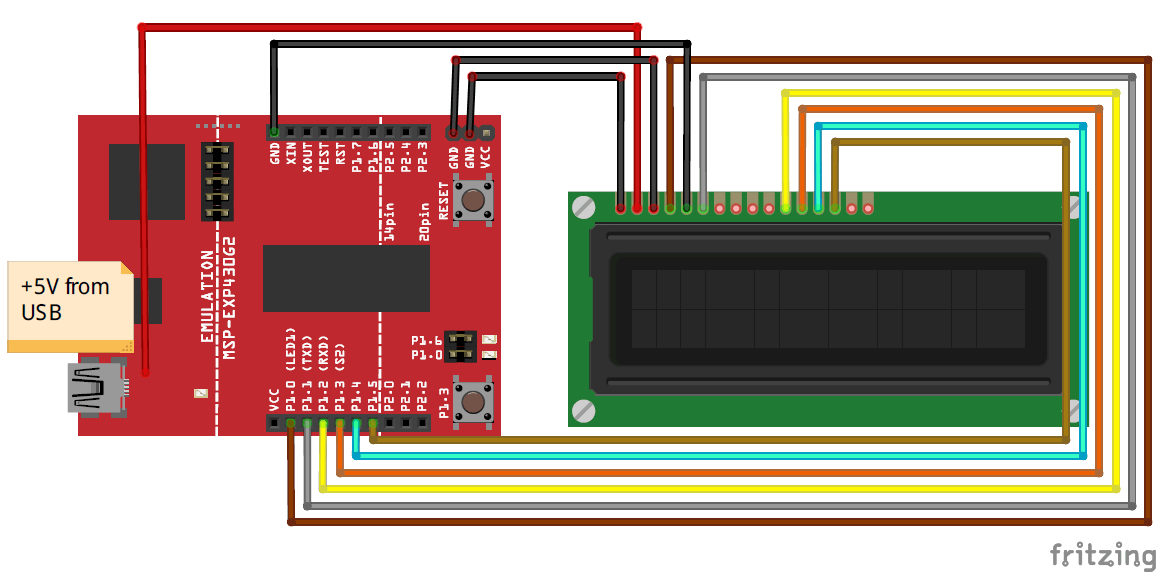

It has an in-built IC hd44780 that can store the command and data passed to it. The LCD Module has about 16 pins. 8 of which are data pins, 4 of them are supply pins for backlight LED and the whole LCD module, 3 for controlling the operation, and 1 pin for contrast adjustment. The tutorial is based on the library created by Dennis Eichmann. It is very easy to use a library with separate functions to print different data types. It also has provisions to display the data in different forms with leading, blanked, and deleted zeroes. It is a pretty expansive and comprehensive library and is configurable to the different connections. Here, the header file is modified to accommodate an 8-pin parallel configuration for data communication.

A generic 16x2 Display has an inbuilt hd44780 IC(circled in red below), that can store the command and data passed to it. The LCD Module has about 16 pins. 8 of which are data pins, 4 of them are supply pins for backlight LED and the whole LCD module, 3 for controlling the operation, and 1 pin for contrast adjustment.

This LCD module is shown above versatile and uses minimum pins compared to other segmented LCDs. If you are curious to know how exactly all this works, you should check out the working of the 16x2 LCD display where we have already discussed how the LCD works in detail.

RS Pin: RS=1 will enable the data register in the LCD, which is used to write the values to the data register in LCD. RS=0 will enable the Instruction register of the LCD.

Enable pin: Negative edge-triggered; when the pin is changed from the HIGH state to LOW state, LCD is prompted to write to the data pins. Positive edge-triggered; when the pin is changed from the LOW state to HIGH state, LCD is prompted to read from the data pins.

The tutorial is based on the library created by Dennis Eichmann. It is very easy to use a library with separate functions to print different data types. It also has provisions to display the data in different forms with leading, blanked, and deleted zeroes. It is a pretty expansive and comprehensive library and is configurable to the different connections. Here, the header file is modified to accommodate an 8-pin parallel configuration for data communication. The library can be download from the below link, after downloading you follow the below steps to add the library to CCS.

In the properties dialog box of the hd44780 project and inside the include options for the MSP430 compiler, add the include folder in file the search path.

In the properties dialog box for the CCS_LCD project and in the file search path of MSP430 Linker tab, include the hd44780.lib located inside the debug folder of the hd44780 project. The debug folder is also included in the file search path.

void hd44780_timer_isr( void ):This is periodically called in the ISR of the Timer A. The Timer A is used to periodically do the LCD functions like clearing the screen, setting the cursor, and displaying the data. The function is to be used in the ISR. It returns nothing.

char * ch__string:The string to be written to the data buffer (inside the hd44780_timer_isrfunction). The data will be copied to the data register and instruction register of the LCD IC when the hd44780_timer_isris periodically called.

uint8_t hd44780_output_unsigned_16bit_value( uint16_t u16__value, uint8_t u8__leading_zero_handling, uint8_t u8__row, uint8_t u8__column, uint8_t u8__cr_lf ):The function will display the unsigned 16-bit value on the desired location of the LCD.

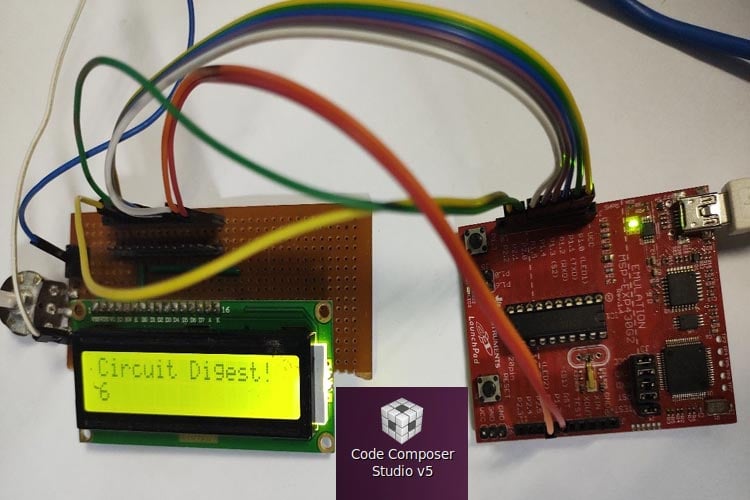

The anode of the LED backlight cannot be connected directly to a 5V supply. It should be connected to a resistance to minimize the current flow through the LCD Module. I have made my connections using a perf board to solder the LCD and then used jumper wires to connect the LCD with the MSP430 board, my set-up looks like this below but you can also simply use a breadboard to make your connections.

The complete code used in this project is given at the bottom of this page. The explanation of using the code is as follows. First, open the header file (hd44780.h) and include the microcontroller part number in the first part of the file.

Inbuilt timer is being used to display values periodically. Timer A is selected with SMCLK (1MHZ) as the clock source and continuous mode being the mode of operation.

Once you have your code compiled, you can upload it to the MSP430 board, as explained in the getting started with the MSP430 tutorial. If everything goes as expected, you should see your LCD display some contrast as shown below.

This is the third tutorial in the sequence of tutorials in which we are learning to program the MSP430G2 LaunchPad using the Energia IDE. In our previous tutorial, we learned how to control the Digital Input and Output pins on our MSP board. In this tutorial, we will learn how to interface an LCD with the board so that we can display useful information.

The LCD that we are using in this project is the most commonly used 16×2 Dot matrix LCD display a.k.an Alphanumeric Displays. Most of us would have come across this either through public PCOs or other electronics projects. A display like this will come in very handy for our future tutorials to display data and other debugging information. Interfacing this LCD with MSP430 is very easy, thanks to the library available. So let’s dive in!!

As told earlier the Energia IDE provides a beautiful library which makes the interfacing a piece of cake and hence it’s not mandatory to know anything about the display module. But, would didn’t it be interesting to show what we are using!!

The name 16×2 implies that the display has 16 Columns and 2 Rows, which together (16*2) forms 32 boxes. One single box would look something like this in the picture below

A single box has 40 pixels (dots) with a matrix order of 5 Rows and 8 columns, these 40 pixels together forms one character. Similarly, 32 characters can be displayed using all the boxes. Now lets take a look at the pinouts.

Out of all these 16 pins, only 10 pins are to be used mandatory for the proper working of the LCD if you want to know more about these LCD display jump to this LCD article.

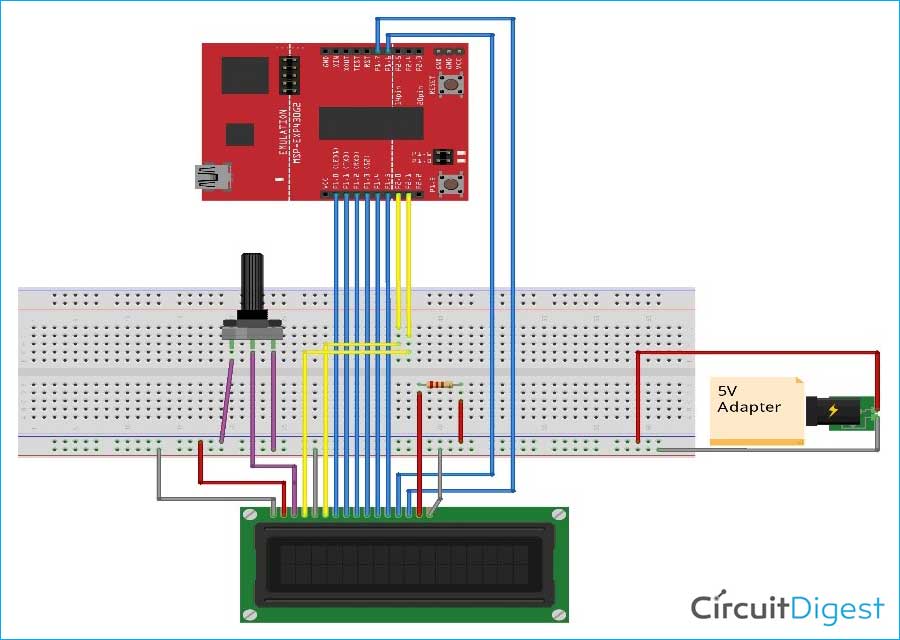

One major constraint while interfacing these two is their operating voltages. The LCD display has an operating voltage of +5V while the MSP operates only with 3.6V. Lucky for us the data pin of LCD interface IC (HD44780U) has a wide operating voltage of 2.7V to 5.5V. So we have to worry only about the Vdd (pin 2) of the LCD while the data pins can work even with 3.6V.

The MSP430G2 board by default does not give you a +5V pin, but by we can do a smallhack to get +5V from MSP430 using the USB port. If you take a close look near the USB port you can find a terminal called TP1, this terminal will give us +5v. All we have to do is to solder a small male header pin as shown below so that we can connect it to our LCD display.

If you are not interested in soldering simply use any +5V regulated supply and power the LCD, in that case, make sure you connect the ground of your power supply to the ground of the MSP board.

The complete program to interface an MSP430G2553 with LCD display is given at the end of this page. The code can be compiled, uploaded and used as such. In the following paragraphs, I will explain how the program works.

Before we proceed with explanation, we have to make a note of the pins that we are using. If you take a look the circuit diagram above and the MSP430 pin-out diagram below

With this in mind let’s start defining the LCD pins used in our program. We will name each pin with a more meaningful name so that we can use it easily later.

The next step would be to include the LCD library. This library would have been installed automatically when you installed the Energia IDE. So just add it by using the following line

The next step is to mention the pins to which the LCD is connected to, as we have already named it using the #define we can now simply mention the names of the LCD pins. Make sure the same order is followed.

Now let us move into the void setup() function. There are so many types of LCD displays varying in size and nature, the one that we are using is 16*2 so let’s specify that in our program

To print something on the LCD we have to mention two things in the program. One is the position of the text which can be mentioned using the line lcd.setCursor() and other is the content to print which can be mentioned by lcd.print().In this line we are setting the cursor to 1st row and 1st column.

Just like erasing a whiteboard after writing on it, an LCD should also be erased once something is written on it. This can be done by using the below line

Next, inside our void loop() function, let’s keep incrementing a number for every 500ms and display the number in the LCD. This number tests and is initialized to 1 as shown below

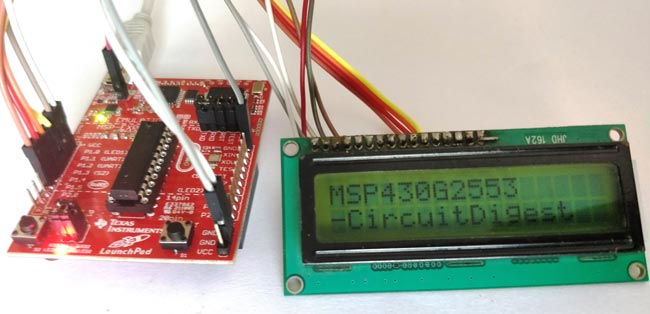

Once your hardware and code is ready, simply connect your board the computer and upload the code as we did in tutorial one. Once the code is uploaded you should see the display showing the following.

After two seconds, the display screen will change from setup to loop and start incrementing the variable and display on the screen as shown the below picture.

The complete working can be found in the video below. Go ahead and try changing what’s being displayed on the LCD and play with it. Hope you understood the tutorial and learned something useful form it. If you have any doubts leave them in the comment section below or use the forums. Let’s meet in another tutorial.

I am using a 16x2 LCD with an MSP430 and am unable to figure out how to print a value from my AtoD. My LCD is using the ST7066U driver, and the setup code for my LCD is this:

In my main code, I read an AtoD value, but I am not too sure how to display it. The AtoD works fine, I can use debug mode in Crossworks and see the AtoD value is what I am expecting. I can display text on the LCD with something like this:

I am a complete novice at this, and the code for setting up the LCD was taken from HERE and edited slightly to fit my MSP and setup. Essentially, I just want to do something like

I get an error saying too many arguments to lcd_print. I assume this means in my setup, I need to change something to the way lcd_print works, but not sure how to do this. Can someone please let me know how to edit this so I can do something along the lines of

I have done certain calculations for calculating rpm in the main code and now i want the values to be printed on the LCD but here i am not able to understand how to do it.

The code of lcd which i have used takes only *char as input , so i am not able to find out a way to convert the integer to char(I know it sounds lame but ...stilll.....) and print it on lcd.

Photo of two experimenter boards for the MSP430 chipset by Texas Instruments. On the left the larger chip version, on the right a small version in USB format.

The MSP430 is a mixed-signal microcontroller family from Texas Instruments, first introduced on 14 February 1992.CPU, the MSP430 is designed for low cost and, specifically, low power consumption

The MSP430 can be used for low powered embedded devices. The current drawn in idle mode can be less than 1 µA. The top CPU speed is 25 MHz. It can be throttled back for lower power consumption. The MSP430 also uses six different low-power modes, which can disable unneeded clocks and CPU. Further, the MSP430 can wake-up in times under 1 microsecond, allowing the controller to stay in sleep mode longer, minimizing average current use.

Some less usual peripheral options include comparators (that can be used with the timers to do simple ADC), on-chip operational amplifiers (op-amp) for signal conditioning, 12-bit digital-to-analog converter (DAC), liquid crystal display (LCD) driver, hardware multiplier, USB, and direct memory access (DMA) for ADC results. Apart from some older erasable programmable read-only memory (EPROM, such as MSP430E3xx) and high volume mask ROM (MSP430Cxxx) versions, all of the devices are in-system programming enabled via Joint Test Action Group (JTAG), full four-wire or Spy-Bi-Wire), a built in bootstrapping loader (BSL) using UART such as RS-232, or USB on devices with USB support. No BSL is included in F20xx, G2xx0, G2xx1, G2xx2, or I20xx family devices.

There are, however, limits that preclude its use in more complex embedded systems. The MSP430 does not have an external memory bus, so it is limited to on-chip memory, up to 512 KB flash memory and 66 KB random-access memory (RAM), which may be too small for applications needing large buffers or data tables. Also, although it has a DMA controller, it is very difficult to use it to move data off the chip due to a lack of a DMA output strobe.

Six general generations of MSP430 processors exist. In order of development, they are: "3xx generation, "1xx generation, "4xx generation, "2xx generation, "5xx generation, and "6xx generation. The digit after the generation identifies the model (generally higher model numbers are larger and more capable), the third digit identifies the amount of memory included, and the fourth, if present, identifies a minor model variant. The most common variation is a different on-chip analog-to-digital converter.

The MSP430x1xx Series is the basic generation without an embedded LCD controller. They are generally smaller than the "3xx generation. These flash- or ROM-based ultra-low-power MCUs offer 8 MIPS, 1.8–3.6 V operation, up to 60 KB flash, and a wide range of analog and digital peripherals.

The MSP430F2xx Series are similar to the "1xx generation, but operate at even lower power, support up to 16 MHz operation, and have a more accurate (±2%) on-chip clock that makes it easier to operate without an external crystal. These flash-based ultra-low power devices offer 1.8–3.6 V operation. Includes the very-low power oscillator (VLO), internal pull-up/pull-down resistors, and low-pin count options.

The MSP430G2xx Value Series features flash-based Ultra-Low Power MCUs up to 16 MIPS with 1.8–3.6 V operation. Includes the Very-Low power Oscillator (VLO), internal pull-up/pull-down resistors, and low-pin count options, at lower prices than the MSP430F2xx series.

The MSP430x3xx Series is the oldest generation, designed for portable instrumentation with an embedded LCD controller. This also includes a frequency-locked loop oscillator that can automatically synchronize to a low-speed (32 kHz) crystal. This generation does not support EEPROM memory, only mask ROM and UV-eraseable and one-time programmable EPROM. Later generations provide only flash memory and mask ROM options. These devices offer 2.5–5.5 V operation, up to 32 KB ROM.

The MSP430x4xx Series are similar to the "3xx generation, but include an integrated LCD controller, and are larger and more capable. These flash or ROM based devices offers 8–16 MIPS at 1.8–3.6 V operation, with FLL, and SVS. Ideal for low power metering and medical applications.

Other integrated peripherals: SCAN_IF, ESP430, 12-bit DAC, Op Amps, RTC, up to 2 16-bit timers, watchdog timer, basic timer, brown-out reset, SVS, USART module (UART, SPI), USCI module, LCD Controller, DMA, 16×16 & 32x32 multiplier, Comparator_A, temperature sensor, 8 MIPS CPU Speed

The MSP430x5xx Series are able to run up to 25 MHz, have up to 512 KB flash memory and up to 66 KB RAM. This flash-based family features low active power consumption with up to 25 MIPS at 1.8–3.6 V operation (165 uA/MIPS). Includes an innovative power management module for optimal power consumption and integrated USB.

The MSP430x6xx Series are able to run up to 25 MHz, have up to 512 KB flash memory and up to 66 KB RAM. This flash-based family features low active power consumption with up to 25 MIPS at 1.8–3.6 V operation (165 uA/MIPS). Includes an innovative power management module for optimal power consumption and integrated USB.

Other integrated peripherals: USB, LCD, DAC, Comparator_B, DMA, 32x32 multiplier, power management module (BOR, SVS, SVM, LDO), watchdog timer, RTC, Temp sensor

Other integrated peripherals: LCD Controller, up to 2 16-bit timers, watchdog timer, RTC, power management module (BOR, SVS, SVM, LDO), USCI module, DMA, 32x32 multiplier, Comp B, temperature sensor

Other possible integrated peripherals: MPU, up to 6 16-bit timers, watchdog timer, RTC, power management module (BOR, SVS, SVM, LDO), USCI module, DMA, multiplier, Comp B, temperature sensor, LCD driver, I2C and UART BSL, Extended Scan Interface, 32 bit multiplier, AES, CRC, signal processing acceleration, capacitive touch, IR modulation

The Low Voltage Series include the MSP430C09x and MSP430L092 parts, capable of running at 0.9 V. These 2 series of low voltage 16-bit microcontrollers have configurations with two 16-bit timers, an 8-bit analog-to-digital (A/D) converter, an 8-bit digital-to-analog (D/A) converter, and up to 11 I/O pins.

The MSP430BQ1010 16-bit microcontroller is an advanced fixed-function device that forms the control and communications unit on the receiver side for wireless power transfer in portable applications. MSP430BQ1010 complies with the Wireless Power Consortium (WPC) specification. For more information, see Contactless Power

Automotive MSP430 microcontrollers (MCUs) from Texas Instruments (TI) are 16-bit, RISC-based, mixed-signal processors that are AEC-Q100 qualified and suitable for automotive applications in environments up to 105 °C ambient temperature. LIN compliant drivers for the MSP430 MCU provided by IHR GmbH.

MSP430 devices are very popular in harsh environments such as industrial sensing for their low power consumption and innovative analog integration. Some harsh environment applications include transportation/automotive, renewable energy, military/space/avionics, mineral exploration, industrial, and safety & security.

Note that when the flash size is over 64K words (128 KBytes), instruction addresses can no longer be encoded in just two bytes. This change in pointer size causes some incompatibilities with previous parts.

The MSP430 peripherals are generally easy to use, with (mostly) consistent addresses between models, and no write-only registers (except for the hardware multiplier).

The MSP430 family defines 11 I/O ports, P0 through P10, although no chip implements more than 10 of them. P0 is only implemented on the "3xx family. P7 through P10 are only implemented on the largest members (and highest pin count versions) of the "4xx and "2xx families. The newest "5xx and "6xx families has P1 through P11, and the control registers are reassigned to provide more port pairs.

Port x interrupt vector ("5xx only). This 16-bit register is a priority encoder which can be used to handle pin-change interrupts. If n is the lowest-numbered interrupt bit which is pending in PxIFG and enabled in PxIE, this register reads as 2n+2. If there is no such bit, it reads as 0. The scale factor of 2 allows direct use as an offset into a branch table. Reading this register also clears the reported PxIFG flag.

The MSP430 line offers two types of analog-to-digital conversion (ADC). 10- and 12-bit successive approximation converters, as well as a 16-bit Sigma-Delta converter. Data transfer controllers and a 16-word conversion-and-control buffer allow the MSP430 to convert and store samples without CPU intervention, minimizing power consumption.

The MSP430"s comparator module provides precision slope analog-to-digital conversions. Monitors external analog signals and provides voltage and resistor value measurement. Capable of selectable power modes.

The BOR circuit detects low supply voltages and resets the device by triggering a power-on reset (POR) signal when power is applied or removed. The MSP430 MCU’s zero-power BOR circuit is continuously turned on, including in all low-power modes.

Although the MSP430"s DMA subsystem is very capable it has several flaws, the most significant of which is the lack of an external transfer strobe. Although a DMA transfer can be triggered externally, there is no external indication of completion of a transfer. Consequently DMA to and from external sources is limited to external trigger per byte transfers, rather than full blocks automatically via DMA. This can lead to significant complexity (as in requiring extensive hand tweaking of code) when implementing processor to processor or processor to USB communications.

The EEM provides different levels of debug features such as 2-8 hardware breakpoints, complex breakpoints, break when read/write occurs at specified address, and more. Embedded into all flash-based MSP430 devices.

Some MSP430 models include a memory-mapped hardware multiplier peripheral which performs various 16×16+32→33-bit multiply-accumulate operations. Unusually for the MSP430, this peripheral does include an implicit 2-bit write-only register, which makes it effectively impossible to context switch. This peripheral does not interfere with CPU activities and can be accessed by the DMA. The MPY on all MSP430F5xx and some MSP430F4xx devices feature up to 32-bit x 32-bit.

The FRAM MPU protects against accidental writes to designated read-only memory segments or execution of code from a constant memory. The MPU can set any portioning of memory with bit level addressing, making the complete memory accessible for read, write and execute operations in FRAM devices.

MSP430 devices have up to 12 digital I/O ports implemented. Each port has eight I/O pins. Every I/O pin can be configured as either input or output, and can be individually read or written to. Ports P1 and P2 have interrupt capability. MSP430F2xx, F5xx and some F4xx devices feature built-in, individually configurable pull-up or pull-down resistors.

The universal synchronous/asychrnous receive/transmit (USART) peripheral interface supports asynchronous RS-232 and synchronous SPI communication with one hardware module. The MSP430F15x/16x USART modules also support I²C, programmable baud rate, and independent interrupt capability for receive and transmit.

Available on the MSP430FR4xxx and MSP430FR2xxx series chips, this feature is configured via the SYSCFG register set. This peripheral ties into other peripherals (Timers, eUSCI_A) to generate an IR modulated signal on an output pin.

The LCD/LCD_A controller directly drives LCDs for up to 196 segments. Supports static, 2-mux, 3-mux, and 4-mux LCDs. LCD_A module has integrated charge pump for contrast control. LCD_B enables blinking of individual segments with separate blinking memory.

The LCD_E controller comes with the newer MSP430FR4xxx series microcontrollers and directly drives LCDs up to 448 segments. Supports static, 2-mux, 3-mux, 4-mux, 5-mux, 6-mux, 7-mux, 8-mux (1/3 bias) LCDs. Segment and Common pins may be reprogrammed to available LCD drive pins. This peripheral may be driven in LPM3.5 (RTC running+Main CPU core shutdown low-power mode).

Texas Instruments provides various hardware experimenter boards that support large (approximately two centimeters square) and small (approximately one millimeter square) MSP430 chips. TI also provides software development tools, both directly, and in conjunction with partners (see the full list of compilers, assemblers, and IDEs). One such toolchain is the IAR C/C++ compiler and debugger (assembly language programs of any size can be developed and debugged with this free toolchain).

TI also combines a version of its own compiler and tools with its Eclipse-based Code Composer Studio IDE (CCS). It sells full-featured versions, and offers a free version for download which has a code size limit of 16 KB. CCS supports in-circuit emulators, and includes a simulator and other tools; it can also work with other processors sold by TI.

For those who are more comfortable with the Arduino, there is also another software Energia, an open source electronics prototyping platform with the goal to bring the Wiring and Arduino framework to the Texas Instruments MSP430 based LaunchPad where Arduino code can be exported for programming MSP430 chips. The latest release of Energia supports the MSP-EXP430G2xxx, MSP-EXP430FR5739, MSP-EXP430FR5969, MSP-EXP430FR5994, MSP-EXP430F5529LP, Stellaris EK-LM4F120XL, Tiva-C EK-TM4C123GXL, Tiva-C EK-TM4C1294XL, CC3200 WiFi LaunchPad.

TI consulted with RedHat to provide official support for the MSP430 architecture to the GNU Compiler Collection C/C++ compiler. This msp430-elf-gcc compiler is supported by TI"s Code Composer Studio version 6.0 and higher.

Other commercial development tool sets, which include editor, compiler, linker, assembler, debugger and in some cases code wizards, are available. VisSim, a block diagram language for model based development, generates efficient fixed point C-Code directly from the diagram.closed loop ADC+PWM based PID control on the F2013 compiles to less than 1 KB flash and 100 bytes RAM.

The MSP430F2013 and its siblings are set apart by the fact that (except for the MSP430G2 Value Line) it is the only MSP430 part that is available in a dual in-line package (DIP). Other variants in this family are only available in various surface-mount packages. TI has gone to some trouble to support the eZ430 development platform by making the raw chips easy for hobbyists to use in prototypes.

TI has tackled the low-budget problem by offering a very small experimenter board, the eZ430-F2013, on a USB stick (now obsolete). This made it easy for designers to choose the MSP430 chip for inexpensive development platforms that can be used with a computer. The eZ430-F2013 contains an MSP430F2013 microcontroller on a detachable prototyping board, and accompanying CD with development software. It is helpful

Texas Instruments released the MSP430 LaunchPad in July 2010. The MSP430 LaunchPad has an onboard flash emulator, USB, 2 programmable LEDs, and 1 programmable push button.shield board is available.

All three of these LaunchPads include an eZ-FET JTAG debugger with backchannel UART capable of 1Mbit/s speeds. The FRAM LaunchPads (e.g. MSP-EXP430FR5969, MSP-EXP430FR4133) include EnergyTrace, a feature supported by TI"s Code Composer Studio IDE for monitoring and analyzing power consumption.

In common with other microcontroller vendors, TI has developed a two-wire debugging interface found on some of their MSP430 parts that can replace the larger JTAG interface. The eZ430 Development Tool contains a full USB-connected flash emulation tool (FET) for this new two-wire protocol, named

The advantage of the Spy-Bi-Wire protocol is that it uses only two communication lines, one of which is the dedicated _RESET line. The JTAG interface on the lower pin count MSP430 parts is multiplexed with general purpose I/O lines. This makes it relatively difficult to debug circuits built around the small, low-I/O-budget chips, since the full 4-pin JTAG hardware will conflict with anything else connected to those I/O lines. This problem is alleviated with the Spy-Bi-Wire-capable chips, which are still compatible with the normal JTAG interface for backwards compatibility with the old development tools.

JTAG debugging and flash programming tools based on OpenOCD and widely used in the ARM architecture community are not available for the MSP430. Programming tools specially designed for the MSP430 are marginally less expensive than JTAG interfaces that use OpenOCD. However, should it be discovered mid-project that more MIPS, more memory, and more I/O peripherals are needed, those tools will not transfer to a processor from another vendor.

The MSP430 CPU uses a von Neumann architecture, with a single address space for instructions and data. Memory is byte-addressed, and pairs of bytes are combined little-endian to make 16-bit words.

The MSP430X extension with 20-bit addressing adds added instructions that can require up to 10 clock cycles. Setting or clearing a peripheral bit takes two clocks. A jump, taken or not takes two clocks. With the 2xx series 2 MCLKs is 125 ns at 16 MHz.

The basic MSP430 cannot support more memory (ROM + RAM + peripherals) than its 64K address space. In order to support this, an extended form of the MSP430 uses 20-bit registers and a 20-bit address space, allowing up to 1 MB of memory. This uses the same instruction set as the basic form, but with two extensions:

If the instruction is register-to-register, a different extension word is used. This includes a "ZC" flag which suppresses carry-in (useful for instructions like DADD which always use the carry bit), and a repeat count. A 4-bit field in the extension word encodes either a repeat count (0–15 repetitions in addition to the initial execution), or a register number which contains a 4-bit repeat count.

There is a new extended version of the architecture (named MSP430X) which allows a 20-bit address space. It allows added program ROM beginning at 0x10000.

The size bit is named A/L, where L (long) is used by other processors to indicate 32-bit operands. Also the description of the SXTX instruction (MSP430F5xx Family User"s Guide alau208f page 237) describes the effect of the instruction in register bits 20–31.

I"m having trouble getting my msp430 to communicate with a 16x4 LCD screen. Data sheet for the LCD screen: https://www.beta-estore.com/download/rk/RK-10290_410.pdf

I"m pretty positive all my pins are connected correctly. The LCD is projecting light but that"s it. I can"t even get the cursor to show up and blink on the screen. I have my bus connected to 8 LED lights so I can be sure the correct commands are being sent. That is also why I have the long delay in between each write operation. Not sure what to do from here to troubleshoot. Any help would be greatly appreciated.

Port 2 can be used to provide the six data signals required to control the LCD. Note how the LCD is connected to the breadboard and that wires can be connected to the pins as shown in figure 1. There is a four bit interface for the data (D4-D7), a RS (select command versus text) and an enable (E). Figure 2 shows the other required connections as well. The datasheet for the LCD can be found here GDM1602K-Extended.pdf. The commands are correct but the electrical specifications may vary between LCDs so make sure you have the correct datasheet for your specific LCD (3.3V versus 5.0V for instance)

Specific to this lab and the corresponding lcd_lib files we will setup the LCD to use all six available pins in Port 2 to write directly to the 16 x 2 LCD in 4-bit operation using only the most significant data nibble.

Show the TA your code, functional board and answer questions posed. 20% credit for functional code and 80% credit for correct answers about the code. You will be expected to explain every line of code for full credit.

In this post will you find some basic tests with 16×2 LCD display using the MSP430. It is a widely used display controlled by the Hitachi HD44780. This display is able to show 2 lines of 16 alphanumeric characters.

Character LCDs use a 16 contact interface, commonly using pins or card edge connections on 0.1 inch (2.54 mm) centers. Those without backlights may have only 14 pins, omitting the two pins powering the light. The pinout is as follows:

The hardware assembly of this project is very simple. The commication with display is done using 8-bits or 4-bits, to save I/O pins is commonly used the 4-bit operation mode. In this case the data is send in two parts: first the upper nibble is sent and after the lower nibble is sent. The connection between LCD and MSP430 is as follow:

Communicating with LCD controller requires to follow a specific initialization sequence. The commands and timings must be respected in order to achieve a proper work in desired mode. The following diagram shows the initialization sequence for the JHD162A (The device that I utilized, some variations in timings can happens depending on lcd display manufacturer).

The full project can be downloaded in the GitHub. At this step you might set the development environment like shown in previous article. More things can be done to improve this code, specially removing the delays. As the LCD is a ‘slow device’, the microcontroller usually hangs much on delays during commands, this time could be used to make other tasks.

The full undertaking can be downloaded on GitHub. At this progression, you may set the improvement climate like appeared in the past Animated Video Production Services article. More things should be possible to improve this code, particularly eliminating the deferrals.

Abstract: LcD interfacing with MSP430 VI-302 "7 segment LcD" display msp430 msp430 lcd subroutine VI-302-DP-S SLAA151 I2C applications msp430 varitronix vi-302 VI-302-DP

Text: Application Report SLAA151 AUGUST 2002 Interfacing the TMP100 Temperature Sensor , of the with a 3.5 digit , : LCD Display 46.9uA Total 2.45uA average 5.9582sec Duration 0.9uA: TMP100, Current Consumption Profile Interfacing the TMP100 Temperature Sensor 6 SLAA151, to develop the with a minimum number of active clock cycles in mind. The fast 6

Abstract: Code Example for MSP430x4xx VI-302 I2C applications msp430 strain gauge sensor 3.5-DIGIT lcd msp430f413 MSP430x4xx I2CRead16 slas340 texas instruments

Text: . Hardware Description The MSP430F413 device used in this application is a low-cost MCU with integrated LCD , results and connects directly to the LCD manufacturer part number is VI-302. Pushbuttons PB1 , conversions, switches off the LCD display, and the Interfacing the ADS1100, Application Report SLAA206 July 2004 Interfacing the ADS1100 to the MSP430F413 Andreas

Abstract: SLAA024 TLV5616 SELECTION GUIDE "7 segment LED" msp430 LCD interfacing with MSP430 MSP430 MSP430C111 MSP430C112 adapter BP-1400 QFP 44 MSP430F1121

Text: function, while the part is drawing just 0.8 µA. The LCD display and await , with RAM, peripherals , 6 MSP430x31x Configuration The MSP430x31x family is the most cost-optimized version with a LCD , interfacing 3V 9 R03 R13 R23 R33 The LCD driver module can drive up to 92 segments in 1-to-4 MUX , needed for a complete system with the MSP430x32x Configuration XIN XOUT XBUF VCC VSS

Abstract: 7 segment LED display project msp430 applications msp430 "mp3 player" msp430 "mp3 player" mp3 player circuit diagram by using msp430 DSK5510 sblcda2 ES449 embedded system projects on msp 430 rtos salvo

Abstract: SmartRF04 user guide MSP430F2013 Manual DN401 CC102X AN023 RS232 MSP430F2013 MSP430X16X usb to serial spi controller board for msp430 PC MOTHERBOARD SERVICE MANUAL

Text: Application Report SLAA209 August 2004 Interfacing the MSOP8EVM to with the LCD screen to display the conversion results. SLAA209 August 2004 Interfacing , www.ti.com. SLAA209 August 2004 Interfacing the MSOP8EVM to Interfacing the MSOP8EVM to SLAA209 August 2004 IMPORTANT NOTICE Texas Instruments

Text: shown on an LCD display. If the bridge sensor gets excited with 3V, it delivers converter (ADC) for , Figure 1). An on-chip LCD driver enables direct interfacing to common LCD modules. +3V DVCC RST , Experience cutting-edge ultra-low-power technology Meet with TI

Abstract: cc2500 microcontroller interfacing interfacing zigbee cc2500 with microcontroller CC1101 MSP430 zigbee interfacing with rs232 CC2500 SWRA116A cc1100 EM UART applications msp430 joystick smartrf

Text: Interfacing CC1100 using SPI with SmartRF04®EB Library for CC1100 and CC2500 Introduction The , Design Note DN400 Interfacing CC1100 - CC2500 to the with this library due to hardware , , interfacing the MSP430F169 and the CC1100 radio transceiver. The motherboard (EB) is populated with 0 , ; Transceiver/Transmitter SI Table 3. Peripherals Connections on SmartRF®EB The with the

Abstract: radio shack-271-110 thermistor radio shack radio shack 271-110 Thermistor 271-110 SLAAE10C digital thermometer program SLAUE10B circuit diagram for lcd digital thermometer SLAA038

Text: components connect directly to the LCD display must also be connected if a , port of a PC, using the interface included with the boards. with a minimum of hardware interfacing . The combination of the , with TI"s standard warranty. Testing and other quality control techniques are utilized to the

Text: onboard 64x128 pixels serial LCD LEDs Serial Flash Buttons Accelerometer Light Sensor , operating in UART Mode. To communicate with a connected RF-IC, the onboard with custom firmware. Please refer to the SWRU294 6.2 with a MSP430F5438A micro controller from Texas , onboard components to break. WARNING! When using the SmartRF TrxEB with a

Text: COMMON SPI Figure 6. Interfacing the ADS1251/52 to the ADS1251 and ADS1252 provide , Application Report SLAA242 May 2005 INTERFACING THE ADS1251/52 TO THE MSP430F449 Joe Purvis , Figure 1 illustrates these functions. SLAA242 May 2005 INTERFACING THE ADS1251/52 TO THE , shows this graphically. 2 INTERFACING THE ADS1251/52 TO THE MSP430F449 SLAA242 May 2005 , specific instance, the pass-band response is as shown in Figure 4. SLAA242 May 2005 INTERFACING THE

Text: Application Report SPRA639 - February 2000 Interfacing TMS320C5000 DSP to with a rich set of built-in hardware features, like LCD driver, A to D , dedicated programmable I/Os. with different sets of , MSP430x33x Pin Connections Interfacing TMS320C5000 DSP to Interfacing TMS320C5000 DSP to

Text: Application Report SPRA639A - October 2000 Interfacing TMS320C5000 DSP to Interfacing TMS320C5000 DSP to with a rich set of built-in hardware features, like LCD driver, A to D , dedicated programmable I/Os. with different sets of , . Interfacing TMS320C5000 DSP to SPRA639A Vdd TMS320C54x DSP

Text: obtained using the LCD display. The portable , solution for this application with not only high resolution ADCs with PGA, but also LCD driver and , LCD driver enables direct interfacing to common LCD modules. In this application, the SBLCDA4, a 4 , mode) and set accordingly. Next, the with interrupts enabled. LPM0 , .

Abstract: f6137b msp430g2553 32x32 LED Matrix stepper motor control with msp430f2013 MSP430F5438 MSP430G2553 EZ430-CHRONOS Bluetooth Module CC2560 Texas Instruments MSP430G2xx led matrix 32X32

Text: Boards are available for all with ZIF target sockets for interfacing with , support for the with technical documents, training, tools and software to help , . High-Performance Integration The 400+ LCD , device for many lowpower applications. The with , affordable, seamless and easy-to-use. Get started with the $4.30

Abstract: softbaugh* SBLCDA4 temperature sensor schematic msp430 schematic LG lcd power supply unit T218010 SD16A SLAA254 MPAK1320 SLAU056 MSP430x42x0

Text: With a supply voltage of 3V, the , SLAA254 The 16-bit sigma-delta ADC can operate with either using a built-in reference of , R7 and R11. The MSP430F4270 on-chip LCD driver enables direct interfacing to common LCD modules. In , is around 3µA with the LCD_A charge pump disabled (set to "CP OFF") and the LCD Display Along with this application report, software, schematics and

Abstract: SBLCDA4 softbaugh* SBLCDA4 swra141 cc2500 microcontroller interfacing DN506 real world applications of msp timer peripheral generic SPI CC2500 cc2500 application notes

Text: Page 1.1 LCD Editor icon taken from version , signals applied to the device pins. Grayed parts belong to or work with the LCD Editor and are described , Installation 2-13 Installation 2 LCD Editor Setup program , Installation 2-16 LCD Editor Topics Page , the LCD Editor 2-2 LCD Editor

Text: -Bit Timer_A With Three Capture/Compare Registers Integrated LCD Driver for 96 Segments On-Chip Comparator D , automatically when applicable LCD module control bits are set, not with PxSEL bits. POST OFFICE BOX 655303 , control 2 Flash control 1 PERIPHERALS WITH BYTE ACCESS LCD LCD memory 20 : LCD memory 16 LCD Memory 15 , Texas Instruments With 16-bit RISC architecture, 16

Text: to run the simulator is to open the with a double mouse click on the , with the Close button. 3-7 Getting Started with the message, that the , the LCD window using the Window| LCD command. Figure 3.13: Window| LCD command 3-14 LCD window. Figure 3.14: LCD

Abstract: Design Seminar Signal Transmission luxmeter "7 segment" msp430 hex bcd assembler conversion MSP430 sms BP-1400 Universal Device Programmer msp430 features AX430 Assembler programming for LCD

Text: Ultra-low power design with Agenda · Low-Power Concept · ROM430 LCD Editor . LCD *. in Programming Adapter with TI Software Pack: LCD Editor Edit Boxes to set the new values of Edit Boxes , Ultra-low power design with TI Programming Adapter HeCh / 02-99/ 8-7 LCD Signals LCD Signals HeCh / 02-99/ 8-8

Text: Using the Linker LCD window and the editor window with the file , with the Close button. 6-7 Using the Linker evma320i.asm" , command. 6-9 Using the Linker with the messages , : Setting a breakpoint 6-11 Using the Linker with the Run , marked with the run bar. Figure 6.12: Run bar 6-13 Using the Linker Now open the LCD window

Abstract: ir sensor interface with msp430 msp430 motor pwm control msp430 TSS721 msp430 led pwm control SLAAE10C MSP430 data loggers msp430 MBUS 16X16 BIT RISC PROCESSOR using the msp430 as a real-time clock

Text: With LCD Driver Without LCD Driver Available In Design Complexity 3 The with the LCD driver in the with the timers and LCD still active. These examples are benefits of the most often used low-power , System Cost Saving with the with the lowest possible

Text: Ultra-low power design with Agenda · Low-Power Concept · with with LCD driver x330 x320 CPU, Timer/Port x310 without LCD driver More to come x11x Complexity HeCh / 02-99/ 3-2 with

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey