flexible lcd display arduino quotation

ePaper is perfect for low-energy devices such as shelf labels or name tags; that require few updates and a slow refresh rate. ePaper displays can be disconnected completely from any power source and their screen will maintain it"s picture indefinitely.

I"ve not bought from them, but Newhaven displays has 5", 5.7", and 7" TFT displays. I don"t know if they have an Arduino driver or not, but it might not hurt to ask: http://www.newhavendisplay.com/tfts-c-1.html.

Now, the problem with the Arduino is it doesn"t have that much memory, is on the slow side, and if it is driving the screen, it can only do lo-res output. When you get to larger screens, it might be that you start seeing pixels.

The animation is still totally corrupted, for some reason I got it running well just once and then it started to mix everything again. Touching the display"s pins improved the results once !

Sometimes one or two shapes, texts or animation are perfectly displayed, sometimes nothing show up ... I always have to wait for about 10 sec before the demo starts after each reset.

I"m wondering on which side is the issue coming from : Wiring (different results depending if I"m touching/maintaining the wires), breadboard connection discontinuity, Arduino itself (having hard time running this tiny program ?), Buffer clearance management, ..

Liquid Crystal Displays or more commonly known as LCDs are one of the most common electronic components which help us interact with an equipment or a device. Most personal portable equipment and even gigantic industrial equipment utilize a custom segment display to display data. For many portable consumer electronics, a segment LCD display is one of the biggest contributors to the overall cost of the device, hence designing a custom segment display can drive the cost down while also utilizing the display area in the most optimum manner. These displays have the lowest cost per piece, low power requirements, and a low tooling fee too.

At first thought, designing a custom segment LCD might look like a Herculean task, but trust me that it is easier than it seems. In this article, we have summarised and compared the display types and available technologies which are required to construct a custom segment LCD. We have also provided a flowchart that can act as a step-by-step guide while you design your own custom LCD. We have also provided the process we followed, a require gathering sheet we used for communicating our needs to the manufacturer, and a few other data and the quotation we received from the manufacturer.

Icons: A silhouette of any shape can be placed on the glass which enhances the ability to display data. For example, a symbol of a heart can be made to denote heart rate or an icon for a low battery to show that the battery needs to be charged. Icons are counted as a single pixel or segment and can give a lot more details than similar-sized text.

LCD Bias– It denotes the number of different voltage levels used in driving the segments, static drives (explained later in this article) only have 2 voltage levels or 2 bias voltage while multiplex drives have multiple voltage levels. For example, 1/3 will have 4 bias voltages.

LCDs utilizes the light modulating properties of liquid crystals which can be observed by using polarizing filters. Polarizing filters are special materials that have their molecules aligned in the same direction. If the light waves passing through polarisers have the same orientation as the filter, then the molecules of lights are absorbed by the filter, hence reducing the intensity of light passing through it, making it visible.

A custom LCD is important for maximizing the efficiency of the display area by adding custom symbols and characters. It also helps in reducing the cost and improving energy efficiency of the product. A higher number of custom symbols and specified placement of numerical and alphanumerical characters make the display more informative and readable for the user. This makes it look better than the plain old boring displays we get in the market. Furthermore, we can specify the viewing angle, contrast, and other specifications which can increase durability or give a better value for money for our intended usage. A typical Custom Segment display is shown below, we will also show you how to design and fabricate the same further in the article.

The LCD display doesn’t emit any light of its own, therefore it requires an external source of illumination or reflector to be readable in dark environments.

While designing a custom segment LCD display, we have the leverage of choosing a lot of parameters that affect the final product. From the color of the display to the illumination technique and color of illumination as well as the type of input pins. Some important considerations we need to take while designing a custom 7 segment display are - the type of display, i.e. positive or negative, illumination method, driving technique, polarising type, and connection method. All these design criteria are explained below:

Positive and negative displays can be easily distinguished by the colour of the background and characters. Some common differences between the positive and negative displays are:

So, which one should you choose? When the displays are to be used in areas with higher ambient light, we should select positive segment LCD display as it has better visibility than negative segment LCD displays without using a backlight.

As we know that LED displays don’t emit any light, hence to illuminate it and make it visible in a dark environment, we can use different methods of illumination. The most common LCD Illumination methods are compared below:

For displays that need to be used for budget-friendly devices that should be small and rugged, LED lights are preferred for the displays due to the high durability and low cost of operations. For high brightness, CCFL and Incandescent lights can be used.

A polarizer film is the most important component of an LCD display, which makes it possible to display characters by controlling the light. There are 3 types of polarizers that can be used in the LCD display, the properties and difference are given below:

Displays can be categorized into two types, passive displays, and active display, passive displays are simpler to construct as they have 2 connections at each segment, the conductors comprise of an Indium Tin Oxide to create an image, whereas the active displays use thin-film transistors (TFT) arranged in a grid. The name is due to its ability to control each pixel individually.

If your displays have fewer segments, then static LCD drive is preferred as it is easier to control and cheaper to construct, and has a better contrast ratio. But let’s say that if the number of segments in the display are more than 30-40 then a multiplex LCD drive should be preferred as it has multiple common pins, hence reducing the total number of pins required to drive the display.

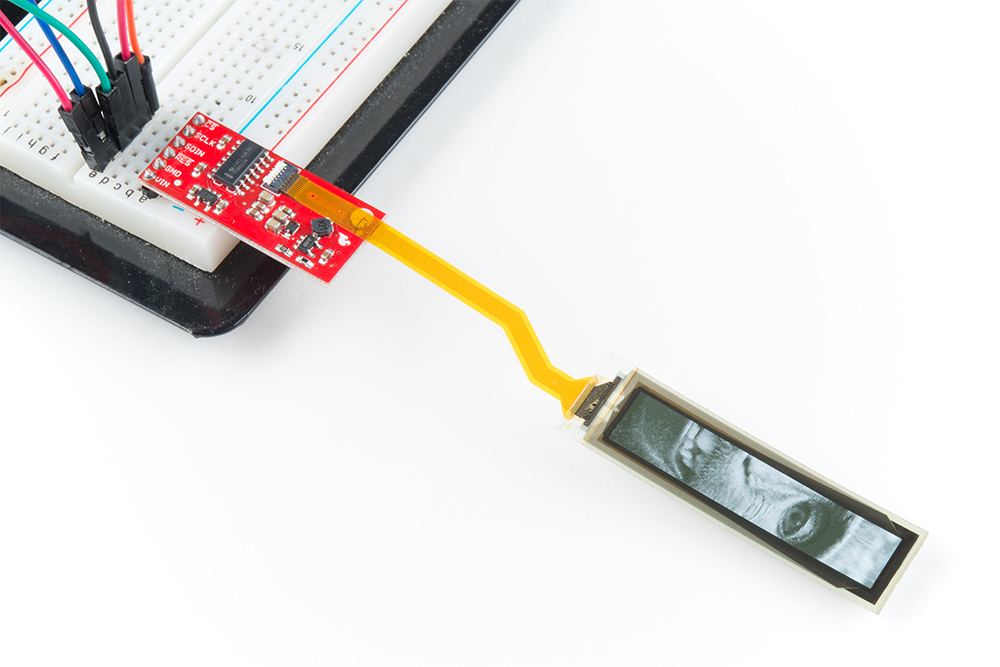

Choosing a connector type!!! For the prototyping phase or if you need to connect your LCD display on a Microcontroller directly, a pin type connector is the best and most economical option you have. If you need to connect your LCD display in a final product with a high volume of production which also requires to be extremely durable, but at the same time should not take up a lot of space, a Flex type LCD Connector will work best for you

LCDs have limited viewing angles and when seen from an angle they lose contrast and are difficult to be observed. The viewing angle is defined by the angles perpendicular to the center of the display towards its right, left, up, and down which are denoted by the notations 3:00, 9:00, 12:00, and 6:00 respectively. The viewing angle of LCD can be defined as the angle w.r.t. to the bias angle at which the contrast of segments is legible.

To improve the viewing angle in an LCD, a Bias is incorporated in the design which shifts the nominal viewing angle with an offset. Another technique is to increase the Voltage, it affects the bias angle, making the display crisper when viewed from a direction.

For example, the viewing angle of a TN type TFT LCD is 45-65 degrees. Extra-wide polarising film (EWP) can increase the viewing angle by 10 degrees, using an O film polariser can make the viewing angles 75 degrees but these come at a cost of reduced contrast.

LCD Control chip or LCD driver chips can be mounted on the flex cable, display, or externally on a PCB. The placement of LCD control chip can affect the cost and size of the display. The 2 most common methods of chip placement are-Chip of Board (COB)and Chip on Glass(COG) which are described below:

We planned to design an air quality monitoring system for which we needed a custom segment LCD panel for an air quality monitoring device. Our product needs to display the following data: 2.5-micron and 10-micron particulate matter (PM) suspended in the air; the units should be in parts per million (PPM). CO2 in the air in PPM along with total volatile organic compounds present in the air in parts per billion (PPB). To make the product more usable, we included time in 24-hour format, Temperature in ºC, Battery status, loudspeaker status, Bluetooth status, and Wi-Fi status. And for some personal touch, we also added how good the air quality in the room is by using 3 different smileys.

We realized that it was impossible to provide all these data in a generic LCD available in the market, thus decided to build a custom LCD for our project.

A step-by-step flowchart is shown below to walk you through each and every step of selecting components and getting your custom segment LCD manufactured.

We started by listing down our requirements and drew a mock-up of the display on paper. After finalizing the placement of all the segments and icons on the prototype sketch of the display, we then decided which all icons and segments have to be kept on for the whole time and which needs to be driven. Realizing that there are too many segments, characters and icons, hence we selected a multiplex drive with 8 common pins which helped us bring down the total pins from an estimated 180 pins to less than 40 pins.

Since the device was meant to be used inside houses and offices, which are more often than not well lit and protected from environmental conditions, we opted for a positive mode display. For superior contrast ratio and better viewing angle, we chose a Film Super Twisted Nematic Display (FSTN) with a drive condition of 1/8 Duty and bias of 1/4.

Usually, the displays are mounted at a height of 4.5 feet from the ground, thus the viewing direction was selected to be 12"O clock with an operating frequency of 64Hz. We selected a Transmissive polarizer for the front glass and a reflective polarizer for the rear glass so that the natural light can pass through the front panel and the display can achieve the maximum contrast without the need for backlighting and we opted for the pin type connectors as they are easy for prototyping and are suitable for harsh environment with a lot of vibrations and shocks which best suited our purpose.

In the above image of a custom display design, we sent to the manufacturer, the red lines over multiple characters indicate that all these are considered as a single segment. For the sake of simplicity, we added test like T, S, U, B to denote Text, Symbols, Units, and Battery respectively. These characters were followed by numbers to simplify communication between us and the manufacturer. For example, if we needed any particular text or symbol to remain on, we can easily specify that to the manufacturer by using the corresponding text for that segment.

We mailed our requirements to multiple LCD manufacturers, (you will find a lot of LCD manufacturers on the Internet). Most LCD manufacturers have competitive pricing, and reply within a week. A sample requirement sheet is shown above which a customer needs to fill to specify all the details to the manufacturer.

This is a sample Custom Segment LCD quotation we got from one of the manufacturers. As you can see, the cost is based on the quantity. Higher the quantity, lower the cost. Apart from the cost per quantity, there is one more component called tooling fees. Tooling fee is a one-time fee charged by the manufacturer. It is for the technical design, support, and customization of the product. Customization of PCB or tooling of LCD can drive the tooling price higher or lower.

A custom segment LCD can help you personalize your product while also saving the overall cost of your product. The whole process will take you around 2-3 months, which will include the designing phase, prototyping phase, and getting your custom segment LCDs delivered to your doorstep. Higher ordering quantity will reduce the cost per piece of each unit, thus driving down the cost of your final product.

There are two types of oled display modules available on Alibaba.com. flexible oled display modules, such as flexible-display oleds, and lcdds are available in bulk.

flexible lcdds are available in the form of flexible-sensitive lcdds, and flexible lcdds are all available. For a more detailed look, Alibaba.com offers a wide range of oled displays in bulk and explore the range of oled displays available.

Find oled display modules that are as flexible as the others. The flexible size of Oled display modules means it can be used in many cases. The oled display is flexible, as the Pixel is short and high-quality.

When looking for a flexible oled display set, you can choose from a wide range of flexible LED display sets, such as the 6-pixel flexible Oled display set, which is suitable for a variety of uses. The flexible LED display set of oled displays with different brightness and dimits, such as 5 12 pixels, or 12- pixel-led oled displays.

Dot matrix displays are something that all Arduino enthusiasts come across at some point. These displays are so popular that almost all modern outdoor LED displays use them to display characters, symbols, and images.

When it comes to controlling dot-matrix displays, there is hardly a better option than the MAX7219. It can easily control a single dot matrix and, for larger projects, it can be chained together to control two or more dot matrices.

An 8×8 dot matrix display typically has 16 pins, 8 for each row and 8 for each column. All rows and columns are wired together in order to reduce the number of pins. If this were not the case, an 8×8 dot matrix display would require 65 pins, one for each LED and one for a common anode or common cathode connector. By connecting rows and columns, only 16 pins are needed to control the entire matrix. This technique of controlling a large number of LEDs with fewer pins is referred to as Multiplexing.

In this technique, each column is activated for a very short time, and at the same time, the LEDs on that column are lit by addressing the corresponding row. As a result, no more than eight LEDs are lit at the same time. The columns are switched so fast (hundreds or thousands of times per second) that the human eye perceives the display as fully lit.

It can fully control 64 individual LEDs while keeping their brightness constant. Once the microcontroller has updated the display, the MAX7219 handles the work of refreshing the display at 800 Hz. This frees up the microcontroller to do other important things.

The MAX7219 has a power saving mode in which the display can be turned off to save power. It also turns off the LEDs during startup, preventing wacky displays for the first few seconds of operation.

The MAX7219 communicates via the SPI interface, so it only needs 3 data pins to connect to a microcontroller. In addition, we can daisy-chain multiple modules together for a larger display using the same 3 wires.

VCC is connected to 5V. Because the display draws a lot of current (up to 1A at maximum brightness), it’s best to use an external power supply instead of the Arduino’s 5V supply. If you want to use the Arduino’s 5V supply, keep the brightness below 25% to avoid overheating the voltage regulator.

Let’s start with the module’s power supply connections. Because the display consumes a lot of current, we’ll use an external power supply instead of the Arduino board’s 5V supply. If you are only using a single MAX7219 module, you can power it directly from the Arduino, but you should avoid doing so if possible.

Let’s wire up the SPI pins. Note that each Arduino board has a unique set of SPI pins that must be connected accordingly. For Arduino boards such as the UNO/Nano V3.0, these pins are digital 13 (SCK), 12 (MISO), 11 (MOSI), and 10 (SS).

If you want to daisy-chain multiple displays to make a larger display, connect the DOUT of the first display to the DIN of the next display. VCC, GND, CLK, and CS will all be shared between displays.

Controlling the MAX7219 module is a lot of work. Fortunately, the MD Parola library was written to hide the complexities of the MAX7219, allowing us to control the display with simple commands.

The second variable, MAX_DEVICES, specifies the number of MAX7219 ICs being used. A single MAX7219 IC counts as one device, so if you want to control an 8×32 display, set MAX_DEVICES to 4 because an 8×32 display has four MAX7219 ICs.

To see the output, the display must be properly oriented. If you’re using a generic module, make sure the MAX7219 IC is on top. If you’re using an FC-16 module, make sure the DIN side is on the right side.

The first step is to include all the necessary Arduino libraries. As previously stated, the MD_MAX72XX library implements the hardware-specific functions of the LED matrix, whereas the MD_Parola library implements the text effect. You must also include the SPI library, which is used to communicate with the display via SPI.

Next, we must specify which hardware is being used. Because we are using an FC-16 module for our experiments, the HARDWARE_TYPE is set to FC16_HW. We’re using 4 MAX7219 ICs, so MAX_DEVICES is set to 4. Finally, the pin to which the display’s CS pin is connected is defined.

In the setup section of the code, we first use the function begin() to initialize the object. The brightness of the display can be adjusted using the function setIntensity(), which accepts values ranging from 0 (lowest brightness) to 15 (maximum brightness). The display is cleared using the displayClear() function.

The string ‘Left’ is then printed using myDisplay.print("Left"). Please keep in mind that the text string should be enclosed in quotation marks " ". When printing numbers, no quotation marks are required; for example, to display 1234, write myDisplay.print(1234). You can also use the setInvert() function to invert the display.

When you want to print a message on a dot matrix display, you will often find that the display is too small to fit the whole message. The solution is the scroll text effect.

You’ll notice that everything from the beginning of the code to the end of the setup section is the same as the previous example. The only difference is that the displayScroll() function is called at the end of the setup section.

Only two functions are used to scroll text in the loop section. First, in an if statement, we use the function displayAnimate(). This function scrolls the text and returns true when it is finished. When the scrolling is finished, we use the function displayReset() to reset the display, resulting in continuous scrolling.

I wanted to learn a little about Arduino this week. It"s an huge and enthusiastic community based around an open-source electronics platform. The hardware is small and relatively inexpensive, and it brings hardware hacking to folks (like myself) that may not feel up to doing really low level electronics work. There or stackable "shields" you can plug on top and easily add new features, screens, sensors, and more.

There"s lots of different choices for Arduino development, including some more interesting versions like the Intel Edison with Arduino Breakout Board. The Intel Edison supports not just Arduino, but also can run a full version of Yocto Linux, and can run Python and node.js. I have an older Arduino Atmega328 which was like $12.99, but I wanted a more flexible option that included on board Wi-Fi. Getting Wi-Fi connectivity is kind of a hassle if it"s not built in.

The Arduino Yún is a great choice, but I figured I"d spend more for the Edison and get a lot more options. I also got the "Seeed Studio Grove Starter Kit." This is a cool Arduino Shield that lets me (and the kids) attached sensors, buttons, screens, and lots of other stuff without soldering!

I download the Arduino software, but also found that Intel now has a complete Integrated IoT Windows 64 Installer that will get everything you need to get started with the Intel Edison. It makes it REALLY easy to start.

Nightscout has a /pebble endpoint that is used to feed the Pebble Watch Face and show folks their blood sugar on their wrist. I thought it would be cool to hook up an Arduino to get my blood sugar from the cloud and display it on an LCD. It"ll show the current value, change the background to green/yellow/red to display risk, and then a custom character to show trends (flat, up, down, etc).

When doing an HTTP call (given the libraries I was learning about) it"s pretty low level. Constrained memory Arduinos (not like the Edison) don"t seem to have SSL support, nor do they have high-level HTTP libraries. I had to craft the HTTP headers manually:lcd.print("Connecting...");

I would likeit to call out to the web service every 5 min and update the LCD. I suspect I am not managing Wi-Fi connection state correctly (as in, not at all).

One other thing I found out, there"s a fantastic add-in for Visual Studio that will give you a great Arduino Development Environment inside of Visual Studio. It includes simple debugging, breakpoints, a nice serial monitor and more. I"m still finding debugging to be challenging as local watches and step over isn"t supported, but it"s vastly superior to the tiny Arduino IDE.

DIY Arduino or "The DIY-Duino": THIS ENTIRE TUTORIAL IS ALSO AVAILABLE ON MY WEBSITE AT http://www.theparsley.com/arduino/diy/ To quote the Arduino website: "Arduino is an open-…

We all know PH is an essential thing for drinking water. If you don’t take care of this crucial ingredient, you might ruin your entire meal in a matter of seconds. This article will teach you how to build an Arduino Ph sensor as a beginner project for someone who doesn’t know what they’re doing.

We can regard an Arduino as a ‘microcontroller.’ This means that it is a tiny computer that you can use for electronic projects (and for much more). It can act as the main component in a huge amount of projects. By combining multiple projects, you can make something even greater.

Before you get started, make sure you set up the Arduino kit by following the instructions that came with it. This takes approximately 1 hour and 30 minutes to do. However, if you’re in a hurry, it’s possible to do this in 20 minutes by following this tutorial.

The PH probe has two wires: one red and one black. The blue wire connects to 5V, and the black wire connects to the Ground(GND). The Red wire is what you use to measure the PH. It’s a very sensitive probe that can measure the pH value. You connect it to the Arduino, and in a concise period, it will tell you if the solution has an acidic or basic value.

There are many different models of Ph Sensor for Arduino. Unfortunately, many of them appear similar. But, if you want to do a good job and make sure your sensor will last for a long time, you should go with one from Rayming PCB & Assembly and get this one.

You can connect the sensor to the Arduino board using two wires. Once the connection is complete, you can start testing the sensor. You should do this by using a small piece of bread. The amount of sugar in bread is close to human skin, so it is easy to see how the sensor will react.

Testing the sensor after connecting it to the Arduino is essential before using other solutions. You should always let the sensor rest for around 24 hours to stabilize and work properly. You will have to do this again when you connect it to a new circuit later.

The Ph probe requires between 3.5V and 5V to read the solution’s pH value properly. Therefore, to monitor the pH level of your Arduino project, you will need to use a voltage regulator or a voltage divider.

This project will use two transistors and two resistors to get the proper readings from different circuits or sensors. For example, if you want to measure the temperature on your Arduino board, you can get that information with a thermistor. However, the readings for both temperatures and pH depend on the circuit’s current level and, therefore, on the value used in your soil ph sensor Arduino.

Other than that, almost everything is as simple as a ‘Plug and Play’ installation. If anything fails to work correctly, try restarting the Arduino IDE. If it still doesn’t work, check all the connections again to ensure there aren’t any loose wires touching other components or parts of the circuit.

You can choose to make the Arduino board a stand-alone device so that you don’t need an enclosure. But, we think it’s better to use an enclosure because it gives you a safer way to store your sensor or Arduino board in the future. But, of course, you could also use the box that comes with your Arduino kit.

1) First, we will install the 220-ohm resistor from the LCD module side so that you can use an external power source. You also want to connect this to your Arduino board’s positive (red) side.

4) You will also have to add an extra ground wire between the transistors and the breadboard since they don’t share a common ground with the Arduino board. Finally, connect the transistor and resistor to GND on the Arduino board.

The Ph probe should be installed like the picture above to connect the wires to your Arduino board. The GND wire should be connected to one of the Arduino’s pins and should go in between both transistors to be grounded.

Finally, you can install the LCD module using two wires. You need to connect one pin to the Arduino board and the other to the transistor that shares a ground with the Arduino. You can use a breadboard for this if you want, but it is much easier just by connecting both circuits directly.

Just connect the parts that are highlighted in green using jumper wires. You can bend the wires to make them fit in between the housing and your Arduino board without causing any harm to them or their circuit.

Once you have your Arduino pH circuit assembled, you can now place your sensor in a safe environment to see how well it works. However, you don’t want to put it in the water yet because you haven’t installed the software to let your sensor know its pH level.

You will have to install and run the Arduino IDE on your computer. You will also have it on your mobile phone for setting up, uploading, and testing sensors in the future.

Once you have finished installing everything, open up your Arduino IDE on your computer, select ‘File/Open and select the code you downloaded from our page.

Now connect your Arduino UNO to your computer with a USB cord and then click on ‘File/Upload’ this will send the code to your sensor so that you can start testing it out.

If you type “M10” in your terminal, you will notice that the temperature is now 10 degrees Celsius hotter, and the LCD screen will now say “Temp 2.0”.

This code will turn on (red LED on) the LED connected to your LED strip (VCC) and display “Temp” on the LCD screen. You can change these values in the sketch to suit your needs!

Then connect your pH source (a five pH) to your Arduino board. Then download a sketch from here. This will let your Arduino board be able to read your pH sensor!

Notice that when you download and upload the program, the LED light will turn blue and red when it recognizes that the sensor and Arduino need a connection.

We tested the pH sensor in an open environment. First, we used a clear jar and filled it up with distilled water so that there was no conductivity of the water, and we stirred for about 30 seconds. Next, we put a piece of pH paper on top of the solution and connected an Arduino board using a USB cable.

We used distilled water again to have no water conductivity in the jar. Next, we used a hard water solution and poured it into the jar. We then put some pH paper on top of the water and connected the other end to our Arduino board. Then we took our pH sensor apart, stripped off its casing, and put it into the hard water solution. From there, we tested both outputs from the Arduino and lab equipment.

If your sketch is too large for the flash memory, you might get this error message, which means your sketch is too big to fit in the flash memory. To fix this problem, comment out unnecessary codes and compile and upload again. If it still doesn’t work, you can use another Arduino IDE instead of using the default one that comes with Arduino boards.

When you compile your code and upload it on your Arduino board, you might get the “Unsatisfied Link Error” message box. This means that there is a library that you need to add to the Arduino IDE before trying to compile and upload again. But, of course, you can always go to this page and download this library into your Arduino IDE to use it in your project.

This error happens when you try to upload a sketch, but nothing happens on your board. This might be because there is something wrong with the code you are trying to upload. First, try removing all the comments from your file and then re-compile it again. If that doesn’t work, you could use this other Arduino board instead.

When you upload sketches onto your Arduino board, you might get a message box telling you that “Serial port is already in use.” This might be because your IDE tried to upload on a serial port and failed because it was not connected. To fix this, try to restart your Arduino IDE by closing it and re-open the IDE.

Sometimes, when you compile your code, a Java error comes up and tells you that the Launch4j cannot run. This is because your Arduino board is not detected by your computer since there might be a problem with the serial connection between your computer and the Arduino board. Connect your Arduino board with a new USB cable to fix this problem.

This error happens when you try to connect an Arduino board to your computer, but your Arduino board doesn’t appear in the list of recognized devices. To fix this, remove the IDE, and after you reboot your computer and then re-plug it into the USB port, this should help.

Sometimes, the code you put into your Arduino IDE doesn’t work when you compile it. This might be because you need to put in the PIN before starting. To fix this problem, comment out the “Serial. begin()” line by putting a “#” at the beginning of that line and then upload the program onto your board again.

Your board may be out of sync with the Arduino IDE. If you can’t upload any sketch onto your board, try resetting and restarting it by disconnecting the power and reconnecting it to a new USB cable. This should sync it up to Arduino IDE to upload sketches onto your board.

This might be because your Arduino board is not compatible with this type of hardware. If you have an Arduino Uno that you cannot use, you might consider finding a different one.

Finally, we have finished our first pH sensor Arduino project. We started by looking at the basic parts that we will need for this project: an Arduino Uno and a pH sensor. After reading about how these sensors work, we decided to use the DS18B20, easy to find and cheap. Fortunately, most of the parts we used were available on Amazon, so there was no need to look everywhere to get what we needed.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey