burned lcd module supplier

Now in the industry, Power IC on the display panel circuit has gradually used programmable IC, because this technology can precisely adjust the Panel drive voltage V_lcd, Vcom, Gamma voltage, and row drive signal to achieve stable performance by burning 7 Power Data bytes to Power IC.

The method of burning the power consumption data of the new LCD screen is that the power consumption data and the display function data are compiled into the same software, and then the required software is burned into the flash memory chip, and after the whole machine is assembled, the control chip of the main board sends instructions to the flash memory chip to burn the power data to the panel driver voltage chip.

Directly attach the drive voltage chip with a preset initial value of 7 bytes of power consumption data to the panel PCB, and no longer burn the power consumption data of the drive voltage chip before and after fitting, and then carry out the next step of welding, followed by the assembly of the liquid crystal display module. Because the initial value of the power consumption data of 7 bytes is built in when the drive voltage chip leaves the factory, even if the new power consumption data is not burned. It will not affect the basic functions of the panel.

When the motherboard is assembled, the 7-byte usage data and the display function data are compiled into the same software, and the software is burned into the flash memory chip.

The power consumption data of the 7 bytes is compared with the initial value of the preset power consumption data of 7 bytes. If it is different, the power consumption data of the flash memory chip is burned to the drive voltage chip, otherwise the power consumption data of the drive voltage chip remains unchanged.

This paper describes a new method of burning the power consumption data of the LCD screen, which uses the power consumption data of the Power IC driver voltage chip to be burned in the later stage when the display motherboard is burned. The new method saves manpower and equipment investment, and can ensure the quality of products. More importantly, it broadens the way of thinking for the factory, is not limited to the inherent methods, and effectively improves the efficiency of the factory.

Yes, all of our pre-burned screens ship pre-stretched on high quality aluminum frames. Most of our screens are stretched to around 20 Newtons. When you receive the screen, simply remove from box, put on your press, tape the edges, and start printing.

Absolutely! You can place as many images as you want in the allotted "Image Area" for your screen size. Just keep in mind that the more images you have burned on the screen, the more taping you will have to do and the more difficult it will be to print with.

Of course! Simply add the amount of screens required to your cart (for example, a 3 color design requires 3 screens), and we"ll take care of the rest. We make sure the color layers get burned precisely in the same spot on the screens to make registration easy on your end, and we also add top and bottom registration marks by default.

As long as the preburned screen is used and cared for properly, the burned image should withstand thousands of prints. Use screen chemicals sparingly, keep mesh away from sharp objects, don"t scrub screen with extremely rough surfaces, etc.

If your pre-burned screen arrived with a tear, please notify us within 48 hours of receipt along with a picture of the torn screen, and we can send out a replacement right away. After 48 hours of receipt, we are unable to offer any replacements or credits.

Pre-burned screens are subject to a $20 cancellation fee per screen if they have already been coated with emulsion. Screens ordered before 4pm PST are coated that night, so please let us know right away if you need to cancel an order to avoid the cancellation fee.

US Micro Products provides a superior solution, whether it is by engineering a custom display module, or by implementing a standard display from our wide selection of technologies.

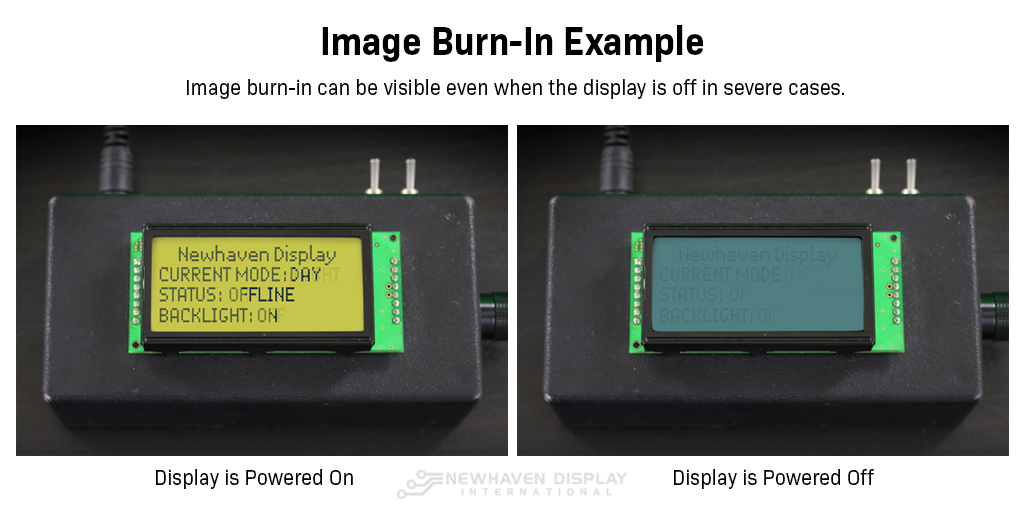

Most of the time, these guides explain how image retention works and how you can speed up its recovery process. We want to clear up any confusion you might have about image burn-in and image retention on LCD and OLED displays.

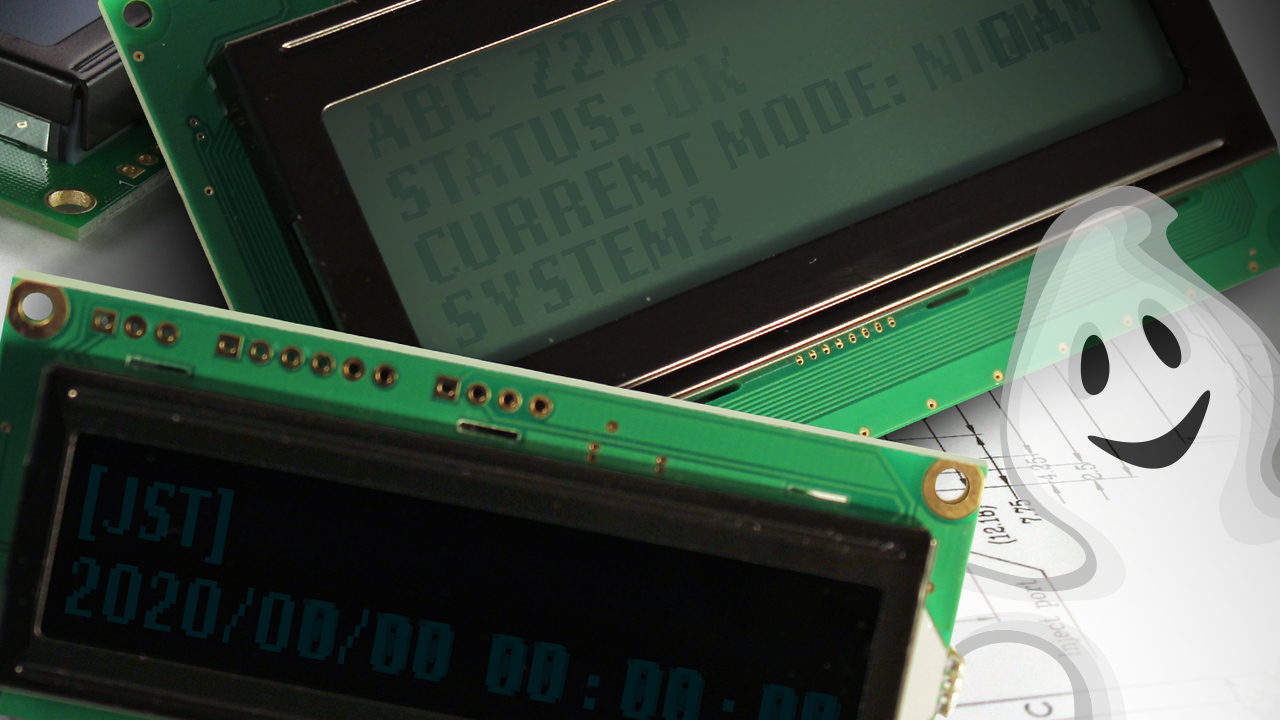

Image retention, also known as ghosting or image persistence, is the temporary effect of images remaining visible on LCDs or OLEDs for a short period, usually a few seconds.

Image burn-in is caused by screen pixels that stay activated in a static position for long periods of time.Think of a TV in a lobby or waiting area that"s always playing the same news channel. The news channel footer and logo get burned into the screen permanently, even when you change the channel.

When LCD or OLED pixels stay activated in a static position, they"ll eventually become "stuck" in that position. When this happens, you"ll notice a faded, stubborn image that persists on the screen.

When pixels fail to activate or deactivate entirely, it results in faded images that won"t clear from the screen. This is common in applications using character LCDs where the alphanumeric characters are updated less frequently.

Get those pixels moving! The longer a pixel stays activated in a static position, the closer it gets to being burned in. You can exercise your screen"s pixels with scrolling text, moving images, or changing colors.

For a LCD display, lowering the contrast will put less stress on the liquid crystals and will help to reduce the rate of pixels becoming weak, or sticking.

Hi again, Andoni here with the same problem this time in another LCD (this one is not from DX, the teacher gave it me after burning 2 , he has used them in a lot of different projects and they work well).

First of all i want to say thank you to everybody who has wasted time in helping, this is my fist DIY proyect, so I"m not any expert but i like this world. I"m doing as final project a Greenhause controlled by arduino (duemilanove), I bought different sensors like DHT22 (temperature and humidity, digital), ambient light sensor, Soil moisture sensor, pH sensor...I need the LCD because I want to make manual and automatic control, and with the help of some Informatic friends control through Internet also.

About your posts, MAS3 I don"t put the shield over the arduino because I change the inputs every day as well as i improve the different parts of the proyect. I put screws in the holes of the green PCB because space problems. After having some problems with sensors (concretly the DHT22 measures always 1% humidity....... ) , i decide to make a simulated inputs board to analyze better the program under different conditions. After burning the second LCD I replace it for a better one but without buttons, so i get the schematic and build a new one as you can see in the photo.

Floresta I"m not really sure but i know that the 3 different LCD i used before worked properly until they crash, so i think the connections and the initialization or commands are OK. Mlowther be sure that when i have time i"ll try to open and clean them carefully...

Have you ever left your TV or monitor on for days, stuck on the same image? You return to your screen, only to find an image burned into the display. No matter what you do, it won"t go away. It is a permanent image burn.

Why do monitors and TVs get image burn? Why can"t manufacturers prevent LCDs and plasma screens from a burnt image imprint? Moreover, what can you do to fix an image burn?

LCD and LED do not work in the same way as CRTs, either. LCD and LED screens use backlit liquid crystals to display colors. Although manufacturers market screens using LED and LCD, an LED screen is still a type of LCD. The white backlight filters through the liquid crystals, which extract particular colors per pixel.

LCD and LED displays don"t suffer from the same type of image burn as CRTs and plasma screens. They"re not completely clear, though. LCD and LED screens suffer from image persistence. Read on to find out more about image persistence.

Before you can fix screen burn-in, take a second to understand why these images burn in the first place. LCDs and LEDs don"t suffer from burn-in as seriously as plasma screens. But static images can leave an imprint on both display types if left alone for too long. So, why does image burn happen?

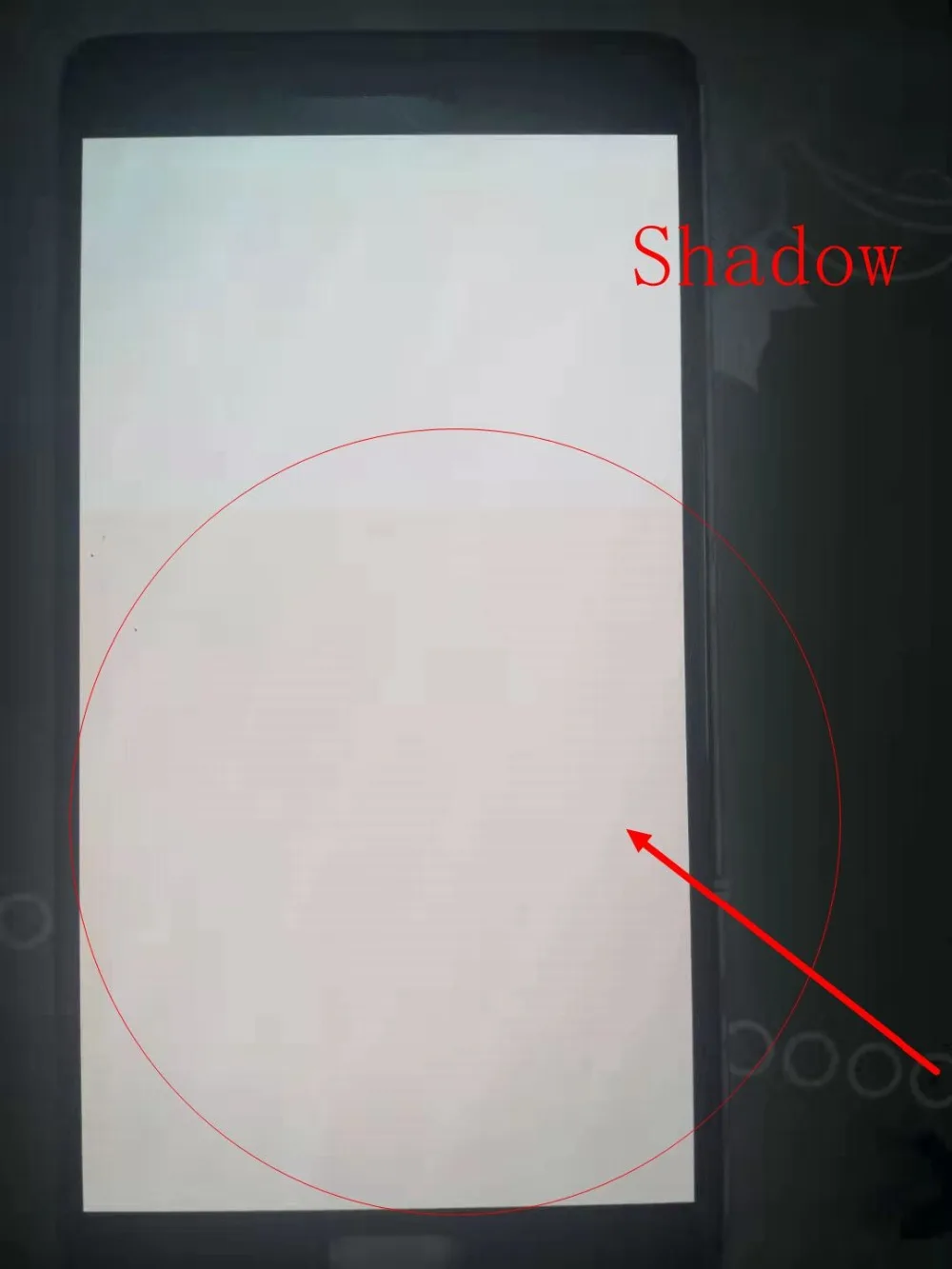

LCD and LED screens can also experience image burn, though the image burn process can take longer to develop into a permanent issue. In addition, LCD and LED screens suffer from another issue, known as image retention (also known as image persistence or an LCD shadow).

Image retention is a temporary issue that you are more likely to notice before it becomes a permanent issue. However, proper image burn can still affect LCD, LED, and OLED screens.

Image burn-in fixes exist for LCD and plasma screens. How effective an image burn-in fix is depends on the screen damage. Depending on the length and severity of the image burn, some displays may have permanent damage.

If your plasma or LCD screen already has image burn-in, you can try turning on white static for 12 to 24 hours. The constant moving of white-and-black across your screen in random patterns can help remove the ghost image from your screen.

Pixel-shift constantly slightly adjusts the image on your screen, which varies the pixel usage to counteract image burn. You might have to enable a pixel or screen shift option in your screen settings. Pixel-shift is a handy feature for LED and OLED screens that cannot recover from image burn and should help counteract an LCD shadow.

While the Deluxe version uses advanced algorithms to repair burned screens and prolong plasma and LCD longevity, the official site is no longer up and running, and there is no way to download the full version officially.

Screen burn on an amber CRT computer monitor. Note that there are two separate burned-in images: one of a spreadsheet program, and another of an ASCII-art welcome screen.

A nearly two-year-old LCD television showing extreme burn-in of CNN"s circa 2008 digital on-screen graphic; this television is in a McDonald"s restaurant where CNN is permanently turned on and displayed throughout the business day.

In the case of LCDs, the physics of burn-in are different than plasma and OLED, which develop burn-in from luminance degradation of the light-emitting pixels. For LCDs, burn-in develops in some cases because pixels permanently lose their ability to return to their relaxed state after a continued static use profile. In most typical usage profiles, this image persistence in LCD is only transient.

Both plasma-type and LCD-type displays exhibit a similar phenomenon called transient image persistence, which is similar to screen burn but is not permanent. In the case of plasma-type displays, transient image persistence is caused by charge build-up in the pixel cells (not cumulative luminance degradation as with burn-in), which can be seen sometimes when a bright image that was set against a dark background is replaced by a dark background only; this image retention is usually released once a typical-brightness image is displayed and does not inhibit the display"s typical viewing image quality.

Other examples: Apple"s iPhone X and Samsung"s Galaxy series both mitigate or delay the onset of burn-in by shifting the pixels every minute or so for the battery, Wi-Fi, location, and service bars. Also, parallax scrolling may be enabled for the home screen to give icons a 3D-like effect, a setting Apple refers to as "perspective zoom". AG Neovo patented Anti-burn-in technology is also using pixel shifting to activate the pixels to move by the designed time interval to prevent burn in effect on LCD monitors.

Google requests that when these techniques are enabled, watch face developers do not use large blocks of pixels so that different pixels are burned in with each shift, reducing the overall wear of the pixels.

Depending on the type of screen, it is sometimes possible to remedy screen burn-in through the use of remedial software and remedial devices. In the case of OLED screens on Android phones, burn-in reduction apps can display an inverted image of the navigation and status bars (which are constantly displayed and therefore the most likely elements to be burned in) to burn in opposite pattern, resulting in a screen whose sub-pixels have more even luminosity and therefore less visible burn-in artifacts.

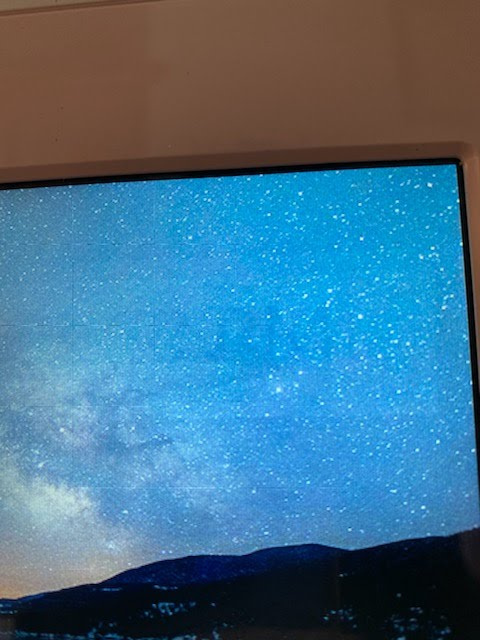

Time, screen brightness, and other factors can cause burn-in, but the circumstances are different for each display technology, as different screens and their pixels operate differently at the hardware level. For LCD panels, like those used in many TVs and computer monitors, burn-in can develop because pixels eventually become unable to return to their unlit state and retain a colored profile.

One of the problems with old CRT monitors, over time, was a condition called burn-in. This phenomenon resulted in an imprint of an image onto the display that was permanent, caused by the continuous display of a particular picture on the screen for extended periods. A breakdown in phosphors on the CRT results in the image being burned into the screen, hence the term. Is there such a thing as LCD screen burn-in?

LCD monitors use a different method for producing the image on the screen and are immune to this burn-in effect. Rather than phosphors generating light and color, an LCD uses a white light behind the screen with polarizers and crystals to filter the light to specific colors. While LCDs are not susceptible to burn-in the same way CRT monitors are, LCDs suffer from what manufacturers call image persistence.

Like the burn-in on CRTs, image persistence on LCD monitors is caused by the continuous display of static graphics on the screen for extended periods. Long-term-static images prompt the LCD crystals to develop a memory for their location to generate the colors of that graphic. When a different color appears in that location, the color will be off and will display a faint image of what was previously displayed.

Today"s LCD and LED monitors do not suffer from image "burn-in" the way CRT monitors of the past did. Today"s monitors have what is called "image retention" or "image sticking."The best way to avoid image retention is to limit the amount of static content on the display. If possible, turn off the display periodically for a period of time between 24 to 48 hours.To reduce the possibility of image retention, we recommend:• Displaying alternating black/white images for 48 to 72 hours• Power down the unit for a period of time (minimum 24 to 48 hours)• Use a screen saver when the touchmonitor is not in useImage retention caused by static (non-moving) images displayed for lengthy periods is not covered under Elo warranty.

If you spend long enough debating the merits of LCD vs. OLED display technologies, eventually, someone will touch upon the subject of the dreaded OLED screen burn in. The point made is that OLED displays will inevitably suffer from horrible-looking artifacts over time, while LCD and new technologies like Mini-LED won’t. But like most of these debates, you’ll probably hear as many overblown anecdotes as you will actual facts about the issue.

The term dates back to old CRT monitors, where phosphor compounds that emit light to produce images lost their luminance with time. LCD panels can exhibit similar problems, but these are much rarer due to the nature of LCD’s backlight and color matrix design.

If OLED screens have a problem with burn in, why do we continue using them? Burn in is a true downside to OLED displays, but there are plenty of reasons consumers and manufacturers like them. For starters, image quality is much better than in LCDs. OLED panels can reproduce more vibrant colors, more contrast, wider viewing angles, and faster refresh rates. Colors tend to be much more saturated, and blacks are much darker.

![]()

The reason why it should not appear: The electronic products designed according to the specifications will have "VCC" and "GND" marks on the power terminals, indicating the connection positions of the positive and negative electrodes, respectively. However, for operators who lack basic knowledge of electrical engineering and electronics, it is still possible to reverse the positive and negative poles of the power supply unconsciously, and even qualified technicians may make mistakes. If the positive and negative poles of the power supply are reversely connected, most of the constant current/constant voltage driver chips on the module will smoke and burn.

Caused by the protection circuit: It is also very common forthe full-color LED display to have a line that is always bright and highlighted, often caused by abnormal cable contact or wrong debugging parameters. Strictly speaking, a well-designed LED display product should have a protection circuit that avoids line highlighting and constant lighting. For products without a protection circuit, after the line highlight is always on, if it is not removed in time, the line driver chip of the module may rise sharply due to continuous high current operation and eventually burn out.

Of course, compared with previous products, the current full-color LED display modules in the industry have relatively low on-load power consumption of line driver chips, and the maximum operating current of most line driver chips is around 3A. It is less likely that the line driver chip will be burned by smoke when the line is always on. Therefore, most products on the market are no longer designed with protection circuits.

Screen burn, also called screen burn-in, ghost image, or display burns are images or icons that are displayed on a screen when they should not be there. Screen burn comes on gradually and gets worse over time and is most common on OLED screens. The navigation bar, the top status bar, or home screen apps are frequent images that get “burned” into the display.

Have you ever been bewildered by the ghost-like images or discolouration that appears on your phone screen, LCD monitor or any other intelligent display screens? You must have also noticed that these stubborn images are mostly found around the areas which have been constantly used or where images have been constantly projected, for example, navigation buttons on a phone or a channel logo on a TV channel.

Burn-in is a visible mark that is left on an intelligent display and remains there even if the content changes on the display. In other words, it appears as if the images were permanently burned-in onto the screen, hence the name burn-in. The burn-in could be in the form of an image outline or a text outline or a discolouration.

Change the screen content frequently. If there is a static image such as a logo or, say, a channel number on the screen, it is likely to get burned-in. The same goes for camera surveillance type systems. Turn the screen off or change to a different input and display every now and then to help keep the image from getting burned-in.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey