tft lcd mega shield v2 2 schematic factory

Voltage type: 5v or 3v voltage input voltage,input is selectable. Because TFT can only work under 3.3 V voltage, so when the input voltage VIN is 5V, need through the 3.3 V voltage regulator IC step down to 3.3V , when the input voltage of 3.3 V, you need to use the zero resistance make J2 short , is equivalent to not through the voltage regulator IC for module and power supply directly.

SainSmart 2.8" TFT LCD Display is a LCD touch screen module. It has 40pins interface and SD card and Flash reader design. It is a powerful and mutilfunctional module for your project.The Screen include a controller ILI9325, it"s a support 8/16bit data interface , easy to drive by many MCU like arduino families,STM32 ,AVR and 8051. It is designed with a touch controller in it . The touch IC is XPT2046 , and touch interface is included in the 40 pins breakout. It is the version of product only with touch screen and touch controller.

Voltage type: 5v or 3v voltage input voltage,input is selectable. Because TFT can only work under 3.3 V voltage, so when the input voltage VIN is 5V, need through the 3.3 V voltage regulator IC step down to 3.3V , when the input voltage of 3.3 V, you need to use the zero resistance make J2 short , is equivalent to not through the voltage regulator IC for module and power supply directly.

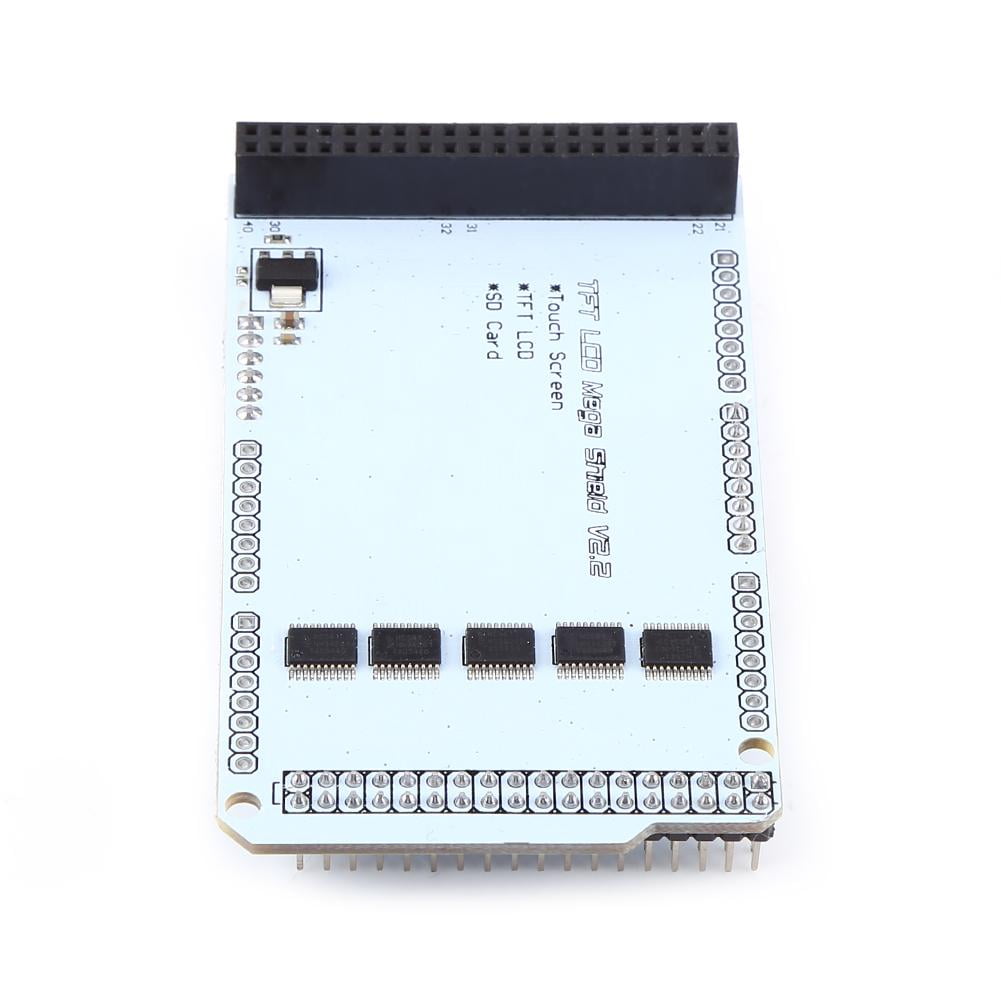

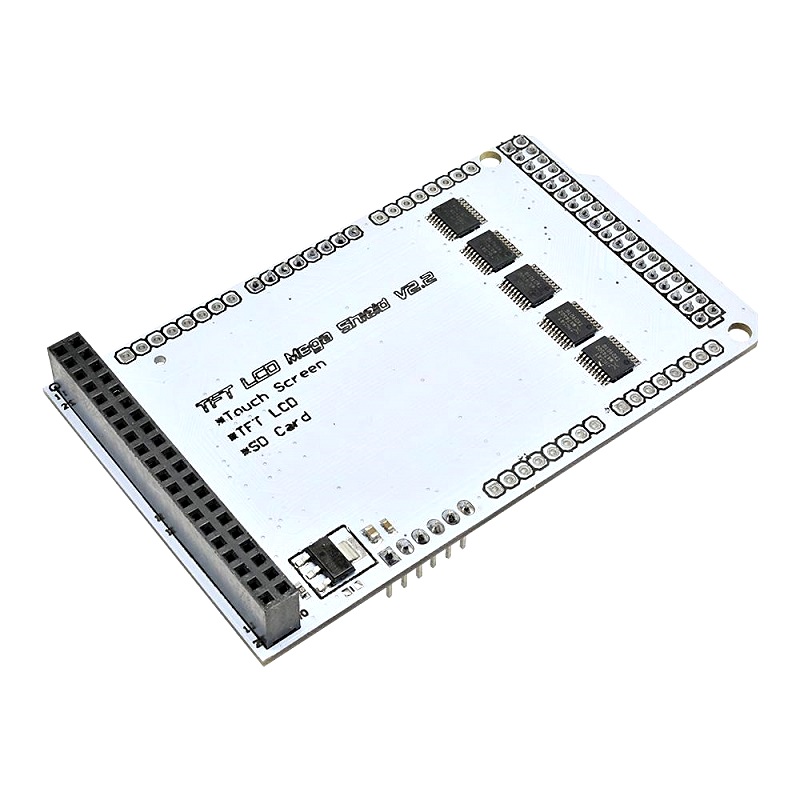

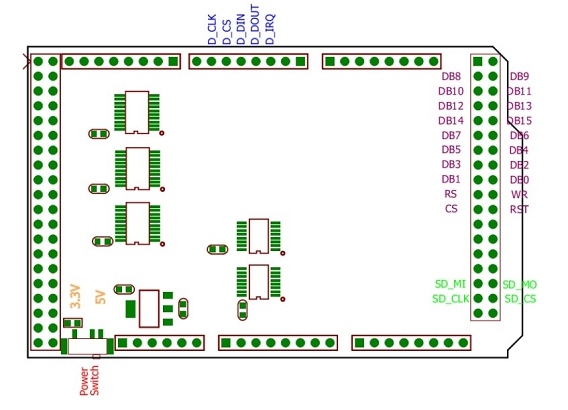

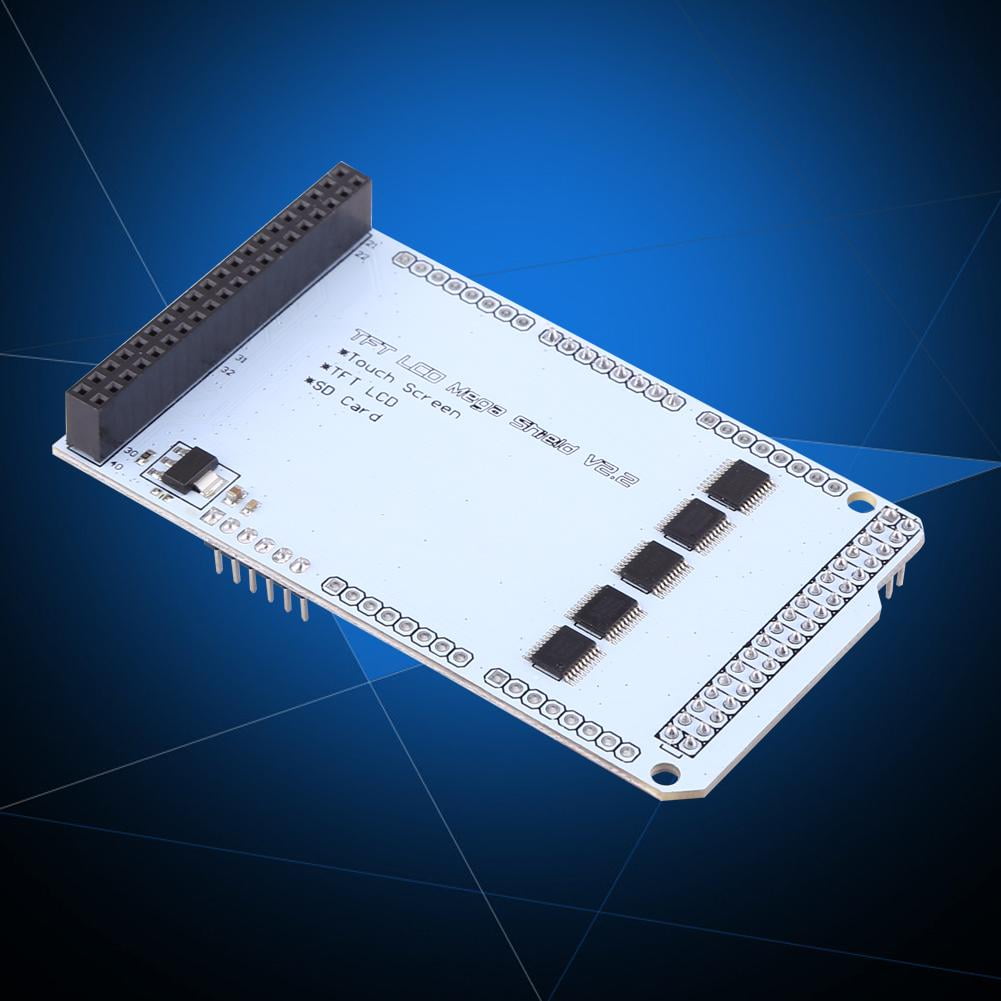

Hello everyone i have been researching about my Elecfreaks Mega tft shield v2.2 and how to read the SD card port from my TFT display attached for weeks to no avail. There is just so little info out there relating to my tft shield and how to read the SD card from a display, however i have the display and touch screen working fine just not the SD card.

I am by no means a pro at electronics and the schematics for the tft shield confuse me. I really really want to get this SD card working so i can start my final year project idea for university but at the moment i have hit a brick wall, every thread i read is either finished unanswered or not relating to my shield or is very old. I have the SD card formatted to 1.96 Gb at FAT16 and i have tried changing the CS pin from 4 to 10 and 53 in the SD library - CardInfo example but still nothing and i get the error message initialization failed. Things to check.

The official SainSmart website - A trusted vendor for desktop 3D Printer, 3D Printing Filament, Desktop CNC machines and accessories, Raspberry Pi & Arduino Projects since 2012.

Arduino Uno is the most popular Arduino board so far, however it is sometimes frustrating when your project requires a lot of sensors or Leds and your jumper wires are in a mess. The purpose of creating the Base Shield is to help you get rid of bread board and jumper wires. With the rich grove connectors on the base board, you can add all the grove modules to the Arduino Uno conveniently! The pinout of Base Shield V2 is the same as Arduino Uno R3.

5-Power Switch: when using Arduino UNO with Base Shield v2, please turn the switch to 5v position; While using Seeeduino Arch with Base Shield v2, please turn the switch to 3.3v.

Spice up your Arduino project with a beautiful large touchscreen display shield with built in microSD card connection. This TFT display is big (5" diagonal) bright (12 white-LED backlight) and colorfu 480x272 pixels with individual pixel control. As a bonus, this display has a optional resistive touch panel attached on screen by default.

The shield is fully assembled, tested and ready to go. No wiring, no soldering! Simply plug it in and load up our library - you"ll have it running in under 10 minutes! Works best with any classic Arduino (UNO/Due/Mega 2560).

This display shield has a controller built into it with RAM buffering, so that almost no work is done by the microcontroller. You can connect more sensors, buttons and LEDs.

For 5 inch screen,the high current is needed.But the current of arduino uno or arduino mega board is low, an external 5V power supply is needed. Refer to the image shows the external power supply position on shield ER-AS-RA8875.

This 2.0”LCD display adopts T7789V driver chip and has 320*240 color pixels (RGB565). It uses IPS TFT display and can display 18-bit color(16-bit is basically used). The module performs excellently in displaying color bitmap. Besides, there is an onboard MicroSD card slot for displaying more pictures. There are two connection ways for this module: pin headers and GDI. Only one fpc cable is needed when working with main-cotnrollers with GDI, which greatly reduces the complexity of wiring.

This is an example of commonly-used icons. 1. We use GIMP2 to convert these icons into codes for better display. 2. We provide some icons for you, Click here to find more"Click here to find more").

In two of my previous articles I showed you how to reverse engineer the Nokia 2730 LCD for connecting to a device with 3.3V I/O’s and then I showed you how to build a 16-channel level converter for connecting devices together that have differing I/O level requirements.

This article brings together the knowledge we have gained in the previous two articles and puts it to use by creating a project that will allow a Nokia QVGA 24-bit colour TFT LCD to be indirectly connected to an Arduino Mega via a level converter, all on one small 50mm PCB.

All quite straightforward so far. The real innovation will be in the graphics library that I present in part two of this article set. The graphics library will use the external memory interface built in to the Arduino Mega to transfer data to the LCD in a single assembly instruction.

There is no faster way to transfer data out of the Arduino Mega to a peripheral. Doing it like this opens up the possibility of full colour bitmap graphics at a respectable refresh speed.

Perhaps the first surprise of this article is my choice of LCD. Given that the previous article showed how to reverse engineer the Nokia 2730 LCD you could have been forgiven for assuming that this was the one I’d use.

The connector is the same 24-pin board-to-board connector used in the Nokia 2730. An eagle-eyed reader has identified the manufacturer and the part number. It is made by JST and the part number is 24R-JANK-GSAN-TF. Here’s the datasheet.

Here’s a photograph of the LCD side of the connector. If you look closely you can see where the ground pins connect directly into the ‘ground pour’ inside the ribbon cable. This helps to identify where pin 1 is located because the big “1” silkscreen’d on to the FPC is in the wrong place.

Like the 2730 before it, the 6300 backlight consists of 4 white LEDs in series requiring around 13V to power them. Just like before, I will use the OnSemi NCP5007 constant current backlight driver to do the heavy lifting here.

The NCP5007 will be configured to supply a constant 20mA through the backlight circuit and we will use a PWM signal on the ENABLE pin to vary the brightness.

We need both 5V and 3.3V inputs for this design. 5V will be used to power the backlight driver as well as set the reference level for the Arduino side of the level converter. 3.3V will be used to set the reference for the LCD side of the regulator.

TFTs like these draw a very small amount of current, typically less than 10mA so I will supply it indirectly from a GPIO pin through the level converter. This allows me to control the order in which power is applied. Many TFTs prefer their I/O supply to come up before the panel supply and for safety I’m going to assume that this is the case with this device. Had the device required significant amounts of current I would have had to use a couple of transistors to switch the current on and off.

The Nokia 6300, like the Nokia 2730, uses an 8-bit 8080 protocol to communicate with the LCD. The 8080 protocol consists of a chip select signal, 8 bits of data, read and write lines and another line that is used to indicate whether you want to transfer data or set a command register value.

The above image summarises the state of the 8080 bus during a write cycle. The key point to note is that data is transferred to the controller on the rising edge of the WR line. Can we get this line from the Arduino Mega’s external memory interface? Well yes, we can. The following diagram from the datasheet shows the timing of the external memory bus.

Selecting a low address line (A8) means that we can free up address lines 10 to 15 for GPIO, saving 6 pins. It doesn’t matter that our selected address locations 0x8000 and 0x8100 are high up in the address range who’s address lines are free’d for GPIO. The ATMega will still correctly control A8. Not only is this design fast, it’s frugal with pins too. Here is the mapping of Arduino pins to their LCD function.

Now that we have a design we can create the schematic in the Eagle designer. All the 5V signals from the Arduino that are destined for the LCD are routed through the level converter and will come out the other side at 3.3V.

After creating the schematic the next stage is to switch to the CAD designer and lay out the board. I placed the components and routed the traces manually. The connector is placed so that the FPC will wrap around the board edge and allow me to mount the LCD on the other side using double-sided sticky tabs.

With the LCD facing up, the interface pins face down and press directly into the sockets on the Arduino. The pin header is placed as close to the edge of the board as possible so that adjacent Arduino pins are not obscured.

After staring at the layout until I’m square-eyed (sound familiar to anyone?) I’m feeling confident that the header pins are all where they should be, the connector positioning will result in the LCD ending up in the right place and the silk-screening will end up on the correct side of the board.

I construct the boards by tinning the pads and then reflowing the larger components such as the level converter, LCD connector socket and the NCP5007 using a hot-plate. I then reflow the smaller discrete components using my Aoyue hot-air gun.

After the completed PCB is cleaned and dried the design is completed by pressing the LCD connector into its socket and mounting the panel on double-sided sticky pads. That it fits comfortably on to the pads was a bit of a relief because the metal back of the panel must stand clear of the traces and particularly the vias on that side of the board.

Type ‘B’ boards support the faster 64K driver. Type ‘A’ boards do not. The raw fill rate for the 64K colour mode is 1.32 megapixels/second. It is 1.06 megapixels/second for the 262K and 16M modes on both boards.

Another controller variant has turned up and we’re going to call this one ‘Type C’. It’s showing up in both 6300 and N82 screens. It behaves the same as Type A screens except for the following differences:

It won’t go into BGR colour transfer mode, only RGB is supported. Since RGB is supported by all variants I’ve seen RGB will become the default mode in my driver code from 2.2.0 onwards.

The price including postage is £4 for UK buyers and £5 for worldwide delivery. I can also include one of the 24-pin JST 0.4mm connectors for a small amount extra. Contact me if you want to take me up on that.

This is a versatile and Arduino/Seeeduino/Arduino Mega compatible resistive touch screen shield which can be used as display device, or sketch pad for user input/interface.

Compared with the previous version (2.8" TFT Touch Shield V1.0) we improved the screen driver with a professional chip (ILI9341) to provide the pin-saving SPI communication protocol without sacrificing the data transmission speed.

Circles isn"t the only thing our library can help you draw, we also have a lines, number, rectangle, and many more examples. Check those out as well to become a pro with the shield.

Function Description: The drawCircle function draws an empty circle with the center at the coordinates poX, and poY. The circle will be of radius r and the border color will be color. The color parameter is a 16-bit Red-Geen-Blue (RGB) integer, in the example code above the words YELLOW, CYAN, RED, and BLUE are defined as integers in the TFTv2.h file.

The TFT Touch Shield"s backlight is on by default since its control circuit is directly powered by the 5V pin. If, however, you wish to control the backlight"s on/off state using the Arduino Digital I/O pin 7, a simple modification will have to be made:

2. Notice that the ON terminal is soldered to the BACKLIGHT terminal as shown in the PCB figure below. Scrape off this connection, or use a soldering iron to remove it.

Now controlling the backlight"s state is as easy as controlling an LED, upload the following code to the Arduino board to see how to toggle the backlight every 500ms (1/2 second):

Combining Arduino and other shield modules, we make a mobile phone named Arduino Phone. Meanwhile, we printed a shell for it with the 3D printer. Although it"s not such fine as you think, even a little bit clunky, it"s still very cool. That is the point this is a cell phone made by ourselves.

Copyright (c) 2008-2016 Seeed Development Limited (www.seeedstudio.com / www.seeed.cc)This static html page was created from http://www.seeedstudio.com/wiki

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey