lcd screen programming quotation

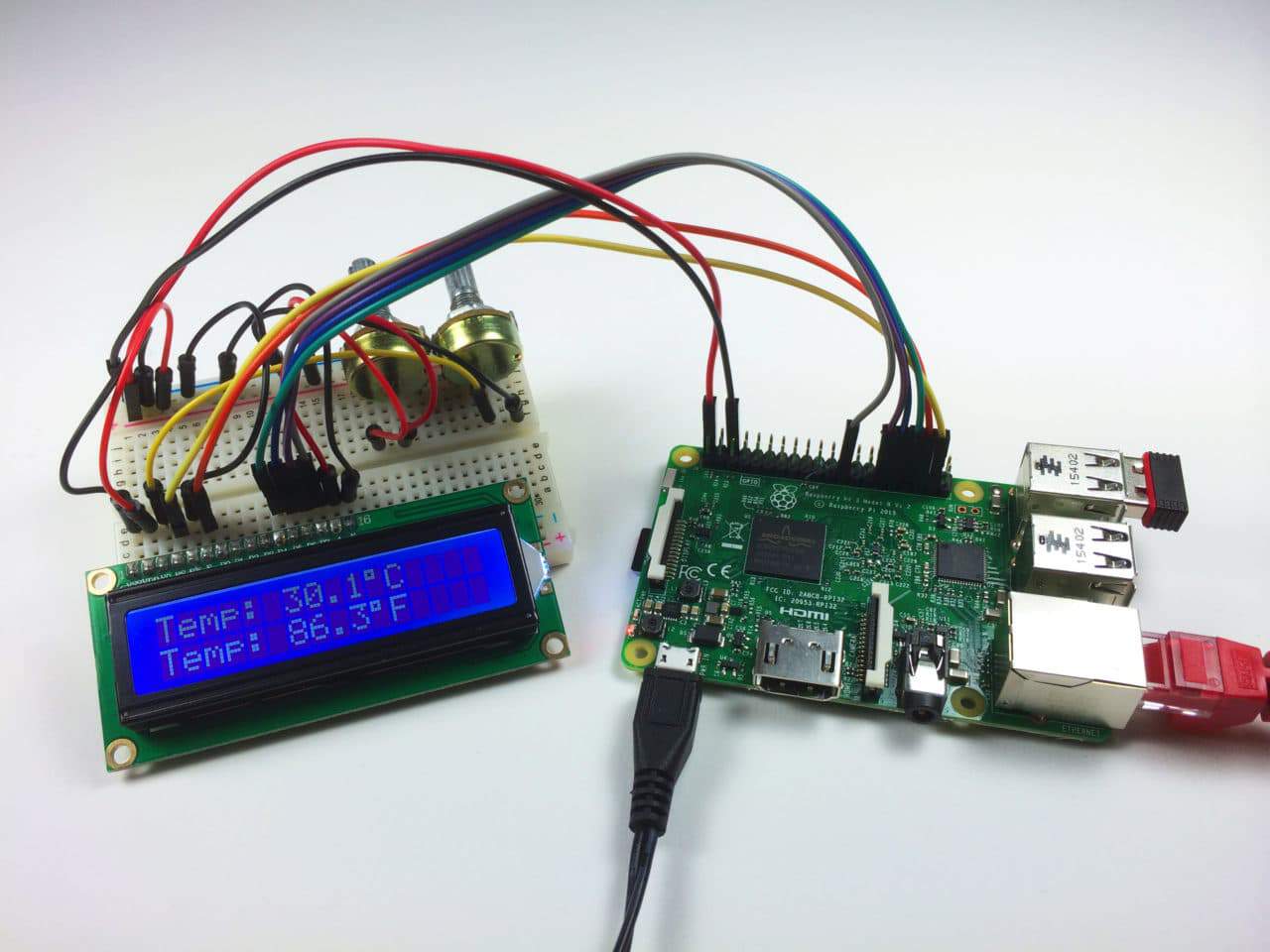

In this tutorial, I’ll explain how to set up an LCD on an Arduino and show you all the different ways you can program it. I’ll show you how to print text, scroll text, make custom characters, blink text, and position text. They’re great for any project that outputs data, and they can make your project a lot more interesting and interactive.

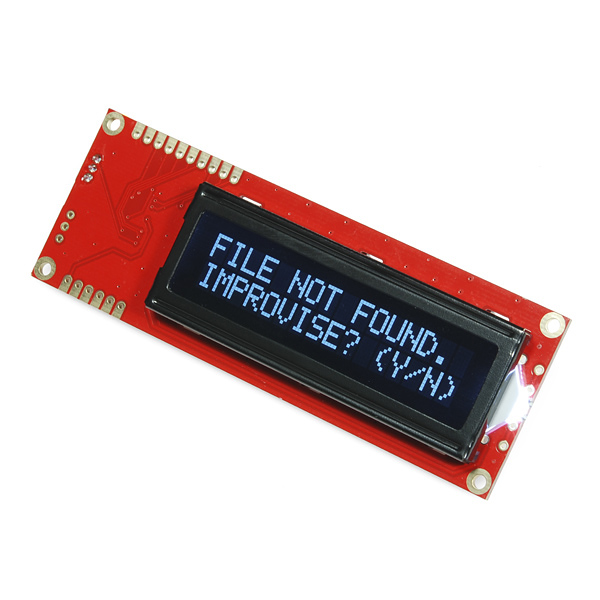

The display I’m using is a 16×2 LCD display that I bought for about $5. You may be wondering why it’s called a 16×2 LCD. The part 16×2 means that the LCD has 2 lines, and can display 16 characters per line. Therefore, a 16×2 LCD screen can display up to 32 characters at once. It is possible to display more than 32 characters with scrolling though.

The code in this article is written for LCD’s that use the standard Hitachi HD44780 driver. If your LCD has 16 pins, then it probably has the Hitachi HD44780 driver. These displays can be wired in either 4 bit mode or 8 bit mode. Wiring the LCD in 4 bit mode is usually preferred since it uses four less wires than 8 bit mode. In practice, there isn’t a noticeable difference in performance between the two modes. In this tutorial, I’ll connect the LCD in 4 bit mode.

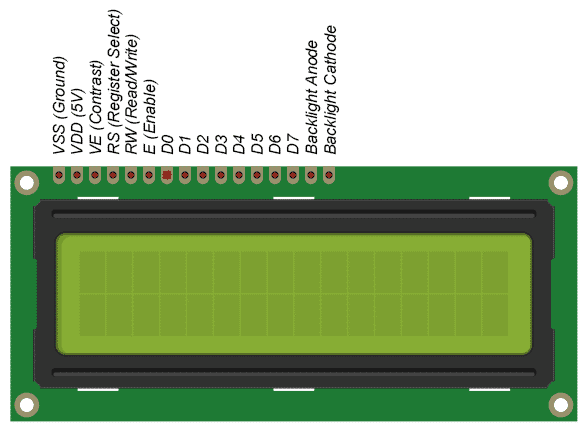

Here’s a diagram of the pins on the LCD I’m using. The connections from each pin to the Arduino will be the same, but your pins might be arranged differently on the LCD. Be sure to check the datasheet or look for labels on your particular LCD:

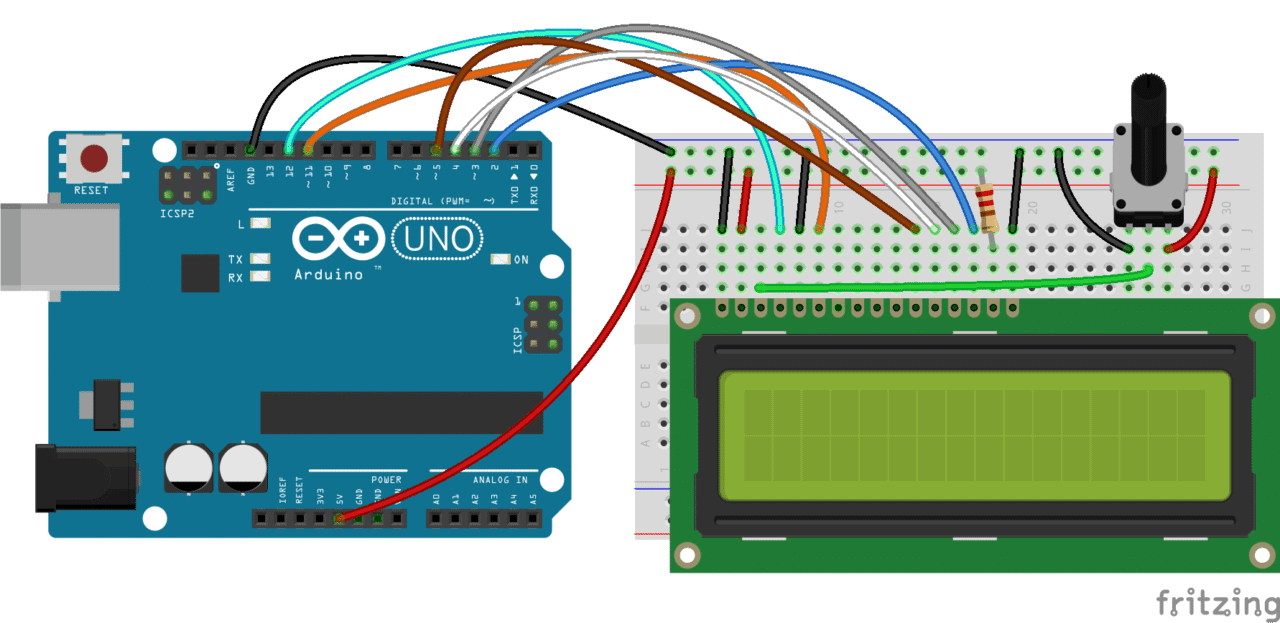

Also, you might need to solder a 16 pin header to your LCD before connecting it to a breadboard. Follow the diagram below to wire the LCD to your Arduino:

Now we’re ready to get into the programming! I’ll go over more interesting things you can do in a moment, but for now lets just run a simple test program. This program will print “hello, world!” to the screen. Enter this code into the Arduino IDE and upload it to the board:

There are 19 different functions in the LiquidCrystal library available for us to use. These functions do things like change the position of the text, move text across the screen, or make the display turn on or off. What follows is a short description of each function, and how to use it in a program.

TheLiquidCrystal() function sets the pins the Arduino uses to connect to the LCD. You can use any of the Arduino’s digital pins to control the LCD. Just put the Arduino pin numbers inside the parentheses in this order:

This function sets the dimensions of the LCD. It needs to be placed before any other LiquidCrystal function in the void setup() section of the program. The number of rows and columns are specified as lcd.begin(columns, rows). For a 16×2 LCD, you would use lcd.begin(16, 2), and for a 20×4 LCD you would use lcd.begin(20, 4).

This function clears any text or data already displayed on the LCD. If you use lcd.clear() with lcd.print() and the delay() function in the void loop() section, you can make a simple blinking text program:

This function places the cursor in the upper left hand corner of the screen, and prints any subsequent text from that position. For example, this code replaces the first three letters of “hello world!” with X’s:

Similar, but more useful than lcd.home() is lcd.setCursor(). This function places the cursor (and any printed text) at any position on the screen. It can be used in the void setup() or void loop() section of your program.

The cursor position is defined with lcd.setCursor(column, row). The column and row coordinates start from zero (0-15 and 0-1 respectively). For example, using lcd.setCursor(2, 1) in the void setup() section of the “hello, world!” program above prints “hello, world!” to the lower line and shifts it to the right two spaces:

You can use this function to write different types of data to the LCD, for example the reading from a temperature sensor, or the coordinates from a GPS module. You can also use it to print custom characters that you create yourself (more on this below). Use lcd.write() in the void setup() or void loop() section of your program.

The function lcd.noCursor() turns the cursor off. lcd.cursor() and lcd.noCursor() can be used together in the void loop() section to make a blinking cursor similar to what you see in many text input fields:

Cursors can be placed anywhere on the screen with the lcd.setCursor() function. This code places a blinking cursor directly below the exclamation point in “hello, world!”:

This function creates a block style cursor that blinks on and off at approximately 500 milliseconds per cycle. Use it in the void loop() section. The function lcd.noBlink() disables the blinking block cursor.

This function turns on any text or cursors that have been printed to the LCD screen. The function lcd.noDisplay() turns off any text or cursors printed to the LCD, without clearing it from the LCD’s memory.

This function takes anything printed to the LCD and moves it to the left. It should be used in the void loop() section with a delay command following it. The function will move the text 40 spaces to the left before it loops back to the first character. This code moves the “hello, world!” text to the left, at a rate of one second per character:

Like the lcd.scrollDisplay() functions, the text can be up to 40 characters in length before repeating. At first glance, this function seems less useful than the lcd.scrollDisplay() functions, but it can be very useful for creating animations with custom characters.

lcd.noAutoscroll() turns the lcd.autoscroll() function off. Use this function before or after lcd.autoscroll() in the void loop() section to create sequences of scrolling text or animations.

This function sets the direction that text is printed to the screen. The default mode is from left to right using the command lcd.leftToRight(), but you may find some cases where it’s useful to output text in the reverse direction:

This code prints the “hello, world!” text as “!dlrow ,olleh”. Unless you specify the placement of the cursor with lcd.setCursor(), the text will print from the (0, 1) position and only the first character of the string will be visible.

This command allows you to create your own custom characters. Each character of a 16×2 LCD has a 5 pixel width and an 8 pixel height. Up to 8 different custom characters can be defined in a single program. To design your own characters, you’ll need to make a binary matrix of your custom character from an LCD character generator or map it yourself. This code creates a degree symbol (°):

For our first project, we’re using both the inbuilt LCD screen and WiFi module to get text data of famous quotes. Since we’re all nerds at DIYODE, we’ve of course chosen to choose famous programming quotes. The center button of the Wio Terminal will be used to load a new quote and display it on the screen.

If you’re new to programming, this code may appear daunting, but it’s really just our Wio Terminal pretending to be a computer sending a web request and reading the response. An API is just an ‘application programming interface’ and is a fancy way of saying it’ll be the source of our data.

There isn’t a ton of libraries we need to import here. We’re using the Arduino JSON, rpcWiFi and HTTPClient libraries to handle the internet connection and data, and the TFT_eSPI library to handle the screen on the Wio Terminal.

Our setup code is verbose but should be fairly self-explanatory as we read through it. We’re starting the TFT screen and setting its rotation, background settings and a placeholder text while we wait for a connection to the WiFi.

The getQuoteResponse() function is where the request actually happens, which consists of opening our URL (feel free to visit the URL shown, it will show a random programming quote in your browser), and loading it from a JSON format. We won’t go into JSON formats and the specifics of it in this project, but essentially its a field and value-based system where attributes are given names. Our response usually comes in this format:{"id":"5a6ce86f2af929789500e824","author":"Ken Thompson","en":"One of my most productive days was throwing away 1,000 lines of code."}

Finally, we can actually draw the quote text on the Wio Terminal’s screen! This isn’t that tricky, except for that weird for loop with the numbers in it. The purpose of this is to provide some basic text wrapping.

Text wrapping is the process of bringing text fields down to the next line on the screen if it’s too long – which is often the case with quotes. The LCD library does have this function built-in, but it wasn’t cooperating for us, so we wrote it ourselves!

Essentially, we’re taking ‘chunks’ out of the text with the substring function and writing each to one line of the Wio Terminal’s LCD screen. The ‘len’ variable describes the number of characters on each line. If the function is confusing, just change some values and observe the effects!

…and boom! It’s all working. Inspiring programming quotes at the press of a button. Obviously, this isn’t the most practical program ever – but it’s a good starting program to experiment with the Wio Terminal and to demonstrate its capabilities with precisely zero external wiring required.

Any kind of quote will do, but because the picture frame scrolls through the images that will contain the quotes it works best if you keep the quotes short. Longer quotes, although interesting, may not remain on screen long enough to be read. If you have a number of longer quotations, see "Some Final Notes" at the end of this instructable for tips that you can consider for longer display times.

Look at the sample images stored on your LCD picture frame. For my frame, all of the sample images were 856x480 pixels. To determine this, right click on the image file, and select Properties. You should see a number of tabs, one of which should be called “Details.” Click on the details tab; under Image you should see a width and height. Write this down or keep the window open, because we will use it to set up PowerPoint.

Take the smaller of the two numbers (usually the height), and divide that by the larger number. In my case, 480/856=0.5607. Checking the table below (which shows common screen image ratios), I can see that the native images on my LCD picture frame are just about in 16:9 format.

Open PowerPoint, and start a new presentation. On the ribbon, click Design, Page Setup. In the setup dialog box, select the image format that matches the native format of your LCD picture frame. We do this because it helps prevent the software driving the frame from cropping or stretching the images unnecessarily. Click Home on the ribbon.

At this point, your presentation should have two slides: The initial default title slide, and your newly inserted blank slide. Click on the first slide (the title slide), click your right mouse button, and select delete. You should be left with a single blank slide in your presentation, sized to the native image size of your LCD picture frame.

In many cases, the picture won’t fill the slide because it’s in a different format than the native format for the LCD picture frame. Thus, we’ll need to resize the image to fit. At the same time, we don’t want to distort the image either. Here’s the most straightforward approach:

4. My LCD picture frame doesn’t let you change the display time for pictures, and some of the transitions happen too quickly to allow you to read the entire quote. You can do what I did, which was to make two copies of every slide. PowerPoint is creative in its naming; the slides are called Slide1.jpg, Slide2.jpg, et cetera. I named my copies Slide1a.jpg, Slide2a.jpg. The file system sorts the original and the copy together when the files are named this way, so every quote is displayed twice with an intervening transition.

5. If you don’t have a lot slides suitable for quotes, consider visiting a site like Interface Lift, which has a wide range of images in a variety of formats for desktop wallpapers. Chances are, you’ll be able to find images in a format suitable for the native format of your LCD picture frame.

LCD connected to this controller will adjust itself to the memory map of this DDRAM controller; each location on the LCD will take 1 DDRAM address on the controller. Because we use 2 × 16 type LCD, the first line of the LCD will take the location of the 00H-0FH addresses and the second line will take the 40H-4FH addresses of the controller DDRAM; so neither the addresses of the 10H-27H on the first line or the addresses of the 50H-67H on the second line on DDRAM is used.

To be able to display a character on the first line of the LCD, we must provide written instructions (80h + DDRAM address where our character is to be displayed on the first line) in the Instruction Register-IR and then followed by writing the ASCII code of the character or address of the character stored on the CGROM or CGRAM on the LCD controller data register, as well as to display characters in the second row we must provide written instructions (C0H + DDRAM address where our character to be displayed on the second line) in the Instructions Register-IR and then followed by writing the ASCII code or address of the character on CGROM or CGRAM on the LCD controller data register.

As mentioned above, to display a character (ASCII) you want to show on the LCD, you need to send the ASCII code to the LCD controller data register-DR. For characters from CGROM and CGRAM we only need to send the address of the character where the character is stored; unlike the character of the ASCII code, we must write the ASCII code of the character we want to display on the LCD controller data register to display it. For special characters stored on CGRAM, one must first save the special character at the CGRAM address (prepared 64 addresses, namely addresses 0–63); A special character with a size of 5 × 8 (5 columns × 8 lines) requires eight consecutive addresses to store it, so the total special characters that can be saved or stored on the CGRAM addresses are only eight (8) characters. To be able to save a special character at the first CGRAM address we must send or write 40H instruction to the Instruction Register-IR followed by writing eight consecutive bytes of the data in the Data Register-DR to save the pattern/image of a special character that you want to display on the LCD [9, 10].

We can easily connect this LCD module (LCD + controller) with MCS51, and we do not need any additional electronic equipment as the interface between MCS51 and it; This is because this LCD works with the TTL logic level voltage—Transistor-Transistor Logic.

Pins 7–14 (8 Pins) of the display function as a channel to transmit either data or instruction with a channel width of 1 byte (D0-D7) between the display and MCS51. In Figure 6, it can be seen that each Pin connected to the data bus (D0-D7) of MCS51 in this case P0 (80h); P0.0-P0.7 MCS-51 connected to D0-D7 of the LCD.

Pins 4–6 are used to control the performance of the display. Pin 4 (Register Select-RS) is in charge of selecting one of the 2 display registers. If RS is given logic 0 then the selected register is the Instruction Register-IR, otherwise, if RS is given logic 1 then the selected register is the Data Register-DR. The implication of this selection is the meaning of the signal sent down through the data bus (D0-D7), if RS = 0, then the signal sent from the MCS-51 to the LCD is an instruction; usually used to configure the LCD, otherwise if RS = 1 then the data sent from the MCS-51 to the LCD (D0-D7) is the data (object or character) you want to display on the LCD. From Figure 6 Pin 4 (RS) is connected to Pin 16 (P3.6/W¯) of MCS-51 with the address (B6H).

Pin 5 (R/W¯)) of the LCD does not appear in Figure 6 is used for read/write operations. If Pin 5 is given logic 1, the operation is a read operation; reading the data from the LCD. Data will be copied from the LCD data register to MCS-51 via the data bus (D0-D7), namely Pins 7–14 of the LCD. Conversely, if Pin 5 is given a voltage with logical 0 then the operation is a write operation; the signal will be sent from the MCS51 to LCD through the LCD Pins (Pins 7–14); The signal sent can be in the form of data or instructions depending on the logic level input to the Register Select-RS Pin, as described above before if RS = 0 then the signal sent is an instruction, vice versa if the RS = 1 then the signal sent/written is the data you want to display. Usually, Pin 5 of the LCD is connected with the power supply GND, because we will never read data from the LCD data register, but only send instructions for the LCD work configuration or the data you want to display on the LCD.

Pin 6 of the LCD (EN¯) is a Pin used to enable the LCD. The LCD will be enabled with the entry of changes in the signal level from high (1) to low (0) on Pin 6. If Pin 6 gets the voltage of logic level either 1 or 0 then the LCD will be disabled; it will only be enabled when there is a change of the voltage level in Pin 6 from high logic level to low logic level for more than 1000 microseconds (1 millisecond), and we can send either instruction or data to processed during that enable time of Pin 6.

Pin 3 and Pin 15 are used to regulate the brightness of the BPL (Back Plane Light). As mentioned above before the LCD operates on the principle of continuing or inhibiting the light passing through it; instead of producing light by itself. The light source comes from LED behind this LCD called BPL. Light brightness from BPL can be set by using a potentiometer or a trimpot. From Figure 6 Pin 3 (VEE) is used to regulate the brightness of BPL (by changing the current that enters BPL by using a potentiometers/a trimpot). While Pin 15 (BPL) is a Pin used for the sink of BPL LED.

4RSRegister selector on the LCD, if RS = 0 then the selected register is an instruction register (the operation to be performed is a write operation/LCD configuration if Pin 5 (R/W¯) is given a logic 0), if RS = 1 then the selected register is a data register; if (R/W¯) = 0 then the operation performed is a data write operation to the LCD, otherwise if (R/W¯) = 1 then the operation performed is a read operation (data will be sent from the LCD to μC (microcontroller); it is usually used to read the busy bit/Busy Flag- BF of the LCD (bit 7/D7).

5(R/W¯)Sets the operating mode, logic 1 for reading operations and logic 0 for write operations, the information read from the LCD to μC is data, while information written to the LCD from μC can be data to be displayed or instructions used to configure the LCD. Usually, this Pin is connected to the GND of the power supply because we will never read data from the LCD but only write instructions to configure it or write data to the LCD register to be displayed.

6Enable¯The LCD is not active when Enable Pin is either 1 or 0 logic. The LCD will be active if there is a change from logic 1 to logic 0; information can be read or written at the time the change occurs.

This tutorial includes everything you need to know about controlling a character LCD with Arduino. I have included a wiring diagram and many example codes. These displays are great for displaying sensor data or text and they are also fairly cheap.

As you will see, you need quite a lot of connections to control these displays. I therefore like to use them with an I2C interface module mounted on the back. With this I2C module, you only need two connections to control the LCD. Check out the tutorial below if you want to use an I2C module as well:

These LCDs are available in many different sizes (16×2 1602, 20×4 2004, 16×1 etc.), but they all use the same HD44780 parallel interface LCD controller chip from Hitachi. This means you can easily swap them. You will only need to change the size specifications in your Arduino code.

For more information, you can check out the datasheets below. The 16×2 and 20×4 datasheets include the dimensions of the LCD and in the HD44780 datasheet you can find more information about the Hitachi LCD driver.

Most LCDs have a built-in series resistor for the LED backlight. You should find it on the back of the LCD connected to pin 15 (Anode). If your display doesn’t include a resistor, you will need to add one between 5 V and pin 15. It should be safe to use a 220Ω resistor, but this value might make your display a bit dim. You can check the datasheet for the maximum current rating of the backlight and use this to select an appropriate resistor value.

After you have wired up the LCD, you will need to adjust the contrast of the display. This is done by turning the 10 kΩ potentiometer clockwise or counterclockwise.

Plug in the USB connector of the Arduino to power the LCD. You should see the backlight light up. Now rotate the potentiometer until one (16×2 LCD) or 2 rows (20×4 LCD) of rectangles appear.

In order to control the LCD and display characters, you will need to add a few extra connections. Check the wiring diagram below and the pinout table from the introduction of this article.

We will be using the LCD in 4-bit mode, this means you don’t need to connect anything to D0-D3. The R/W pin is connected to ground, this will pull the pin LOW and set the LCD to WRITE mode.

To control the LCD we will be using the LiquidCrystal library. This library should come pre-installed with the Arduino IDE. You can find it by going to Sketch > Include Library > LiquidCrystal.

The example code below shows you how to display a message on the LCD. Next, I will show you how the code works and how you can use the other functions of the LiquidCrystal library.

After including the library, the next step is to create a new instance of the LiquidCrystal class. The is done with the function LiquidCrystal(rs, enable, d4, d5, d6, d7). As parameters we use the Arduino pins to which we connected the display. Note that we have called the display ‘lcd’. You can give it a different name if you want like ‘menu_display’. You will need to change ‘lcd’ to the new name in the rest of the sketch.

In the loop() the cursor is set to the third column and first row of the LCD with lcd.setCursor(2,0). Note that counting starts at 0, and the first argument specifies the column. If you do not specify the cursor position, the text will be printed at the default home position (0,0) if the display is empty, or behind the last printed character.

Next, the string ‘Hello World!’ is printed with lcd.print("Hello World!"). Note that you need to place quotation marks (” “) around the text. When you want to print numbers or variables, no quotation marks are necessary.

Clears the LCD screen and positions the cursor in the upper-left corner (first row and first column) of the display. You can use this function to display different words in a loop.

This function turns off any text or cursors printed to the LCD. The text/data is not cleared from the LCD memory. This means it will be shown again when the function display() is called.

This function turns on automatic scrolling of the LCD. This causes each character output to the display to push previous characters over by one space. If the current text direction is left-to-right (the default), the display scrolls to the left; if the current direction is right-to-left, the display scrolls to the right. This has the effect of outputting each new character to the same location on the LCD.

The following example sketch enables automatic scrolling and prints the character 0 to 9 at the position (16,0) of the LCD. Change this to (20,0) for a 20×4 LCD.

With the function createChar() it is possible to create and display custom characters on the LCD. This is especially useful if you want to display a character that is not part of the standard ASCII character set.

Technical info: LCDs that are based on the Hitachi HD44780 LCD controller have two types of memories: CGROM and CGRAM (Character Generator ROM and RAM). CGROM generates all the 5 x 8 dot character patterns from the standard 8-bit character codes. CGRAM can generate user-defined character patterns.

/* Example sketch to create and display custom characters on character LCD with Arduino and LiquidCrystal library. For more info see www.www.makerguides.com */

After including the library and creating the LCD object, the custom character arrays are defined. Each array consists of 8 bytes, 1 byte for each row. In this example 8 custom characters are created.

In this article I have shown you how to use an alphanumeric LCD with Arduino. I hope you found it useful and informative. If you did, please share it with a friend that also likes electronics and making things!

I would love to know what projects you plan on building (or have already built) with these LCDs. If you have any questions, suggestions, or if you think that things are missing in this tutorial, please leave a comment down below.

I hope you are all well. I"ve just finished creating a font for my LCD which consists basically out of a lot of special characters / symbols which I want to make use of.

The Canadian mechanical engineering student hacked the dashboard display screen in his car, so it’s now displaying funny quotes from Reddit. Specifically, it’s displaying those weird “Shower Thoughts” — the headlines from Reddit’s forum for the brilliant one-off insights that pop into your head at random moments.

“I have no programming experience other than a few Arduino projects around the house,” De Mel wrote in a blog post, “so my code is definitely not optimal.” But within one month, he’d already finished the project, and shared its Python code on GitHub. “Hopefully, this will at least give you some kind of starting point for your own project, and you will be able to see the underlying process for making this work.”

Luckily, all the digital devices in his 2012 Hyundai Genesis Coupe were connected using a fairly common standard — the “Controller Area Network bus” (or CAN bus). So Harin grabbed one of his Arduino’s — plus a cheap SPI CANBUS circuit board — and just started doing some experiments. When he first installed his Arduino circuit board into the dashboard, the LCD began showing the time of day — every ten milliseconds — and any new messages that he sent to the screen were simply being wiped out when the system re-transmitted. But Harin had already built up a strong motivation to keep moving forward, according to a recent write-up in Make: magazine, because “I hated that stupid little blue LCD. It would just sit there staring at me brightly with the words ‘AUX’…”

So he re-routed the LCD’s input. And fortunately, Harin’s other Raspberry Pi board could accommodate a WiFi dongle. By using an iPhone for connectivity, it was now able to draw down the funny Reddit quotes. And Make: also reported that his next project may be to install a router directly into his car.

Harin’s even mounted his Nexus 7 Android tablet into his car’s dashboard and is using it to play music. In the comments on his blog, he talks about one day transmitting the “now playing” information from the tablet to the LCD. Somewhere in the mix, there’s even an SQL database. “My main script retrieves the top post from Shower Thoughts and converts the characters to their hexadecimal equivalents, adds the message ID and row identifier, and stores it in an SQL database.”

There’re two more scripts just for retrieving the quote from the database and display it on the screen, which Harin says will be building blocks for more features down the road. “Eventually, I’ll be able to screen the messages intended for the LCD on the primary [CAN bus] network and add the ones I want to keep to the SQL database while removing the ones I don’t need anymore.”

Now instead of seeing the external temperature on his display, he sees bits of mind-blowing amateur philosophy. But maybe it goes to show you that if you’re going someplace strange, your journey there can be just as unpredictable. According to his blog post, the screen was originally intended for displaying song information (title and artist) for Sirius XM.

Because of this, the Reddit quotes were originally preceded by a musical note, and one screenshot makes it look like he’d been listening to a song titled “Being a cop must be awful…”

In line 8, we clear the lower 4 bits of the LATCregister by implementing the bitwise AND operation between this register and the 0xF0 constant. This sets the pins RC0-RC3 to which the DB4-DB7 pins of the LCD are connected, low. Now we assign the upper nibble of the data to these pins, which we do in line 9. Let’s consider it in more detail.

In line 10, we perform the short delay of 1us which is needed by the LCD driver. Actually the minimal length of the E pulse is 230 ns according to the data sheet, but as we’re not going to display dynamic information, 1 us is fine.

After that, we consider that the 8 bits of the data byte are sent to the LCD. Finally, we implement the 40us delay to complete the operation. According to the HD44780 driver data sheet the time of execution of most commands is 37us. So 40us is quite enough. For the commands that need more execution time we will implement the additional delay beyond this function.

The lcd_command (lines 21-24) and lcd_data (lines 26-29) functions are very similar: they both consist of one line, in which the lcd_send function is invoked (lines 23 and 28). But in the lcd_command function the rs parameter is 0, and in the lcd_data function the rs parameter is 1. We couldn"t use these functions and replace them with the lcd_send, but using them makes code more readable.

The lcd_init function (lines 31-42) initializes the LCD according to the routine suggested in the Figure 24 of the datasheet of the HD44780 driver but with slight changes.

In lines 44-52 there is the lcd_write function. It displays the string ‘s’ in the LCD. The parameter s should be the c-type string with the terminating zero. This means that the string should end with the “0” character, which is the sign of the end of the line. This puts certain limitations, because we can’t display the character which is located at address 0 of the DDRAM but we can send it separately using the lcd_data function.

So, in line 46 we declare the variable iand assign its value as 0. This is the counter of the characters in the string. In line 47 we start the while loop which will be implemented while the current character is not 0. The content of the loop is quite simple. First, we send the current character to the LCD (line 49), and then we increment the character counter i (line 50).

In lines 54-61 there is the lcd_set_cursor function. In this function we consider that the first cursor position has the coordinates [1;1] but as the physical coordinates inside the display start with 0, we will need to subtract 1 from each parameter.

The last function, lcd_create_char, is located in lines 63-72. In this function we also first check if the address is bigger than 7 (line 65) and set it as 7 in this case (line 66). This is needed because there are only eight available custom characters with addresses 0 to 7.

In line 67, we send the “Set CGRAM address” command, in which we shift the addr parameter 3 bits to the left. This is needed because the last 3 bits set the line address within one character (see Figure 4). After that, we implement the for loop (line 68) inside which we send the 8 bytes to the LCD which will form the required character (line 70).

And that are all functions that are required for operation with the LCD in the current and following projects. Please save these two files, we will copy-paste them to other projects as well.

Most off-the-shelf displays are not designed to operate in extreme environments although the use of TFT LCD displays is now common in many outdoor, rugged and/or public access applications. Concerns for high performance viewability, protection against damage and functionality in EMI/RFI sensitive applications can be addressed with combinations of a Display Logic LED Backlight Enhancement and the following solutions.

Liquid crystal display (LCD) is a flat panel display that uses the light modulating properties of liquid crystals. Liquid crystals do not produce light directly, instead using a backlight or reflector to produce images in colour or monochrome.

This particular post will cover a bit of technology that most people simply know as "the LCD display". I"m not talking about the computer monitor type of LCD display; no, I"m talking about that small screen on many common pieces of electronics, the one that looks like this.

I"m going to talk about the LCM1602C LCD. The purpose of this post is to get away from a lot of the esoteric "how tos" of this particular display. Ya see, this display is based on the Hitachi HD44780 LCD controller. The nice thing about that is the specifications are readily available. The problem is that the specifications are not readily understood. Yes, I believe that this is an example of "lost in translation".

I used an Arduino to drive my LCD display simply so that I could drive the various logic lines. I didn"t use any of the specialized Arduino libraries for driving a LCD; instead, I simply used the standard digitalWrite command to send the commands and data. The digitalWrite command merely sets the targetted output pin to either 0 V (GND, or LOW) or to +5 V (HIGH). This is equivalent to opening (LOW) or closing (HIGH) a switch. The difference is that using the Arduino means you don"t have the "bounce" problem. The hard part is that you have to code each HIGH and LOW of each line.

To simplify the steps, I"m going to use a table in which each HIGH is replaced by a 1, and a LOW is replaced by a 0. After each step, the EN (enable) line on the system has to be set HIGH, then LOW. This tells the LCD to read in the data or instructions.

If you happen to be using the normal LCD library for an Arduino, or programming the LCD using a C or C++ based system, then when you program it to, say, show the letter "H", or program it to have the cursor blink, then your programming has to be setting the various lines in a manner similar to what we just did above. Think of this as "assembly language for the LCD".

I have read through a lot of post here and other forums, and I found things similar to this (I found a post about random fortune cookie quotes), but those were all a bit more focused on the coding in itself, which is not really accessible to me (i have only very basic programming knowledge, and I am not sure if I have time to learn the basics fully). I am trying to catch up on everything myself, but thought that asking my be helpful. So I just wanted to ask for opinions on the following things:

Programmable display graphics for alphanumeric characters and animated sequences. 64 colors of backlighting can be controlled dynamically. Pushbutton switch with LCD, RGB LED backlighting.

64 colors of backlighting can be controlled dynamically. Pushbutton switch with LCD, RGB LED backlighting. Low energy. Dust-tight construction. Viewing area: 17.0mm x 13.0mm (horizontal x vertical).

Broad and even light distribution. Consistent backlighting. Low energy consumption. Programmable LCD with a variety of LED backlighting colors. Rubber dome.

Low-energy-consumption programmable LCD with a variety of LED backlighting colors. Rubber dome. High reliability and long life of one million actuations minimum.

Part Number: IS-S04G1LC-S -- Human-Machine Interface with four programmable 64x32 LCD SmartDisplay pushbuttons that monitor and control four 7V-12V fans or lights over eight levels of speed/brightness

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey