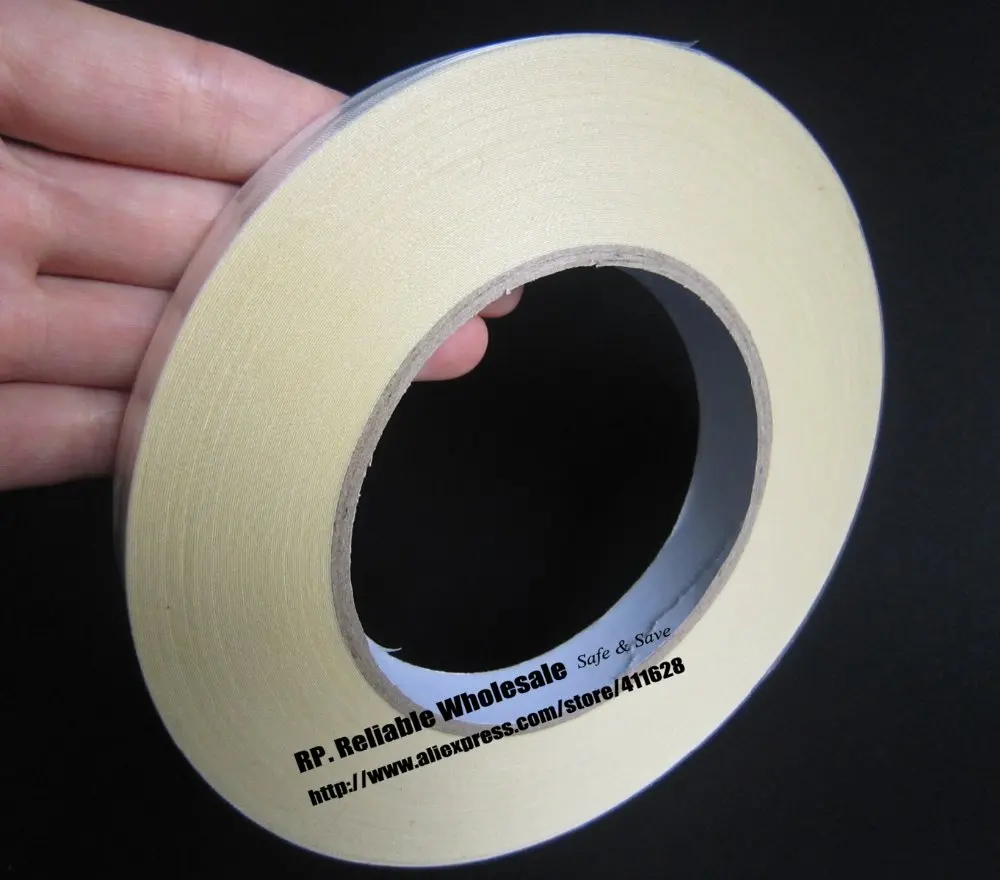

lcd screen adhesive tape free sample

The most important property of the raw materials for adhesive transfer tape is stability at any given condition. R&D department selects the appropriate raw materials based on functionality which should encompass multiple areas. Their characteristics can contribute to the identified characteristics of the finished product, such as organoleptic characteristics (color and texture), product safety characteristics, and physical properties (durability). Raw materials are the lifeblood of your business and they must flow to where they are needs in the right amount. Capable of providing customers with a sufficient supply of PET Adhesive Tape, CROWN ADHESIVE PRODUCTS CO.,LTD. plays a leading role in this industry. hot melt adhesive tape series manufactured by CROWN Adhesive Tape include multiple types. And the products shown below belong to this type. The controls and tests CROWN are carried out in line with the procedures and guidelines approved by the rubber and plastic industry. It provides surface protection on goods, preventing wear and reducing scratch. The product is highly valued by most engineers because of its corrosion and heat resistance as well as its strength and elasticity. The product is popular for its moisture resistance property.CROWN welcomes all the customers around the world to experience the best shopping protective film service. Please contact.

The most important property of the raw materials for adhesive transfer tape is stability at any given condition. R&D department selects the appropriate raw materials based on functionality which should encompass multiple areas. Their characteristics can contribute to the identified characteristics of the finished product, such as organoleptic characteristics (color and texture), product safety characteristics, and physical properties (durability). Raw materials are the lifeblood of your business and they must flow to where they are needs in the right amount. Capable of providing customers with a sufficient supply of PET Adhesive Tape, CROWN ADHESIVE PRODUCTS CO.,LTD. plays a leading role in this industry. hot melt adhesive tape series manufactured by CROWN Adhesive Tape include multiple types. And the products shown below belong to this type. The controls and tests CROWN are carried out in line with the procedures and guidelines approved by the rubber and plastic industry. It provides surface protection on goods, preventing wear and reducing scratch. The product is highly valued by most engineers because of its corrosion and heat resistance as well as its strength and elasticity. The product is popular for its moisture resistance property.CROWN welcomes all the customers around the world to experience the best shopping protective film service. Please contact.

UltraTape’s semiconductor cleanroom tapes are designed specifically for use inside semiconductor and critical environment cleanrooms. Operators will like the easy release from the roll, ease of handling, low static charge on unwind, and excellent conformability.

UltraTape 1110 is designed specifically for cleanroom packaging, wafer shipping boxes and bags. Specially formulated adhesive leaves no residue or ghosting on plastic boxes, even after prolonged storage. Extremely low levels of metals, halogens, and outgassing. Additional Product Specifications for 1110.

UltraTape 1112 is designed specifically for cleanroom packaging, wafer shipping boxes and bags. Specially formulated adhesive leaves no residue or ghosting on plastic boxes, even after prolonged storage. Extremely low levels of metals, halogens, and outgassing. Additional Product Specifications for 1112.

UltraTape 1114 is a low tack version of the 1110 and 1112 cleanroom packaging product. It also works well for other applications in your cleanroom where removability is necessary after short term or long term applications. Additional Product Specifications for 1114.

UltraTape 1153 is ideal for any application needing a strong hold. The rubber adhesive bonds quickly to most surfaces and s considered low residue for glass, metal, and plastic. A good replacement for vinyl tape in cleanroom environments. Additional Product Specifications for 1153.

UltraTape 1164 is a zero residue cleanroom tape that looks and performs like vinyl tape, yet has much lower metals, is lead-free, and environmentally superior. It has low stretch and is removable from all surfaces. UltraTape’s high purity medium adhesion tape has a very easy release from the roll and is excellent for sealing bags, taping wafer boxes, sealing garment cuffs, taping signs to walls and equipment and general cleanroom production and maintenance use. 1164 is excellent for long term applications. Additional Product Specifications for 1164.

UltraTape’s unique tapes are designed specifically for Medical and Pharmaceutical applications. All tapes can be irradiated to meet the strict requirements of these industries.

UltraTape 1114P is a low adhesion, cuff sealing polyethylene tape used to ensure an effective seal between the glove and garment, protecting the product and worker. 1114P low adhesion tape is perforated at convenient 4-inch intervals to allow the operator to use one hand to apply the tape. Gamma irradiated version also available. Additional Product Specifications for 1114P.

UltraTape 7155 is a high tensile, premium grade, saturated crepe paper with a tinted stripe of color changing ink that produces a dramatic color change upon autoclave process completion. Autoclavable steam indicator paper is designed for high temperatures. Adhesion to non-woven and muslin fabric as well as plastic and metals. Additional Product Specifications for 7155.

UltraTape 7160 is a medium adhesion tape able to withstand 273° F (134° C) for +30 minutes, entire roll can be autoclaved. Medium adhesion vinyl tape is writable with a ball point pen. Vinyl tape is used for product labeling, color coding, and bag sealing during the autoclave process. 7160 medium adhesion vinyl tape is also available in gamma irradiated for use in a sterile environment. Additional Product Specifications for 7160.

UltraTape 7512 is a medium density polyethylene tape, excellent for gap sealing of doorways and pass-throughs. 7512 gap sealing tape offers excellent conformability, is removable and residue-free. Additional Product Specifications for 7160.

In their simplest form, a temporary surface protection film is a thickness of plastic coated with a thickness of a specialized pressure sensitive adhesive (PSA). A key word when describing protective film adhesives is “temporary.” By design, a temporary surface protection film is not intended to be left on a surface indefinitely. We have all experienced the irritation of trying to remove a supposedly temporary price tag from a new gizmo and the tag tore into strips and/or left a gooey residue behind. That is quite undesirable in a protective film. Read How to Select a Protective Film to avoid having that happen with your protective film.

Film thickness is normally described as the combined thickness of the plastic and that of the adhesive. In the USA, film is measured in thousands of an inch, or mils. (This is not the same as millimeters.) Typical film thicknesses range from 1 mil to 6 mil, occasionally higher. The thicker the film, the more protection it offers against abrasions, scratching, etc. Thicker films tend to be more rigid and can be more difficult to apply to contoured surfaces.

Adhesive type is also an important consideration. Textured surfaces usually require thicker and softer adhesives. If the adhesive is just contacting the “peaks” of the surface, it may be touching less than 5% of the total surface area and be prone to falling off the surface. Adhesives for textured surfaces also tend to be higher in tack value.

Tack, or adhesive stickiness, is measured in ounces per inch. For best performance, it is desirable to use the lowest tack value that adheres sufficiently well enough to keep the film on the surface during its life cycle. Using a higher tack level than is necessary can increase the risk of the film being difficult to remove or of leaving adhesive residue behind. For example, protective films that are used to protect the LCD screens on cell phones have a tack of about one ounce/inch. Films that are used to protect carpeting have a tack of 25 ounces/inch or higher. Using carpet film on an LCD display would probably pull the display apart when the film was removed.

Use this guide to correctly apply replacement adhesive under your iPhone"s display after a repair. Replacing the adhesive can help maintain your iPhone"s water resistance. The pre-cut adhesive strips are very delicate and are easily damaged if not applied correctly, so you may want to have a spare on hand if following this guide for the first time.

This procedure applies to all iPhone 6s, 6s Plus, 7, 7 Plus, 8, 8 Plus, X, XS, XS Max, and SE 2020 models. (Prior models did not use display adhesive.)

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey