tft lcd addressing made in china

In recent time, China domestic companies like BOE have overtaken LCD manufacturers from Korea and Japan. For the first three quarters of 2020, China LCD companies shipped 97.01 million square meters TFT LCD. And China"s LCD display manufacturers expect to grab 70% global LCD panel shipments very soon.

BOE started LCD manufacturing in 1994, and has grown into the largest LCD manufacturers in the world. Who has the 1st generation 10.5 TFT LCD production line. BOE"s LCD products are widely used in areas like TV, monitor, mobile phone, laptop computer etc.

TianMa Microelectronics is a professional LCD and LCM manufacturer. The company owns generation 4.5 TFT LCD production lines, mainly focuses on making medium to small size LCD product. TianMa works on consult, design and manufacturing of LCD display. Its LCDs are used in medical, instrument, telecommunication and auto industries.

TCL CSOT (TCL China Star Optoelectronics Technology Co., Ltd), established in November, 2009. TCL has six LCD panel production lines commissioned, providing panels and modules for TV and mobile products. The products range from large, small & medium display panel and touch modules.

Established in 1996, Topway is a high-tech enterprise specializing in the design and manufacturing of industrial LCD module. Topway"s TFT LCD displays are known worldwide for their flexible use, reliable quality and reliable support. More than 20 years expertise coupled with longevity of LCD modules make Topway a trustworthy partner for decades. CMRC (market research institution belonged to Statistics China before) named Topway one of the top 10 LCD manufactures in China.

Founded in 2006, K&D Technology makes TFT-LCM, touch screen, finger print recognition and backlight. Its products are used in smart phone, tablet computer, laptop computer and so on.

The Company engages in the R&D, manufacturing, and sale of LCD panels. It offers LCD panels for notebook computers, desktop computer monitors, LCD TV sets, vehicle-mounted IPC, consumer electronics products, mobile devices, tablet PCs, desktop PCs, and industrial displays.

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Microtips Technology is a global electronics manufacturer based in Orlando, Florida. The company was established in 1990 and has grown into a strong fixture in the LCD industry.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

All products feature high-bright LCD systems that come from the company’s proprietary low-power LED backlight technology. The modules and screens also come in ruggedized forms perfect for highly-demanding outdoor industrial use.

LXD Incorporated is among the earliest LCD manufacturers in the world. The company was founded in 1968 by James Fergason under the name International Liquid Xtal Company (ILIXCO). Its first headquarters was in Kent, Ohio. At present, LXD is based in Raleigh, North Carolina.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

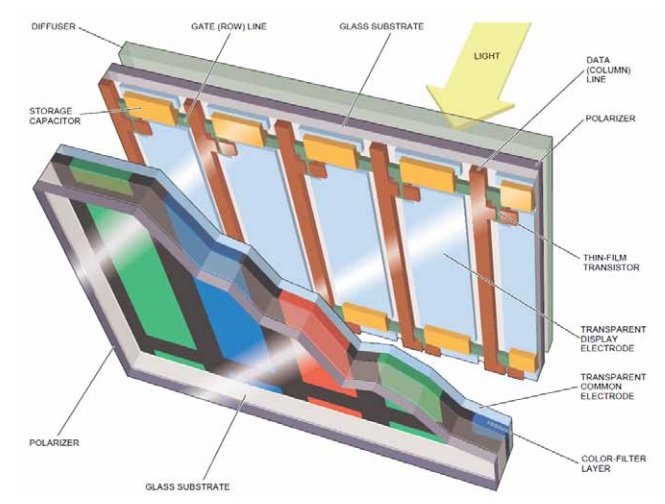

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

SHANGHAI, Aug 26 (Reuters) - China"s BOE Technology Groupwill soon start building the country"s first eighth generation TFT-LCD (thin-film transistor liquid crystal display) production line with an investment of 28 billion yuan ($4.1 billion), a source close to the situation said on Wednesday.

with an annual production capacity of 1.2 million pairs of LCD (14 * 16"), 800,000 pieces of LCM, 600,000 pieces of backlight. LCD products can be divided into TN, HTN, STN and FSTN. LCM products can be divided into COG and COB.

A:We are professional manufactory, which specializes in TN, HTN, FSTN, STN monochrome LCD, LED backlights, LCD modules more than 12 years in Shenzhen . Our advanced full set equipments make sure good quality and competitive price!

Common LCD panel specification custom:1. Any digital, some graphics, icons can be designed by our engineers and OEM and ODM service are available.2. LCD type: TN, HTN, STN, FSTN3. Polarizer mode: Reflective, transflective and transmissive4. Connector: Pin, heat seal, zebra5. Display mode: Positive, negative6. Connector: Pin, heat seal, zebra7. Glass thickness: 1.1mm, 0.7m

As the key component behind liquid crystal displays (LCD), these materials change light polarization to create vibrant, high-resolution images on digital screens. The growth of LCD technology has helped propel the larger display panel market enormously, with industry valuation projected to reach $178.20 billion by 2026.

A prolific variety of LCD types has been developed to best meet their exact use-cases and end-environments. Displays may be optimized for power consumption, contrast ratio, color reproduction, optimal viewing angle, temperature range, cost, and more.

Passive Matrix LCDs are addressed with common and segment electrodes. A pixel or an icon is formed at the intersection where a common and a segment electrode overlap. Common electrodes are addressed one-at-a-time in a sequence. Segment electrodes are addressed simultaneously with the information corresponding to all pixels or icons connected to the current common electrode. This method is referred to as multiplexing.

Passive Matrix LCDs offer a cost advantage (both parts and tooling) and are highly customizable. The counterpart to Passive Matrix displays are Active Matrix displays.

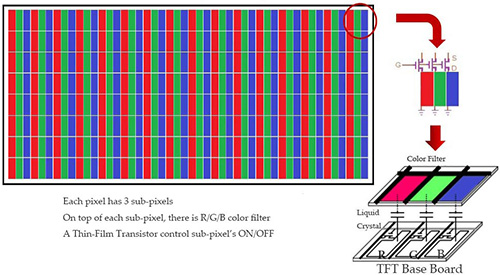

Active-Matrix LCDs were developed to overcome some of the limitations of Passive Matrix LCDs – namely resolution, color, and size. Within an Active-Matrix LCD, an “active element” is added to each pixel location (the intersection between a horizontal row and vertical column electrode). These active elements, which can be diodes or transistors, create a threshold and allow control of the optical response of the liquid crystal structure to the applied voltage. Transistors are used as switches to charge a capacitor, which then provides the voltage to the pixel. Whenever a row is turned on, one at a time, all transistor switches in that row are closed and all pixel capacitors are charged with the appropriate voltage. The capacitor then keeps the voltage applied to the pixel after the row is switched off until the next refresh cycle.

Furthermore, the processes used for manufacturing Active-Matrix LCDs can create much finer details on the electrode structure. This allows splitting each pixel in three sub-pixels with different color. This together with the better voltage control allows full color displays.

The transistor switches used in Active Matrix Displays must not protrude significantly above the surface of the display substrates lest they might interfere with a uniform liquid crystal layer thickness. They must be implemented in thin films of suitable materials. Hence, the name Thin Film Transistors (TFT). While AM and TFT have a different meaning, they are often used interchangeably to indicate a higher performance display.

TFTs can be formed by amorphous silicon (denoted α-Si TFT), by poly-crystalline silicon (LTPS for Low Temperature Poly Silicon), or by semiconducting metal oxides (Ox-TFT or IGZO-TFT for Indium Gallium Zinc Oxide).

Currently the most common Electronics Display Technology on the market is LCD technology and among LCD technologies, TFT display technology is the most widely used across consumer applications (laptops, tablets, TVs, Mobile phones, etc.) as well as many industrial, automotive, and medical applications.

As the first commercially successful LCD technology, Passive Matrix Twisted Nematic (TN) LCDs use a 90° twist of the nematic LC fluid between two polarizers to display information. The twist of the LC fluid either blocks light from passing through the LCD cell or allows light to pass, depending on the applied voltage. The applied voltage changes the twisted nematic orientation into an orientation that does not change the polarization of tight. This is called the TN effect.

Initially, Passive TN LCDs were used in segmented, icon, or character displays where an image element was turned “on” and “off” depending on how the fluid was driven. Improvements were made along the way to address the limited viewing angle of TN technology, which can suffer from contrast loss or even inversion at shallow angles.

The numbers of rows or icons that can be addressed in a TN display without Active Matrix addressing is very limited. This is related to how strongly the liquid crystal responds to the applied voltage. Twisting the LC nematic fluid more than 180 degrees (typically between 210 and 270 degrees) causes the display to require a much smaller voltage difference between on and off pixels. This in turn allows addressing of many more rows without an active matrix. Displays with a twist between 210 and 270 degrees are called Super Twisted Nematic displays.

The advantage of these technologies is a much wider and more symmetrical viewing angle along with the elimination of the contrast inversion (or color shift) seen in TN TFT LCDs when viewed from various angles. IPS and FFS displays also are less sensitive to pressure, which is a big advantage in touchscreen displays.

The integrated circuit is a patterned piece of silicon or other type of semiconducting material. A modern IC contains millions or even billions of tiny transistors. Their tiny size allows for the fabrication of smaller, faster, more efficient, and less expensive electronic circuits. The driver chips addressing electronics displays are ICs.

Legacy LCDs normally have the driver ICs (integrated circuit) mounted on a printed circuit board (PCBA) which consists of a flat sheet of insulating material used to mount and connect the driver IC and electronic periphery to the LCD. PCBs can be a single-sided, double-sided or multi-layer.

Proculus is one of the most reliable LCD display manufacturers in China. Our intelligent LCM solutions allow you to create amazing GUls for all your products, from Customer Aplances to life-sustaining Medical Devices. You can make quick prototypes, in-house control interfaces, one-time projects, high-volume appliances, and everything you can imagine that would benefit from an affordable yet comprehensive GUI system.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey