lcd panel shortage free sample

The global integrated circuits / chip shortage has impacted many industries across the globe, and though it does seem to slowly be getting better, we’re still a ways out from things stabilizing and turning back to normal.

Though many factories had shut down during the pandemic, the chip shortage was already apparent. It was exacerbated during the onset of COVID-19 and has now become a commonly accepted fact of life for most markets, such as automotive, healthcare (particularly eHealth), consumer tech, IoT devices, and in general, most devices requiring embedded processing and wireless connections.

For low volume proof-of-concept and prototype PCB applications, one approach to consider is harvesting chips from reference or evaluation boards. This is a bit of a desperate act, but if planned right, can provide temporary relief of parts shortages and help to develop a more ideal solution for a project while waiting for back-ordered parts and factory lead times to improve.

To understand why we are having a prolonged shortage of integrated circuits, we need to understand something about the economic factors driving the semiconductor industry. Leading-edge semiconductor fabs cost billions of dollars to build and take time to develop and reach satisfactory yields. However, the large, complex chips from the leading edge fabs are sold in high volume and at high prices for servers, laptops, and phones.

The Semiconductor industry uses a metric of revenue/wafer as a metric to decide on investments and prioritize customers in times of capacity shortage.

The bottom line is that we expect the shortages to slowly ease over the next year as many older fabs make incremental capacity improvements. However, we will still see prices increase as the fabs look at the revenue per wafer for each product. We also think there is some double ordering in the market, but fabs are strict about NCNR (No Cancellation, No Return) rules, which will minimize this. USMP will continue to use our Display Industry relationships to mitigate the impact of this crisis on our customers. Please place your orders early to help us to help you.

Emerging smartphone penetration across the globe is one of the prominent reasons, due to which the demand for display panels is on the rise. The global smartphone permeation rate stood at 68.7% in 2021, with 5.4 billion smartphone users worldwide in the same year out of the 7.8 billion worldwide population. The number of smartphone users is expected to reach 6.27 billion by 2025. This would represent the smartphone penetration rate globally to 76.6% by 2025. As per data from the UN’s International Telecommunications Union (ITU), the World Bank, and the UN, in the middle of this decade number of active cellphone subscriptions grew larger, compared to the number of actual people on the planet.

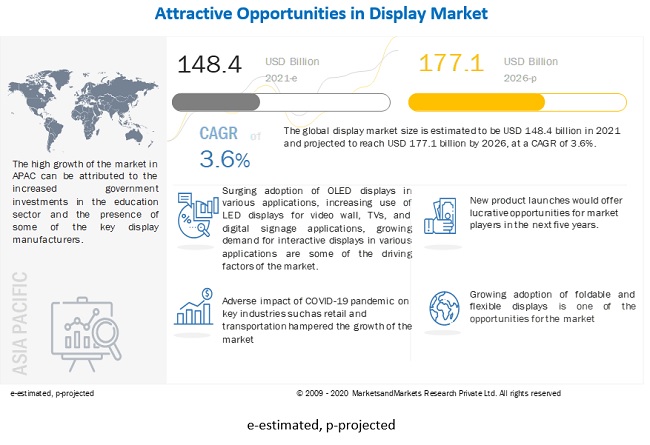

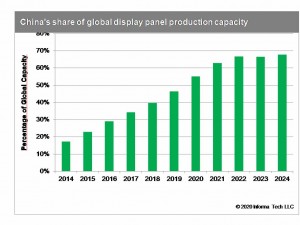

The COVID-19 pandemic has created a mixed impact on the global display panel market. The work-from-home culture and rise in the demand for smartphones boosted the market during the pandemic. As it has been noticed that due to shut down most of the manufacturing sites have been closed which has negatively impacted the market during the pandemic due to the disruption in supply chains and shortage of semi-conductor. LCD production in China is slowing as a result of the COVID-19 outbreak, LCD panel makers are seeking sharp price increases from their original equipment manufacturer (OEM) customers, with a month-to-month jump of as much as 10% in some cases. As per Omdia Display, the price for the notebook displays witnessed a hike, due to the 30–40% decrease in production for 2020’s first financial quarter (Q1), because of shortages in LCD modules. However, during the period when the unlock procedure started a steep rise in the market in terms of revenue was noticed.

Based on the type of display, the market is fragmented into LCD, OLED, and Others (AMOLED, Micro LED, etc). The OLED segment grabbed major market share and dominated the market. The segment captured the USD XX Mn market in 2020. The key advantages of OLED display such as Improved image quality, better contrast, higher brightness, fuller viewing angle, a wider color range, much faster refresh rates, lower power consumption, and a simpler design that enables ultra-thin, flexible, foldable, and transparent displays are contributing to the growth of the segment.

Additionally, the report provides detailed initiatives that are being taken in the field of Pet Display panel. The market is classified into distinct regions including North America (the U.S, Canada, Rest of North America), Europe (Germany, France, Spain, Italy, and United Kingdom and the Rest of Europe), Asia-Pacific (China, Japan, Australia, India, and the Rest of APAC), Rest of World has been conducted. Asia Pacific region grabbed XX% market and captured USD XX Mn market share in 2020. Surging demand for smart consumer electronics, the emerging number of manufacturing facilities, and the low cost of labor are some of the factors that are supporting the market growth of the display panel in the Asia-Pacific region.

Apple is an example of how demand for consumer products is impacting component supplies. The company is one of the pandemic winners in terms of sales revenue and has experienced a boom in demand for its Mac, iPad and 5G iPhone, which launched in late 2020. The company’s Q1 2021 revenue increased 54% to $89.6bn and its iPhone sales increased 66% to $47.9bn – effectively 54% of all revenues in Q1 2021. Part of this success has been achieved through its ability to avoid shortages by stockpiling critical components.

Up until now, many sectors including telecoms have been able to shelter themselves from shortages by advance ordering and stockpiling. Susquehanna Financial Group’s ongoing trend research on the lead time between ordering a chip and taking delivery illustrates the extent of the supply situation, where in July 2021 the lead time increased to 20.2 weeks up from 17 weeks in April.

Both Susquehanna and Bloomberg analysis suggest the increasing lead time gap is an indicator of buyers committing to future supply orders in order to avoid shortages down the line, but also evidence of stockpiling and over ordering which further exacerbates the situation.

The situation has the potential to impact the telecommunications industry where there are shortages of semiconductors in areas such as power management, memory, and screen display for telecommunications equipment. In April 2021, Bloomberg reported broadband providers (ISPs) were facing delays more than a year on internet router orders with carriers been quoted twice the normal order lead time of up to 60 weeks. The potential lack of supply of broadband routers could for example impact ISP broadband subscription sales/upgrades.

Advanced vision sensing will be increasingly required for facial recognition, computational photography, long range scanning, augmented reality and robotics. In July 2021, Semiconductor Engineering highlighted a shortage in CMOS image sensors, which enable camera functions for cars, smartphones, security cameras, and industrial/medical systems, assisting also in computational photography and augmented reality applications.

2. Analog/radio frequency (RF) / mixed signal (SoC) – Semiconductor Engineering highlighted shortages in areas such power management integrated chips (PMIC) and display driver integrated chips (DDIC) in July 2021. PMICs manage flow and direction of power in products such as smartphones as well as wearables and hearables. PMIC are also critical for PCs and servers.

Susquehanna’s May 2021 research highlighted power management lead times of 23.7 weeks in April, an increase of four weeks on the previous month, however in August research indicated a reduction in lead times for power management chips. DDIC manage power to flat-panel displays such as liquid-crystal displays (LCDs) and organic light-emitting diodes (OLEDs). The shortages are impacting automotive, PCs, smartphones, TVs and industrial equipment. Flat-panel displays are also in increasing demand in the automotive sector.

Cloud computing (server) requirements have increased further as people have shifted to fully or partially working from home. Hyperscalers such as Amazon, Microsoft and Google continue to make considerable investments in cloud infrastructure and platforms that also aim to support network operators. Semiconductor Engineering (July 2021) and Susquehanna Financial Group research highlighted shortages in microcontroller MCUs which integrate CPU and memory on the same chip and are used across cars, communications equipment, appliances and industrial equipment. Semiconductor Engineering also noted comments from the CEO of Tokyo Electron that DRAM (flash short term memory) supply was also “tight due to higher 5G mobile, PC, and data center demand”. Smartphones such as the 5G iPhone 12 for example come with 4GB DRAM.

Commenting on the shortage situation in its Q2 2021 analyst call, TSMC acknowledged the challenges caused by a structural increase long-term market demand as well as the short-term imbalances in the supply chain caused by COVID and geopolitical tensions. While the foundry does rule out an inventory correction in future, the CEO confirmed that he expected capacity to remain tight throughout this year and extend at least into 2022. TSMC believes even if an inventory correction were to occur the strength in demand for 5G and HPC applications means the downturn will be less volatile.

However, the combination of the current shortage with geopolitical tensions has resulted in governments stepping up efforts to ensure security of supply such as CHIPS for America Act and actions in Europe, China, India, Japan and South Korea.

Global shipping continues to be an issue across many sectors of the economy as shortage fears lead to over ordering of supplies across many sectors, which in turn contributes to container shortages (as containers are used for temporary storage). This combined with staff furloughing has created bottlenecks across global supply chains.

The fear of shortages itself became a self-fulfilling prophecy as companies fearing shortages (due to high demand, Brexit, upcoming US trade embargos) over ordered and stockpiled inventory to ensure supplies.

A comprehensive overview of the display Panel market is recently added by UnivDatos Market Insights to its humongous database. The display panel report has been aggregated by collecting informative data on various dynamics such as market drivers, restraints, and opportunities. This innovative report makes use of several analyses to get a closer outlook on the display panel market. The display panel report offers a detailed analysis of the latest industry developments and trending factors in the market that are influencing market growth. Furthermore, this statistical market research repository examines, and estimates display panel at the global and regional levels. TheDisplay Panel Marketis expected to grow at a CAGR of ~10% from 2021-to 2027.

Surging internet penetration coupled with the adoption of smart technology-enabled devices such as mobiles, laptops, and tablets is contributing to the growing market for display panels. Global retail e-commerce sales stood at US$2,290 billion in 2017 and reached US$2,774 billion in 2018. Global e-commerce sales are expected to total US$4.891 trillion worldwide in 2021. Thus, global e-commerce sales are predicted to show 20% growth, representing a huge number for business and certainly a steady trend with no signs of decline soon. Online sales are expected to show a rising trend and take a larger piece of the retail pie. By 2024, it is estimated that global retail e-commerce sales would reach US$7.09 trillion by 2025. The overall e-commerce share of retail sales will represent 21.8%.

Also, a decline in the prices of semiconduction globally is one of the prominent reasons which is driving the growth of consumer goods, so the demand for display panels is also uplifting. Globally, the price of semiconductors has decreased significantly over the past few decades. The steady price reduction is caused indirectly by Moore’s Law, an observation that the number of transistors that can be inexpensively placed on a circuit board doubles every two years. As computing capacity grew exponentially every year, manufacturers around the world can create more powerful chips using less expensive silicon.

The COVID-19 pandemic has created a mixed impact on the global display panel market. The work-from-home culture and rise in the demand for smartphones boosted the market during the pandemic. As it has been noticed that due to shut down most of the manufacturing sites have been closed which has negatively impacted the market during the pandemic due to the disruption in supply chains and shortage of semi-conductor. LCD production in China is slowing as a result of the COVID-19 outbreak, LCD panel makers are seeking sharp price increases from their original equipment manufacturer (OEM) customers, with a month-to-month jump of as much as 10% in some cases. As per Omdia Display, the price for the notebook displays witnessed a hike, due to the 30–40% decrease in production for 2020’s first financial quarter (Q1), because of shortages in LCD modules. However, during the period when the unlock procedure started a steep rise in the market in terms of revenue was noticed.

The smartphones and tablets segment grabbed XX% market share in 2020. The emerging adoption of smartphones coupled with the availability of affordable phones across countries is one of the prime reasons which is contributing to the growth of display panels. In India, around 71% of smartphone repairs are related to screen damage. As the most common part, the screen is repaired 77% of the time in India.

The degree of competition among prominent regional companies has been elaborated by analyzing several leading key players operating worldwide. The specialist team of research analysts sheds light on various traits such as global market competition, market share, most recent industry advancements, innovative product launches, partnerships, mergers, or acquisitions by leading companies in the display panel market. The leading players have been analyzed by using research methodologies for getting insight views on global competition.

The high volume in 4Q20 was fueled by a combination of strong demand due to working and learning from home requirements and display panel component shortages that further expanded shipments

Looking ahead, IDC expects component shortages to last at least through the first half of 2021. Changes in work style will also lead to shifts in the market’s customer mix and geographic focus. IDC expects both hybrid work and the popularity of gaming to drive continued strength in the consumer market that will complement a recovery in commercial spending as office occupancy improves.

The high volume in 4Q20 was fueled by a combination of strong demand due to working and learning from home requirements and display panel component shortages that further expanded shipments. Although some geographies have seen life move closer to pre-pandemic levels, ongoing restrictions of varying degrees continued to help funnel consumer budgets to furnish their homes for work or entertainment, even as low office occupancy inhibited commercial monitor spending.

At the same time, a shortage of components like display driver integrated circuits (ICs) and rising shipping costs also contributed to shipment growth as some manufacturers opted to amass stock ahead of component price hikes that could last through the middle of 2021.

If you sell products that fall into any of the scarce product categories — or craft items that useany of those materials — you may be scrambling to figure out just how to handle things. Let’s take a look at a few ways you can handle supply chain shortages, maintain revenue, and keep your customers happy and informed.

Take the time to analyze all the pieces of your manufacturing and fulfillment process. Understand where every item and material comes from, what each one costs, how long each one takes to arrive, and where there are any gaps or delays. Visibility is absolutely key to improving the process and overcoming any shortages.

If you’re having issues getting items from one supplier, you may want to search for an alternative. While this won’t always help in cases of global shortages, it could be a good option for specific cases. If the issue is with overseas providers, for example, a local manufacturer may have more availability. And, though they could be a bit more expensive, it’s better than having no products to sell at all.

One of the most important things you can do is keep customers abreast of shortages, items that are out of stock, and shipping delays. In most cases, people will understand if you let them know ahead of time. But if they find out after they’ve already placed an order, they might become frustrated. So how can you do this?

Add a notice to your entire store. One of the best ways to display an important message is with a store notice that appears on every page of your site. Inform customers about production delays or item shortages so they know ahead of time.

You may also want to keep an emergency stock of manufacturing materials, packaging materials, and products on hand in case you do encounter a delay or shortage. This will enable you to keep things going as planned for as long as possible until you get the items you need or find an alternative solution.

Even though supply chain shortages can be frustrating and scary at times, there are ways you can push through and keep your store running smoothly. It’s all about staying on top of your processes, understanding ways you can improve, and keeping in touch with customers as much as possible.

Rapid growth of the computer microchips industry, surging demand for computer chips and micro computer chips, escalating use of efficient and faster memory chips in industrial applications, surge in adoption of internet of things (IoT), and persistent technological advancements to drive the the global computer microchips market growth. Closed manufacturing facilities, reduction in workforce, and shortage of raw materials during the pandemic had a negative impact on the market.

In addition, lack of workforce and shortage of essential raw materials due to ban on import and export of items further aggravated the impact on the market.

Computer Monitor MarketBy Size (Small and Large), Type (LCD Monitor, LED Monitor, CRT, and Others), Application (Commercial, Gaming, and Others): Global Opportunity Analysis and Industry Forecast, 2021-2031

/cdn.vox-cdn.com/uploads/chorus_asset/file/22863257/akrales_210917_4760_0166.jpg)

We wanted to give you a quick update on the global component shortage that is affecting displays and other products in this rapidly changing scenario and the issues we are all facing.

CDS is working very closely with our manufacturing partners and factories, who are putting in a huge amount of effort to try to secure TFT panels, interface boards, touchscreens, panel PC and the driver ICs needed for all those products to keep shipping schedules on time and reduce any delays that may become evident. Now there are constant negotiations and bartering to get the best allocation of product that we possibly can, and our factories are doing their best to secure all the stock they and we require.

With the increased use of LEDs, the worldwide LED phosphor industry has become more well-known. This expansion can be largely attributable to them because of the operational efficiency they offer in terms of energy and cost. The end-user applications and the technology employed can be used to segment the LED phosphor market. The large range of lighting applications for LEDs is driving their increased adoption. Additionally, LEDs are more effective, last longer, and use less electricity. These factors have consequently caused the market to see spectacular expansion during the anticipated era. Market growth has been further driven by technology advancements,. LED phosphor is used in a variety of products, including cars, portable computers, cellphones, LCD TVs, and home and business lighting. Remote phosphor, direct contact, package-free, modular light engine, thin-film, and embedded LED chip (ELC) technologies are among those utilised in LED phosphor. The end-user applications and the technology employed can be used to segment the LED phosphor market. Numerous products, including cars, portable computers, smartphones, LCD TVs, and home and business lights, use LED phosphor. For instance, according to Statista, in 2018, the number of smartphone users in China were 969.85 million and this number is projected to increase up to 1287.28 million in 2026. However, shortage in raw material is restraining the growth for the market.

The key regions considered for the global LED Phosphor Market study include Asia Pacific, North America, Europe, Latin America, and the Rest of the World. North America is the leading region over the globe. Since LED lighting is a superior and more affordable option to most current lighting solutions, it is attracting a lot of customers and accelerating market growth in this area. The Asia Pacific is growing with the fastest CAGR across the world in terms of market share due to the increasing use of LED Phosphor in the production of consumer electronics including LED and LCD TVs and displays, lighting fixtures, portable PCs like smartphones, laptops, and netbooks, and automotive components.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey