lifetime of lcd displays free sample

Perhaps you’ve wondered how long a digital display lasts. It’s a great question. One quick search on Google will tell you that an LCD panel has a lifespan of about 60,000 hours, which is equivalent to almost seven years.

Of course, LCDs aren’t the only kind of displays. You also have LED, OLED, QLED, ELD, PDP, and MicroLED, plus many other variations. Obviously, that 7-year estimation will not apply across the board. For the sake of ease, let’s just focus on some of the common types of displays that most of us are familiar with.

Here’s some LCD alphabet soup: There are LED LCD displays, CFFL LCD displays, LED displays, and more. With all these acronyms, it can get a bit confusing. What"s important to note is whether or not the display uses an LCD panel, and how the LCD panel is illuminated. You can read more about thedifferences between types of LCD and LED signage, but these are the most common types:

LCD displaysgenerate images and colors via a Liquid Crystal Display (LCD) panel, which is not self-emitting and requires an external light source to illuminate the image, typically an LED backlight. Their full name "LED-backlit LCD display" is commonly shortened to "LED displays", which is why they"re often confused with the true LED displays we"ve identified above.

Unfortunately, LED backlights used in LCD displays burn out over time. If used at high or maximum brightness, which is necessary for outdoor applications,an LED backlight will last between 40,000 to 60,000 hours. Or, about 4.5 to 7 years.

OLED stands for Organic Light Emitting Diode. OLED displays differ from common LCD displays in that their pixels are self-illuminating. In other words, there is no LED backlight required to illuminate the the display image; everything occurs within the OLED pixels themselves. According to onearticle from the US Department of Energy,OLED screens have a life expectancy of about 40,000 hours at 25% brightness, and 10,000 hours at full brightness. That equates to about 1 to 4.5 years, which is a much shorter (albeit, brilliant) lifetime than an LCD display.

Perhaps you noticed that the acronym QLED closely resembles the acronym OLED. This is not accidental. QLED is basically Samsung’s original design built to compete with OLED technology. However, the two are not the same. QLED stands for Quantum Light Emitting Diode. While QLED is similar to a regular LED design, it in fact differs by using nanoparticles called “Quantum dots” to achieve its unique brightness and color. Samsung approximates that the lifespan ofQLED panels are likely to last 7-10 years. After that, a user is likely to notice traces of degradation.

MicroLED is an emerging display technology, consisting of small LEDs in tiny arrays within each pixel. This technology goes beyond the offerings of the formerly frontrunning OLEDs, with much darker blacks and more radiant contrast levels. And, unlike OLEDs, MicroLEDs are not organic. They are not as subject to burn-in, and thus, have a longer lifespan than OLEDs. However, they are significantly more expensive - so much, in fact, that they aren’t considered a viable option for the majority of consumers.According to Samsung, the lifespan of its MicroLED panels should last about 100,000 hours, or, roughly 11 years.

PDP stands for Plasma Display Panel, and it refers to displays that use small cells full of plasma. The atoms within the plasma emit light upon being charged by electricity. While PDP is generally considered to offer better colors than LCDs, they consume a lot more power and usually cannot be battery-operated.The average lifespan of the newest generation of PDPs is approximated to be 100,000 hours, or 11 years of continual use.

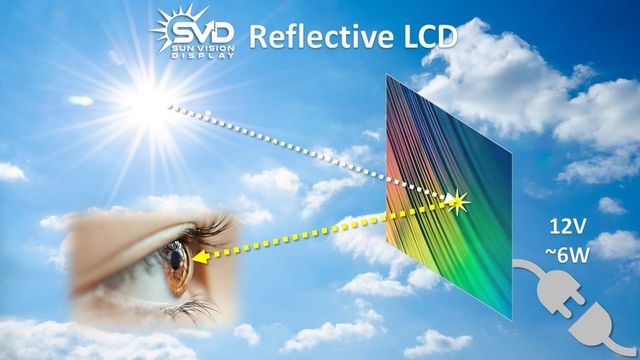

In some ways,reflective LCD panelsoperate similarly to other LCDs, only they have one key difference - they do not require a backlight. Instead, they rely on ambient light (or sunlight) in order to produce images. This opens the door to some groundbreaking possibilities. The first (and most appreciable) is low power consumption. Reflective displays use up to 95% less energy. Not bad - especially in a world that is continually looking for new ways to go green. Take into consideration the financial implications of this. Lower power means less money spent on operating costs.

Being that reflective displays do not require a backlight (a component that is particularly subject to degradation), and since they do not generate as much heat, it is safe to say that the lifespan of these displays should far exceed that of backlit LCD panels (which was 7 years at the high end). However, being that thisinnovative technologyis relatively new, its actual lifespan is therefore more difficult to estimate -- simply because it has yet to be reached.

There are also a few challenges that can affect reflective displays. For one, they rely on ambient light. On a nice sunny day, these displays perform beautifully and can be easily seen in even the brightest of conditions. This performance wanes as the available ambient light decreases. And, since they do not generate light of their own, they are not designed to be viewed under nighttime or extremely low light conditions (without additional lighting features). In short, their images are visible to the degree that ambient light is present. However, in light of this, side light (and front light) options are being explored.

One company at the front lines of this research isAzumo. Azumo has created a light guide that laminates to the front of a display. It requires 90% less energy than the backlight of a traditional LCD display. This greatly improves the problem of low light visibility otherwise encountered, and keeps reflective displays in the same low energy consumption ballpark. One issue, however, is that Azumo currently only offers its light guides for smaller-sized units. If you happen to want this feature applied to a display that is over 10” diagonally, then you’re still on the search for a solution.

Other “pioneer companies” are at the frontier of this research as well, and many are already innovating new solutions to increase the viability of reflective technology - both in their low light visibility and in the screen sizes they are available in. Due to the huge potential offered by reflective technology, it is fair to assume that we will see even greater enhancements to it in the very near future.

One other factor to consider regarding reflective technology is its cost. That reflective layer is more costly to manufacture than many of the backlights it replaces, creating a seemingly greater upfront cost for those who are interested in investing in energy-efficient signage. However, these initial price points are quickly justified as buyers will recognize the significantly lower operating costs and increased longevity (not even including replacement costs of other “expired” displays) that comes with their purchase of reflective display signage. If a backlit LCD panel only lasts 7 years, for example, you’ll have paid for that LCD twice in the period of ten years. A very valid question arises… is that “cheaper” backlight really cheaper? Probably not. It only feels that way at first.

Sun Vision Displayis working hard to create reflective display solutions for the digital signage world. We are currently offering them in 32" and 43" diagonal sizes, with a 55” size in development. These displays are built formany environments. We are thrilled to be bringing such innovative solutions to the market.

If you have any questions, or if you would like to talk to a representative about how our solutions might work for you, please don’t hesitate to contact us. Simply scroll down to the bottom of the page to our form, and we’ll get back to you in a timely manner. We look forward to the possibility ofworking with you!

For real-life application we used many of these in a commercial automated capuccino machine, and they had no problems (using a reputable Asian brand name of module) provided they were mounted in a stress-free way.

In one of the previous articles in Uni’s ABC series, we have discussedthe crucial parameters of LCDs, pointing out, e.g., resolution, brightness, contrast ratio, or viewing angles, which impact the readability of the presented content. In some applications, there is also another worth noticing factor, that is, the LED’s durability. In datasheets, this parameter is usually called as “LED life time”.

LED – a light-emitting diode, is a basic element of LED backlights used in LCDs. The manufacturers define the backlight’s LED life time, so the average time of LEDs’ failure-free operation. It is specified as the number of hours followed by degradation of LEDs; then their luminance is 50% compared to its original value.

Well, there is no one-size-fits-all answer for such a question, besides “it depends”; mainly, it depends on the type of application that requires LCD. In the case of, e.g., consumer electronics, let’s say – TVs, we can choose a 30 000 h LED life time model. If we suppose that we will use it for 8 hours in each of 365/366 days in a year, it can function properly for about 10 years. Then, we can assume that the “standard” LED life time for this type of device is 30 000 h. It seems like a long time, especially for a TV’s users – nowadays, at galloping technological progress, the 10-years old devices may be perceived as “bygone”. (Just think about the dynamic extending of the resolutions applied in TVs – in 2014/2015, the 4K technology has popularized, today, in 2020, the 8K technology is on the tapis.)

In many applications, the LED life time will not be a crucial parameter that will preordain a particular LCD’s choice. Let’s conceive of assembling a 3.9-inch WF39BSQASDNN0# by Winstar, which LED life time has been estimated at 50 000 h, in a coffeemaker. If we suppose that this device will be intended to use in the office, e.g., for 10 hours each day, this screen will function properly even for 14 years. (All in all, such intensively used coffeemaker probably will be able to operate only for a few years due to the wear of other machine components.)

However, a few applications require LCD of “standard” LED life time at the level of even… 100 000 h (what kind of applications are they? – just read on ;-).

In datasheets, the manufacturers indicate the factors that should be maintained on a steady level to provide the longest LED life time at the optimal intensity of emitted light. Among them, e.g., temperature. Example: for AUO’s displays – 54.6-inch P55HVN12.0 and 85.0-inch P850QVN03.1, the LED life time has been estimated at 70 000 h, so about 8 years of continual functioning, as long as the environment temperature is 25 +/-2°C. Any fluctuations may influence the LED life time, which is related to the structure of LEDs – they are made of silicon, which properties contingent on temperature.

The extended LED life time is crucial for devices intended to work in continuous mode, 24/7. These are solutions used in, e.g., digital signage systems. Litemax is a pacemaker among the producers of extended LED life time LCDs. Its offer is full of solutions, which LED life time is estimated at 100 000 h. These are, e.g., LCDs of Spanpixel and Durapixel, as well as Squarepixel series. They can be used, e.g., in transportation to provide up-to-date information about, e.g., timetables or route courses (in this case, you should learn more about SSF2845-E, SSH2845-E, and SSD2845-E, which meet the requirements of EN 50155 standard). These solutions can also be applied in other public spaces as various information carriers in, e.g., shops, hotels, restaurants, and coffeehouses, as well as offices. What is more, the LED life time of SCD2365-Y, so the circular LCD, has also been estimated at 100 000 h; it can be an attractive element of the windows of, e.g., customer service points.

PS. In recent years, LCDs with LEDs getting more and more advanced. One of the developed functionalities is local dimming, also implemented in some of Litemax’s solutions. Learn more about selective backlighting – here.

Keeping the screen clean by wiping the surface with a microfiber cloth is actually the very last step in "cleanliness” and is up to the end user of the module....

One could say that screens are all around us, blended into the public space. We can hardly imagine a comeback of traditional forms of travel without high-tech passenger information services....

We have already talked about e-paper many times. This is a topic that becomes more and more interesting with the passage of time and the rapid development of this technology....

We all love to binge-watch our favorite shows over long weekends and after long days. It allows us to passively socialize and judge the mistakes of others without ever leaving the living room. A good home theater is built around a solid TV, and that technology has grown by leaps and bounds over the past two decades. But, how do you know which of these technologies will deliver the best picture for the next two decades?

The act of selecting the television screen that suits your needs can be difficult enough, but when you consider all the different technologies available out there, it can become downright confusing. If you aren’t into buying a new set every couple of years, you’ll want to take the TV lifespan into consideration. Thankfully, we’re going to cover

Many of us are unaware of the technical aspects regarding televisions, which often leads to blindly purchasing products with a short shelf life. In fact, the more people shift their shopping habits into the online world, many consumers never even see the screen until it’s up in their living rooms. It doesn’t always work out the way they’d hoped.Selecting a set in person will allow you to see the differences in the different technologies, and you won’t find any surprises when you mount it in your home. It can make or break a purchase in regards to how one wants their favorite show or film presented, so knowing what you’re looking for can be incredibly helpful.

In many cases, the location where the television is being used in the household/building can change opinions regarding a purchase. For example, a room full of windows will cause glare on the screen. If the television is at an angle or mounted up high, the picture may not be visible at all. Since these factors have a huge impact on the usage of the televisions, here’s what the most popularscreensoffer:

LED & LCD –LED and LCD televisions are the big players in the market today. They are basically the same backlit setup and each technology has similar perk/setbacks. LED and LCD televisions work excellent in bright rooms, they’ve outsold plasma televisions (and they have taken over the market). They consume less power, they’re thin/light to transport, and they’re bright. However, both LCD and LED televisions fall short when it comes to motion blur (on lower-end models), they sometimes have backlight issues, and they offer limited viewing angles.

Plasma –Although the plasma screen market has been declared “dead”, some still floating around on the market for a decent price. Plasma screens are known for working the best in dark/dimly lit areas, they have no motion blur, and they have the best black coloring in their picture. Unfortunately, plasma screens fall short when it comes to performing in rooms with lots of windows, so this might be a good purchase on the second-hand market for the basement. They’re bulkier than the competition, and they sometimes have image retention issues. Also, they consume more power and can make a buzzing noise.

People generally want to know the lifespan of a TV in years. The average life of LED TVs and LCD sets is typically somewhere from 4 to 7 years of active use. Most of us don’t watch our TVs twenty-four hours a day, so a simple calculation on your watching habits can give you a good estimate. If you watched for 6 hours a day, you could theoretically multiply that lifespan by 4 (6×4=24), giving you 16 to 28 years.

Considering the regular defects and issues that occur over time, LCD and LED televisions basically have the same lifespan. With each of these technologies, the likely failure will come in the form of a worn-out backlight, so decreasing your backlight levels can significantly extend your set’s lifespan. A higher-quality set with a better backlight can also net you a few more years of use.

If you want your purchase to last a long time, your best bet is to choose a decent set from a reputable manufacturer. Purchasing a quality set will ensure that your new television is built from quality materials that should hopefully last a little longer. Purchasing from a reputable manufacturer gives you the peace of mind that comes with solid customer service and warranties.

To evaluate the performance of display devices, several metrics are commonly used, such as response time, CR, color gamut, panel flexibility, viewing angle, resolution density, peak brightness, lifetime, among others. Here we compare LCD and OLED devices based on these metrics one by one.

A fast response time helps to mitigate motion image blur and boost the optical efficiency, but this statement is only qualitatively correct. When quantifying the visual performance of a moving object, motion picture response time (MPRT) is more representative, and the following equation should be used

From Figure 5, we can gain several important physical insights: (1) Increasing the frame rate is a simple approach to suppress image motion blur, but its improvement gradually saturates. For example, if the LC response time is 10 ms, then increasing the frame rate from 30 to 60 fps would significantly reduce the MPRT. However, as the TFT frame rate continues to increase to 120 and 240 fps, then the improvement gradually saturates. (2) At a given frame rate, say 120 fps, as the LC response time decreases, the MPRT decreases almost linearly and then saturates. This means that the MPRT is mainly determined by the TFT frame rate once the LC response time is fast enough, i.e., τ≪Tf. Under such conditions, Equation (1) is reduced to MPRT≈0.8Tf. (3) When the LC response is <2 ms, its MPRT is comparable to that of an OLED at the same frame rate, e.g., 120 fps. Here we assume the OLED’s response time is 0.

The last finding is somehow counter to the intuition that a LCD should have a more severe motion picture image blur, as its response time is approximately 1000 × slower than that of an OLED (ms vs. μs). To validate this prediction, Chen et al.

If we want to further suppress image blur to an unnoticeable level (MPRT<2 ms), decreasing the duty ratio (for LCDs, this is the on-time ratio of the backlight, called scanning backlight or blinking backlight) is mostly adopted

As Figure 6 depicts, there are two types of surface reflections. The first one is from a direct light source, i.e., the sun or a light bulb, denoted as A1. Its reflection is fairly specular, and in practice, we can avoid this reflection (i.e., strong glare from direct sun) by simply adjusting the display position or viewing direction. However, the second reflection, denoted as A2, is quite difficult to avoid. It comes from an extended background light source, such as a clear sky or scattered ceiling light. In our analysis, we mainly focus on the second reflection (A2).

To investigate the ACR, we have to clarify the reflectance first. A large TV is often operated by remote control, so touchscreen functionality is not required. As a result, an anti-reflection coating is commonly adopted. Let us assume that the reflectance is 1.2% for both LCD and OLED TVs. For the peak brightness and CR, different TV makers have their own specifications. Here, without losing generality, let us use the following brands as examples for comparison: LCD peak brightness=1200 nits, LCD CR=5000:1 (Sony 75″ X940E LCD TV); OLED peak brightness=600 nits, and OLED CR=infinity (Sony 77″ A1E OLED TV). The obtained ACR for both LCD and OLED TVs is plotted in Figure 7a. As expected, OLEDs have a much higher ACR in the low illuminance region (dark room) but drop sharply as ambient light gets brighter. At 63 lux, OLEDs have the same ACR as LCDs. Beyond 63 lux, LCDs take over. In many countries, 60 lux is the typical lighting condition in a family living room. This implies that LCDs have a higher ACR when the ambient light is brighter than 60 lux, such as in office lighting (320–500 lux) and a living room with the window shades or curtain open. Please note that, in our simulation, we used the real peak brightness of LCDs (1200 nits) and OLEDs (600 nits). In most cases, the displayed contents could vary from black to white. If we consider a typical 50% average picture level (i.e., 600 nits for LCDs vs. 300 nits for OLEDs), then the crossover point drops to 31 lux (not shown here), and LCDs are even more favorable. This is because the on-state brightness plays an important role to the ACR, as Equation (2) shows.

Calculated ACR as a function of different ambient light conditions for LCD and OLED TVs. Here we assume that the LCD peak brightness is 1200 nits and OLED peak brightness is 600 nits, with a surface reflectance of 1.2% for both the LCD and OLED. (a) LCD CR: 5000:1, OLED CR: infinity; (b) LCD CR: 20 000:1, OLED CR: infinity.

Recently, an LCD panel with an in-cell polarizer was proposed to decouple the depolarization effect of the LC layer and color filtersFigure 7b. Now, the crossover point takes place at 16 lux, which continues to favor LCDs.

For mobile displays, such as smartphones, touch functionality is required. Thus the outer surface is often subject to fingerprints, grease and other contaminants. Therefore, only a simple grade AR coating is used, and the total surface reflectance amounts to ~4.4%. Let us use the FFS LCD as an example for comparison with an OLED. The following parameters are used in our simulations: the LCD peak brightness is 600 nits and CR is 2000:1, while the OLED peak brightness is 500 nits and CR is infinity. Figure 8a depicts the calculated results, where the intersection occurs at 107 lux, which corresponds to a very dark overcast day. If the newly proposed structure with an in-cell polarizer is used, the FFS LCD could attain a 3000:1 CRFigure 8b), corresponding to an office building hallway or restroom lighting. For reference, a typical office light is in the range of 320–500 luxFigure 8 depicts, OLEDs have a superior ACR under dark ambient conditions, but this advantage gradually diminishes as the ambient light increases. This was indeed experimentally confirmed by LG Display

Calculated ACR as a function of different ambient light conditions for LCD and OLED smartphones. Reflectance is assumed to be 4.4% for both LCD and OLED. (a) LCD CR: 2000:1, OLED CR: infinity; (b) LCD CR: 3000:1, OLED CR: infinity. (LCD peak brightness: 600 nits; OLED peak brightness: 500 nits).

For conventional LCDs employing a WLED backlight, the yellow spectrum generated by YAG (yttrium aluminum garnet) phosphor is too broad to become highly saturated RGB primary colors, as shown in Figure 9aTable 2. The first choice is the RG-phosphor-converted WLEDFigure 9b, the red and green emission spectra are well separated; still, the green spectrum (generated by β-sialon:Eu2+ phosphor) is fairly broad and red spectrum (generated by K2SiF6:Mn4+ (potassium silicofluoride, KSF) phosphor) is not deep enough, leading to 70%–80% Rec. 2020, depending on the color filters used.

Transmission spectra of color filters and emission spectra of (a) YAG WLED, (b) KSF WLED, (c) QDEF and (d) Vivid Color LED. KSF, potassium silicofluoride; QDEF, quantum dot enhancement film; WLED, white light-emitting diode; YAG, yttrium aluminum garnet.

A QD-enhanced backlight (e.g., quantum dot enhancement film, QDEF) offers another option for a wide color gamutFigure 9c), so that high purity RGB colors can be realized and a color gamut of ~90% Rec. 2020 can be achieved. One safety concern is that some high-performance QDs contain the heavy metal Cd. To be compatible with the restriction of hazardous substances, the maximum cadmium content should be under 100 ppm in any consumer electronic product

Recently, a new LED technology, called the Vivid Color LED, was demonstratedFigure 9d), which leads to an unprecedented color gamut (~98% Rec. 2020) together with specially designed color filters. Such a color gamut is comparable to that of laser-lit displays but without laser speckles. Moreover, the Vivid Color LED is heavy-metal free and shows good thermal stability. If the efficiency and cost can be further improved, it would be a perfect candidate for an LCD backlight.

A color filter array is another effective approach to enhance the color gamut of an OLED. For example, in 2017, AUO demonstrated a 5-inch top-emission OLED panel with 95% Rec. 2020. In this design, so-called symmetric panel stacking with a color filter is employed to generate purer RGB primary colors

As mentioned earlier, TFT LCDs are a fairly mature technology. They can be operated for >10 years without noticeable performance degradation. However, OLEDs are more sensitive to moisture and oxygen than LCDs. Thus their lifetime, especially for blue OLEDs, is still an issue. For mobile displays, this is not a critical issue because the expected usage of a smartphone is approximately 2–3 years. However, for large TVs, a lifetime of >30 000 h (>10 years) has become the normal expectation for consumers.

Here we focus on two types of lifetime: storage and operational. To enable a 10-year storage lifetime, according to the analysis−6 g (m2-day)−1 and 1 × 10−5 cm3 (m2-day)−1, respectively. To achieve these values, organic and/or inorganic thin films have been developed to effectively protect the OLED and lengthen its storage lifetime. Meanwhile, it is compatible to flexible substrates and favors a thinner display profile

The next type of lifetime is operational lifetime. Owing to material degradation, OLED luminance will decrease and voltage will increase after long-term drivingT50) can be as long as >80 000 h with a 1000 cd m−2 luminanceT50, half lifetime) with an initial luminance of 1000 nits. However, this is still ~20 × shorter than that of red and green phosphorescent OLEDs

To further enhance the lifetime of the blue OLED, the NTU group has developed new ETL and TTF-EML materials together with an optimized layer structure and double EML structureFigure 10a shows the luminance decay curves of such a blue OLED under different initial luminance values (5000, 10 000, and 15 000 nits). From Figure 10b, the estimated T50 at 1000 nits of this blue OLED is ~56 000 h (~6–7 years)

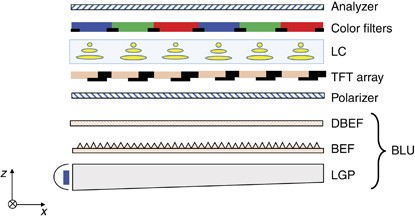

Power consumption is equally important as other metrics. For LCDs, power consumption consists of two parts: the backlight and driving electronics. The ratio between these two depends on the display size and resolution density. For a 55″ 4K LCD TV, the backlight occupies approximately 90% of the total power consumption. To make full use of the backlight, a dual brightness enhancement film is commonly embedded to recycle mismatched polarized light

The power efficiency of an OLED is generally limited by the extraction efficiency (ηext~20%). To improve the power efficiency, multiple approaches can be used, such as a microlens array, a corrugated structure with a high refractive index substrateFigure 11 shows the power efficiencies of white, green, red and blue phosphorescent as well as blue fluorescent/TTF OLEDs over time. For OLEDs with fluorescent emitters in the 1980s and 1990s, the power efficiency was limited by the IQE, typically <10 lm W−1(Refs. 41, 114, 115, 116, 117, 118). With the incorporation of phosphorescent emitters in the ~2000 s, the power efficiency was significantly improved owing to the materials and device engineering−1 was demonstrated in 2011 (Ref. 127), which showed a >100 × improvement compared with that of the basic two-layer device proposed in 1987 (1.5 lm W−1 in Ref. 41). A white OLED with a power efficiency >100 lm W−1 was also demonstrated, which was comparable to the power efficiency of a LCD backlight. For red and blue OLEDs, their power efficiencies are generally lower than that of the green OLED due to their lower photopic sensitivity function, and there is a tradeoff between color saturation and power efficiency. Note, we separated the performances of blue phosphorescent and fluorescent/TTF OLEDs. For the blue phosphorescent OLEDs, although the power efficiency can be as high as ~80 lm W−1, the operation lifetime is short and color is sky-blue. For display applications, the blue TTF OLED is the favored choice, with an acceptable lifetime and color but a much lower power efficiency (16 lm W−1) than its phosphorescent counterpartFigure 11 shows.

Power efficiency of white, red, green and phosphorescent blue and fluorescent/TTF blue OLEDs over time. Data are compiled from Refs. 41, 45, 114, 115, 116, 117, 118, 119, 120, 121, 122, 123, 124, 125, 126, 127, 128, 129, 130, 131, 132, 133.

To compare the power consumption of LCDs and OLEDs with the same resolution density, the displayed contents should be considered as well. In general, OLEDs are more efficient than LCDs for displaying dark images because black pixels consume little power for an emissive display, while LCDs are more efficient than OLEDs at displaying bright images. Currently, a ~65% average picture level is the intersection point between RGB OLEDs and LCDs

Flexible displays have a long history and have been attempted by many companies, but this technology has only recently begun to see commercial implementations for consumer electronics

In addition to the aforementioned six display metrics, other parameters are equally important. For example, high-resolution density has become a standard for all high-end display devices. Currently, LCD is taking the lead in consumer electronic products. Eight-hundred ppi or even >1000 ppi LCDs have already been demonstrated and commercialized, such as in the Sony 5.5″ 4k Smartphone Xperia Z5 Premium. The resolution of RGB OLEDs is limited by the physical dimension of the fine-pitch shadow mask. To compete with LCDs, most OLED displays use the PenTile RGB subpixel matrix scheme

The viewing angle is another important property that defines the viewing experience at large oblique angles, which is quite critical for multi-viewer applications. OLEDs are self-emissive and have an angular distribution that is much broader than that of LCDs. For instance, at a 30° viewing angle, the OLED brightness only decreases by 30%, whereas the LCD brightness decrease exceeds 50%. To widen an LCD’s viewing angle, three options can be used. (1) Remove the brightness-enhancement film in the backlight system. The tradeoff is decreased on-axis brightness

In addition to brightness, color, grayscale and the CR also vary with the viewing angle, known as color shift and gamma shift. In these aspects, LCDs and OLEDs have different mechanisms. For LCDs, they are induced by the anisotropic property of the LC material, which could be compensated for with uniaxial or biaxial films

Cost is another key factor for consumers. LCDs have been the topic of extensive investigation and investment, whereas OLED technology is emerging and its fabrication yield and capability are still far behind LCDs. As a result, the price of OLEDs is about twice as high as that of LCDs, especially for large displays. As more investment is made in OLEDs and more advanced fabrication technology is developed, such as ink-jet printing

FlexEnable’s glass-free organic LCD (OLCD) delivers high-brightness, long lifetime flexible displays that are low cost and scalable to large areas, while also being thin, lightweight and shatterproof.

OLCD is a plastic display technology with full colour and video-rate capability. It enables product companies to create striking designs and realise novel use cases by merging the display into the product design rather than accommodating it by the design.

Unlike flexible OLED displays, which are predominantly adopted in flagship smartphones and smartwatches, OLCD opens up the use of flexible displays to a wider range of mass-market applications. It has several attributes that make it better suited than flexible OLED to applications across large-area consumer electronics, smart home appliances, automotive, notebooks and tablets, and digital signage.

OLCD can be conformed and wrapped around surfaces and cut into non-rectangular shapes during the production process. Holes can be also added to fit around the functional design of the system – for example around knobs and switches.

As with glass-based LCD, the lifetime of OLCD is independent of the display brightness, because it is achieved through transmission of a separate light source (the backlight), rather than emission of its own light. For example OLCD can be made ultra-bright for viewing in daylight conditions without affecting the display lifetime – an important requirement for vehicle surface-integrated displays.

OLCD is the lowest cost flexible display technology – it is three to four times lower cost that flexible OLED today. This is because it makes use of existing display factories and supply chain and deploys a low temperature process that results in low manufacturing costs and high yield.

Unlike other flexible display approaches, OLCD is naturally scalable to large sizes. It can be made as small or as large as the manufacturing equipment used for flat panel displays allows.

The flexibility of OLCD allows an ultra-narrow bezel to be implemented by folding down the borders behind the display. This brings huge value in applications like notebooks and tablets where borderless means bigger displays for the same sized device. The bezel size allowed by OLCD is independent of the display size or resolution. In addition, OLCD can make a notebook up to 100g lighter and 0.5mm thinner.

OLCD is the key to the fabrication of ultra-high contrast dual cell displays with true pixel level dimming, offering OLED-like performance at a fraction of the cost. The extremely thin OLCD substrate brings advantages in cost, viewing angle and module thickness compared to glass displays. At the same time OLCD retains the flexibility required for applications such as surface-integrated automotive displays.

Due to its unique properties, OLCD has the potential to transform how and where displays are used in products. The videos below give a glimpse into this innovative technology.

OLCD brings the benefits of being thin, light, shatterproof and conformable, while offering the same quality and performance as traditional glass LCDs. The mechanical advantages of plastic OLCD over glass LCD are further enhanced by the technology’s excellent optical performance, much of which originates from the extreme thinness of plastic TAC substrates compared to glass.

Responsible for performing installations and repairs (motors, starters, fuses, electrical power to machine etc.) for industrial equipment and machines in order to support the achievement of Nelson-Miller’s business goals and objectives:

• Provide electrical emergency/unscheduled diagnostics, repairs of production equipment during production and performs scheduled electrical maintenance repairs of production equipment during machine service.

Consumer grade displays are essentially regular TVs. Most people watch TV for a few hours everyday. It is a product that is only one when in use. In other words they are not meant to be used more than 6-8 hours per day. Additionally, these screens are typically in a small space. For instance, if there isn’t enough space and ventilation, this often increases the thermal stress on all electronic components, which shortens the operational life of the product.

Commercial displays are expected to have long operating hours. In other words these displays were specifically created to last for long periods of time. Adding to this, they also have unique features to minimize the total cost of ownership.

Commercial grade products are designed to work for long periods of time. To accomplish this, we have additional ventilation, cooling fans, and heat sensors that reduces the temperature in the chassis. These displays use “A” grade LCD module glass with tighter specifications and have additional specifications, such as:

LCD displays don’t emit light by themselves. They need a light source, and LED backlights are now dominating the market. In this article, Orient Display’s Bill Cheung provides a complete overview of LED backlight technology, discussing different types, driver technologies, color deviation, brightness options and more.

LCD (liquid crystal display) has long been the dominant technology in the display world. Certainly, there are some emerging competing display technologies—such as OLED (Organic Light Emitting Diode) [1] and micro-LED—that have the potential to threaten LCD’s position in the market. But both are currently only used for niche and high-end markets.

An LCD display can’t emit light by itself. In order to have an LCD display [2] used in a dim environment, a backlight has to be used as the light source. There are a few different technologies that are able to produce backlight ranging from EL (electroluminescent), CCFL (cold cathode fluorescent lamps) and LED (light emitting diode). However, a breakthrough in blue LED technology by Shuji Nakamura [3] led to LED backlights dominating the market.

One of the greatest benefits of LED backlighting is its long lifetime. Normally, LED lifetime can be measured with half-life when the original brightness decreases by 50%. With different LED chip manufacturing materials, technologies and environment used, the LED life can vary from 20,000 hours to well over 100,000 hours.

LED backlights have low power consumption and produce much less heat than other backlight technologies, which extends the durability and performance of the other display components. Furthermore, this reduces the risk of fire and explosion. LED backlights are also driven with DC (direct current) and low voltage (can be as low as 1.5V), which are good for battery drive and emit no interference to the circuitry. With the development of LED technology, the LED chips become small. So, it is possible to produce very thin backlight (0.5mm thick or thinner).

LED backlight can be classified as bottom (array) lit and side (edge) lit backlights, and each have their plusses and minuses. The advantages of the bottom lit (array) backlight are that it is uniform and bright. Its disadvantage is high current draw, thickness, heat dissipation and cost. Meanwhile, the advantages of the side lit backlight are its thinness, flexibility in design, low current and lower cost. The main disadvantage of the side lit backlight is its non-uniformity—hot spots can be seen from most of the side lit backlight from certain angle. Figure 4 compares the bottom lit and side (edge) lit backlight LCD types.

Now let’s look at LED backlight structures. An LED backlight can be simplified into layers starting with a LED chip, light guide, diffusor and reflector (Figure 5). This is the lowest cost structure. Except for some very low current efficiency LCD displays—such as utility meters, battery-powered clock, watch, GPS and so on—most LCD displays need backlights to be visible in the dim lighting. Most often the backlight is actually at the back of the LCD. In rare cases, this light can be done as front light. The traditional LCD structure with LED backlight shown in Figure 6.

Direct current driving: This is the simple and low-cost way to drive a LED backlight, however, be mindful of the current limit otherwise the LED life can deteriorate quickly. The solution is simply to add a current limiting resistor in the circuit. Current limitation resistors value calculation formula: R = (V0– Vf)/If.Also be mindful of reverse drive, otherwise, the LED chip can break down easily.

LED driver with constant current: The advantage of constant current LED driver is that it will be the best option to use when building your own fixture or working with high powered LED because they avoid violating the maximum current specified for the LEDs, therefore avoiding burnout/thermal runaway. They are easier for designers to control applications, and help create a more consistent bright light.

LED driver with constant voltage: Using a constant voltage LED driver makes sense when using an LED or array that has been specified to take a certain voltage. This is helpful because constant voltage is a much more familiar technology for design and installation engineers. Moreover, the cost of these systems can be lower, especially in larger scale applications.

There are a variety of ways to connect a backlight and LCD module electrically. It can be done with wires that are soldered on the LCD or LCD module. It can be connected using pins, which can be soldered onto the LCD or LCD module. A third way is to use a FPC (flexible printed circuit), which can be soldered or plugged in a ZIF (zero insertion force) connector. And finally, there is the connector method. With this method you use connectors which can be plugged into mating connectors.

As the LED is manufactured via the semiconductor process, there are some color deviations that can be a quality control issue. One way to solve the issue is through a process of selection and sorting after manufacturing the LEDs. The LEDs are sorted into different categories or bins. How this sorting is done and what each bin actually contains is defined differently by each LED manufacturer. The backlight manufacturer can choose from which bin they take the LEDs for backlight color hue.

Some customers might request very fine binning by the LED manufacturer, which can be very expensive since only a very small percentage of the LEDs manufactured would meet the requirements for a specific bin. Figure 7 shows an example of the bin selection from Nichia, the most renowned LED manufacturer in the world. Figure 8 shows the 1931 CIE chromaticity diagram. And Figure 9 shows the color deviations (bin definition) by Cree for a qualified production lot.

In actual LED backlight production, most customers will accept the LED color for two big categories: white with yellowish (warm) and white with bluish (cold). Of course, the LED brightness will also need to be defined. For general application, most customers will accept a brightness tolerance of 70 percent.

It is extremely hard to estimate the LED backlight lifetime or MTBF (mean time between failures) because there are so many variable factors. However, the most important is the temperature on the LED chip. The factors that can affect the LED chip temperature include: surrounding temperature, humidity, driving current, voltage, backlight design (how many LED chips to be used, how close to each other, heatsink design), backlight manufacturing process (type and thickness of adhesive), quality of the LED chip and so forth.

To test the LED life is also very time consuming, requiring at least 1,000 hours. That’s the reason why no LED manufacturers can guarantee LED backlight life and most backlight manufacturers also are reluctant to provide lifespan data. As for LCD manufacturers, they need to discuss it with the customer to understand the applications and provide suggestions. It is normal that the LCD datasheet lists the typical life time and avoids providing a minimum lifetime. From Figure 10, we can see that over room temperature, the current needs to decrease as the temperature increases. At over 85°C, the LED is not usable.

To estimate LED backlight lifetime, you can use ballpark estimation or theoretical calculation. Let’s first examine the ballpark method. To take white LED as example, the nominal biasing current is 20mA. If we use a safe lifetime estimation, we can estimate using Table 1.

Now let’s use the theoretical calculation approach. As we previously mentioned, LED life is affected by a lot of factors: surrounding temperature, humidity, driving current, voltage, backlight design (how many LED chips to be used, how close to each other, heatsink designed), backlight manufacturing process (type and thickness of adhesive), quality of the LED chip and so on. LED chip manufacturers are not willing to give absolute values of LED chip lifetimes, but there is a theoretical calculation that we can use.

Where Tjis PN junction temperature (°C); Ts1 is solder temperature cathode side (°C); Rthj-s1 is thermal resistance of junction to Ts1 measuring point (°C/W); W is IF × VF; and, for Nichia NS6W083A Tj Max = 120°C, Rthj-s1= 10°C/W.

Finally, let’s look at ways to increase LED backlight brightness. There are many ways to increase LED backlight brightness, but all these measures are balanced with performance and cost. Here are some of the methods:

For the LCD module side, using better aperture opening ratio, anti-reflection coating on surface, optical bonding. This results in higher cost. Actually, this measure is not to increase LED backlight brightness directly but to increase to the visibility to users.

Note: We’ve made the May 2020 issue of Circuit Cellaravailable as a free sample issue. In it, you’ll find a rich variety of the kinds of articles and information that exemplify a typical issue of the current magazine.

Bill Cheung is an engineering lead and marketing manager at Orient Display, an LCD and display technology provider with over two decades of industry experience in delivering cutting edge display solutions. You can browse Orient Display"s knowledge base [7] to learn more about LCDs.

In response to customer demand, General Digital has engineered a multitude of sunlight readable and daylight readable LCD display solutions that feature OEM LCD displays and our custom-designed LED backlights (edge-lit and direct-lit), light optimization films and overlay enhancements. Our standard LCD display solutions range in size from 6.5 inch to 24.0 inch. New flat panel display sizes and resolutions, and subsequently, complete LCD monitor models, are being added regularly, or can be engineered upon customer request. Many of our sunlight and daylight readable display solutions also provide night vision goggle compatibility, as well.

Our enhanced display solutions may be purchased “off the shelf” for integration into your own product designs, or you may opt to have General Digital technicians expertly integrate the display of your choice into almost any of our monitor and display kit products. In addition, we can design and integrate the sunlight / daylight readable displays into a custom solution to meet customer-supplied design and performance requirements.

Increasingly, LCD manufacturers are producing their LCDs with LED backlights, rather than with the traditional/legacy cold cathode fluorescent lamps (CCFL). Their decision is motivated by the many advantages that LED backlights provide, such as:

If LCD manufacturers are already manufacturing their LCD displays with LED backlights, you may wonder why General Digital produces its own value-add LED backlights. Most LCD manufacturers target large-volume markets for their LCD designs, where they can maximize their return on investment (ROI). Since competitive pressures from other suppliers exist in these markets, their products are designed to meet the bare essential requirements at a minimum cost in an attempt to achieve product acceptance and market competitiveness.

Traditionally, Original Equipment Manufacturers (OEMs) of liquid crystal displays have underserved niche markets (e.g., military, avionics, marine, outdoor usage) that require very specialized display performance, such as extended operating temperatures, sunlight readability, night vision capability and long product life cycle. General Digital prides itself on solving industry problems and providing product solutions to these underserved and specialty markets. Customers find our LED backlights to be necessary to meet one or more of the following application requirements:

To convert a legacy LCD design (that meets a specific need) from a CCFL backlight to a comparable design using less power, with increased durability and efficiency.

To provide an LED backlight with greater reliability than the OEM design. Many OEM backlights have a mean time between failure (MTBF) between 30,000 and 70,000 hours. Typically, General Digital uses LEDs that have a have brightness rating in excess of 110,000 hours.

OEMs provide the contrast performance of their LCDs in dark room conditions within their display specifications. While this information is an important indicator for consideration if the LCD is to be used indoors, it provides an inconclusive indication of how well the LCD will perform when exposed to high ambient lighting conditions (read our white paper, Not All Brightness is Created Equal). For this reason, General Digital quantifies the performance of our LED enhanced LCDs in our Optics Laboratory following the guidelines of MIL-STD-3009 (formerly MIL-L-85762-A).Often, users prequalify panels by how bright they are, employing the “if it is brighter, it must be better” mentality. While brightness may indeed be an important performance consideration for many applications, General Digital holds that the display’s contrast is even more important. Ultimately, it is the user’s ability to discern a difference between colors (contrast) that enables them to properly view information under varying lighting conditions—from total darkness to direct sunlight.

Following these guidelines, General Digital provides our customers with a host of performance metrics, most notably its Weber Contrast, its contrast under 10,000 foot candles of direct light and a Display Class. These metrics allow customers to compare our performance to the military’s standard of approval for display usefulness in direct sunlight, as well as the type of information that can be read under these conditions, ranging from numeric-only to live video. This data also will allow customers to compare our products to competitive alternatives on a level playing field.

General Digital’s Optical Laboratory was created to provide quantification of the optical performance of an LCD under a variety of extreme ambient conditions along with raw intrinsic system characteristics. The data provided by the laboratory tests allows for numerical performance descriptions of each LCD display system. This enables the customer to compare displays across the entire General Digital display catalog and provide the ability to choose the correct product for the target environment while removing guesswork. To ensure accuracy and cross correlation, sunlight and NVIS measurements adhere to procedures and regulations outlined in MIL-L-85762A, and its successor, MIL-STD-3009. Other applicable measurements adhere to procedures and regulations outlined in “Video Electronics Standards Association Display Metrology Committee” (VESA) Flat Panel Display Measurement Standard Version 2.0 (June 1, 2001).

On the LED BACKLIT HIGH BRIGHT DISPLAYS: SPECIFICATIONS tab, we provide a table that summarizes our LED solutions (see sample below). Within the table, you will find a part number for each display configuration listed. As changes are made to a baseline configuration, General Digital will assign a new and unique part number to the resulting configuration. In addition to the part number, a variety of data is supplied for each display configuration.

Typically, General Digital attempts to standardize its measurements by applying an antireflective film to the surface of the LCD. However, it is not unusual for us to test the displays using a variety of other combinations of overlays (EMI filters, touch screens, vandal shields or films) that may be required to meet a specific application requirement.

Lastly, a link to a photometric report (see sample below) has been provided that will summarize and compare the optical performance of the OEM LCD before our enhancements and improvements, as well as after modification. Much of this data has been acquired under the guidelines of MIL-STD-3009 (formerly MIL-L-85762-A). In some instances, General Digital has also included optical data for other multiple test configurations of the same reference LCD.

The following is a standard list of carefully chosen measurements performed by General Digital’s Optical laboratory that provide all relevant information on dark/night, direct sunlight, ambient sunlight and night vision conditions. These measurements are found on all display and monitor photometric data sheets.

Measured in a dark room at maximum display brightness and contrast, providing maximum brightness; however, display readability is reduced through loss of contrast. This metric is provided for inter-vendor comparisons.

Weber contrast (as defined by MIL-L-85762A) of the display under full diffuser and specular simulation. This simulates an outdoor bright sun condition (10,000 fc) with a secondary reflection of the sun (2,000 fL) off the monitor system.

Contrast ratio of the display under full diffuse and specular simulation sources. This simulates an outdoor bright sun condition (10,000 fc) with a secondary reflection of the sun (2,000 fL) off the monitor system.

Classification of the display usability, 0 being not sunlight readable with text, image or video, black and white or otherwise, and 6 being readable given full color motion video.

Each measurement is performed under a variety of LCD and backlighting drive schemes to provide a diverse and rich data set, allowing the customer the ability to choose the correct product for the target driving scheme, while removing guesswork. These drive conditions are found on all display and monitor photometric data sheets, as outlined below.

Driven with the OEM (if possible) or General Digital LED backlights to produce 1000 nits. This luminance is chosen as it is an industry recognized number for sunlight readability; however, the importance of contrast over brightness for sunlight readability must be emphasized. Please see white paper under the download tab on “MIL-STD-3009 Sunlight Simulation and Measurement Test Setup”.

Driven with General Digital LED backlights to determine the maximum output of the display with no active cooling. Many displays can be pushed beyond this threshold; however, active cooling or heat sinks may be required.

The metrics outlined above represent most common conditions; however, due to General Digital’s vast array of capabilities, experience and equipment, many more display measurements can be performed. Should further assistance be necessary, a Sales Engineer can be consulted for additional clarification.

General Digital also designs and integrates our own line of intelligent LED backlight controllers to provide command, control and status of our LED-equipped NVIS-enhanced and NVIS/Sunlight Readable-enhanced displays and backlights. Again, these ruggedized products can be purchased from our stock or integrated by General Digital. Additionally, our software engineering staff can tailor our controller firmware to provide the precise performance necessary to meet a customer’s operational requirements. Typical requests include, but are not limited to, the following:

General Digital also designs and assembles standard and custom microelectronic assemblies in house (e.g., embedded display heaters, cooling fans, touch screens, bezel buttons and potentiometers, OSD controls) that may be included in the final configuration. Since these designs are under our control, it is a simple task for us to program or tailor their performance to meet a variety of needs. More information is available on our controller products page or by speaking with a Sales Engineer.

Often, some tailoring to our enclosure designs are necessary to meet a customer’s specific requirements. The requests vary widely from military requirements for environment, shock/vibration, and/or emissions, to unique mounting requirements or specialty cooling, to name just a few.

Limited only by the size of the enclosure, a variety of standard or custom interfaces may be provided on the configurable connector panel. Other interfaces are available for field programmability and firmware upgrades, CompactFlash readers, USB ports and more.

Watertight (NEMA 4/6) gaskets are installed between the LCD (or overlay) and the front bezel to prevent liquids from entering the enclosure through the display opening.

Dust gaskets are often supplied for monitors that do not require a liquid-tight seal between the display and/or overlay and the bezel, or for systems that use a touch technology that are only compatible with certain gasket types.

All Saber models are available with an integrated or externally attached power supply. For applications requiring a thinner enclosure or a unique power source, we optionally offer a separate external supply, DC input and/or DC-DC converters with a wider input range.

General Digital offers a wide range of video controllers, allowing you to fine tune the display features and support to your specific video requirements.

We can reprogram the video controller firmware/BIOS to support a variety of video timings and specialty needs, such as STANAG 3350 A, B and C, RS-343 and RS-170. Most of our video controllers will also support interlaced and non-interlaced analog video (separate, composite and Sync-On-Green), and live video signals such as NTSC, PAL or SECAM.

The Saber monitor can be configured with a variety of standard or custom user controls, most often in the form of membrane or silicone keypads. Choices of LED and NVIS backlighting are available, as well as configuration with electronics that allow backlight dimming.

Much like your home TV, the On-Screen Display controls allow the user to adjust important display parameters, such as input signal, brightness, contrast, color temperature, sharpness, phase, scaling (aspect ratio), language and dozens of others.

General Digital can integrate virtually any LCD display size/resolution, from almost any panel manufacturer (OEM), into our enclosures. To assist in selecting the right panel for your application requirements, we have provided a list of commonly used or recommended panels for standard/low luminance, high brightness, sunlight readable and NVIS compatible needs.

New display models are constantly being introduced to the market by the LCD manufacturers, making it extremely difficult for us to maintain a comprehensive list. For this reason, we encourage you to speak with a Sales Engineer to share your price and performance objectives, so we can assist you in making the best display selection.

General Digital has provided a sample listing of some common transmissive displays that are not sunlight readable. Typically, these displays are suitable for applications that are not going to require specialty functionality, such as sunlight readability or NVIS compatibility, and for customers with cost-sensitive budgets.

LCD backlight produces sufficient luminance for use in office, shaded and low ambient/darkness light levels. However, luminance is insufficient to overcome reflected light for use in direct sunlight.

This type of technology boosts the efficiency of the backlight’s light utilization and minimizes surface reflection of ambient light. It is a transmissive LCD module that produces high contrast images, even in bright outdoor light and direct sunlight. These displays feature a wider color reproduction range than reflective LCDs. Featuring an LED backlight, these displays consume very little power and produce very little heat, making them ideal for integration into fully sealed enclosures, which are devoid of ventilation holes and cooling fans to dissipate heat. They also provide the additional benefit of a wide operating/storage temperature (as great as -30°–85° C), so that they can endure exposure to greater internal ambient temperatures.

As a design note, we have found that these panels work best when coupled with an overlay that has an antireflective (AR) coating. Overlays that inhibit transmissivity (e.g., resistive touch screen) or have antiglare (AG) coatings will significantly reduce the panel’s performance in high ambient lighting conditions. Since transmissive displays produce greater brightness from their LED backlights than traditional transflective displays, they are regarded as a better outdoor solution, as they can generate high contrast in total darkness, in direct sunlight or on a cloudy/hazy afternoon.

T-EVT technology uses the high brightness/efficiency LED backlight as a light source while minimizing the surface reflection of ambient light. The result is an LCD that produces high contrast images even in bright outdoor light or direct sunlight.

This type of panel incorporates a highly reflective backlight that reflects the ambient lighting back out of the display to enhance its native brightness produced by its active backlight. Like the Transmissive-Enhanced View Displays, GenFlective panels work best when coupled with anAR-coatedoverlay. They are least effective with overlays that retard the light transmission (e.g., resistive touch sensors) or have a matte finish.

T-EVT technology uses the high brightness/efficiency LED backlight as a light source while minimizing the surface reflection of ambient light. The result is an LCD that produces high contrast images even in bright outdoor light or direct sunlight.

These displays feature a value-add backlight, typically made from high efficiency LEDs. These displays produce significant active luminance. Often, the peak luminance is limited by internal ambient temperature constraints or must be connected to an intelligent backlight controller and thermal sensor that will automatically reduce brightness/power to avoid over-temperature conditions or thermal shutdown. The high luminance output makes them ideal for use with a wide variety of overlays such as touch sensors, EMI filters, heaters, etc.

Sunlight readable displays use a Genera

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey