tft lcd principle manufacturer

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

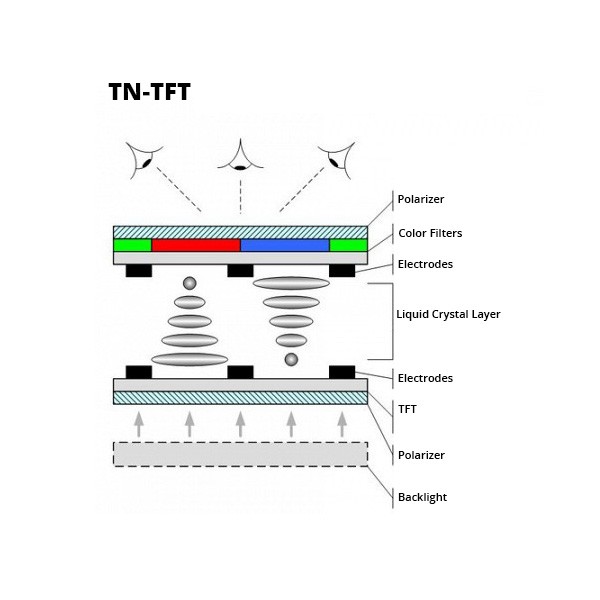

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Distributor of component LCDs for equipment which provide high-contrast ratio, color saturation, luminance and performance enhancements such as advanced wide viewing (AWV) for true color fidelity, super-high brightness (SHB) and wide temperature range. Focus on industrial, instrumentation, hand-helds, medical and other low-to-medium volume markets. High-bright LED backlights for outdoor use. LVDS interfaces decrease EMI. Factory installed touch screen solutions. 3.5" to 12.1" QVGA, HVGA, VGA, WVGA, SVGA, XGA, WXGA. Also distributes other related products including LED drivers, lamps, indicators, LED assemblies, segment displays, LED mounts, LEDs, and light pipes. Distributor of electronic components, hardware and fasteners and provides design/value engineering support, fulfillment strategies, procurement services and transactional models to meet specific needs and priorities.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

STONE TFT LCD modules come with a microcontroller unit that has a 1GHz Cortex-A8 CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to them.

Becoming a reputable TFT LCD manufacturer is no piece of cake. It requires a company to pay attention to detail, have excellent manufacturing processes, the right TFT display technology, and have a consumer mindset.

Now, we list down 10 of the best famous LCD manufacturers globally. We’ll also explore why they became among the top 10 LCD display Manufacturers in the world.

LG Display is a leading manufacturer of thin-film transistor liquid crystal displays (TFT-LCD) panels, OLED, and flexible displays.LG Display began developing TFT-LCD in 1987 and currently offers Display panels in a variety of sizes and specifications using different cutting-edge technologies (IPS, OLED, and flexible technology).

Samsung Electronics is South Korea’s largest electronics industry and the largest subsidiary of the Samsung Group. In the late 1990s, Samsung Electronics’ independent technology development and independent product innovation capabilities were further enhanced. Its product development strategy not only emphasizes “leading the technology but also using the most advanced technology to develop new products to meet the high-end market demand at the introduction stage”.In addition to the matching principle, it also emphasizes the principle of “leading technology, developing new products with the most advanced technology, creating new demand and new high-end market”.

With innovative and differentiated technologies, QINNOOptoelectronics provides advanced display integration solutions, including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch solutions. Qinnooptoelectronics sets specifications and leads the market. A wide range of product line is across all kinds of TFT LCD panel modules, touch modules, for example, TV panel, desktop and laptop computer monitor with panels, small and medium scale “panels, medical, automotive, etc., the supply of cutting-edge information and consumer electronics customers around the world, for the world TFT – LCD (thin-film transistor liquid crystal display) leading manufacturers.

AU Optronics Co., LTD., formerly AU Optronics Corporation, was founded in August 1996. It changed its name to AU Optronics after its merger with UNIOPtronics in 2001. Through two mergers, AU has been able to have a full range of generations of production lines for panels of all sizes.Au Optronics is a TFT-LCD design, manufacturing, and r&d company. Since 2008, au Optronics has entered the green energy industry, providing customers with high-efficiency solar energy solutions.

Sharp has been called the “father of LCD panels”.Since its founding in 1912, Sharp developed the world’s first calculator and LIQUID crystal display, represented by the living pencil, which was invented as the company name. At the same time, Sharp is actively expanding into new areas to improve people’s living standards and social progress. Made a contribution.

BYD IT products and businesses mainly include rechargeable batteries, plastic mechanism parts, metal parts, hardware electronic products, cell phone keys, microelectronics products, LCD modules, optoelectronics products, flexible circuit boards, chargers, connectors, uninterruptible power supplies, DC power supplies, solar products, cell phone decoration, cell phone ODM, cell phone testing, cell phone assembly business, notebook computer ODM, testing and manufacturing and assembly business, etc.

Tianma microelectronics co., LTD., founded in 1983, the company focus on smartphones, tablets, represented by high order laptop display market of consumer goods and automotive, medical, POS, HMI, etc., represented by professional display market, and actively layout smart home, intelligent wear, AR/VR, unmanned aerial vehicles (UAVs) and other emerging markets, to provide customers with the best product experience.IN terms of technology, the company has independently mastered leading technologies such as LTPS-TFT, AMOLED, flexible display, Oxide-TFT, 3D display, transparent display, and in-cell/on-cell integrated touch control. TFT-LCD key Materials and Technologies National Engineering Laboratory, national enterprise Technology Center, post-doctoral mobile workstation, and undertake national Development and Reform Commission, The Ministry of Science and Technology, the Ministry of Industry and Information Technology, and other major national thematic projects. The company’s long-term accumulation and continuous investment in advanced technology lay the foundation for innovation and development in the field of application.

A TFT LCD, or a thin film transistor liquid crystal display, is one of the fastest growing forms of display technology today. The thin film transistor (TFT) is a type of semiconductor device used in display technology to enhance efficiency, compactness, and cost of the product. In conjunction with its semiconductor properties, the TFT LCD is an active matrix display, controlling pixels individually and actively rather than passively, furthering the benefits of this semiconductor device.

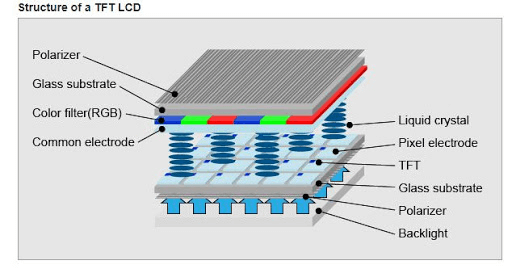

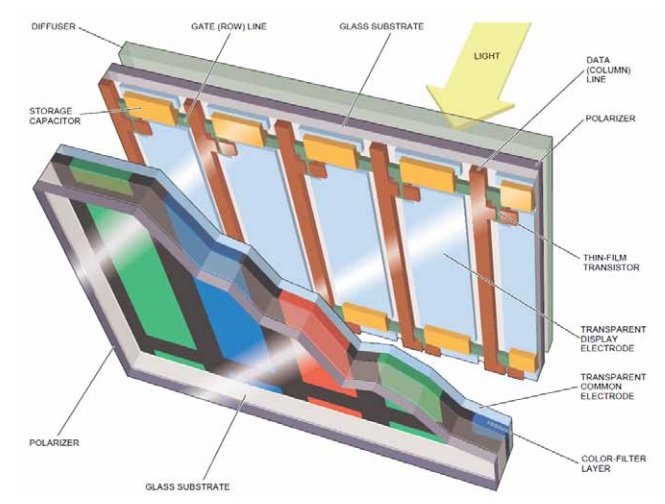

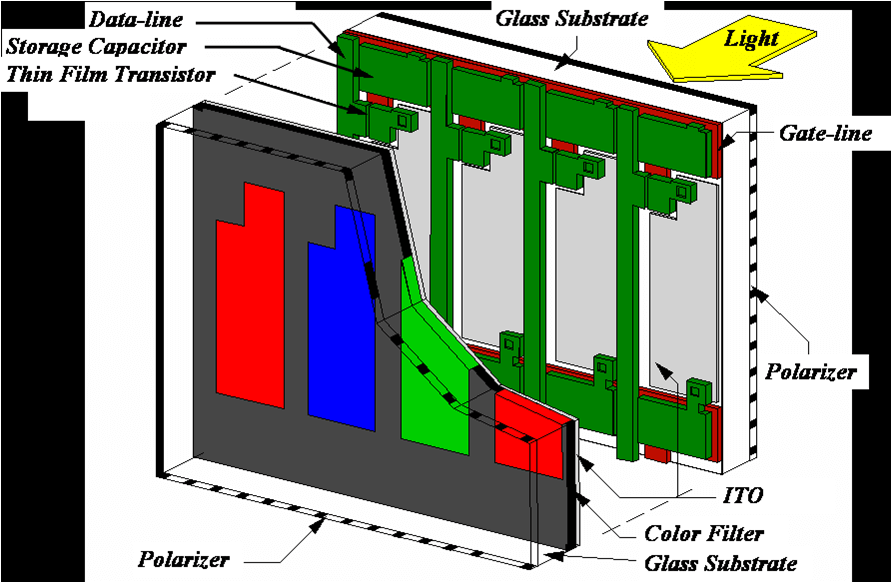

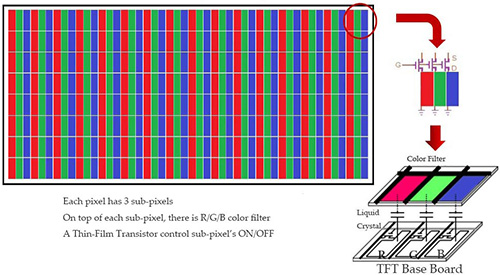

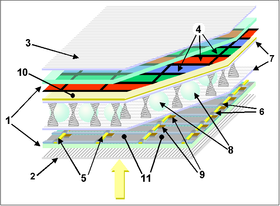

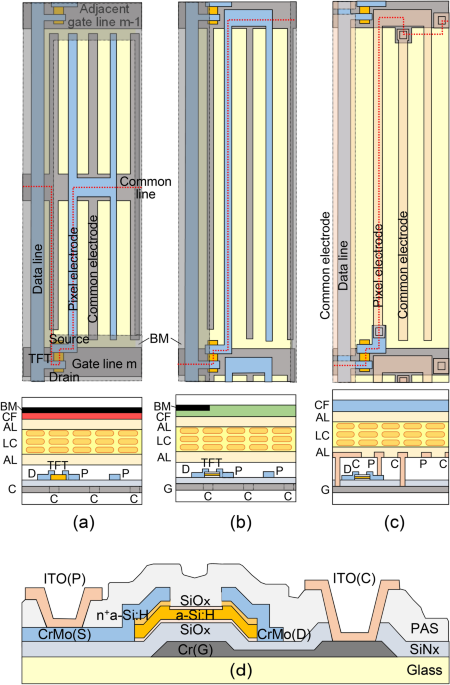

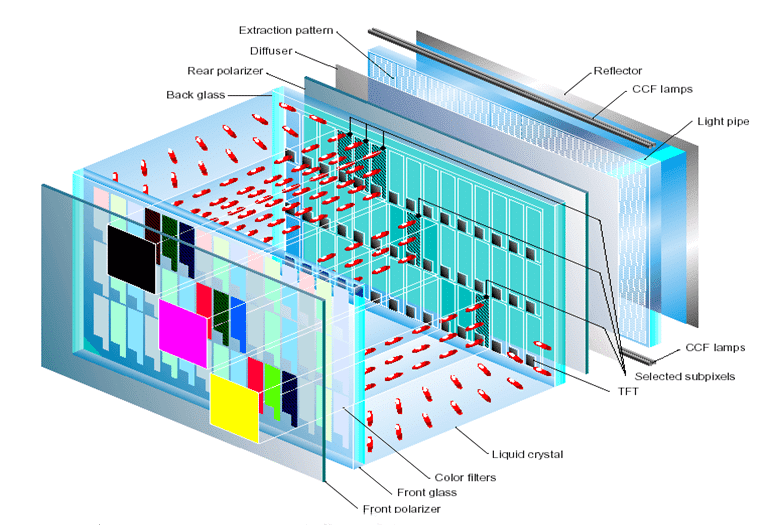

The TFT LCD is built with three key layers. Two sandwiching layers consist of glass substrates, though one includes TFTs while the other has an RGB, or red green blue, color filter. The layer between the glass layers is a liquid crystal layer.

The Architecture of a TFT Pixelbelow) from the other substrate layer of the device and control the amount of voltage applied to their respective sub-pixels. This layer also has pixel electrodes between the substrate and the liquid crystal layer. Electrodes are conductors that channel electricity into or out of something, in this case, pixels.

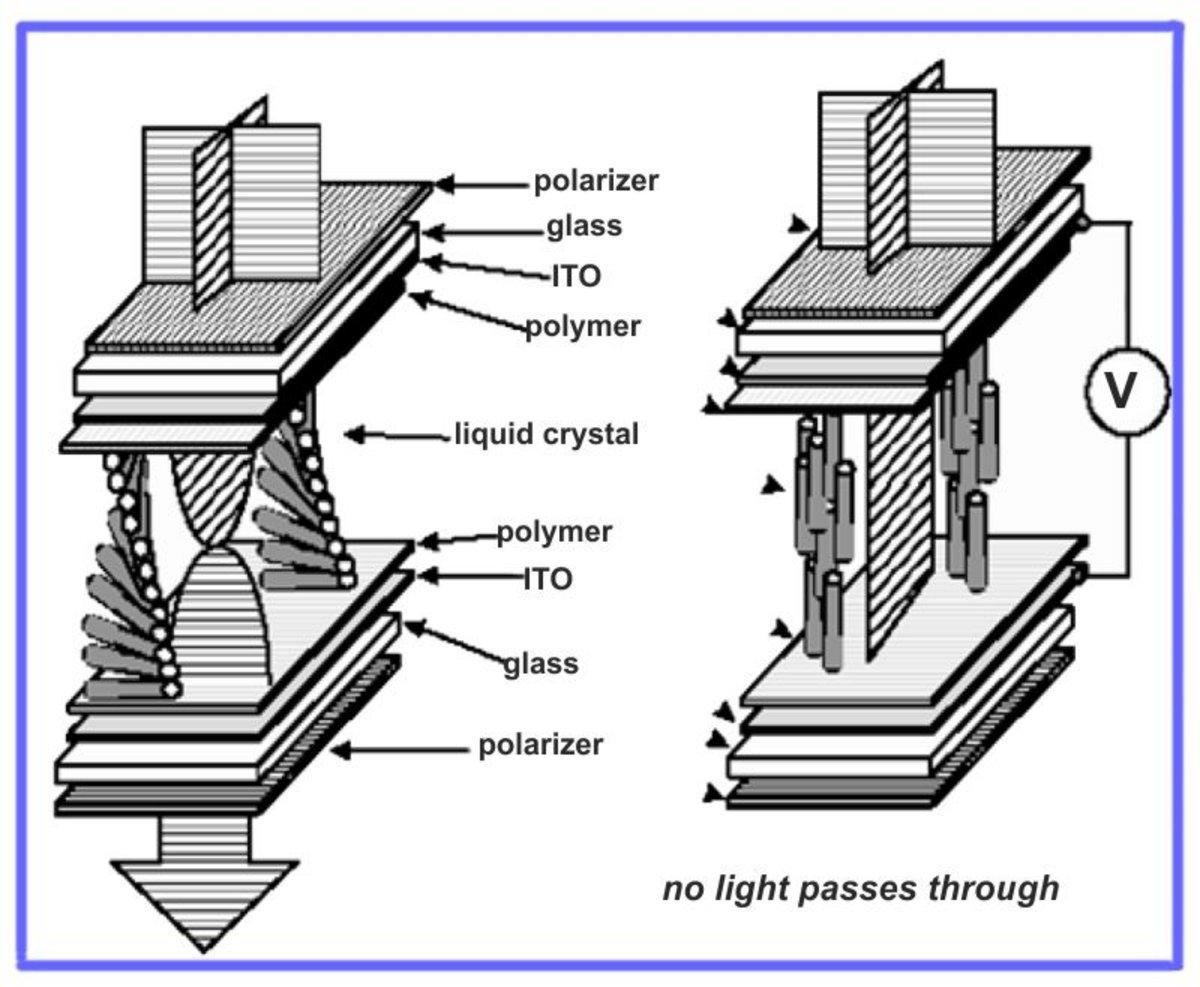

The outer sides of the glass substrates (closest to the surface or closest to the back) have filter layers called polarizers. These filters allow only certain beams of light to pass through if they are polarized in a specific manner, meaning that the geometric waves of the light are appropriate for the filter. If not polarized correctly, the light does not pass through the polarizer which creates an opaque LCD screen.

The twisted nematic effect is one of the cheapest options for LCD technology, and it also allows for fast pixel response time. There are still some limits, though; color reproduction quality may not be great, and viewing angles, or the direction at which the screen is looked at, are more limited.

The light that passes through the device is sourced from the backlight which can shine light from the back or the side of the display. Because the LCD does not produce its own light, it needs to use the backlight in the OLED) have come into use as well. Typically white, this light, if polarized correctly, will pass through the RGB color filter of the surface substrate layer, displaying the color signaled for by the TFT device.

Within an LCD, each pixel can be characterized by its three sub-pixels. These three sub-pixels create the RGB colorization of that overall pixel. These sub-pixels act as capacitors, or electrical storage units within a device, each with their own independent structural and functional layers as described earlier. With the three sub-pixels per pixel, colors of almost any kind can be mixed from the light passing through the filters and polarizer at different brightness based on the liquid crystal alignment.

TFT-LCD technology is based on semiconductor IC manufacturing processes, and is unique in that it uses glass substrates rather than traditional silicon wafers. For the TFT manufacturing process, thin film formation, such as CVD and PVD processes, is a very important part. The ODF process has been developed for the assembly of color filters and TFT substrates, and is used in large size LCDs.

First of all, the movement and arrangement of liquid crystal molecules need electrons to drive, so in the carrier of liquid crystal – TFT glass, there must be able to conduct the part to control the movement of liquid crystal, here will use ITO (Indium TIn Oxide, transparent conductive metal) to do this thing. ITO is transparent, also known as thin film conductive crystal so that it will not block the backlight.

The different arrangement of liquid crystal molecules and the rapid movement changes to ensure that each pixel accurately display the corresponding color, and the image changes precisely and quickly, which requires precision control of the liquid crystal molecules. ITO film requires special processing, as if printed circuitry on a PCB board, drawing conductive lines throughout the LCD board.

For array panels with back-channel etched TFT structure.The main process can be divided into 5 steps (5 lightings) according to the sequence of the layers to be made and the interrelationship between the layers.

The process includes: PECVD triple layer continuous film formation, island lithography, island dry lithography and other processes. After these processes, the final amorphous silicon island for TFT is formed on the glass substrate. The graphics obtained after the process is completed are shown in the following figure.

PVD (Physical Vapor DeposiTIon), i.e. physical vapor deposition, is an advanced surface treatment technology widely used in the international arena. Its working principle is to use gas discharge to partially dissociate the gas or evaporated material under vacuum conditions, and to deposit the evaporated material or its reactants on the substrate while the gas ions or the evaporated material ions bombard the action. At present, the most used PVD technology on the market is mainly divided into three categories: magnetron sputtering plating, multi-arc ion plating and evaporation plating.

Specific processes include: S/D metal layer sputtering into a film, S/D lithography, S/D wet lithography, channel dry lithography and other processes. After these processes, the source, drain, channel and data lines of the TFT are finally formed on the glass substrate. At this point, the TFT has been produced. The graphics obtained after the process is completed are shown in the following figure.

The process includes PECVD, photolithography, and dry lithography of vias. After these processes, the final TFT channel protective insulation layer and guide through the hole are formed on the glass substrate. The graphics obtained after the process is completed are shown in the following figure.

Color filters can be produced by various methods; photolithography is a typical method. In photolithography, color filters are produced by exposing a glass substrate coated with a photographic color resist through a photomask. The resist is hardened to form the RGB pattern of the LCD.

When making LCD panels it is impossible to produce them one by one, which is too inefficient, so multiple pieces are processed at once and separated by cutting.

A liquid crystal display (LCD) has liquid crystal material sandwiched between two sheets of glass. Without any voltage applied between transparent electrodes, liquid crystal molecules are aligned in parallel with the glass surface. When voltage is applied, they change their direction and they turn vertical to the glass surface. They vary in optical characteristics, depending on their orientation. Therefore, the quantity of light transmission can be controlled by combining the motion of liquid crystal molecules and the direction of polarization of two polarizing plates attached to the both outer sides of the glass sheets. LCDs utilize these characteristics to display images.

An LCD consists of many pixels. A pixel consists of three sub-pixels (Red/Green/Blue, RGB). In the case of Full-HD resolution, which is widely used for smartphones, there are more than six million (1,080 x 1,920 x 3 = 6,220,800) sub-pixels. To activate these millions of sub-pixels a TFT is required in each sub-pixel. TFT is an abbreviation for "Thin Film Transistor". A TFT is a kind of semiconductor device. It serves as a control valve to provide an appropriate voltage onto liquid crystals for individual sub-pixels. A TFT LCD has a liquid crystal layer between a glass substrate formed with TFTs and transparent pixel electrodes and another glass substrate with a color filter (RGB) and transparent counter electrodes. In addition, polarizers are placed on the outer side of each glass substrate and a backlight source on the back side. A change in voltage applied to liquid crystals changes the transmittance of the panel including the two polarizing plates, and thus changes the quantity of light that passes from the backlight to the front surface of the display. This principle allows the TFT LCD to produce full-color images.

The liquid crystal cannot emit light by itself, and the backlight should be added behind the LCD panel. A few years ago, CCFL cold cathode backlighting was the dominant market application, but with the development of technology, the LED backlight has gradually replaced the traditional CCFL backlight.

When compared to the ordinary LCD, TFT LCD gives very sharp and crisp picture/text with shorter response time. TFT LCD displays are used in more and more applications, giving products better visual presentation.

TFT is an abbreviation for "Thin Film Transistor". The colorTFT LCD display has transistors made up of thin films of Amorphous silicon deposited on a glass. It serves as a control valve to provide an appropriate voltage onto liquid crystals for individual sub-pixels. That is why TFT LCD display is also called Active Matrix display.

A TFT LCD has a liquid crystal layer between a glass substrate formed with TFTs and transparent pixel electrodes and another glass substrate with a color filter (RGB) and transparent counter electrodes. Each pixel in an active matrix is paired with a transistor that includes capacitor which gives each sub-pixel the ability to retain its charge, instead of requiring an electrical charge sent each time it needed to be changed. This means that TFT LCD displays are more responsive.

To understand how TFT LCD works, we first need to grasp the concept of field-effect transistor (FET). FET is a type of transistor which uses electric field to control the flow of electrical current. It is a component with three terminals: source, gate, and drain. FETs control the flow of current by the application of a voltage to the gate, which in turn alters the conductivity between the drain and source.

Using FET, we can build a circuit as below. Data Bus sends signal to FET Source, when SEL SIGNAL applies voltage to the Gate, driving voltage is then created on TFT LCD panel. A sub-pixel will be lit up. A TFT LCD display contains thousand or million of such driving circuits.

Topway started TFT LCD manufacturing more than15 years ago. We produce color TFT LCD display from 1.8 to 15+ inches with different resolutions and interfaces. Here is some more readings about how to choose the right TFT LCD.

Powertip has grown to become a leading manufacturer of small to mid-size full color TFT and monochrome displays as well as resistive and capacitive touch panels. Powertip is headquartered in Taichung, Taiwan with production facilities located in Taiwan and Nanjing, China. Powertip’s product offerings address major industries to include medical, industrial, automotive, consumer, white goods, communications, test and measurement and gas pumps / parking meters.

Powertip’s manufacturing capabilities comprise Surface Mount Technology (SMT), Chip-On-Board (COB), Chip-On-Glass (COG), Chip-On-Flex (COF), Tape Automated Bonding (TAB) and screen printing. Production of a typical LCD panel would require Powertip to take Mother Glass, scribe, cut, fill the cells with liquid crystal and then seal the two sandwiched glass panels. Powertip would then add polarizers, color filters and all other required backend manufacturing processes to create a completed LCD module to specification.

If you are TFT LCD module users, we will provide you with the most suitable TFT LCD products, including the selection of control board, accessories, testing, maintenance and a series of services.

Operating principle of LCD screen.The working principle of LCD screen. Lcd display is the mainstream technology in the display field at present, with a wide range of products. The following focuses on the working principle of LCD display.

LCD is the abbreviation of liquid crystal display. At present, TFT-LCD is the mainstream technology. LCD needs a backlight and a polarizer. The most important thing is that in two parallel glass sheets, a TFT thin film transistor (you can understand that there are many circuits), and on the above substrate, a CF filter (red, green, blue and RGB). Since the CF color filter has RGB color blocks, we will first pass through the TFT transistor substrate, then through the liquid crystal molecules, and then to the CF color filter according to the above order in the process of passing through the fluorescent screen. In each color block, because of the difference in transmissivity, there will be red, green, and blue colors.

Since the CF color filter has RGB color blocks, we will first pass through the TFT transistor substrate, then through the liquid crystal molecules, and then to the CF color filter according to the above order in the process of passing through the fluorescent screen. In each color block, because of the difference in transmissivity, there will be red, green, and blue colors. Of course, these color blocks must be much smaller to form a colorful picture, which is called "pixel"!

Let"s take a look at our hero, LCD, which is a special physical form. What we know most is gas, water vapor, liquid, ice, and a kind of plasma that everyone has heard of. This time, we need to get familiar with the shape of liquid crystal, which has the characteristics of both crystal and liquid. Most liquid crystal molecules are "rod molecules". They originally have various directions, but under different voltages, they will show different luminous properties, just like the metal in the magnetic field. When affected by the electric field, they will have specific directivity. Therefore, we can properly control the arrangement of liquid crystal molecules, so that some light can pass through, while others cannot, which will cause the difference in light transmittance.

Operating principle of LCD screen.The above is a purely theoretical explanation. I hope this article can help you understand the working principle of LCD more deeply.

LG Display"s oxide TFT technology can be applied to various display products. Since its performance is more than 50 times higher than that of the existing a-Si TFT, it can be applied to the entire product lines from mobiles to laptops and large TVs.

By reducing the size of the TFTs that make up individual pixels and increasing their performance, a display with high resolution and rich colors can be achieved.

By applying oxide TFT, the size of the circuit part of the panel outside the screen can be drastically reduced, making it possible to create a slim design display.

Oxide TFT is highly energy-efficient because the leakage current is very small when the screen is not working, so it can extend the battery life of notebooks or tablets.

LG Display is a pioneer in the industry"s first successful mass-production by researching and developing oxide TFT technology for the longest period of time. LG Display guarantees product reliability that customers can trust and use for a long time.

in-TOUCH products with built-in touch function can maintain slim design and superior image quality compared to add-on (out-cell) touch products with added touch electrodes. It is a technology unique to LG Display that can be applied not only in IT but also in various fields such as home application, health, industrial, and medical products. in-Touch has a built-in touch electrode in the LCD, optimized for slim & light products that can perform touch operation without additional touch electrodes or cover glass.

First, what is the LCD junior physics to learn the material has three states: solid, liquid and gaseous. The following LCD screen manufacturers tell about the difference between STN LCD and TFT LCD. In fact, the so-called three-state is only a general distinction, some of the solid matter can be subdivided into different states of the state. Similarly, the liquid can also have a different "state", where the molecular arrangement of the direction of the liquid we call it "liquid crystal", referred to as "liquid crystal". Ordinary solid crystals have directionality, so many of their physical properties also have directionality. Liquid crystals have a general crystal in the direction of the same time with the liquid flow. If you want to change the direction of the solid crystal must rotate the entire crystal, and the liquid crystal is different, and its direction can be controlled by the electric field or magnetic field. Both STN and TFT use a so-called "nematic" liquid crystal (Nematic), it is filamentous, the use of electric field to control the "filament" liquid crystal direction is the application of commonly used method. Liquid crystals are usually made of liquid crystal in two pieces of glass. The surface of the glass is coated with a layer of substances called the agent, by its type and treatment methods can be controlled in the absence of external electric field when the liquid crystal arrangement. Second, STN LCD principle The world"s first liquid crystal display appeared in the early seventies, known as the TN-type liquid crystal display (Twisted Nematic, twisted nematic). In the 1980s, the STN type liquid crystal display (Super Twisted Nematic) appeared, while the TFT liquid crystal display (Thin Film Transistor) technology was proposed. We first talk about the principle of TN-type LCD, STN LCD and TN LCD display the same principle, but the distortion of the liquid crystal molecules are different. The nematic liquid crystal is sandwiched between two pieces of glass, and the surface of the glass is first plated with a transparent and electrically conductive film for the electrode, and then plated with a surface alignment agent on the glass with the film electrode so that the liquid crystal A specific and parallel to the direction of the glass surface. The natural state of the liquid crystal has a twist of 90 degrees, the use of electric field can make liquid crystal rotation, the refraction coefficient of liquid crystal with the direction of the liquid crystal changes, the result is light after TN type LCD polarized polarity changes. As long as the appropriate thickness is chosen so that the polarity of the light changes just 90 °, two parallel polarizers can be used so that the light can not pass at all. And a large enough voltage can make the liquid crystal direction parallel to the direction of the electric field, so that the polarity of the light will not change, the light can pass through the second polarizer. So, you can control the light of the light and dark. As mentioned earlier, STN-type liquid crystal and TN-type liquid crystal display the same principle, but it will be incident light rotation 180 ~ 270 degrees, rather than 90 degrees. Moreover, the simple TN-type liquid crystal display itself only two changes in light and shade. While the STN LCD is light green and orange-based. However, if the traditional monochrome STN LCD display with a color filter, and the monochrome display matrix for each pixel is divided into three sub-pixels, respectively, through the color filter display red, green and blue primary colors, you can display Out of color.

Due to the principle of TN and STN type liquid crystal display, if the display part of it is bigger and bigger, then the central part of the electrode reaction time may be longer. In fact, this is not a big problem for the phone, because the current mobile phone display are relatively small, the impact of liquid crystal reaction time is relatively small. But for notebooks and other equipment need large-screen LCD display, too slow LCD reaction time will seriously affect the display, so TFT LCD technology has aroused the attention of manufacturers. In addition, the color screen in the application of more and more mobile phones in a new generation of products are supported 65536 color display, and some even support 16 million color display, when the TFT"s high contrast, rich color advantage even more important The

LCD screen manufacturers STN LCD is a reflective LCD device, its advantage is small power consumption, but in a dark environment, poor resolution, so have to be equipped with external lighting. The TFT LCD with "back through" and "reflection" in combination, in the back of the LCD set a special light pipe. This is why we see some mobile phone next to the screen seems to have "lights", and some of the phone"s light is like the screen itself issued a reason. Moreover, the LCD screen manufacturers of liquid crystal display backlight technology is also constantly progress, from monochrome to color, from thick to thin, from the side of the fluorescent lamp to flat fluorescent lamp.

By the way, the reflective LCD device has black and white characters (NB) and black and white (NN) two, recently we see the V70 display is belonging to the NB type, of course, this is certainly the integration of the latest technology Enhanced NB. Well, we still get down to business, continue to TFT LCD display principle. TFT liquid crystal display technology using the "active matrix" approach to drive. Method is the use of thin film technology made of the transistor electrode, the use of scanning method "initiative" to control any one of the display points on and off. Light source when exposed through the lower polarizing plate up through the liquid crystal molecules through the light. When the electrodes are turned on, the liquid crystal molecules change like the TN liquid crystal arrangement, and also through the shading and light transmission to achieve the purpose of the display. Sounds like this and TN-type LCD display principle is almost, indeed so. But the difference is that since the FET transistor has a capacitive effect, it is possible to maintain the potential state, and the liquid crystal molecules that have been transmitted will remain in this state until the FET electrode is energized again to change its arrangement. And TN-type liquid crystal does not have this feature, liquid crystal molecules once the electric field, immediately return to the original state, which is TFT LCD and TN liquid crystal display the principle of the biggest difference.

TFT LCD for each pixel are equipped with a semiconductor switch, the processing technology is similar to large-scale integrated circuits. Because each pixel can be directly controlled by the point pulse, therefore, each node is relatively independent, and can be continuous control, this design not only improves the reaction speed of the display, and can accurately control the display gray, so TFT LCD The color is more realistic.

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Microtips Technology is a global electronics manufacturer based in Orlando, Florida. The company was established in 1990 and has grown into a strong fixture in the LCD industry.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

All products feature high-bright LCD systems that come from the company’s proprietary low-power LED backlight technology. The modules and screens also come in ruggedized forms perfect for highly-demanding outdoor industrial use.

LXD Incorporated is among the earliest LCD manufacturers in the world. The company was founded in 1968 by James Fergason under the name International Liquid Xtal Company (ILIXCO). Its first headquarters was in Kent, Ohio. At present, LXD is based in Raleigh, North Carolina.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

LCD enables the display to be thinner rather than the cathode ray tube. LCDs consume only less power than LED and gas displays; this is work on the principle of blocking light fairly than emitting it. TheLCD Display Moduleis used in various kinds of applications and is the most common module used in various devices and then circuits.

A TFT is employed in both direct and indirect capture as a ground for the picture receptor in medical radiography. Of course, all kinds of high-resolution and then and then high-quality electronic visual displays utilize theTFT Modulebased active matrix displays. It is perfect for more applications, including industrial control, coffee machine, automation, GPS, POS system, and so on. This technology may offer the full-colour RGB showcasing a range of colours and hues.

In order to buy the LCD module, you must pick the best manufacturer because they offer a greater and more high-quality product. The TFT LCD module gives greater benefits to the user the lower power consumption. The expert will offer greater items to the people.

Are you looking for high-qualityTFT LCD Modules? Then you can choose the expert production touch panel platform to get affordable and high-quality products. The expert supplier will be using all high quality materials for the product, bringing the product worth to first quality in the market.

It is familiar that each product will be passed through the test; this indicates that product quality is high worth the cost. The durability will be longer compared to the low quality of the touch panel. Before the product reaches the customer"s hand, it will ensure in the production platform itself that it is highly worth able. In addition, expertTFT LCD Panelservices even can work with the custom touch panel. These will help the business that is developing the production. They are a custom product in the market.

We"re committed to furnishing easy,time-saving and money-saving one-stop purchasing support of consumer for Industrial Tft, Panel Lcd Short, Latop Lcd Panel, High Brightness Customize Tft Lcd Module,Lcd And Touch Screen. If needed, welcome to help make speak to with us by our web page or cellular phone consultation, we are going to be delighted to serve you. The product will supply to all over the world, such as Europe, America, Australia,Guyana, Barcelona,Tunisia, Cairo.With more and more Chinese products around the world, our international business is developing rapidly and economic indicators big increase year by year. We have enough confidence to offer you both better products and service, because we are more and more powerful, professional and experience in domestic and international.

![]()

A method of manufacturing an LCD in which a pixel electrode is formed on a photosensitive passivation layer uses an etching gas including at least one of CF4+H2, CxFy+H2, CxFy+CxFyHz, CxFy+CxFyHz+H2and CxFyHz. As a result, a surface of the patterned passivation layer is easily and reliably made to be even. Furthermore, the gate insulating layer is simultaneously patterned to form a gate contact hole without experiencing any over-etching and/or undercut portions.

The present invention relates to a method of manufacturing a liquid crystal display device (LCD) and more particularly, the present invention relates to a method of manufacturing an LCD in which a pixel electrode is formed on a photosensitive passivation layer.

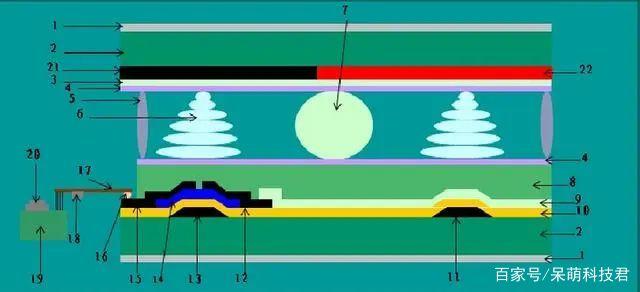

Generally, a conventional liquid crystal display device in which a pixel electrode is formed on a photosensitive passivation layer includes a gate bus line 60 and a data bus line 70 which are arranged in a matrix array, as shown in FIG. 1. At the end portions of the gate bus line 60 and the data bus line 70, a gate pad 60 cand a data pad 70 cconnected to an output of a driving IC are formed, respectively. The LCD further includes a TFT which functions as a switching element and is driven by an electrical signal from the gate bus line 60 and the data bus line 70. The TFT is disposed at the intersection portion of the gate bus line and data bus line. The LCD also includes a pixel electrode 40 connected to the TFT.

The TFT includes a gate electrode 60 aderived from the gate bus line 60, a source electrode 70 aderived from the data bus line 70 and a drain electrode 70 barranged to face the source electrode 70 a. The gate electrode 60 ais covered by a gate insulating layer (not shown). A semiconductor layer 90 is disposed over the gate electrode 60 aon the gate insulating layer. The source electrode 70 aand the drain electrode 70 bare disposed at each side of the semiconductor layer 90. The drain electrode 70 bis connected to the pixel electrode 40 through a contact hole 30 aformed at a passivation layer (not shown). At the overlapped portion of the adjacent gate bus line 70, a storage capacitance electrode 35 is connected to the pixel electrode 40 through a storage contact hole 30 b.

Referring to FIG. 2 which is a cross-sectional view of FIG. 1 cut along line A—A in FIG. 1, the structure and method of manufacturing of the LCD in which a pixel electrode is formed on the photosensitive passivation layer will be explained in detail.

On a transparent substrate 10, a gate bus line 60, a gate electrode 60 aderived from the gate bus line 60 and a gate pad 60 bdisposed at the end of the gate bus line 60 are formed. A gate insulating layer 50 including SiNxor SiOxis formed so as to cover the entire surface of the substrate including the gate bus line 60, the gate electrode 60 aand the gate pad 60 b. An island-shaped semiconductor layer 90 including a-Si (amorphous silicon) is formed on the gate insulating layer 50 over the gate electrode 60 a. Ohmic contact layers 90 aand 90 bincluding n+ type a-Si are formed separately on the semiconductor layer 90. A source electrode 70 aand a drain electrode 70 bare connected to the ohmic contact layers 90 aand 90 b, respectively. A data bus line 70 connected to the source electrode 70 ais formed on the gate insulating layer 50. A TFT is completed by forming the gate electrode 60 a, the semiconductor layer 90, the ohmic contact layers 90 aand 90 b, the source electrode 70 aand the drain electrode 70 b.

A passivation layer 80 including a photosensitive acrylic resin is formed on the entire surface of the substrate having the TFT. A drain contact hole 30 a, a storage contact hole 30 b(FIG. 1) and a gate pad contact hole 30 care formed by patterning the passivation layer 80. The method of forming the contact holes includes the steps of exposing the photosensitive passivation layer with a mask, developing the passivation layer with a developer and removing the remaining passivation layer material at the contact holes with an etchant which is CF4+O2or SF6+O2gas. At the same time, some portions of the gate insulating layer 50 covering the gate pad 60 bare removed to form a gate pad contact hole 30 cexposing the gate pad 60 bby using the CF4+O2or SF6+O2gas.

According to the conventional method, the metal layer disposed under the passivation layer can be cut off or over-etched by the CF4+O2or SF6+O2etching gas, when the passivation layer is patterned so that the quality of the LCD becomes inferior.

In order to overcome the problems in the conventional methods described above, preferred embodiments of the present invention provide a method of manufacturing an LCD in which a passivation layer including a photosensitive acrylic resin has a smooth, even surface after the passivation layer is patterned and a metal layer under a passivation layer including a photosensitive acrylic resin is not cut off. In addition, preferred embodiments of the present invention provide a method of manufacturing an LCD in which a gate pad and a gate insulating layer are not over-etched when the gate insulating layer is patterned to form a gate contact hole.

To solve the above-described problems with the conventional methods and to achieve the results described in the preceding paragraph, preferred embodiments of the present invention provide a method of manufacturing an LCD using an etching gas including one of CF4+H2, CxFy+H2, CxFy+CxFyHz, CxFy+CxFyHz+H2and CxFyHz. The method according to preferred embodiments of the present invention includes the steps of forming on a substrate, a switching element, bus lines connected to the switching element and pads at the end of each of the bus lines, coating a photosensitive passivation layer on an entire surface of the substrate, forming contact holes exposing an electrode and a pad by exposing and developing the passivation layer such that a portion of the passivation remains, removing a remaining portion of the passivation layer at the contact hole using an etching gas including at least one of CF4+H2, CxFy+H2, CxFy+CxFyHz, CxFy+CxFyHz+H2and CxFyHzand forming a pixel electrode connected to the exposed electrode through the contact hole.

Referring to FIGS. 3a-3 e, a preferred embodiment of the present invention will be explained in detail. FIGS. 3a-3 eare cross-sectional views showing a method for manufacturing an LCD panel according to the present invention.

A gate electrode 60 ais formed preferably using a metal such as aluminum (Al), chromium (Cr), molybdenum (Mo) or molybdenum-tungsten (MoW) alloy on a transparent substrate 10. A gate insulating layer 50 is formed on the gate electrode 60 ausing an inorganic material such as a SiNx or SiOx or an organic material such as a BCB (benzoCycloButene). An island-shaped semiconductor layer 90 is formed on the gate insulating layer 50 over the gate electrode 60 ausing an amorphous silicon (a-Si). Ohmic contact layers 90 aand 90 bare formed on the two sides of the semiconductor layer 90. A source electrode 70 aconnected to one ohmic contact layer 90 aand a drain electrode 70 bconnected to the other ohmic contact layer 90 bare formed by using aluminum or chromium. Therefore, a TFT is completed and adapted to function as a switching element. When the gate electrode 60 ais formed, a gate bus line is connected to the gate electrode 60 aand a gate pad 60 bis connected to the end of the gate bus line 60. When the source electrode 70 aand the drain electrode 70 bare formed, a data bus line 70 connected to the source electrode 70 aand a storage capacitance electrode overlapping with some portion of the gate bus line are formed, as shown in FIG. 3a.

Thus, the present invention provides a method of manufacturing an LCD using a photosensitive material as the passivation layer to simplify the manufacturing process. According to preferred embodiments of the present invention, the photosensitive passivation layer is patterned to form a contact hole using an etching gas which includes at least one of CF4+H2, CxFy+H2, CxFy+CxFyHz, CxFy+CxFyHz+H2and CxFyHz. Therefore, the surface of the patterned passivation layer is reliably smooth and even and there is no remaining portion of the passivation material at the patterned contact hole. Furthermore, the gate insulating layer can be simultaneously patterned to form a gate contact hole exposing some portion of the gate material without any over etched portion or undercut portion of the gate insulating layer and the gate material. So the pixel electrode and/or the gate terminal formed on the smooth surface of the passivation layer have a desired pattern shape and the drain electrode and/or the storage capacitance electrode are not cut off during the formation of the contact holes.

While preferred embodiments of the invention have been disclosed, various modes of carrying out the principles disclosed herein are contemplated as being within the scope of the following claims. Therefore, it is understood that the scope of the invention is not to be limited except as otherwise set forth in the claims.

LCD panel having a broad-gap region having a dent within a non-display region of the panel and an electrical transfer section and a sealing portion both at least partially within the dent for first and second substrates forming the panel

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey