lcd panel market share made in china

Data from China Optics and Optoelectronics Manufactures Association Liquid Crystal Branch (CODA) shows that in 2021, the output value of China"s display industry was about 586.8 billion yuan (about $84.05 billion), nearly eight times higher than 10 years ago while delivered display panels totaled about 160 million square meters, more than seven times that of a decade ago.

According to CODA, China"s proportion of industry scale and display panel delivered area in the global market has increased to 36.9 percent and 63.3 percent respectively, ranking first in the world.

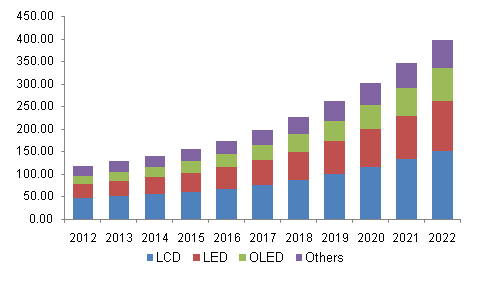

As for the organic light-emitting diode (OLED), domestic enterprises have mastered the core technologies and are making technological innovations in high refresh rate and pixel geometry and other fields. Meanwhile, production scale has expanded rapidly, and the market share of small- and medium-sized OLED increased.

Statistics show that in the third quarter of 2022, the market share of OLED panels for domestic smart phones accounted for 30 percent of the global market, an increase of 10 percent over the same period last year.

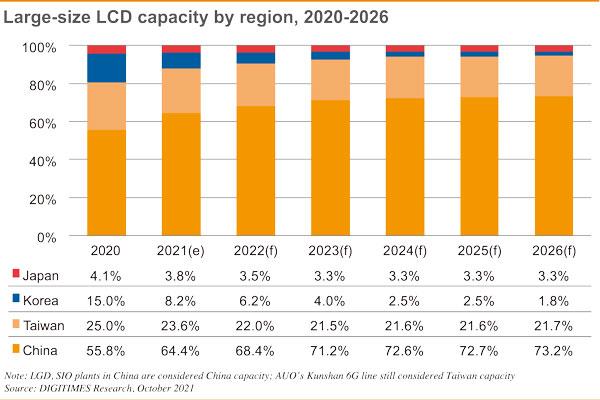

China is the leader in producing LCD display panels, with a forecast capacity share of 56 percent in 2020. China"s share is expected to increase in the coming years, stabilizing at 69 percent from 2023 onwards.Read moreLCD panel production capacity share from 2016 to 2025, by countryCharacteristicChinaJapanSouth KoreaTaiwan-----

DSCC. (June 8, 2020). LCD panel production capacity share from 2016 to 2025, by country [Graph]. In Statista. Retrieved December 20, 2022, from https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. "LCD panel production capacity share from 2016 to 2025, by country." Chart. June 8, 2020. Statista. Accessed December 20, 2022. https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. (2020). LCD panel production capacity share from 2016 to 2025, by country. Statista. Statista Inc.. Accessed: December 20, 2022. https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. "Lcd Panel Production Capacity Share from 2016 to 2025, by Country." Statista, Statista Inc., 8 Jun 2020, https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC, LCD panel production capacity share from 2016 to 2025, by country Statista, https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/ (last visited December 20, 2022)

August 2, according to the Taiwan media “Economic Daily News” reported that the latest report of the research agency RUNTO (RUNTO) shows that the first half of 2022 Chinese mainland panel manufacturers to 84 million shipments as well as 67% market share claimed the title, a record high. Taiwan panel makers Guntron, AUO shipments have declined, a combined market share of 18%, slightly better than Japan and South Korea’s combined 15%. Market expectations, with the mainland domination of the LCD panel market, the next three years, the panel factory is afraid of a merger tide.

According to the “Global LCD TV panel market monthly tracking” released by LOTUS, the first half of this year, the world shipped 125 million LCD TV panels above 32 inches, an increase of 1.9% year-on-year, with mainland manufacturers BOE, Huaxing Optoelectronics and Huike firmly in the top three.

To strengthen the core position of the industry chain, the Chinese mainland TV panel factory to maintain a high crop rate, shipments in the first half of 84 million pieces, the global market share of 67%, an increase of 6.2 percentage points, compared with the second half of last year, an increase of 3.4 percentage points.

The top ten panel manufacturers in the analysis of the Luotu technology, land-based panel factory shipments are showing year-on-year growth, Huaxing photoelectric, rainbow photoelectric shipments were up 12% and 16%. Most of the non-China panel factory decline, Taiwan panel factory Grouptron decline by about 10%, AUO reduced by 14%, the two combined market share of 18% in the first half.

Samsung Display (SDC) began to gradually reduce production at the beginning of the year to a complete shutdown in June, resulting in a year-on-year reduction of 50%. Sharp because of the active adjustment of production capacity, production decreased by 28% year-on-year, Japan and South Korea panel factories in the first half of the combined market share fell to a low of 15%.

Accordingly, the top ten panel makers are divided into four camps, with BOE, which shipped more than 30 million pieces in the first half of the year, firmly taking the lead in the large-size LCD panel industry. Next, 20 million pieces of Huaxing photoelectric, Huike. 10 million pieces of camp for the grouptron and Lejin display (LGD). Million-chip rank AUO and Sharp, with 8 million and 6 million pieces shipped, fell to the tail camp with Rainbow Photoelectric, CEC Panda and Samsung Display SDC.

Looking ahead to the second half of the year, Luotu Technology expects that, as the TV panel each main size has fallen below the cash cost, the panel factory strives to stop bleeding, start large-scale production reduction operations, the panel market is expected to usher in a turnaround. It is expected that before September this year, the major panel factory crop rate will be less than 75%, as to whether the price can stabilize the key observation point also falls in September.

It is the first time that China took over the No. 1 spot in the display market, which Korea has always been a leader in. The title of “the strongest country in display market” is lost after 17 years. It would not be possible to reclaim the No. 1 spot if Korea cannot find a way to expand investment in next-generation displays such as organic light emitting diodes (OLED).

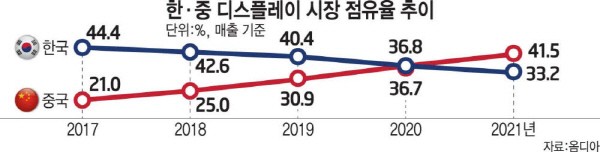

According to market research firm Omdia, China recorded $64.8 billion in sales including LCD and OLED in the global display market last year. China took over Korea’s No. 1 spot with a market share of 41.5%. Korea"s market share fell 8.3 points (p) to 33.2%. This is the first time since 2004, in 17 years, that Korea had to hand over the No. 1 spot. Korea had a 9.4 p advantage in market share over China up until 2019.

China overtook Korea and seized power in the LCD market by offering a low-priced products. BOE, China"s largest panel manufacturer, has become the world"s largest LCD manufacturer with help of the subsidy from the Chinese government. LCD sales was $28.6 billion last year, accounting for 26.3% of the total LCD market. The sales of Chinese companies such as BOE, CSOT, Tianma, and Visionox increased significantly as demand for TV and information technology (IT) devices increased with the prolonged COVID 19 and increased price of LCD panel.

After taken over in the LCD market, Korea is focusing on the highly-valued OLED market. Samsung Display and LG Display are transforming their LCD production lines to OLED. Korea is the No. 1 with 82.3% of the global OLED market shares according to Omdia, and China’s market share only accounts for16.6%.

China"s dominance is expected to continue for some time because the large display market such as TVs and laptops still depends on LCD. Only when Korea starts to reduce OLED panel prices by mass producing OLED, then Korea can replace the LCD market led by China.

China has also started to narrow the gap with Korea in OLED industry. BOE and other companies have commercialized OLED for small and medium-sized displays such as mobile, laptop, and tablet. Following LCD market, China is threatening Korea in OLED market as well as China expands OLED market share mainly in the Chinese smartphone market.

Critics are pointing out that Korea needs to expand in OLED market and develop new technologies in order to maintain the OLED gap with China. Korea must take control over the large TV panel market, which has a large technological gap with China, and create a new form factor with new technologies such as flexible, rollable, and bendable panels.

An official from the display industry said, “With the government-led industrial promotion policy and copious domestic market, China is making an effort to solidify its leading position in the display industry. There is a neglect on display industry in Korea since the display promotion policy is almost non-existent compared to semiconductors and batteries.”

China’s share of the world"s large display market is expected to exceed 50 percent for the first time ever. This year, Samsung Display and LG Display pull the plug on their LCD panel businesses due to declining profitability, letting China further strengthened its LCD market dominance.

Large-area display shipments this year are estimated at 894 million units, down 8 percent from 976 million units in the previous year, said market research firm Omdia on Dec. 16. Shipments based on display areas are also expected to decrease by 3 percent on year.

Omdia said IT displays, such as those for tablet PCs, notebook PCs and monitors, led the decline in shipments this year. TV manufacturers have also reduced panel procurement since the second quarter.

Chinese companies are strengthening their stranglehold on the large-size display market. China’s large-size display shipments are projected to account for 55.2 percent this year, outdistancing 24.9 percent of Taiwanese display makers and 14.7 percent of Korean display makers. In area-based shipments, China’s share is expected to reach 61.3 percent. During the same period, only 17.1 percent was projected for Taiwan and 15.4 percent for Korea.

In terms of shipments by company, China’s BOE is expected to rank first with a 33.1 percent share, followed by China’s Innolux with a 13.3 percent. In terms of area-based shipments, BOE ranked first with 26.1 percent and China Star second with 17.4 percent.

Chinese display makers are in hot pursuit of Korean display makers in the OLED panel domain, where Korean display makers have technological prowess. DSCC, a market research firm, predicted that China will account for 47 percent of OLED panel production in 2025, running shoulder to shoulder with Korea.

LG Display and Samsung Display are struggling to find their ways out of the deterioration of their performance even after withdrawing from production of liquid crystal display (LCD) panels. The high-priced organic light emitting diode (OLED) panel sector regarded as a future growth engine is not growing fast due to the economic downturn. Even in the OLED panel sector, Chinese display makers are within striking distance of Korean display makers, experts say.

On Aug. 30, Display Supply Chain Consultants (DSCC), a market research company, predicted that LCD TV panel prices hit an all-time low in August and that an L-shaped recession will continue in the fourth quarter. According to DSCC, the average price of a 65-inch ultra-high-definition (UHD) panel in August was only US$109, a 62 percent drop from the highest price of US$288 recorded in July in 2021. The average price of a 75-inch UHD panel was only US$218, which was only about half of the highest price of US$410 in July last year. DSCC predicted that the average panel price in the third quarter will fall by 15.7 percent. As Chinese companies’ price war and the effect of stagnation in consumption overlapped, the more LCD panels display makers produce, the more loss they suffer.

As panel prices fell, manufacturers responded by lowering facility utilization rates. DSCC said that the LCD factory utilization rate descended from 87 percent in April to 83 percent in May, 73 percent in June, and 70 percent in July.

Now that the LCD panel business has become no longer lucrative, Korean display makers have shut down their LCD business or shrunk their sizes. In the LCD sector, China has outpaced Korea since 2018. China’s LCD market share reached 50.9 percent in 2021, while that of Korea dropped to 14.4 percent, lower than Taiwan’s 31.6 percent.

Samsung Display already announced its withdrawal from the LCD business in June. Only 10 years have passed since the company was spun off from Samsung Electronics in 2012. LG Display has decided to halt domestic LCD TV panel production until 2023 and reorganize its business structure centering on OLED panels. Its Chinese LCD production line will be gradually converted to produce LCD panels for IT or commercial products. TrendForce predicted that LG Display will stop operating its P7 Plant in the first quarter of next year.

Korean display makers’ waning LCD business led to a situation in which Korea even lost first place in the display industry. Korea with a display market share of 33.2 percent was already overtaken by China with 41.5 percent) in 2021 according to market researcher Omdia and the Korea Display Industry Association. Korea’s market share has never rebounded in for five years since 2017 amid the Korean government’s neglect. Seventeen years have passed since 2004 when Korea overtook Japan to rise to the top of the world in the LCD industry. Korea’s LCD exports amounted to more than US$30 billion in 2014, but fell to US$21.4 billion last year.

A bigger problem is that Korean display makers may lose its leadership in the OLED panel sector although it is still standing at the top spot. While Korea’s OLED market share fell from 98.1 percent in 2016 to 82.8 percent last year, that of China rose from 1.1 percent to 16.6 percent. Considering that the high-end TV market is highly likely to shrink for the time being due to a full-fledged global consumption contraction, some analysts say that the technology gap between Korea and China can be sharply narrowed through this looming TV market slump. According to industry sources, the Chinese government is now focusing on giving subsidies to the development of OLED panel technology rather LCD technology. On the other hand, in Korea, displays were also wiped out from national strategic technology industry items under the Restriction of Special Taxation Act which can receive tax benefits for R&D activities on displays.

BOE Technology Group and TCL China Star Optoelectronics Technology (TCL CSOT) are among the Chinese panel makers to have ramped up output since around 2019 with generous state subsidies. China is gaining on South Korea, whose share of capacity is seen reaching 55% for 2022 in an October estimate by U.S. market intelligence firm Display Supply Chain Consultants (DSCC).

It appears too soon to say that Samsung Display and LG Display, the nation’s top display makers, will exit from the less lucrative LCD market amid a cutthroat competition with Chinese rivals with cheaper pricing.

Until a few years ago, the two firms had hinted at retiring from the old-school LCD business to focus on more advanced technologies such as upgraded LCDs or OLEDs to widen the gap with Chinese runner-ups.

But experts here say there has been a sign of change in the attitudes more recently, pointing out that their full shutdown of LCD operations ultimately would hinge on elevating profitability of their high-end push.

In 2020 alone, Samsung Display posted a deficit of more than 1 trillion won ($841.5 million) in its LCD business. But it has no other option but to continue production to meet the demand from its parent Samsung Electronics, the world’s largest TV maker.

The firm last year sold its LCD production facility in China to its Chinese rival TCL China Star Optoelectronics Technology, a key supplier to Samsung TVs. But the LCD line in Suzhou, China recently cut its panel supply almost in half, with Samsung’s display unit highly likely to be tasked with filling the void.

“(Samsung Electronics) have few choices but to contract with Samsung Display to make up for its LCD TV set capacity,” said Yi Choong-hoon, chief analyst at UBI Research.

This put Samsung Display‘s full exit plan in disarray. After the sell-off of the Chinese facility, the firm is also scaling down its LCD plant in Asan, South Chungcheong Province, to convert part of the facilities to its quantum-dot OLED lines to supply to set makers including Japanese firm Sony.

LG Display’s LCD business -- with production lines in Paju, Gyeonggi Province and Guangzhou, China -- is poised to generate 2.5 trillion won in operating profit for 2021, up fourfold from the previous year, according to Kim Jung-hwan, an analyst at Korea Investment & Securities, on Thursday.

This comes in sharp contrast with OLED TV earnings estimate. According to Kim, LG Display‘s OLED TV operations will post 152 billion won in operating loss, as its fourth-quarter forecast to generate 62 billion won income was dwarfed by 214 billion won losses for the previous three quarters. Since inception, LG’s OLED panel business has been in the red due to heavy spending.

Now, the question is whether the company is ready to be fully dedicated to next-generational OLED panels for premium TVs featuring self-lit pixels. Yi of UBI Research says it is too premature.

“A bigger penetration of OLED TVs to consumers is a prerequisitie for a conversion of (LG Display’s) existing LCD TV lines to OLED TV lines,” he said.

Analysts also said LG Display has already streamlined its LCD TV lines under a series of restructuring of LCD TV lines, including a conversion to lines for IT devices including mobile phones.

“(LG Display‘s) LCD TV fabs with low profit margin have completed a retreat in the first half of 2021,” said Kim Sun-woo of Meritz Securities. “LG is now capable of maintaining LCD capacity with a decent profit margin.”

This comes against the backdrop of industry projections that LCD TV panel prices continue to fall steadily over the course of the first quarter, and Chinese rivals are forecast to ramp up dominance in LCD market,

According to US-based market intelligence firm Display Supply Chain Consultants, Chinese firms’ LCD market share on a capacity basis are forecast to rise to 71 percent by 2025, from 53 percent in 2020, far outpacing Korea, Japan and Taiwan, as of June 2020.

Another estimate, released earlier this week, showed the price for LCD TV panels regardless of size -- ranging from 32- to 65-inch -- is projected to fall until March, giving up almost entire gains from July 2020 to July 2021 that is partly attributable to announced exits of Korean LCD panel makers.

The quarter-on-quarter price declines in the first quarter of 2022 to range between 10 percent and 23 percent and average 15 percent, with mid-sized panels taking the largest dip.

“Although the declines are slowing down in the first quarter, they are still severe for panel makers,” noted Robert O‘Brien, co-founder and principal analyst at DSCC.

In recent time, China domestic companies like BOE have overtaken LCD manufacturers from Korea and Japan. For the first three quarters of 2020, China LCD companies shipped 97.01 million square meters TFT LCD. And China"s LCD display manufacturers expect to grab 70% global LCD panel shipments very soon.

BOE started LCD manufacturing in 1994, and has grown into the largest LCD manufacturers in the world. Who has the 1st generation 10.5 TFT LCD production line. BOE"s LCD products are widely used in areas like TV, monitor, mobile phone, laptop computer etc.

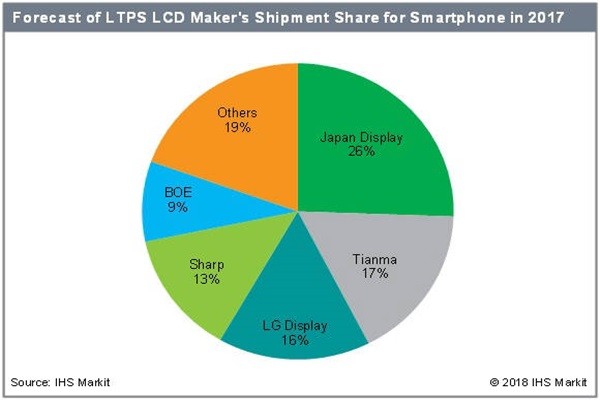

TianMa Microelectronics is a professional LCD and LCM manufacturer. The company owns generation 4.5 TFT LCD production lines, mainly focuses on making medium to small size LCD product. TianMa works on consult, design and manufacturing of LCD display. Its LCDs are used in medical, instrument, telecommunication and auto industries.

TCL CSOT (TCL China Star Optoelectronics Technology Co., Ltd), established in November, 2009. TCL has six LCD panel production lines commissioned, providing panels and modules for TV and mobile products. The products range from large, small & medium display panel and touch modules.

Established in 1996, Topway is a high-tech enterprise specializing in the design and manufacturing of industrial LCD module. Topway"s TFT LCD displays are known worldwide for their flexible use, reliable quality and reliable support. More than 20 years expertise coupled with longevity of LCD modules make Topway a trustworthy partner for decades. CMRC (market research institution belonged to Statistics China before) named Topway one of the top 10 LCD manufactures in China.

The Company engages in the R&D, manufacturing, and sale of LCD panels. It offers LCD panels for notebook computers, desktop computer monitors, LCD TV sets, vehicle-mounted IPC, consumer electronics products, mobile devices, tablet PCs, desktop PCs, and industrial displays.

Chinese manufacturers are expected to raise their market share from 39% this year to 52% next year in the monitor panel market, and 36% to 39% in the notebook panel market

Chinese manufacturers are expected to raise their market share from 39% this year to 52% next year in the monitor panel market, and 36% to 39% in the notebook panel market, according to TrendForce’s preliminary shipment forecast of panel makers for 2021. As such, these manufacturers are expected to maintain their plans of transitioning some production capacities from TV panel manufacturing to IT panel manufacturing in spite of the TV panel shortage in 2H20 caused by various factors such as the closedown of SDC’s LCD panel manufacturing operations, the rise of the stay-at-home economy, and the stimulus policies instituted by governments worldwide.

TrendForce indicates that, with regards to the standing of Chinese manufacturers in the IT panel industry, BOE has long established itself as the market leader, while CSOT and HKC are each also catching up fast. After acquiring SDC’s Suzhou-based Gen 8.5 fab, CSOT will possess even more production capacities for monitor panels. At the same time, HKC currently maintains three Gen 8.6 fabs, located in Chongqing, Chuzhou, and Mianyang, and plans to capture additional shares in the monitor panel and notebook panel markets.

Chinese panel makers have been gradually transitioning their current panel capacities to monitor panel production. Most significantly, as more Gen 10.5 production lines become available, TV panel production will most likely take place in Gen 10.5 fabs instead of Gen 8.5 fabs in the future, while the existing Gen 8.5 and Gen 8.6 production lines will be reallocated to monitor panel production in order to expend the excess capacity made available after TV panel production moves to Gen 10.5 fabs. In addition, after SDC’s forecasted closing of LCD panel manufacturing operations at the end of this year, CSOT and HKC will look to capture the resultant supply share of SDC’s absence in the market. On the other hand, since both TCL, which is CSOT’s parent company, and HKC possess monitor ODM operations, should the two companies decide to vertically integrate by making panels for their own monitor products, they will be able to effectively optimize their cost structures.

Although CSOT’s Wuhan-based T3 LTPS Gen 6 production line is primarily dedicated to smartphone and notebook panel manufacturing, the considerable reduction of LTPS smartphone panel demand from Huawei caused by U.S. sanctions means CSOT is expected to make plans for an increase in notebook panel shipment in order to make up for the shortfall. As well, thanks to high demand for TV panels this year, HKC’s production lines have been operating at maximum capacity utilization rates, in turn slowing down its notebook panel business. However, in light of the fact that the COVID-19 pandemic has brought about a rapid surge in TN notebook panel demand, HKC is therefore looking to TN panels as a new commercial opportunity in the notebook display market and subsequently prioritizing TN panel development over IPS panel development as its product strategy. Not only will this reprioritization allow HKC to align its strategy with the current market trend, but it will also quickly raise the yield rate of HKC’s Mianyang-based fab, which had never manufactured NB panels, by instead having the fab manufacture TN panels, which have a relatively simpler manufacturing process.

TrendForce analyst Jeff Yang indicates that, despite Chinese panel makers’ strong intention to enter the IT panel manufacturing business, success in the IT panel market is not solely decided by a company’s production capacity. For instance, with regards to monitor panels, CSOT’s technical competency is mostly focused on VA panels, meaning the company is constrained in its product mixes due to its lack of mainstream IPS offerings. Although HKC is equipped with both IPS and VA technologies, it lacks experience in manufacturing curved VA panels, leading its clients to take on a wait-and-see approach before placing additional orders. For notebook panels, although CSOT is primarily focusing on the mid-range and high-end LTPS notebook panel market, it faces intense competition from Samsung’s OLED notebook panels, which are gradually extending from the high-end segment to the mid-range segment as well. Likewise, HKC will have to take time in order to make headways in the notebook panel market, since it has not reached any production milestones, and it requires time to cultivate a significant client base.

The panel supply chain has seen oversupply with prices falling. In consequence of the waning epidemic, TV sales which could have been boosted by WFH economy can hardly regain momentum in the fourth quarter. On top of that, Samsung and LG are gradually fading out the traditional panel industry. Taiwanese firms on the other hand focus on cockpit panels, advanced TV models, gaming businesses and IT products. The global panel industry structure is transforming.

Chinese presence in the LCD panel industry continues its expansion. Samsung used to dominate in the high-end panel market but is now no longer obsessed with the business as before. Samsung has sold its panel production line to China"s CSOT. China-made panels are expected to dominate the market before OLED panel is mature enough to erode the market share of LCD panels. It is predicted China-made panels will account for over 70% of the global panel market share.

In terms of applications, cockpit dashboards and central control systems both maintain double-digit growth. Interactive digital signage displays also perform well with good sales. The market preference is tilting towards the large-sized models. After taking over Samsung"s production line, CSOT is to be a significant player and poses threats to Taiwanese firms.

Since the pandemic is waning, the global TV market as a panel end-user segment is facing a downturn in demand. Components shortage, port congestion, China"s policy on power restrictions, coupled with typhoons in Asia have exacerbated the issues. Considering quarterly output between 7-8 million units, Taiwanese TV makers like TPV and Hon Hai (Foxconn) willl report moderate sequential growths in third-quarter and fourth-quarter 2021, but will see declines of about 15% year-on-year. Apparently, the big demand cycle of panels has come to an end.

This indicates that China"s development of its own semiconductor industry remains a significant part of its national development plan. The semiconductor industry is different from the panel industry. There is no telling if China"s semiconductor can duplicate the model of its panel industry to capitalize on domestic support with massive capital funds.

Workers manufacture display panels on an assembly line in Huainan High-Tech Industrial Development Zone in East China"s Anhui Province, on April 24, 2022. Photo: VCG

The news outlets proclaimed that South Korea"s title of "the strongest country in display market" was lost after 17 years and that it would not be possible for South Korea to reclaim the No. 1 spot if it cannot find a way to ramp up investment in next-generation displays such as organic light emitting diodes (OLED).

The year 2021 was a milestone for China"s display panel industry. Chinese display panel makers, led by companies such as BOE Technology Group Co, Shenzhen China Star Optoelectronics Technology Co, Tianma, and Visionox, accounted a combined 40.4 percent of global market share in turnover, outstripping South Korea"s 36.3 percent, data from Beijing-based market research provider Sigmaintell revealed.

It is the first time that Chinese companies held a larger market share that their South Korean rivals, mainly Samsung Display and LG Display, as in 2020, South Korean companies led with 39.8 percent of market share, 4.8 percentage points higher than China.

A different set of data published by market research firm Omdia showed the same pattern. China recorded $64.8 billion in sales including liquid crystal display (LCD) and OLED in the global display market in 2021. China overtook South Korea"s No. 1 spot with a market share of 41.5 percent while South Korea"s market share fell to 33.2 percent.

On March 30, BOE, the world"s largest flat-panel display manufacturer, said its total revenue stood at 219.31 billion yuan ($33.57 billion) in 2021, up 61.79 percent from a yearly basis, while its net profit surged 412.96 percent year-on-year to hit 25.83 billion yuan.

Market competition in display panel, an indispensable part for consumer electronics, is fierce. And the competing relations between Chinese and South Korean companies exist in display panels for smartphones, televisions, monitors, among other product segments.

Display panel are comparable to today"s high-end semiconductors, for years the production of display panels had been monopolized by foreign companies. But after a decade of strenuous work to catchup, experts said that Chinese players now dominate today"s display panel manufacturing and the proliferation of display panel technology benefited global consumers by reducing the cost of a wide range of downstream electronic components and has in recent years caused domestic upstream business such as material-supplying company to flourish.

In terms of LCD, Chinese companies have long surpassed their South Korean counterparts in shipments, and in recent years Chinese companies also invested heavily in advanced production lines for small-size OLED screens that is used in smartphones.

Etnews suggested South Koran companies reduce OLED panel prices by mass producing OLED, which requires substantial investment in production capacity, only then can South Korea replace the LCD market led by China. The battlefield of choice for South Korean firms would be in large TV panel market, in which they still enjoy large technological gap with China.

Even as South Korean companies seek to entrench their lead position in large-size OLED, their efforts may not turn out to be as effective as imagined, Lee said, as large OLED may not prove to be a worthy barrier behind which South Korean companies could fall back upon as it does not have unique functions that could not be fulfilled by LCD.

In 2021, shipments of large-size OLED display panels were just 6.7 million units while in the same period the shipments of LCD reached 210 million units.

"Back in the days of LCD phasing out cathode ray tube and plasma display panel, LCD could fulfill unique functions the other two types could not. That is something we don"t see in OLED. The things OLED can do, LCD can also do and are being constantly perfected," Lee said. "That means fall back behind the OLED castles may not be enough to fend off challenges lurched out by Chinese players."

Lee said as the display panel industry moves forward, Chinese companies are betting big on research & development in new emerging display technologies such as mini-LED and micro-LED.

South Korean companies would be increasingly willing to export their advanced technology once they realized they are losing market shares, according to Lee.

Attendees visit the booth of TV panel maker Shenzhen China Star Optoelectronics Technology during an international exhibition in Shanghai on July 11, 2019. [Photo by Lyu Liang/For China Daily]

Chinese companies have gained a competitive edge in the large-screen display industry and the exit of South Korean counterparts such as Samsung Electronics and LG Display from the liquid crystal display market will bring opportunities for China"s panel makers despite the challenges posed by the COVID-19 pandemic.

Market research firm Sigmaintell said BOE Technology Group Co Ltd-a leading Chinese supplier of display products and solutions-became the world"s largest shipper of LCD TV panels for the first time in 2019.

The Beijing-based company shipped 53.3 million units of LCD panels in 2019, with production capacity increasing by more than 20 percent on a yearly basis.

The consultancy said the LCD TV panel production area of Chinese manufacturers will account for more than 50 percent of the global total this year, surpassing South Korean competitors who are accelerating the shutdown of large-sized LCD panel production capacity due to competition from Chinese manufacturers.

It estimated the production capacity of large-sized LCD panels will continue to increase in China over the next three years. In addition, global LCD TV panel shipments stood at 283 million pieces last year, a slight decrease of 0.2 percent year-on-year. Meanwhile, the shipment area was 160 million square meters, an increase of 6.3 percent year-on-year.

"Chinese companies have gained an upper hand in large-screen LCD displays. Samsung and LG"s decision to exit from the LCD sector means Chinese panel makers will take a dominant position in this field," said Li Dongsheng, founder and chairman of Chinese tech giant TCL Technology Group Corp.

Li said South Korean firms will focus on organic LED screens and quantum dot LED displays, while Chinese TV panel makers are catching up at a rapid pace.

"The outbreak has caused a periodic drop in demand in the global display market and sped up the restructuring of the entire industry. Chinese enterprises are in a favorable position, and I believe that they will further enhance their competitiveness," Li said.

Data consultancy Digitimes Research said it comes as little surprise that Samsung has opted to withdraw from the LCD panel sector as its LCD business was losing money in every quarter of 2019 due to challenges from Chinese competitors.

"China"s semiconductor display industry has made large advances in the past decade, changing the display industry"s global competitive landscape. China has transformed into the world"s largest consumer market and manufacturing base for display terminals, with huge market potential," said BOE Vice-President Zhang Yu.

BOE said its Gen 10.5 TFTLCD production line achieved mass production in Hefei, Anhui province, in March 2018. The plant mainly produces high-definition LCD screens of 65 inches and above. With a total investment of 46 billion yuan ($6.5 billion), the company"s second Gen 10.5 TFT-LCD production line launched operations in Wuhan, Hubei province, in December.

The Gen 11 TFT-LCD and active-matrix OLED production line of Shenzhen China Star Optoelectronics Technology, a subsidiary of TCL, officially entered operations in November 2018, producing 43-inch, 65-inch and 75-inch LCD screens.

Chen Lijuan, an analyst at Sigmaintell, said panel manufacturers should not just invest in production lines, but also pay more attention to the establishment of the whole supply chain, including raw materials, equipment and technology.

Bian Zheng, deputy director of research at AVC Revo, a unit of market consultancy firm AVC, said China will have a 51 percent market share in global TV shipments in 2020, while South Korea will have 25 percent, adding that large-screen TV panels will bolster healthy development of the industry.

Bian said the OLED and QLED will be the next-generation flat-panel display technologies to be in the spotlight. LG Display is currently the world"s only supplier of large-screen OLED TV panels.

OLED is a relatively new technology and part of recent display innovation. It has a fast response rate, wide viewing angles, super high-contrast images and richer colors. It is much thinner and can be made flexible, compared with traditional LCD display panels.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey