can lcd displays be put on clothing quotation

There has been some confusion about what, exactly, a fur fabric display is. Philips Electronics filed a patent application with the simple title "Fabric Display," though some science blogs and magazines have referred to it as "furry television." At its most basic level, this fur fabric display relies on a very simple technology. Patches of fur cover an image, and when the fur moves, it reveals the image underneath. It"s a simple way to conceal and reveal designs.

The fabric display has three layers. The bottom layer is conductive, which means it can carry electricity from a power source -- like a small battery pack -- to the rest of the fabric to create an electrostatic field across the fur, which gives each strand of fur the same electrical charge.

The next layer in a fur fabric display is the fabric"s base color or design. This could be a company logo, a picture or just a particular color. The furry display doesn"t change the design on the cloth; it just hides or reveals portions of the design at a given time.

The third layer is the fur. It can be any color, but it must be short enough so that when the user turns on the electrostatic field, the strands stand on end and reveal the design or color of the fabric underneath. For example, in a simple fur fabric display, you could use red fur to cover a blue shirt. When you turn on the power for the conductive layer, the red fur would stand on end, revealing the blue shirt underneath. To a distant observer, it would appear that the shirt had just magically changed colors.

The patent application refers to each small, visible section of the base fabric as a "pixel," which may be why some articles refer to the display as furry television. While it might be possible to approximate primitive animation techniques by printing one image across the fur layer and a slightly adjusted image on the fabric underneath, it"s not quite the same as watching television on someone"s jacket.

To understand static electricity, we need to start all the way down at the atomic level. All matter is made up of atoms, which contain charged particles. Atoms have a nucleus consisting of neutrons and protons and a surrounding shell that is made up of electrons. Neutrons carry no charge, but protons have a positive charge and electrons have a negative charge. So, if an atom has more protons than electrons, its charge is positive, and if it has more electrons than protons, its charge is negative. Similar charges repel each other and opposite charges attract one another. An electrostatic field applied to fur creates a similar charge across the fur and the base of the material. Since similar charges repel one another, the fur moves as far away from the base of the material and other strands of fur as it possibly can, causing the strands to stand on end.

Quotes for t-shirt printing will be provided upon request. The following information must be included in your email in order to receive an accurate quote:

We require a minimum of 25 shirts, no exceptions. The 25 shirts must be identical in ink color but shirt color/style can vary. Price breaks occur at 50 and 150 items. Printing one design and switching ink colors on an order of 50 will not qualify for the price break and will be counted as two individual orders of 25. We do not charge a setup fee for screens, as this cost is absorbed into our standard price per shirt, guaranteeing an accurate quote without any hidden fees.

The choice for apparel brands and styles are nearly endless, although our recommended brand is Bella+Canvas for a great combination of quality, ft, and price, but others also have their advantages. Below is a link to our main wholesaler if you would like to browse available products. Please include the brand, item number, and color in your quote request for an accurate total.

Standard-size prints are limited to 11”x17” and allow up to 8 colors. Add $1 per additional ink color or print location per shirt. Any order with 3+ colors must meet the minimum of 50 shirts. Any order with 5+ colors must meet the minimum of 100 shirts.

Large-format prints are limited to 15.5”x21.5” and allow up to 2 colors. Add $2 for the larger format, plus $1 per additional ink color or print location per shirt. Any order with 3+ colors must meet the minimum of 50 shirts. Any order with 5+ colors must meet the minimum of 100 shirts.

Artwork must be sent in full-resolution, 300dpi+ raster images or as vector files in any format of your choosing. Files can be emailed directly or shared via your preferred file-sharing site. Digital mockups will be provided upon request at no additional charge.

Quotes for poster printing will be provided upon request. The following information must be included in your email in order to receive an accurate quote:

We require a minimum of 25 posters, no exceptions. The 25 posters must be identical in ink color. Price breaks occur at 50 and 150 posters. We do not charge a setup fee for screens, as this cost is absorbed into our standard price per poster, guaranteeing an accurate quote without any hidden fees.

LCD displays are extensively used for various purposes, like attracting customers, presenting information and promoting purposes. Also, LCD displays can be used to display direction and signs, increase customer engagement and enhancing beauty. Using indoor LCD displays has been a popular choice for various industries, especially for the retail industry. Shop and malls are places that require the attention of people the most, and digital signage or indoor LCD display is the most effective way to attract customers. There are two types of LCD displays used in the retail industry: indoor LCD display and outdoor LCD display. But this article will only cover the former one in the retail industry.

The indoor LCD display offers many benefits to the retail industry. They are a popular choice to increase the engagement of your store or mall. Through the application of indoor LCD display, the shopper turnover can be shortened. The other key benefits of using an indoor LCD display include better shop branding, better customer engagement, and better presentation of information. The primary purpose of installing an indoor LCD display is to increase the sales of the shop. It has been already proven that you will see a noteworthy difference between the volume of sales before and after installing an indoor LCD display for your shop.

If you own a mall or a shop, you need to get these magic displays. But the problem lies with the fact that there are hundreds of dealers in the market. And whom you should trust? Well, we have got the solution for you. Uniview is the right choice, let me tell you why? We deal with three digital signage types to better suit your requirements, such as free-standing, wall-mounted, and video wall. Moreover, as an LCD display manufacturer, we produce the best quality of indoor LCD displays, which can yield multiple advantages. In the article, we will mention the top 4 benefits of Uniview indoor LCD display.

Uniview offers you a wide range of products to better suit your requirements. The product can be customized with different sizes and locations. The indoor LCD display can be installed in curved spaces, ceilings, walls, and entrances.

Uniview manufactures indoor LCD displays that have vivid and crisp visuals. The display can easily support large image resolutions. Our screen can be calibrated to give you a uniform alignment, brightness, and color combination, thus creating a pleasant viewing experience for the users.

The LCD advertising display made at Uniview can be integrated with other technologies and gadgets. For example, through their integration with sensors, you can measure people’s movement around the malls. Our digital signage’s integration with technology helps system management and efficient execution of operations at the store.

Uniview has brought you a system that can give you a hundred of thousands of color combinations. Customizing the color type for your business is right in your control. Our signage comes in standard black or silver, but it can be modified with antimicrobial black, white. Moreover, you can achieve any color that best suits your brand standards. With the finest quality of color, they can be a significant attractive feature of your shop.

Our products come in the most robust design and fashion models. And they have many advantages. Firstly, our indoor LCD displays have flexible functions, longer battery life and a moveable screen design. Secondly, they are light-weighted and portable. Thirdly, they are easy to clean and maintain. Fourthly, they have clear pictures, good video quality and temperature control. Finally, they are easy to operate and install. With a wide range of products, Uniview presents to you an out of box solution for your problem.

Uniview is a company that produces the most refined quality of the product that both meet international standards. We are the authorized dealers in the business with a long successful history. We offer specialized technical support and a 24/7 helpline to our customers. Furthermore, our prices are the most reasonable in the market, so our solution is the most cost-effective. If you want your stores to stand out in the crowd, attract more customers, and result in more sales, you should acquire our service. Equip your store with our premium quality products and experience a boost in your sales overnight.

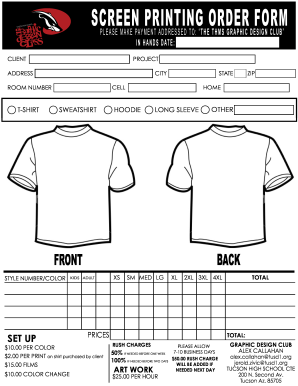

A screen printing quote is used to estimate how much a screen printing order will cost. If you’re selling screen printed clothing in bulk, use our free Screen Printing Quote Template to quickly draft up custom quotes for your business. Just customize the template, fill in the attached form with product information and pricing, and submit the form to instantly generate a polished PDF quote, easy to download or print for your records. You can even share it with clients at the same time using our autoresponder feature!

By keeping your paperwork professional, you can boost the reputation of your business. Our free Screen Printing Quote Template already looks great, but if you’d like to personalize the design to fit your business, just use Jotform’s drag-and-drop PDF Editor to get the look you want! Add your logo, change fonts and colors, upload a custom banner image, and sign off each document with an e-signature. No matter how you customize your Screen Printing Quote Template, you’ll enjoy a tool that will help you save time on manual data entry, organize your paperwork, and streamline your workflow all at once.

This screen printing quote template can be customized and used for any screen printing, whether you print on fabric, plastic, metal, wood, or glass. This template makes it easy for both you and the client to see what exactly is being requested, how much everything costs, and clearly outlines your company’s terms and conditions.Grab your customer’s attention by providing a visually attractive cover with photos of some of your products with beautiful screen printing designs on them. This makes a great first impression and distinguishes your document from other screen-printing quotes.

Address: [Client.StreetAddress][Client.City][Client.State][Client.PostalCode]Add a quotation number – this will allow you and your client to have an easier time referencing the quote if necessary.

Basic Setup PricesMake the quote as straightforward as possible by listing all basic prices plus anything extra you charge for, including modifications. The last thing a client wants is to be surprised by any hidden costs they were unaware of from the beginning. Be as specific as you can about the price. For example, re-orders: within three months of the original order, $15, after three months, $25.

Rush work charges: Note that for any work that needs to be completed within (number of hours/days), we charge an additional $(price). For any work that needs to be completed within 24 hours, we charge an additional $(price).

Our Screen Printing Services and PricesFeel free to modify the table to suit your company’s needs. Add or remove items and their specifications to make the orders as clear as possible.

ArtworkHere, describe the artwork, and if possible, add photos or mock images of what the final product will look like from the front and back (for clothing) and from all sides (for 3-D items).

(Premade/custom) artwork. (Enter the premade artwork style number or describe it, for example, artwork #123, the yellow star. Or describe the custom artwork and where it comes from, for example, the company logo supplied by the company).

Final PricingHere, include a final list of all the items ordered and the price breakdown – in the case of large orders with several different items, it is easy to see everything in one place.

3. (Company Name) is open to printing any artwork provided by the client, however, has the right to deny printing any artwork or text that is deemed controversial, racist, or morally wrong by the company.

4. In the case that the client does not have any specific artwork in mind, the designers at (Company Name) will design custom artwork at the cost of $(price). [Client.FirstName][Client.LastName] will be shown the artwork prior to production. In the case that it is not to the client"s satisfaction, the designers will re-design the artwork at the cost of $(price).

8. (Company Name) will notify the client when the order is ready by (method). Orders must be picked up (specify by when, for example, no later than one week later).

Acceptance of QuoteIt is always better to have a written acceptance rather than a verbal one. It’s also a good idea to give them a timeline to accept – no longer than 3 to 5 days. If you haven’t heard from the client by then, send them a gentle reminder by email, or call them if you haven’t heard from them. If your client is far, consider having them sign it by e-signature.

This free Case Study Proposal Template was created for B2B and B2C businesses in mind. Case studies are essential in any business, especially a growing one. Use this template to help build trust with prospective clients and let them know how others just like them have been successful using your product/service.

Provide your employees with an easy-to-complete TD1 2021 form. Tailor the form to your specifications, host it digitally, and store sensitive data on secure PandaDoc serversDisclaimer

Parties other than PandaDoc may provide products, services, recommendations, or views on PandaDoc’s site (“Third Party Materials”). PandaDoc is not responsible for examining or evaluating such Third Party Materials, and does not provide any warranties relating to the Third Party Materials. Links to such Third Party Materials are for your convenience and does not constitute an endorsement of such Third Party Materials.

__CONFIG_colors_palette__{"active_palette":0,"config":{"colors":{"1d752":{"name":"Main Accent","parent":-1},"b755f":{"name":"Accent Low Opacity","parent":"1d752"},"a3efe":{"name":"Accent Medium opacity","parent":"1d752"}},"gradients":[]},"palettes":[{"name":"Default","value":{"colors":{"1d752":{"val":"var(--tcb-skin-color-0)"},"b755f":{"val":"rgba(116, 190, 70, 0.08)","hsl_parent_dependency":{"h":97,"l":0.51,"s":0.48}},"a3efe":{"val":"rgba(116, 190, 70, 0.2)","hsl_parent_dependency":{"h":97,"l":0.51,"s":0.48}}},"gradients":[]},"original":{"colors":{"1d752":{"val":"rgb(47, 138, 229)","hsl":{"h":210,"s":0.77,"l":0.54,"a":1}},"b755f":{"val":"rgba(47, 138, 229, 0.08)","hsl_parent_dependency":{"h":210,"s":0.77,"l":0.54,"a":0.08}},"a3efe":{"val":"rgba(47, 138, 229, 0.2)","hsl_parent_dependency":{"h":210,"s":0.77,"l":0.54,"a":0.2}}},"gradients":[]}}]}__CONFIG_colors_palette__

__CONFIG_colors_palette__{"active_palette":0,"config":{"colors":{"d8d0c":{"name":"Main Color","parent":-1},"4a715":{"name":"Dark Accent","parent":"d8d0c"}},"gradients":[]},"palettes":[{"name":"Default","value":{"colors":{"d8d0c":{"val":"rgb(26, 188, 156)","hsl":{"h":168,"s":0.75,"l":0.41}},"4a715":{"val":"rgb(21, 162, 136)","hsl_parent_dependency":{"h":168,"s":0.77,"l":0.35}}},"gradients":[]}}]}__CONFIG_colors_palette__Subscribe

__CONFIG_lead_generation_code__

Screen printing is accomplished by pushing ink through a fine screen stencil onto your garment (t-shirt) or whatever substrate you are printing on. The ink is then put through a conveyor belt oven and heated up (in most cases) to a set temperature until it is cured (wash-fast.) Before the printing can start, the screen (stencil) with your image has to be created. This is why screen printers charge setup/screen fees and why there are usually minimum quantities required for a screen printing job. Each color in the design is printed separately and requires it’s own screen to be made.

We need your art to be vectorized in order for it to be printed. Preferred file types are: Adobe Photoshop files, Illustrator files, EPS, PDF, TIFF, or high resolution JPEG files. For those of you who are design savvy, please set your artwork to the final print size (300 DPI) and outline/rasterize all fonts and shapes.

Low resolution images will not be printable (although you may send low resolution images to give us a general idea of the design for quoting). Microsoft Word and PowerPoint files do not transfer well and are not recommended!If you"re still a bit confused, please ask or show us what we"re looking for. If needed, we"ll do our best to recreate your idea and make sure you"re well aware of any additional design fees beforehand.

One of the biggest things you can do to cut costs is to reduce the number of colors in the design. Another important factor is the quantity of shirts you order. The more you order, the bigger the discounts.

Our embroidery minimum on shop provided garments is currently 24 units with a 2-3 week standard turn-around time. Ask your sales person about minimums for customer provided garments.

Our custom patch minimum is currently 100 units, we do not offer custom patches or labels without garments and sewing included. There will be a 3-5 week standard turn-around time.

If there are garments being used in this project would The Foundry be providing them?Please SelectYes I will purchase them through the shopNo I will will provide themI"m not sure or does not apply

AlabamaAlaskaArizonaArkansasCaliforniaColoradoConnecticutDelawareDistrict of ColumbiaFloridaGeorgiaHawaiiIdahoIllinoisIndianaIowaKansasKentuckyLouisianaMaineMarylandMassachusettsMichiganMinnesotaMississippiMissouriMontanaNebraskaNevadaNew HampshireNew JerseyNew MexicoNew YorkNorth CarolinaNorth DakotaOhioOklahomaOregonPennsylvaniaRhode IslandSouth CarolinaSouth DakotaTennesseeTexasUtahVermontVirginiaWashingtonWest VirginiaWisconsinWyomingState

Please upload your art files and/or inspiration here. For retained resolution and accurate color matching please provide your art in vector format if possible. We also accept high resolution bitmaps and provide graphic mastering services.

Screen printing is the process of pressing ink through a stencilled mesh screen to create a printed design. It’s a popular technique used in a whole range of different industries, so even if you"ve never heard of the term before today, it’s likely that you’ve worn or used a screen-printed product at some point without even realising. The process is sometimes called serigraphy or silk screen printing, but all of these names refer to the same basic method.

Screen printing is an effective technique for creating bold canvases, posters and artwork, but the method can also be used to print fabrics and textiles, so it"s great for creating all sorts of custom clothing and products. In this guide, we"ll cover all of your questions about silk screen printing, including:

Screen printing is the process of transferring a stencilled design onto a flat surface using a mesh screen, ink and a squeegee. Fabric and paper are the most commonly screen-printed surfaces, but with specialised inks it’s also possible to print onto wood, metal, plastic, and even glass. The basic method involves creating a stencil on a fine mesh screen, and then pushing ink (or paint, in the case of artwork and posters) through to create an imprint of your design on the surface beneath.

The process is sometimes called "silk screening" or "silk screen printing" and while the actual printing process is always fairly similar, the way the stencil is created can vary, depending on the materials used. Different stencilling techniques include:Using masking tape or vinyl to cover the desired areas of the screen.

Designs made using the screen printing technique may use just one shade of ink, or several. In the case of multicoloured items, the colours must be applied in individual layers, using separate stencils for each ink.

One of the reasons that the screen printing technique is so widely used is because it produces vivid colours, even on darker fabrics. The ink or paint also lies in layers on the surface of the fabric or paper, which gives the print a pleasingly tactile quality.

The technique is also favoured because it allows the printer to easily reproduce a design multiple times. Because the same stencil can be used to replicate a design again and again, it"s very useful for creating multiple copies of the same garment or accessory. This makes screen printing a very efficient technique for creating large batches of custom clothing for sports teams or work uniforms.

When carried out using professional equipment by an experienced printer, it"s also possible to create intricate multicoloured designs. While the complexity of the process does mean there"s a limit to the number of colours the printer can use, it does allow for more intense colouring than is possible to achieve with digital printing alone.

There are different methods of screen printing, but they all involve the same basic technique. The form of printing we"ll talk about below uses a special light-reactive emulsion to create a custom stencil; this tends to be the most popular type of commercial printing, as it can be used to make intricate stencils.

Here, we"ll talk you through the screen printing process step by step. We’ve also put together a video of the process taking place in our workshop, so you can see how we create our top-quality custom screen-printed clothing.

To start, the printer takes the design they want to create on the finished product, and prints it out onto a transparent acetate film. This will be used to create the stencil.

Next, the printer will choose a mesh screen to suit the complexity of the design, and the texture of the fabric being printed. The mesh screen is then coated with a layer of light-reactive emulsion, which will harden when developed under bright light.

The acetate sheet featuring the design is then laid onto the emulsion-coated screen, and the whole thing is exposed to a very bright light. The light hardens the emulsion, so the parts of the screen which are covered by the design remain in liquid form.

If the final design is going to include more than one colour, then a separate screen must be used to apply each layer of ink. To create multi-coloured products, the printer must use his skill to design each stencil, and line them up perfectly to ensure the final design is seamless.

After the screen has been exposed for a set time, the areas of the screen not covered by the design will have turned hard. Any unhardened emulsion is then carefully rinsed away. This leaves a clear imprint of the design on the screen for the ink to pass through.

The screen is then dried, and the printer will make any necessary touch-ups or corrections to make the imprint as accurate as possible to the original design. The stencil is now ready to be used.

There are a number of different presses, including manual and automatic styles, but most modern commercial printers will use an automatic rotary carousel printer, as this allows several different screens to work at once. For multicoloured prints, this sort of printer can also be used to apply the separate colour layers in quick succession.

The screen is lowered down onto the printing board. Ink is added to the top end of the screen, and a squeegee is used to pull the ink along the full length of the screen. This presses the ink through the open areas of the stencil, imprinting the design on the product underneath.

If the printer is creating multiple items, then the screen is raised and a new garment is placed onto the printing board. The process is then repeated.

Once all the items have been printed and the stencil has served its purpose, the emulsion is removed using a special washing fluid so the mesh can be reused to create new stencils.

The printed product then passes through a dryer, which "cures" the ink and creates a smooth, colourfast finish. The final product will be checked and washed thoroughly to remove any residue, before being passed on to its new owner.

To get a clean, sharp print, a screen printer needs to have the right tools for the job. Here, we’ll talk about every piece of screen printing equipment, including what function they serve during the printing process.

While it is possible to screen print with just a mesh screen and a squeegee, most printers prefer to use a press, as it allows them to print lots of items more efficiently. This is because the press holds the screen in place between prints, making it easier for the user to swap out the paper or clothing being printed.

There are three types of press: manual, semi-automatic, and automatic. Manual presses are operated by hand, meaning they’re quite labour intensive. Semi-automatic presses are partially mechanised, but still require human input to swap over the items being pressed, while automatic presses are completely automated and require little to no input.

Businesses that need to print items in large quantities will normally use a semi- or fully automatic press, as this allows faster, more efficient printing and minimises mistakes. Smaller companies, or those who do screen printing as a hobby, might find that a manual table-top press (sometimes called a "handbench" press) is better suited to their needs.

The ink, pigment or paint is pushed through the mesh screen and onto the item being printed, transferring a coloured imprint of the stencil design onto the product.

There’s much more to choosing an ink than just picking a colour. There are lots of specialist inks, which can be used to create different effects on the finished product. For instance, a printer may use glittery inks, texturised inks, or puff inks (which expand to create a raised surface) to create a unique look or feel. The printer will also take into account the type of fabric being screen printed, as some inks will work better on certain materials than others.

When printing clothing, printers will use a type of ink which becomes machine washable once it has been heat-treated and set. This produces a colourfast, long-wearing item that can be worn again and again.

The silk screen in silk screen printing is a metal or wooden frame with a fine mesh fabric stretched over the top. Traditionally, this mesh was crafted from silk thread, but nowadays this has been superseded by polyester fabrics, which offer the same performance for a lower price. The thickness and thread count of the mesh can be chosen to suit the texture of the surface or fabric being printed, with smaller spaces between threads allowing for greater detail in the print.

Once the screen has been coated in emulsion and exposed, it is ready to be used as a stencil. After the screen printing process has finished, it can be washed and re-used.

A squeegee is a rubber blade attached to a long wooden, metal or plastic handle. It’s used to push the ink through the mesh screen and onto the surface being printed. The printer will usually pick a squeegee that is a similar size to the frame of the screen, as this will give better coverage.

A firmer rubber blade is better for printing intricate designs with lots of detail, as it ensures all the nooks and crannies in the stencil receive an even layer of ink. A softer, more yielding rubber squeegee is often used when printing less detailed designs, or when printing onto fabric.

The screens need to be washed to remove all traces of emulsion after use, so they can be reused again for future prints. Some larger printworks may use large tubs of special cleaning fluid or acid to remove the emulsion, while other printers simply use a water trough or sink and a power hose to clean their screens.

If a garment has been properly screen printed by a trained professional using a heat-treated washable ink, then the design shouldn’t wash out. To ensure a colourfast finish, the printer needs to make sure that the ink is set according to the manufacturer"s guidelines. The correct drying temperature and time vary depending on the type of ink and the fabric used, so the printer needs to follow the instructions to the letter if they want to create a long-lasting, washable item.

Direct to garment (DTG) digital printing uses a specialised fabric printer — a bit like an inkjet computer printer — to transfer an image directly onto a textile. It differs from screen printing because a digital printer is used to transfer the design directly onto the fabric. Because there’s no stencil, multiple colours can be applied all at the same time, rather than in separate layers, meaning this technique is often used to print intricate or very colourful designs.

Unlike screen printing, there’s very little setup required, which means that digital printing is a more cost-effective option for printing small batches of clothing or single items. And because it uses a computerised image rather than a stencil, it’s great for producing photographic or highly detailed designs. However, as the colours are printed using CMYK-style dots of colour, rather than solid blocks of ink, it doesn’t provide quite the same intensity of colour that you get with screen printing. You can’t create texturised effects with a digital printer, either.

Heat transfer printing is the name given to any kind of printing that uses heat to bind a design to a fabric. The design is printed out onto a material coated with heat-reactive adhesive, called transfer or sublimation paper. When a heat press is applied to the transfer paper, the adhesive reacts to the heat and sticks to the surface of the fabric beneath, creating a printed textile.

Heat transfer printing is easy and cost effective, so it"s great for smaller batches of personalised printing. It can also be used to transfer detailed photographic designs, which screen printing can"t do. Digital transfer printing can also be used to get great results on items like bags, hats, or footwear, which can be tricky to screen print owing to their awkward shape.

It’s also possible to combine the heat transfer process with digital techniques, to get the best of both worlds. With digital heat transfer printing, a design is created using computer software and printed onto white transfer paper. The design is then cut out using a machine called a plotter, which follows a digital outline to get accurate results. The finished transfer is placed on the desired spot on the garment or accessory, and is then heat-treated to bind it to the fabric.

If there’s a downside to heat transfer printing, it’s that the quality can vary drastically depending on the materials used, and certain printers using low-quality materials and shoddy techniques have given it something of a poor reputation in recent years. But, as long a good transfer material is used and the design is applied with care, the resulting garment will be a high-quality, long-lasting piece. All of our digitally printed garments are created using premium, soft-feel transfer materials, applied using state-of-the-art printers and plotters, so we’re confident that we offer some of the best digital printing on the market.

Screen printing is an ancient art form. An early version of the technique was first pioneered in China, around AD 950, as a method of printing patterns onto fabric. Several centuries later, Japanese artisans adopted the practice to transfer designs onto paper and fabric, using a stiff brush to push ink through a mesh screen woven from human hair.

Screen printing arrived in Europe in the 18th century, but it was slow to catch on as a fabric printing method owing to the high cost of silk mesh at the time. Once the Silk Road made imported silk more affordable, screen printing gradually became a popular — and profitable — way to print fabric. By the early 20th century, printers had developed photo-sensitised emulsions, allowing artisans to create complex stencil designs much more easily.

In the 1930s, artists began experimenting with screen printing as an artistic medium, naming their new-found form "serigraphy" to distinguish it from industrial printing. By the 1960s, artists such as Eduardo Paolozzi and Andy Warhol were using screen printing to create fine art. Dubbed "pop-art", the artist used screen-printing to create multiple copies of a single image, essentially questioning what constituted fine art. Warhol"s famous Marilyn Diptych is perhaps the best-known example of screen printing as an artistic form.

Nowadays, screen printing is used both as an artistic medium and as a commercial printing process. One stencil can be used to reproduce the same design hundreds — or even thousands — of times, so it’s a brilliant technique for producing large orders of custom clothing.

So there you have it: a complete guide to the ins and outs of the screen printing process. Here at Custom Planet, our printers are all professionally trained to deliver the best results, so you can be sure our service is the best on the market. We use top-of-the-range equipment to create custom designs on a huge range of clothing, including T-shirts, hoodies, and sweatshirts, so be sure to take a look and see what personalised items you could create today.

If you need any more help finding the right promotional products for your business, sports team, or band, then check out our helpful guides to learn more.

LED stands for Light Emitting Diode. SMD refers to Surface Mounted Diode, a technology that utilizes a process of mounting each LED chip (pixel) directly to a printed circuit board (PCB). Mounting the diodes in this fashion allows displays to be thinner and sleeker than older LED technology. SMD also allows for finer pixel pitch. Simply put, pixel pitch refers to the distance between the diodes and is responsible for resolution. Fine pixel pitch translates into high resolution. Fine pixel pitch is what makes HD and UHD LED possible.

LCD panels are made of a layer of liquid crystal between two pieces of polarized glass. Liquid crystal can not emit light. Backlights are therefore used to illuminate the display. LCD panels are sleek in design, but typically limited to specific sets of dimensions.

LED technology is modular in nature. This means that LED panels fit together seamlessly and can be used to make displays to fit any space. Custom cabinets can even be built to accommodate unusual shapes or dimensions.

LCD video walls on the other hand take on a tiled approach. This means that screens are jutted against one another. This approach creates bezels or seams and the final dimensions of the wall is directly dependent on the dimensions of the individual screens.

LED is a versatile display option. Thanks to various IP options, LED video walls can be displayed indoors or outdoors. LED video walls can be built with a variety of internal mechanisms as well. Quick refresh rates and dual power backup can ensure that LED video walls look great on camera. Various pixel pitches can ensure the proper resolution for the right context.

LCD is a more straightforward product and consumers are generally more familiar with LCD. LCD is used for cell phones, computer screens, and most TVs, but is it the best choice for video walls? Ultimately that choice is up to the consumer. LCD is cheaper, but generally less customizable. LCD does not work well for outdoor uses and is generally very limited in terms of size and shape.

LED technology has improved drastically in recent years improving quality while driving costs down. LED is a bigger investment up front but generally has a lifespan of about 100,000 hours.

Just like anything else, the best video wall product is largely dependant on context. If you like LED technology but are unsure of the process associated in obtaining a LED video wall read: How to Purchase a LED Video Wall Display.

Find below a chart that shows the price of the print. The chart compares different prices based on the quantity of pieces ordered (shown in a range) vs. the number of colors in the design that will be printed. For example, if an order calls for 50 t-shirts with a 3 color design printed, simply locate the range of quantity in the left-hand column and line it up with the number of colors in the top row and the price of $3.62 per shirt can be found. In this example, the quantity of 50 falls into the 48 - 71 range price point and under the 3 colors row.

Some of the products we can create for you, but are not limited to, include hats, ties, socks, shirts, jackets, sweaters, hoodies, bandanas. We pride ourselves on a quick and simple process that allows us to convey what our clients want into a reality

Promotional items have been used in sales and marketing for decades. Handing out of pens, calendars, book markers, letter openers and other items and gadgets.

High-quality screen printed products include: T-shirts, tank tops, hoodies, sweatshirts, polos, sport shirts, woven shirts, outerwear, headwear, tote bags, aprons, and accessories. Choose from our large catalog of imprintable apparel, bags, and accessories to be screen printed with your logo or design for your business, school, organization, cause, or band.

Screen printing costs are determined by the number of colors in your design, garment style, and quantity. Simply fill out our Get A Quote! form and we’ll get back to you with a detailed estimate for your screen printing project.

• Turnaround times for screen printing depends upon the quality of artwork (if customer-supplied) and the availability of the garments or accessories chosen (due to manufacturing schedules and any material shipping concerns).

Rocky Mountain Apparel in Denver, Colorado, has been producing high quality screen printing, embroidery, promotional products, banners and graphic design services for over 25 years to Colorado. We have a very large variety of apparel and promotional products to choose from and we can screen print or embroider on just about anything. Our staff has many years of combined experience in all areas of the services we provide and we strive for excellence. We feel the need to keep updated on new processes and techniques, so we are always learning to offer you every possible solution in one location.

We specialize in high-quality plastisol, waterbase, and discharge printing. With many different options of garments to choose from, we can accommodate single prints to 10,000+ quantity jobs, from simple one color designs up to tencolor designs.

Whether it’s a logo on a hat, or a letter on a jacket, custom embroidery is a great way to get a professional look on your goods. With 40 heads, in combination with our in-house digital art and editing ability, we can process small to large scale projects with ease.

With tens of thousands of promotional products out there, it can be hard to find just the right item for your next event, employee gift or client giveaway. Contact one of Rocky Mountain Apparel’s experienced CSRs and let them find the perfect product for you.

For a quote on your next printing, embroidery, sticker or marketing and promotional project, please click on the buttons below or call (303) 292-3331.

Transparent LCD’s provide an innovative display solution opening up new ways for brands to promote their products and services. Examples include retail stores looking to advertise a new fashion clothing or accessory, museums securely housing a precious artifact with information displayed on screen or brands looking to launch a new product at a live event or show. The opportunities are endless!

Our Transparent LCD Displays include a Grade A LCD panel with metal bezel protecting the edges / electronics and a media board supporting HDMI or VGA inputs from your PC, Laptop or Media Player.

Transparent screen technology offers intriguing ways to deliver visual information to your audience, being used to reveal or conceal products, objects or artefacts behind the screen.

The combination of HD LCD technology (4K on our 65″, 86″, 98″ version) with a transparent screen substrate opens up creative avenues that were previously closed with traditional LCD displays. Solid black pixels on a transparent background can be used in intriguing ways to hide (and gradually reveal) whatever is behind the screen.

Our Transparent LCD monitors are designed for integration into the customers own furniture housing or display case while our Transparent LCD showcases offer a complete solution including the display, housing and backlight with white or black options available on request. We can also offer custom freestanding options for POP / POS displays. Transparent LCD’s are predominantly fully housed however we’ve recently developed an innovative housing method using a high brightness LED panel which allows the display case sides to remain transparent for improved visibly into the display case.

On July 30th 2020, Nike opened it’s largest ‘House of Innovation’ yet in Paris, France following the opening of stores in Shanghai and New York. The 3rd of Nikes specialist flagship stores stands in a prime location on the prestigious avenue des Champs-Élysées, measuring 2,400sqm with the latest and greatest in Nike innovation spreading over 4 floors.

Using their original design as a starting point, we worked closely with the team at Nike to adapt to the mechanical aspects of the design, the result was a sleek and minimalist set of nine Transparent LCD Display Screens, custom built to suit the applications requirements, bringing Nike’s original concept ideas to life.

These screens can also be granted multi-touch capability by combining them with infrared touch frames or PCAP touch overlays, to add an interactive element to your installation. This creates a very powerful impact when the content on screen integrates with real life objects behind the screen, encouraging viewers to interact on a level that will exceed expectations.

Retail windows, interactive booths, display cases, interactive games, vending machines, drinks coolers… the uses for this amazing technology are limited only by your creativity.

Transparent LCD’s comprise of an LCD panel without the backlight with white pixels appearing as transparent. In order to display an image, the Transparent LCD needs to be integrated into a housing with a high bright LED backlight.

We can also offer more complete solutions like our Transparent LCD Showcase that comes fully contained and ready to use with a powerful backlighting system to guarantee the best picture quality.

Yes in order to display an image Transparent LCD’s need to have a strong backlight. Notoriously Transparent LCD’s have also needed some form of housing to achieve optimum image quality, however, Nike’s House of Innovation paired our Transparent LCD’s with powerful, oversized backlights that allowed the screens to be mounted with no surround but still producing a high-quality image.

Transparent LCD’s are arguably the most popular transparent screens but are hindered by their need for a backlight to operate. For applications looking for a similar effect without the backlighting, Transparent OLEDs require no housing or surround but are only currently available in a 55″ screen size with HD quality. For larger transparent screen applications, Transparent LED’s are recommended with external and internal solutions usually installed to glass facades for the impact of an led screen without compromising the view from inside the building.

We also offer transparent projection technologies including our Clearview Rear Projection Film featured in Guardians of the Galaxy as well as at the 83rd Oscars celebration and MTV EMA awards.

Transparent LCD’s are a great way to combine physical and digital displays in one central place making them a popular choice for museums and exhibitions. Our transparent screens can also be integrated into display furniture and appliances & vending machines like freezer doors for supermarkets. Other uses include POS displays, store window displays, trade shows and product launches.

We manufacture in Britain and ship worldwide – if you need further information, a pricing quote, or want to discuss ideas for using our Transparent LCD Display click the link below to contact us, email us via info@prodisplay.com or call us on +44 (0)1226 361 306.

As advantageous as screen printing is for transferring designs (e.g., brand logos) onto fabric for commercial products such as T-shirts and bags, you may want to eventually get rid of your designs. Fortunately, this is possible because the thick ink used for this technique doesn’t become fully absorbed into the fibers of the fabric. Here are seven effective ways to remove unappealing or outdated screen printing designs from clothing and other items.

Acetone is a chemical found in nail polish remover that can be highly useful in removing cracked and old designs made via screen printing. You can either use nail polish remover or a bottle of pure acetone to dissolve your designs. However, be sure to exercise caution with this chemical as it’s a strong solvent.

Plastisol is one of the most popular types of ink utilized for screen printing. This ink is made of polyvinyl chloride (PVC) or other similar polymer particles. Like acetone, plastisol is strong, so you must always wear gloves to handle it and use it in a well-ventilated space. For this technique, begin by soaking a soft cloth in plastisol and placing it on top of your design.

A good old-fashioned cold-water rinse in the washing machine (or by hand) also can be effective to remove screen printing designs. However, it’s highly recommended that you only choose this technique for brand-new designs.

This method involves using an iron to “melt” a printed design onto a bag (ideally a grocery store paper bag). The leftover ink can then be easily peeled away. This is the only technique that involves using heat, which can typically make removing ink more difficult. However, be sure you’re not using steam (e.g., keep your iron on a relatively low setting.). A plastic scraper can also help you get rid of any remaining ink.

Believe it or not, sugar can help to gently remove screen-printed designs, especially fresh ones. If part of your design is left even after a cold-water rinse, try adding a tablespoon of regular sugar to your design. Gently rub your design with either a soft cloth or your hand.

All of these methods are highly effective for removing screen printing designs. However, keep in mind that some solutions may work better than others, depending on factors such as the size of your designs, the type of garment (e.g., T-shirt, hoodie, etc.), and the material of the fabric they’re printed on (e.g., cotton, wool, polyester, nylon, denim, etc.). Be sure to also consider the amount of time and effort you’re prepared to devote to removing your designs.

Contact the experts at Professional Graphics Inc. to learn more about how to remove screen printing designs and to receive high-quality screen printing services. We’re a full-service commercial printing company headquartered in Norwalk, Connecticut that has been committed to providing high-quality services to diverse organizations since 1979.

We use advanced technology and processes to efficiently produce clear, accurate designs and can work with your budget and needs. Regardless of the type of products and fabrics from which you wish to remove designs, we can provide thorough guidance on what methods you can use. Call PGI today at (203) 439-6120 or contact us online for more information about our products and services.

This is a placeholder for the Yext Knolwedge Tags. This message will not appear on the live site, but only within the editor. The Yext Knowledge Tags are successfully installed and will be added to the website.

The Yext script you entered is empty or incorrect: <script async src="https://knowledgetags.yextpages.net/embed?key=M26bOZn2vhQ8iWsbSTwpBWhpdytNpXVcd_IlaD3neb4XAqrg5UsDnv-E_S10NQYf&account_id=7007247221&location_id=7007247221" type="text/javascript"></script>.

<script async defer src="https://knowledgetags.yextpages.net/embed?key=KEY&account_id=ACCOUNT_ID&location_id=LOCATIONS_ID" type="text/javascript"></script>

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey