identify lcd panel quotation

Most laptop LVDS displays have at least kinda-weird connectors. I don"t support Panelook, and actively avoid that site -- it"s got a paywall between users and documentation, and I refuse to support such a thing in absolutely all cases.

...you will get a number of links of various sorts. Look *specifically* for links that have a little [PDF] icon next to them, i.e., the acronym "PDF" in a (very!) thin outline of a box. If the entire first page doesn"t have anything for you, look for results from eg datasheetspdf.com datasheet4u.com datasheetarchive.com etc. Datasheet Archive (the last one) is actually my favorite. *Absolutely avoid* Panelook if you"re at all like me, but also twscreen.com hkinventory.com etc -- those are sales sites and you"ll never ever *ever* get a PDF out of them so long as you live. Also avoid lcds-center.com lcds-display.com lcds-source.com etc -- these are particularly egregious, because they"ll return [PDF] results, but the PDFs are generated when you click the link and are in fact sales info only -- nothing actually useful in the sense of a technical document, and nothing that gives you even the faintest glimmer of hope of a way to get one. Screw "em.

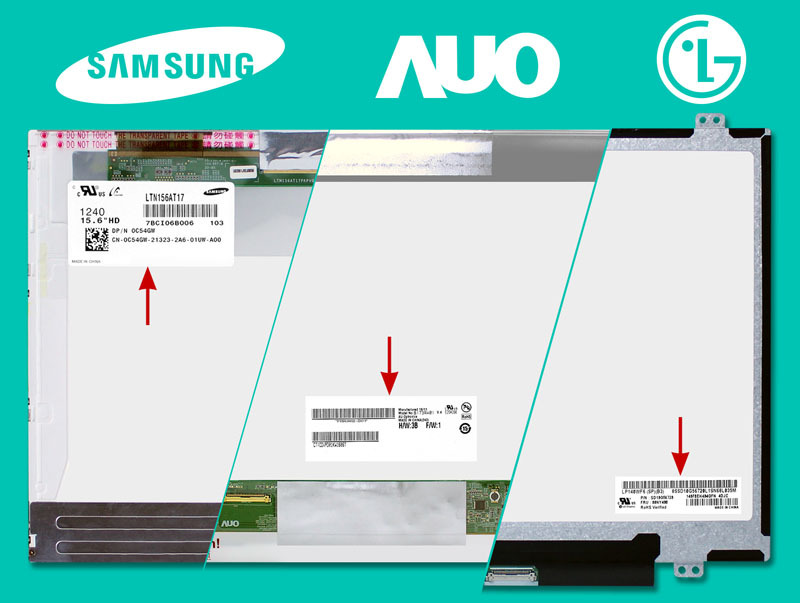

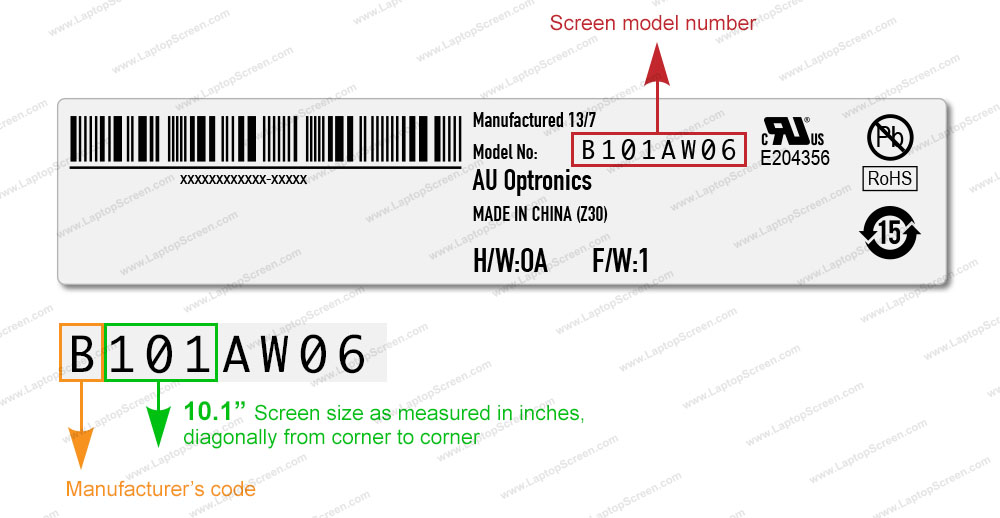

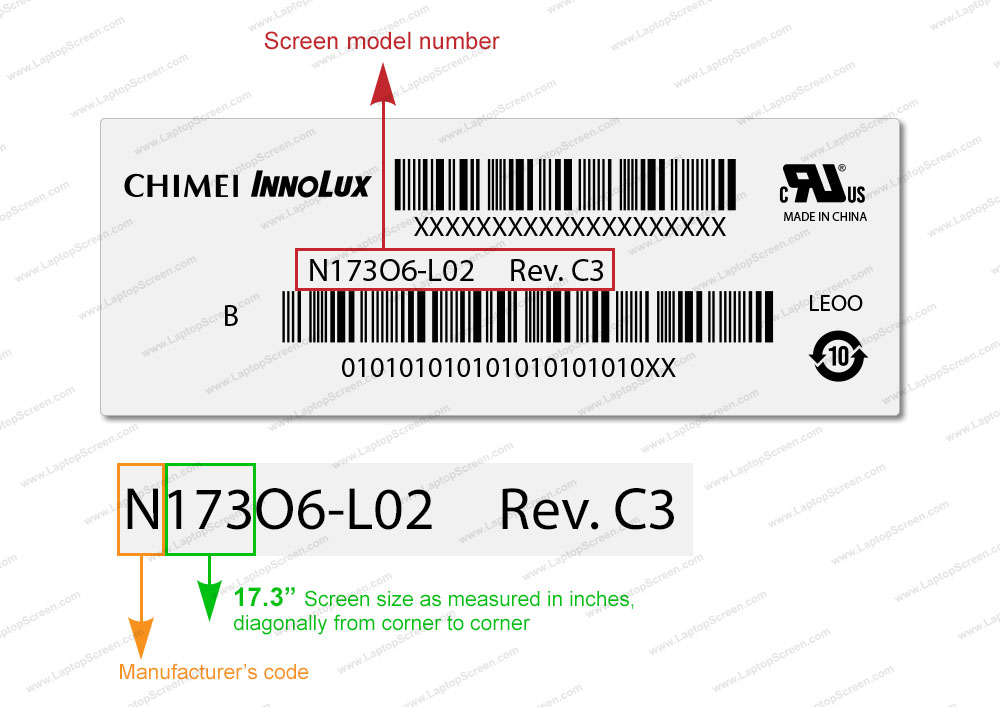

One of the most precise ways to identify which replacement LCD will work on your computer is by your original LCD"s manufacturer model number. And since your original LCD will need to be removed during the replacement procedure you may as well remove it now and get the right info!

LCD manufacturers decide for themselves where to put their LCD model number labels, so the location of the individual label will vary by the manufacturer and the type of the display, but the manufacturer"s prefix code will remain standard for each manufacturer.

A lot of consumers wonder how manufacturers determine the LCD display panel prices. After all, display solutions such as TFT LCDs and HMI touch screens do not always come cheap. And sometimes, a few products that can indeed be purchased for lower prices may come with several quality issues.

Hence, we’ve rounded up a list of factors that influence how to display modules such as TFTs, LCD, and touch screens are priced. You can also use these factors to evaluate to whom you should place your next orders for your display solutions.

LCD fluids are used in altering the light orientation passing through glass substrates. Hence, this causes the panel’s active pixels to darken. Different kinds of LCD panel fluids provide unique characteristics and change a panel’s viewing angle, temperature range, and display clarity.

The viewing angle is limited in a panel containing TN fluid. This means that the text or image display becomes harder to read if you rotate the device away from its center. The display is also not that sharp compared to displays using other technologies.

Another characteristic of this fluid is that it works well even in colder temperatures. It’s because TN fluid has the quickest response time among the other LCD fluid types.

TN fluid is considered the cheapest LCD fluid type. However, this doesn’t mean that TN isn’t widely used. The display technology is greatly utilized in digital clocks, pagers, and gas pumps.

LCD modules with STN fluid enjoy a wider display angle, greater multiplexing, higher image contrast, and sharper response than devices using TN fluids. However, modules with STN fluids may have slower response times when used in lower temperatures due to the fluid freezing inside the device.

STN fluid falls under the moderately cheap LCD module price. Furthermore, STN fluid is widely utilized in several monochrome LCD devices such as POS machines, inexpensive feature phones, and informational screens of some devices.

CSTN is a bit pricier than TN and STN fluids. But it’s a good choice if you need to display color images on your LCD device. In fact, a lot of color feature phones use CSTN as an alternative to the TFT displays, saving almost half the manufacturing costs.

In terms of cost, the LCD display module price of a unit with FSTN is higher compared to TN and STN. But this is concerning the better visual quality that FSTN offers.

To cap off this part, the fluids used in a screen is a big factor in determining the overall LCD screen display panel price. As you can see, the four fluid types often used in LCD screens rise in costs with respect to the visual quality produced by each technology.

The temperature range in which LCD screen displays may work varies intensely. Some displays continue to work at optimal performance even when used in cold or hot outdoor temperatures. Lower-quality LCD panels may start having glitches at the slightest change of temperature and humidity. Hence, the temperature range may have a huge impact on the LCD display panel price as well.

Now, most LCD screen panels don’t experience such temperature extremes. In fact, a typical LCD TV can operate properly between approximately o°C and 32°C (32° – 90° F). Meanwhile, other screen modules (usually the industrial-grade ones) have unique capabilities to work in even more extreme ends of the temperature scale.

If you want to look for the most cost-effective type of LCD panel for your device, then you must consider the following standard LCD unit temperature types:

Normal temperature units work well in environments that have indoor temperatures at approximately 20-35°C (68-95°F). Some LCD modules may work well above up to 50°C (122°F). Such LCD modules can be used in daily settings by the typical consumer public.

LCD units under this type are made to withstand lower and higher temperature ranges. Extreme operating temperatures may range anywhere from -30°C to 85°C (-22-185°F). Most LCD modules with wide/extreme temperature capabilities are used in extremely cold areas such as Artic places and ski resorts, as well as humid and moisture-rich hot outdoor areas.

Generally, the LCD module price goes up if the entire display unit can withstand higher temperature ranges. Those who can operate under normal temperature ranges only are usually cheaper.

Hence, you must consider the places where you’ll be installing your LCD display devices. You can’t just use cheaper LCD modules for an industrial-grade display machine. Treat your LCD panel as an investment and select a panel that will yield better screen performance that’ll last several years for you and your business.

Color LCDs have three subpixels that hold red, blue, and green color filters. Each subpixel can have as much as 256 color shades, depending on the variation and control of the voltage applied to it.

Now, when you combine 256 shades of both red, blue, and green subpixels, color LCDs can display a color palette of up to 16.8 million colors. And all these are made possible by millions of transistors etched onto the glass modules.

Display size also plays a large role in an LCD device’s color capability. Smaller screens need fewer pixels and transistors since they have smaller display sizes. These screens are also less costly to make. Now, larger screens with high color resolution and huge display sizes require more transistors and pixels, justifying the higher prices of such monitors.

Resistive touch screen panels are used in most bank ATMs and some older models of cellular phones. They carry the lowest HMI touch screen price among all other touch screen technologies.

Capacitive touch screens are the most common in the display industry today. This technology uses transparent conductors, insulators, and glass to create the panel. An electrostatic field change in the screen’s module happens when a human finger touches the screen surface. This ultimately creates signals that are sent to the touch screen controller for processing.

We’ve explained the following factors at length for both public consumers and business clients to understand the variations in TFT, LCD, and HMI touch screen prices.

Cheap doesn’t necessarily mean low-quality. Also, expensive options aren’t always a wise choice, either. You can maximize your buying or manufacturing options if you know how to compare LCD modules and panels depending on the specifications you truly need for your display machines and devices.

VISLCD has been engaged in LCD production and sales for 9 years, and we have met many customers who shared with us that they had encountered unreliable LCD suppliers.

For example, the answer is not what you asked for, the LCD product cannot be delivered on time, the price of the LCD suddenly increases, the LCD module suddenly breaks down during the use of the product, or even the LCD is discontinued after less than 1 year of delivery…etc. In addition, there are many customers who are not sure what type of LCD supplier they are looking for.

In view of all the above, VISLCD has written this article to share knowledge about LCD suppliers and other issues related to LCD. We believe it will be helpful to LCD customers.

To understand LCD suppliers, we first need to know what kinds of LCD suppliers are available. Then LCD customers can find the right supplier based on information such as their product applications, LCD requirements and forecast volume.

LCD original manufacturer refers to the original manufacturer of LCD panel. Originated from the USA in the 1960’s, after more than 50 years of development, the manufacturers are now mainly located in China mainland, Korea and Taiwan. Among them, the Chinese manufacturers in recent years rely on the rapid scale, technology development and price advantage, has gradually occupied the main market share.

The video below is an official video presentation of the BOE display factory and Century Display (CTC), which will give you a more visual understanding of the original LCD manufacturer.

The 5.1 generation TFT-LCD line of Century Display in Shenzhen, China, for example, has been put into operation since 2008 with a cumulative fixed investment of more than $4 billion, and the cost of water, electricity, employee wages and equipment depreciation is as high as $0.5~100 million/month. The monthly production capacity is about 100,000 sheets ( 1300*1200mm/sheet). If all of them are used to produce 7-inch LCD panels, then the monthly shipment volume is up to 9,000,000 pcs. Therefore, a very large monthly shipment volume is required to meet the normal operation of the factory.

This is only the 5.1 generation TFT-LCD line, if it is 8.5 generation line or even 10 generation line or more, then the cost and shipment volume may be several times or even ten times more. It should be noted that the number of generations of LCD lines does not mean that the technology is high or low. The higher the generation, then the larger the size of the LCD can be put into production, of course, the greater the volume of shipments and investment amount.

LCD original manufacturers generally provide mainly LCD panels, but also provide COG (LCD + IC), FOG (LCD + IC + FPCA cable) and other kinds of LCD semi-finished products. Also includes a small amount of the original LCD module. But the original LCD factory will only deal with the famous brand companies directly (such as Apple, Dell, Xiaomi, etc.), or through agents to ship. And the MOQ quantity requirement is very high (generally 1,000,000 pcs/month or more), the unit price of original LCD module is also high and the degree of customization is low.

LCD original manufacturers usually have an order MOQ requirement for their agents, which translates into an LCD unit quantity of no less than 100,000pcs/month. When the LCD demand is high, this will not be a problem; but when the market is low, the agent must buy the agreed MOQ quantity of LCD from the original LCD manufacturer even if there is no customer demand for the time being. So when the low season, if your order quantity is large enough, then you may get a very good LCD panel price from the LCD agent, which may even be lower than the agent’s purchase price.

LCD module manufacturers is to purchase LCD semi-finished products (such as LCD panel, COG or FOG) from LCD agents, then purchase ICs from IC agents, produce or purchase backlight, FPCA cable and touch screen components, and then integrate all the above components into LCD module or touch LCD module. LCD module factories vary in size from tens of millions of pcs to hundreds of thousands of pcs shipped per month.

Medium and large size module factory generally get the semi-finished products are FOG LCD (also known as open cell LCD) from the original LCD manufacturers or LCD agents, and then add the backlight assembly into the finished LCD module. The advantage of doing so is that the quality is relatively stable, but the degree of customization will be much lower. Because FOG LCD already includes FPCA cable, generally speaking, the only thing that can be customized is the brightness of the backlight and the touch panel and cover glass (if needed). The rest are difficult to change, unless the customer’s LCD demand is very large.

The small and medium size module factory after years of mature development of the industry, the degree of customization will be much more flexible. The semi-finished products are mainly LCD panels, which means that the backlight size, backlight brightness, FPCA cable design, shape and PIN number, as well as the touch panel and cover glass can all be customized according to the customer’s requirements. But the MOQ requirement is higher for the backlight size. Other parts of the customization generally require LCD MOQ of at least 2,000~5,000 pcs, which varies depending on the LCD size.

Since LCD module manufactures vary in size and quality control(especially small and medium size LCD module factories), and most of the components are sourced, the selection of module factories is particularly important if customers want to buy LCDs with good quality and competitive prices.

For example, if the factory’s customers are mostly low-cost products or repaired product manufacturers, then it can be assumed that the quality of his products is not too good, LCD panels and some other components may be B-grade products, not A, can only meet short-term use.

This is essential to ensure supply. In case of supply shortage, many module factories with insufficient upstream channels sometimes cannot even start production. Because they can not buy raw materials such as LCD panels and ICs.

As the name implies, trading companies do not have their own factories, but directly sell finished LCD products from LCD resellers or LCD modules from module manufacturers. Generally speaking, the LCD prices of trading companies are relatively high and the quality and reliability are a little weaker. However, there is no shortage of good trading companies with good quality management teams and good upstream channel resources. The biggest advantage of trading companies is their flexibility, which can meet the diversified needs of customers.

2) Shenzhen has 3 types of buildings related to lcd (including other electronic products): office buildings, factories and markets. Almost all LCD panel and IC agents are located in various office buildings in Shenzhen, while component factories such as FPCA, Touch panel and backlight are located in various industrial parks in the suburbs. It is possible to find the right components and develop new products in the shortest time. Of course, there is also the famous Huaqiang bei(north) Electronic Market, a very complex place.

VISLCD was a trading company in the early days. But after nearly 9 years of development, it has developed into a combination of LCD module factory and LCD agent. The company is located in LCD base Shenzhen, China and operates in both Hong Kong and Shenzhen. We have our own module factory and have direct relationship with Century Display, LG, HKC and other LCD original manufacturers. Our main employees are also from these LCD manufacturers. We also accept all kinds of customized LCD business. Therefore, VISLCD is one of the best choices for medium-sized customers in terms of quality stability, semi-finished parts supply and customization.

Prices for large-sized LCD panels for notebooks and LCD monitors have begun declining this month, bringing an end to a five-quarter period of consecutive increases.

Panel makers are cutting prices, as they attempt to burn off their inventories, which are rising due to increased production levels and a slowdown in present and expected system demand, which partly reflects a disappointing outlook for back-to-school PC sales.

Panel prices began to increase in April 2003, and rose about 21-28% from that time until last month. The price of 15-inch notebook and LCD monitor panels in the XGA format increased to the US$230 to US$235 range in June, up from US$180 to US$190 last April.

In June, panel buyers’ biggest concerns were component shortages and cost increases, as well as hikes in panel prices. Concern over future supply constraints, combined with worries over further price increases, prompted notebook and LCD monitor makers to keep boosting their orders for panels in the second quarter, even though they had detected signs of a slowdown in demand.

However, by the end of June, the system suppliers started cutting down the size of their panel orders, as their inventory levels expanded to four to six weeks, which is much larger than their normal two-week stockpiles. Inventories have been building up both for systems and panels.

Combined with increasing production among panel suppliers, the inventory inflation has resulted in a 3-5% monthly price reduction in large-size panels in July.

The most surprising drop came in the 15-inch monitor panel area, where prices declined by US$13 from June to July, despite an acute shortage over the past few months. However, as demand softened for 17- and 19-inch products, suppliers were forced to increase production of 15-inch panels to drive down prices. Nonetheless, price reductions for 15-inch models are expected to boost demand for low-end products, especially those used as CRT replacements.

A similar situation is also occurring in the 14-inch notebook panel market, where prices declined on month by US$9 in July. iSuppli/Stanford Resources expects price reductions to continue in August, with declines ranging from US$8 to US$20 for notebook and LCD monitor panels and from US$20 to more than US$50 for TV panels. Average price reductions in the third quarter are expected to be 5-10% for notebook and monitor panels and 10-15% for TV panels.

Large-sized LCD panel supply increased 9% on quarter in the second quarter. Supply is expected to increase 14% by the third quarter because most panel suppliers are expanding their capacity, following establishment of new fifth-generation (5G) and 6G fabs.

The LCD TV market was slow in the first half due to high panel and system prices and the sluggish adoption of LCD TVs by consumers, compared to PDP (plasma display panel) or rear-projection microdisplay televisions (RPTVs) using LCD technology or Texas Instruments’ (TI) digital light processing (DLP).

Prices for 30-inch LCD TVs in the first half were in the same range as 42-inch PDP and 50-inch RPTV sets. Because end-user demand for 30-inch LCD TVs was lower than expected, manufacturers scaled back their expectations for the product and instead increased their focus on smaller-sized panels. Panels in the 20-inch and 26/27-inch range appeared to have better prospects in the market.

In the notebook area, panel demand was slow in the first quarter, following normal seasonal patterns. Although demand improved in the second quarter, lower-than-expected back-to-school sales have dampened the outlook for third-quarter demand.

In LCD monitors, panel demand was notably strong in the first quarter. Although end-user monitor demand declined in the second quarter, panel demand remained very high. However, in the third quarter, demand started to experience a slowdown due to the inventory buildup.

About 53% of large-size LCD panel unit demand and 56% of the area demand still come from monitor applications. Thus, any change in the level of monitor demand has a major impact on the large-size LCD market.

Although overall demand for large-size panels is expected to rise in the third quarter compared to the second quarter, sales will rise less than the planned increase in production capacity. Furthermore, it will take time to clear up inventories already accumulated in the supply chain.

Despite the present inventory and demand challenges, panel price reductions in the third quarter are expected to allow system makers to cut the cost of their wares in the coming months – particularly during the all-important holiday season. This will allow suppliers not only to reduce their inventories, but to stimulate demand during the fourth quarter holiday season.

Many suppliers are now raising capital in the stock market for their future expansion plans. However, panel price reductions and slides in stock prices are decreasing their capability to raise capital. This may further impact their production expansion plans for the fourth quarter.

Increasing demand, combined with production adjustments, may bring supply and demand into balance – thus stabilizing prices – by the end of the fourth quarter. iSuppli/Stanford Resources continues to predict higher revenue growth for the LCD market in 2004.

We are experts in providing replacements for damaged laptop, tablet, portable and industrial LCD screens. We provide best quality, brand new A+++ replacement LCD for all major Laptop Brands.

If your Laptop LCD screen is broken, damaged or cracked during use or has dead pixels / lines or the picture sharpness is reduced and backlight is not working, don’t panic. We can provide you excellent quality replacement LCD screen at very reasonable prices.

We take pride in our quality and price. You need not buy a new laptop if your LCD screen is damaged as you can easily replace it yourself with these simple DIY steps.

To ensure that you purchase the right screen for your needs we are happy to assist you in identifying exactly the right he correct screen for your Notebook LCD Screen, tablet, portable computer, etc. You can contact us anytime between 10AM EST to 8PM EST on Monday thru Friday either through the chat function at the bottom right of the screen, or by calling us at (201) 442-0091.

In the end, Sony agreed to pay half of the $1,400 repair to replace the panel. The service tech, a Sony gold standard place, says the set is defective.

Many TVs use LCD (Liquid Crystal Display) panels that are lit by LED backlights. There are two popular types of LCD panels: In-Plane Switching (IPS) and Vertical Alignment (VA), and there are two main differences between each type. A VA panel usually has a high contrast ratio and narrow viewing angles. However, an IPS panel has low contrast and wide viewing angles. These are the main differences between each, and for the most part, panel type doesn"t affect other aspects of picture quality, like peak brightness, color gamut, or color accuracy.

For the purposes of this article, we"re going to compare two LED-backlit LCD TVs: the Sony X800H, which has an IPS panel, and the Hisense H9G, which has a VA panel. Due to their different panel types, there are three noticeable differences in picture quality: viewing angles, contrast, and black uniformity, so we"re going to look at each one.

Viewing angle refers to the angle at which you can watch the TV without seeing a noticeable drop in picture quality. IPS TVs are the clear winner here, as the image remains accurate when viewing from the side - you can see the differences in the videos above. This is their main advantage over VA panels. Most VA panel TVs have a noticeable loss in image accuracy when viewing from the side. The narrow viewing angle of VA-type TVs is also problematic when the TV is used as a PC monitor from up close since the edges of the display look washed out.

VA panels are far superior to IPS panels when it comes to this, so if you tend to watch movies in the dark, you likely want to get a TV with a VA panel. Most TVs use VA panels due to this main advantage, and high-end models may have a local dimming feature that further enhances black levels. On the other hand, IPS panels normally have low contrast, so blacks look closer to gray, but you may not notice the difference in contrast in bright environments.

Our black uniformity tests determine how well a TV displays a dark scene with a bright image in the center. Ideally, you want to see a completely black screen with the center cross being the only part that"s lit up, and this is important for people watching movies. No LED TV has perfect uniformity, and unlike viewing angles and contrast, the panel type doesn"t completely determine its black uniformity. However, most VA panels that we"ve tested have good black uniformity, while most IPS panels have sub-par black uniformity. This doesn"t mean that every VA panel TV has good uniformity, as this can change between units, and you can also improve uniformity using the local dimming feature.

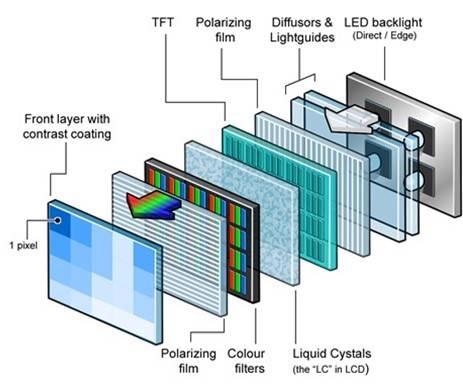

LCDs function by having liquid crystals in little groups to form the pixels. These crystals react and change position when charged with electricity and, depending on their position, they allow a certain color of light to pass through.

There"s also another type of IPS panel, called Plane-to-Line Switching (PLS), which can be seen with the Sony X800H. This panel type was designed by Samsung and technically performs the same as an IPS panel. When you compare the pixels visually, IPS panels look like chevrons, VA looks like very straight rectangles, and PLS looks like round-edged capsules. You can learn more about pixels here.

The way the pixels are laid out can also affect text clarity. Many IPS panels, like the ones on the Sony X800H or the LG SK9000, use RGB sub-pixel layouts, while many VA panels have a BGR layout, like on the Hisense H9G. The sub-pixel layout doesn"t directly affect picture quality unless you"re using it as a PC monitor. Some applications may expect an RGB layout, so if you have a BGR sub-pixel layout, text may not look clear. You may need to increase the text scaling to read it properly, but this issue isn"t common with an RGB layout. You can learn more about it here.

Unlike LED TVs, OLEDs don"t use a backlight and instead have self-emitting pixels. This allows the pixels to individually turn on and off, resulting in perfect blacks. This means that they also have perfect black uniformity as there"s no blooming around bright objects like on some LED TVs. They also have wide viewing angles, sometimes even wider than some IPS panels, so OLEDs are a good choice for wide seating arrangements.

Samsung released quantum dot TVs in 2015, which they later labeled as QLED in 2017. These TVs include a quantum dot layer between the LED backlights and the LCD panel to achieve a wider color gamut. Other companies like Vizio and TCL also use this quantum dot technology on their TVs. Adding this extra quantum dot layer doesn"t change the characteristics of the panel type; the VA panel on the TCL 6 Series/S635 2020 QLED still has a high contrast ratio and narrow viewing angles. Although most QLED TVs use VA panels, you can easily use an IPS panel as well.

Manufacturers have tried different techniques to improve the viewing angles on VA panels over the years, aiming to produce a perfect LCD panel with both wide viewing angles and high contrast. While they have yet to achieve that goal, a few TVs have hit the market that try to combine the best of both panel types. The first TVs with this viewing angle technology came out in 2018, and only a few high-end models like the Samsung Q90/Q90T QLED and the Sony X950H had this technology in 2020. These TVs are a bit unique, delivering noticeably better viewing angles than their pure VA counterparts, but still worse than true IPS panels. This comes at the expense of a lower contrast ratio, as these TVs have worse native contrast than most VA panels, but they"re still better than IPS panels. Combined with their local dimming features, they still produce deep blacks.

Between IPS and VA panels, neither technology is inherently superior to the other as they both serve different purposes. In general, IPS TVs have wide viewing angles suitable for when you want to watch the big game or your favorite show in a large seating arrangement. They"re also beneficial for use as a PC monitor since the edges remain accurate if you sit up close. However, VA panels are a better choice for watching content in dark rooms, as their improved contrast allows them to display deep blacks. Choosing between the two is a series of trade-offs and qualities, so choosing the best TV for your needs depends on your usage.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey