mks tft lcd factory

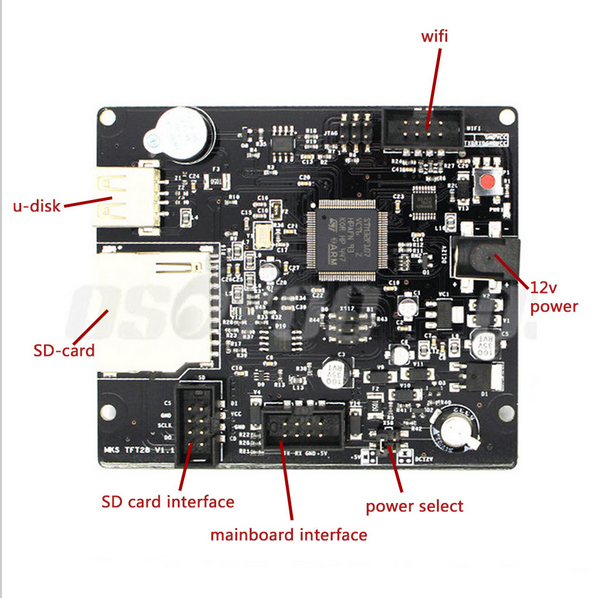

It is highly recommend to use external 12V/1A adapter to supply power to MKS TFT 2.8″ screen. Before plug the 12V power adapter to 2.8″ screen, please plug the “power select” jumper into DC12V position.

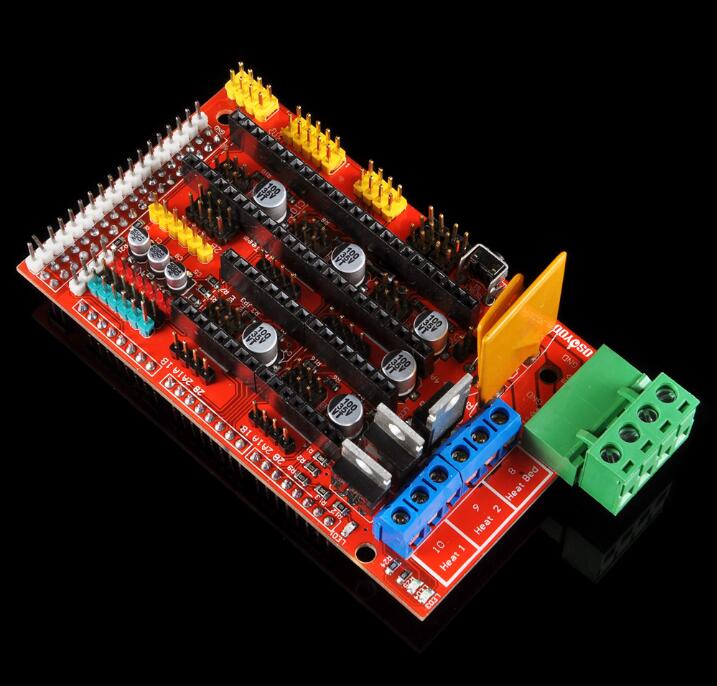

MKS TFT2.8″ use a special 8 pin parallel cable to connect the board to ramps1.4 main board. This cable is different from traditional 8 pin parallel cable which is often used to connect DVD and hard driver. We highly recommend you to use the Osoyoo factory 8 pin cable which comes with the 2.8 inch screen.

5) After setting baud rate, you can test MKS-TFT2.8″ screen now. If you find the motor does not move, please check the wire connection first, then check if thermistance(heat sensor) is connected, then check if external 12V power and 12VDC jumper is connected. If these 3 connection is not properly done, motor will not move.

If you want to change some function or add new function and so on, you can refer to MKS TFT source code and build it, update it to MKS TFT, Link as below:

For more product dynamic information and tutorial materials, you can always follow MKS"s Facebook/Twitter/Discord/Reddit/Youtube and Github. Thank you!

can you confirm if this is a flying bear reborn board and lcd ? if so its using the stm32f103 cpu on the main board/tft35 lcd and the mkstft35 uses stm32f407+tft 35 which means the tft35/2.8/3.2 firmwares are not compatible (they uses stm32f107/407 ) , are there any links to manufacture pages/schematics ?

The A5 and A3S printers have separate main motherboard and LCD modules, and each has their own separate firmware. The firmware on the LCD module can be upgraded quite easily. The firmware files must be placed on an SD card, which must be inserted into the hidden slot inside the printer, located on the back side of the LCD module. When the LCD is powered up, it will begin the firmware update automatically.

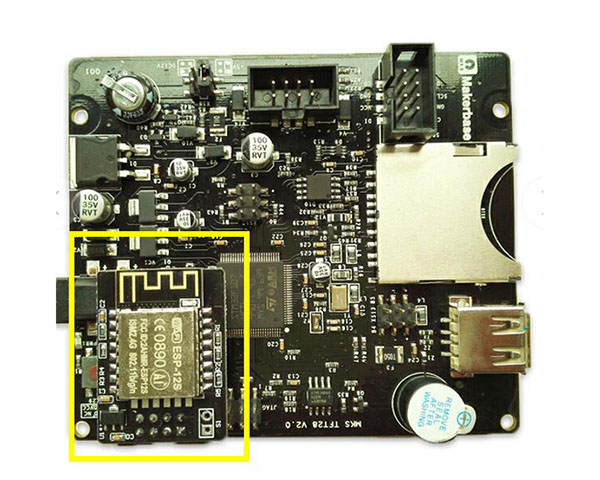

JGAurora do not supply any source code for the LCD module, as they are using a proprietary 3rd party product LCD module made by MakerBase (MKS-TFT28 v1.3). However, the firmware configuration is set by a text file, making it easy to change some of the settings. However, the raw unconfigured LCD firmware is available from the LCD module manufacturer “MakerBase” at Github.

The custom community LCD firmware is the same as the original JGAurora LCD firmware, with some changes to the configuration. These changes add the “babystepping” control feature to the LCD module - for more infomation on this feature see this article on babystepping with the A5. Please note, this feature requires that you have upgraded the main motherboard firmware to the community firmware. Thanks to Karl Johnson for the hard work adding baby stepping and other features to the LCD firmware configuration.

MKS TFT 2.4 inch touch screen to control a 3D printer or CNC machine. This high quality touch screen is a controller on its own, because it has own processor onboard and does not rely on the processor of the 3D printer or CNC machine. Due to this the screen features a 2.4 inch full colour touch screen, can be integrated with WIFI upgrade, can read a SD card, can detect power failure with power detection module and filament runout with runout module.

The LTPS backplane conducts electric current to the OLEDs so light is emitted. This layer is created by vacuum deposition of a-Si either directly on strengthened glass or onto a polyimide layer attached to a glass carrier. The thin film is then laser annealed to create the crystalline LTPS structure. To ensure the correct composition and uniformity of the a-Si thin film, it is important to directly measure pressure within the deposition chamber. Direct Pressure Measurement devices from MKS operate in situ, with low pressure measurement drift and EtherCAT® communication. This makes it highly reliable and quick to communicate with the overall system ensuring correct composition and uniformity of a-Si thin films.

Our high performance optics have various coatings that are optimized for different wavelengths, enabling tight beam delivery - important for tight radius corner cuts for both glass and film cutting. Combined with our linear stages that have high, stable velocity with on-off laser synchronization, MKS is uniquely positioned to provide a variety of solutions that enable precise radius cutting at the micron level for both film and glass.

Touch screen / intelligent controller MKS TFT35 for 3D RepRap printers. The MKS TFT35 is a 3.5 "color touch screen for various RepRap or open source 3D printers. The screen is compatible with MKS boards such as MKS Base, MKS Gen and MKS Mini. It is easy to connect and can be easily used with marlin.It is completely open software and allows any adjustment. To simplify an individual project, various projects can be selected in the standard internal software. In addition, 13 buttons can be freely assigned to activate various functions at the touch of a button. The firmware can be quickly and easily customized using a file on the SD card and can be changed without external programs..

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey