tft lcd displays wide viewing angles factory

TFT (Thin Film Transistor) LCD (Liquid Crystal Display)technology is currently dominant in the display world right now due to its lightweight, low power consumption, low manufacturing cost, etc. But LCDs do have several generic drawbacks. A narrow viewing angle is one of the main issues compared with other display technologies, such asOLED (Organic Light Emitting Diodes), CRT(Cathode-Ray Tube), Plasma, VFD(Vacuum Fluorescent Display), and most recent SamsungMicroLEDdisplays. They also don’t have a response time issue.

LCD scientists and engineers took more than 30 years of effort to improve the TFT LCD viewing angle which has made TFT screens widely applicable in different applications ranging from automotive, home appliances, medical, military, industrial, consumer, etc. The following is a summary of the different TFT wide viewing angle technologies.

When we talk about TFT LCD, we normally mean TN LCD. Thetwisted nematic effect(TN-LCD) takes advantage of the ability of the nematic substance to rotate the polarization of light beams passing through it. Two polarizing filters, parallel planes of glass with their polarizing lines oriented at right angles with respect to each other, are positioned on either side of the liquid crystal. When light enters the display, it is polarized by the input filter. In the absence of an electric field, all the incoming light is transmitted. This is because the light polarization is rotated 90 degrees by the nematic liquid crystal, and the light, therefore, passes easily through the output filter, which is oriented to match the 90-degree shift. With the application of a voltage, an electric field is produced in the nematic liquid crystal. Under these conditions, the polarization effect is reduced. If the voltage is large enough, the polarization effect disappears altogether, and the light is blocked by the output polarizing filter. Refer to Fig.1

In this case, when the display is observed from a vertical direction to the substrate, the display shows a dark state, because the optical axis of the liquid crystal is perpendicular to the substrate. However, when the display is observed from the tilted direction, the display does not show completely a dark state because light leaks due to the birefringence. The birefringence becomes predominant with an increase in the voltage. At different viewing angles, the birefringence is different and the transmission is different in each direction. This is the reason for the poor viewing angle of TFT LCDs. See Fig.3.

The most cost-effective and common way is to use a wide viewing angle polarizer. Of course, the improved viewing angle is not wide enough for some applications. Another limitation is that the wide viewing angle polarizer will not be able to change the Gray Scale Inversion shown at the bottom photo in Fig.3.

O-Film is an optical film that is applied to the TN TFT LCD and redirects light, providing all round viewing angles to any TN TFT LCD to which it is applied. It is easy to apply and relatively low cost.

The best advantage of O Film is to eliminate grayscale inversion. The drawback is to reduce the contrast and brightness. With the wider adoption of IPS, O Film gradually fell out of favor with the market.

This article is an original piece of content written by the engineering and technical support team atOrient Display. We are an LCD and display technology provider with over two decades of industry experience in delivering cutting edge display solutions. Please browse ourknowledge baseif you would like to learn more about LCDs!

Displaytech IPS displays are the premium option within our standard TFT LCDs. Our IPS TFT displays offer improved color accuracy and crisper images compared to non-IPS displays of the same size. They also provide a very wide viewing angle and a high refresh rate of the screen’s contents.

IPS screens have a special technology within the liquid crystals that allow the screen’s contents to maintain color and overall visibility from any viewing direction. This enhances the user experience since the user can interact with the LCD from any vantage point.

Get rich colors, detailed images, and bright graphics from an LCD with a TFT screen. Our standard Displaytech TFT screens start at 1” through 7” in diagonal size and have a variety of display resolutions to select from. Displaytech TFT displays meet the needs for products within industrial, medical, and consumer applications.

TFT displays are LCD modules with thin-film transistor technology. The TFT display technology offers full color RGB showcasing a range of colors and hues. These liquid crystal display panels are available with touchscreen capabilities, wide viewing angles, and bright luminance for high contrast.

Our TFT displays have LVDS, RGB, SPI, and MCU interfaces. All Displaytech TFT LCD modules include an LED backlight, FPC, driver ICs, and the LCD panel.

We offer resistive and capacitive touch screens for our 2.8” and larger TFT modules. Our TFT panels have a wide operating temperature range to suit a variety of environments. All Displaytech LCDs are RoHS compliant.

We also offer semi-customization to our standard TFT screens. This is a cost-optimized solution to make a standard product better suit your application’s needs compared to selecting a fully custom TFT LCD. Customizations can focus on cover glass, mounting / enclosures, and more - contact us to discuss your semi-custom TFT solution.

As an active-matrix LCD device, the TFT LCD’s individual pixels consist of red, green, and blue sub-pixels, each with their own TFT and electrodes beneath them. These sub-pixels are controlled individually and actively, hence the name active-matrix; this then allows for smoother, fast response time. The active-matrix also allows for larger display modes that continue to uphold quality of color, refresh rate, and resolution when aspect ratio is increased.

Within the pixels composing the TFT LCD display, electrodes play a role in conducting the circuit between them. If layered on both insides of the two glass substrates, the electrodes, along with the TFT, create an electrical pathway within the liquid crystal layer. There are also other placements of electrodes besides on the surface and back of the device that change the effect of the electrical pathway between the substrates (to be discussed later in this article). This pathway has an effect on the crystals through its electric field, which is one of the TFT concepts responsible for the low, minimized power consumption of TFTs, making them so efficient and appealing.

Though there are a variety of ways to align the crystal molecules, using a twisted nematic (TN) to do so is one of the oldest, most common, and cheapest options for LCD technology. It uses the electric field between the electrodes organized with one on the surface substrate layer and the other on the back substrate layer to manipulate the liquid crystals.

Though this is one of the cheapest options for display technology, it has its own problems. The TN TFT LCD does not have top response times compared to other types, and it does not provide for as wide a viewing angle as other TFT LCDs using different alignment methods. A viewing angle is the direction at which a screen can be looked at before the displayed image cannot be seen properly in terms of light and color. TN displays mostly struggle with vertical viewing angles but also have somewhat limited horizontal angles as well. This TN LCDs viewing angle limit is called the gray scale inversion issue.

Generally, when viewing angle is not ideal, image quality as a whole decreases. Things like contrast ratio (the luminance ratio between the brightest white and darkest black) and readability of the screen are not preserved due to this issue.

Among the methods of liquid crystal alignment, TN is only one option for LCD technology. There are various other common ways to align the crystals for a wide viewing angle, such as the multi-domain vertical alignment or in-plane switching. In addition, because of the abundance of TN devices, something called O-film has also been introduced to pair with TN screens so that users do not have to buy whole new devices.

Simply put, this method divides the cell beneath each pixel into multiple domains. With the division, molecules in the same cell can be oriented differently, and so as users shift their views of the display, there are different crystal directional alignments that allow for the preservation of the display properties over these angles such as high brightness and high contrast. This solves the problem of what is known as a mono-domain vertical alignment.

Though mostly similar to the TN, the MVA has one notable feature in its cell that TN cells do not have: glass protrusions. Between the sandwiching electrodes, angles glass protrusions reorient the light traveling within the layer so that when exiting the surface polarizer, it travels in a multitude of directions to satisfy the need for a wide viewing angle.

In recent developments of the MVA TFT LCD, contrast ratio, brightness, and response times have all increased in quality. Contrast ratio, being 300:1 when first developed in 1997, has been improved to 1000:1. Similarly, response time, characterized by rising (black to white) and decay (white to black) time, has reached times that are the fastest that human eyes can process, demonstrating the appropriateness of MVA-based displays for moving images.

With this type of alignment, viewing angles were preserved in much wider directions compared to the TN. Recently, IPS displays have improved qualities like response time to make the IPS screens more desirable to consumers. However, this type of TFT LCD will tend to cost more than TN devices.

While the TN TFT LCD has the smallest cost, that is for a reason. O-films, MVAs, and IPS TFT LCDs have greater costs due to their more intricate technologies that improve viewing angle to retain resolution and general display quality.

The O-film specifically is unique because rather than changing the liquid crystal alignment technology and for a relatively low cost, it can swap the surface polarizer of a TN device with a special film to widen the viewing angle. Because it is combined with TN, it can only improve viewing angle slightly.

IPS has the most potential for improved viewing angle, reaching higher possible angles than all the other options. With IPS, though, there is a higher power consumption than the regular TN device due to the need for a brighter backlight in this device.

All these technologies are viable options depending on the consumer’s desires and price range. MVA and IPS TFT LCDs tend to be more practical for consumer products like LCD monitors and phone screens, while TN and O-film LCDs can cross over into industrial applications. Nonetheless, with the growth of the IPS and MVA LCDs, their applications are widening.

The AFFS is similar to the IPS in concept; both align the crystal molecules in a parallel-to-substrate manner, improving viewing angles. However, the AFFS is more advanced and can better optimize power consumption. Most notably, AFFS has high transmittance, meaning that less of the light energy is absorbed within the liquid crystal layer and more is transmitted towards the surface. IPS TFT LCDs typically have lower transmittances, hence the need for the brighter backlight. This transmittance difference is rooted in the AFFS’s compact, maximized active cell space beneath each pixel.

Since 2004, Hydis, who developed the AFFS, has licensed the AFFS to the Japanese company Hitachi Displays, where people are developing complicated AFFS LCD panels. Hydis has improved display properties like outdoor readability of the screen, making it even more appealing to use for its main application: mobile phones displays.

TFT (Thin Film Transistor) LCD (Liquid Crystal Display) dominates the world flat panel display market now. Thanks for its low cost, sharp colors, acceptable view angles, low power consumption, manufacturing friendly design, slim physical structure etc., it has driven CRT(Cathode-Ray Tube) VFD ( Vacuum Fluorescent Display) out of market, squeezed LED (Light Emitting Diode) displays only to large size display area. TFT LCD displays find wide applications in TV, computer monitors, medical, appliance, automotive, kiosk, POS terminals, low end mobile phones, marine, aerospace, industrial meters, smart homes, handheld devices, video game systems, projectors, consumer electronic products, advertisement etc. For more information about TFT displays, please visit our knowledge base.

What we are talking about TFT LCD, it is a LCD that uses TFT technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments without TFT in each pixel.

The TN type TFT LCD display is one of the oldest and lowest cost type of LCD display technology. TN TFT LCD displays have the advantages of fast response times, but its main advantages are poor color reproduction and narrow viewing angles. Colors will shift with the viewing angle. To make things worse, it has a viewing angle with gray scale inversion issue. Scientist and engineers took great effort trying to resolve the main genetic issues. Now, TN displays can look significantly better than older TN displays from decades earlier, but overall TN TFT LCD display has inferior viewing angles and poor color in comparison to other TFT LCD technologies.

IPS TFT LCD display was developed by Hitachi Ltd. in 1996 to improve on the poor viewing angle and the poor color reproduction of TN panels. Its name comes from its in-cell twist/switch difference compared with TN LCD panels.The liquid crystal molecules move parallel to the panel plane instead of perpendicular to it. This change reduces the amount of light scattering in the matrix, which gives IPS its characteristic of much improved wide viewing angles and color reproduction. But IPS TFT display has the disadvantages of lower panel transmission rate and higher production cost compared withTN type TFT displays, but these flaws can’t prevent it to be used in high end display applications which need superior color, contrast, viewing angle and crispy images.

The mono-domain VA technology is widely used for monochrome LCD displays to provide pure black background and better contrast, its uniformly alignment of the liquid crystal molecules makes the brightness changing with the viewing angle.

MVA solves this problem by causing the liquid crystal molecules to have more than one direction on a single pixel. This is done by dividing the pixel into two or four regions – called domains – and by using protrusions on the glass surfaces to pretilt the liquid crystal molecules in the different directions. In this way, the brightness of the LCD display can be made to appear uniform over a wide range of viewing angles.

This is an LCD technology derived from the IPS by Boe-Hydis of Korea. Known as fringe field switching (FFS) until 2003, advanced fringe field switching is a technology similar to IPS offering superior performance and color gamut with high luminosity. Color shift and deviation caused by light leakage is corrected by optimizing the white gamut, which also enhances white/grey reproduction. AFFS is developed by Hydis Technologies Co., Ltd, Korea (formally Hyundai Electronics, LCD Task Force).

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan’s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation. (Reference)

The AFFS is similar to the IPS in concept; both align the crystal molecules in a parallel-to-substrate manner, improving viewing angles. However, the AFFS is more advanced and can better optimize power consumption. Most notably, AFFS has high transmittance, meaning that less of the light energy is absorbed within the liquid crystal layer and more is transmitted towards the surface. IPS TFT LCDs typically have lower transmittances, hence the need for the brighter backlight. This transmittance difference is rooted in the AFFS’s compact, maximized active cell space beneath each pixel.

Logic Technologies began it"s life as a custom display design and manufacturing company back in 2008. Over the past 8 years we have developed hundreds of custom display solutions from 1.1" TFT displays for gaming button consoles, small true transflective TFTs, ruggedised 7" TFT and Touch Panel modules all the way to full-customised 15" computers, complete with IP67-rated stainless steel housing for ruggedized environments.

Industrial and medical applications can benefit from the high contrast ratios and black level uniformity, wide viewing angles and high resolutions afforded by the P-series (Professional series) TFT display modules by Tianma. They are available from Review Display Systems (RDS).

According to RDS, the display modules deliver consistent, reliable operation for human machine interface (HMI) in demanding environments. They also have long-life, high brightness backlights, are readable in sunlight and are equipped with LVDS interfaces. The display modules have a wide operating temperature range and are available with projected capacitive (PCap) touch options.

The Tianma P-series is available in three performance grades: Advanced, Basic and Entry. Advanced displays will have a wide colour gamut, black level uniformity, high contrast ratios, wide viewing angles and high pixel densities. The Basic displays will be able to meet standard specification requirements for the industrial market and offer a good performance versus cost ratio, said RDS. Entry level displays are intended for use in price sensitive applications.

Tianma’s capabilities include TFT LCD production, display module assembly and the ability to add PCap touch sensors in-house. This enables Tianma to actively support long term manufacturing; the P-series displays will be available for a minimum of five years.

Review Display Systems was established in 1982. It supports and supplies display and embedded hardware solutions. The company supports a comprehensive range of display technologies, touch screen and embedded computing solutions from manufacturers worldwide.

Review Display Systems has partnerships with customers in a wide range of industry sectors including industrial control and instrumentation, medical devices, facilities management, marine, aerospace, point-of-information, and process control.

Usually customer-oriented, and it"s our ultimate focus on to be not only by far the most reliable, trustable and honest provider, but also the partner for our customers for Tft Viewing Angle, Thin Lcd Panel, Tft Monitor Computer, Touch Display Panel,Computer Monitor Tft. We"ve been confident that there"ll become a promising future and we hope we can have long lasting cooperation with consumers from all over the world. The product will supply to all over the world, such as Europe, America, Australia,Hungary, Poland,Cambodia, Frankfurt.Our solutions have national accreditation standards for experienced, premium quality goods, affordable value, was welcomed by people around the globe. Our products will continue to increase in the order and look forward to cooperation with you, Truly must any of people goods be of interest to you, make sure you letus know. We"re likely to be delighted to give you a quotation up on receipt of one"s in depth specs.

Color TFT LCDs (Thin Film Transistor LCDs) give your product a beautiful appearance with high-resolution, full-color graphics. Our modern, automated LCD factories can create custom TFT displays for extreme temperature functionality, sunlight readability, shock and vibration durability, and more. Whether you need a stand-alone TFT LCD display or fully integrated assembly with touch and cover lens, custom FPC, or custom backlight, our experienced team can develop the right solution for your project.

Take your design to the next level with our range of TFT Displays including latest IPS TFT, circular and bar shape as well as large size TFT. With or without touch, these are fully customisable to your system requirements.

TFT-LCD technology is now fairly mature. As a result, manufacturing processes are efficient and production yields are high, leading to very competitive unit prices. Upgrading from a monochrome display to a TFT is now an affordable way to give your product an uplift.

Users of industrial display devices are wanting the same experience they have come to expect from a consumer device with all-round viewing angles. Switching to a superior IPS TFT display has become very cost effective as production increases and unit prices decrease.

Choosing a circular display for your next product design could really set you apart from your competition. Models are available from 1" to 4.2"in TFT, PMOLED and AMOLED, we have something to suit every application.

It is now possible to transform from a monochrome display to a colour display in space constrained systemsby using a letterbox shaped display. These ultra-wide displays are ideal for applications with restricted build height such as rack mount systems or landscape format front panels.

Large TFT display systems are increasingly being used for transportation information, retail signage and vending machines and kiosks. We can supply a large range of TFT solutions up to 65" diameter and in bar-style, square or rectangular configurations.

We are now offering increasing cover lens customisation options and processes to make your TFT LCD user interface truly stand out! Anders’ experienced marketers and engineers work with our manufacturing partners around the world to keep informed of the latest innovations, including mirrored glass,tinted glass, spot-facing, three dimension glass, and many more!

See below our range of TFT Displayswith sizes ranging from0.96" to 64.5" and including circular and bar type shape. All our displays can be tailored to suit your application antimicrobial coating technology,

A TFT display is a form of Liquid Crystal Display with thin film transistors for controlling the image formation. The TFT technology works by controlling brightness in red, green and blue sub-pixels through transistors for each pixel on the screen.

There are many display technologies, but do you know which one would be better for your application? Particularly when considering optimum viewing angle and contrast. We discuss 2 of the best options.

Compare IPS vs TFT displays - the TFT display is the display of choice for industrial designs, but it can have its limitations. A newer technology called IPS (in plane switching) offers better viewing angles and colours, but is it really the best choice - we discuss benefits and negatives of both types of TFT display.

Pacer offers an extensive range of colour TFT LCD panels from 1.8″ through the popular 3.5″ and 5.7″ sizes to 82″. Our range includes sunlight readable panels from 5.6″ to 70″, bar cut panels, and SMART TFT displays with built-in control. We offer TFT displays with high brightness, high contrast ratio, wide viewing angle, wide temperature operation, longer lamp life, and lower power consumption.

TFT displays are used extensively in many industrial, commercial and scientific applications, including ATMs, POS terminals, kiosks, security systems, lottery and gambling gaming machines, medical equipment, factory automation, digital advertisement signage, transportation information, and marine equipment.

TFT technology is being used to replace Mono LCD in many applications, and Raystar Optronics now offers a 5.2″ TFT module designed specifically to fit the footprint of the industry standard RG24064-series 240×64 mono graphic STN LCD. The RFS520A can replace traditional STN displays of 8×2 or 16×2 format as it shares the same 16 pin footprint.

Our TFT modules are fully supported with a variety of options including wide operating temperatures, high brightness and contrast, built-in DC-DC and temperature compensation circuitry and most with white LED backlights. Resistive Touchscreens and Projected Capacitive Touchscreens are available for most models. Many panels can be configured as a kit – see our Interface Kits page for more details.

IMPORTANT ANNOUNCEMENT – Mitsubishi has decided to end production of TFT-LCD modules, as the company is no longer able to maintain the products’ competitiveness after significant price falls in the global market. Production of TFT-LCD modules is scheduled to end in June 2022 with a Last Time Buy date of June 2021. Please contact us as soon as possible to discuss last time buy or identification of suitable alternative displays.

Raystar is a professional TFT (Thin Film Transistor) module manufacturer. Whether you need a TFT display with control board, high brightness, wide viewing angle, monochrome or bar type, we have TFT active matrix display models for you to choose from.

LITEMAX® Industrial Display solution provide a wide range of reliable displays from 5.7″ to 85″ including LCD panel modules, open frame LCD displays, outdoor displays, and panel mount monitors. LITEMAX have developed and focused on LCD display technologies such as high brightness technology, optical bonding solutions, and color enhancement technology that bring more add-on value to enhance their products.

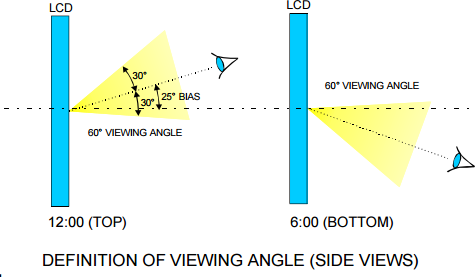

Viewing angle is a very important factor when evaluating LCD display"s performance. Understanding how to locate the optimum viewing angle and choose the right LCD display will make your product looks sharp without extra cost.

LCD viewing angle is the maximum angle from which customer can view the screen well. "Viewing well" is commonly recognized as having at least 10:1 contrast and without grayscale inversion.

At time of manufacturing, LCD manufacturer designs LCD panel in a way that it is best viewed from an angle (called Bias) offset from the perpendicular by certain degrees, to accommodate as many applications as possible. Viewing angle is the angle covers both side of Bias angle, where the LCD is still "viewing well".

When reading an LCD"s specification, you will see the term "viewing direction". Viewing direction is defined following the format of a clock. Like figure below, Z axis is Normal, X axis is Horizontal and Y axis is Vertical. An LCD"s viewing angle "above" Z axis is having 12 o"clock viewing direction. So 6 o"clock viewing direction LCD is best viewed from "below" Z axis.

Theoretically, LCD manufacturer can produce LCD with 3, 12, 9 and 6 o"clock viewing direction. But in practice, we usually look at LCD display from 12 or 6 o"clock angle.

Using a simple TN type TFT LCD as example, its viewing angle is typically 45~65 degrees. Adding extra wide polarizer film (EWP) to the TN type LCD, the viewing angle may be increased about 10 degrees. Similarly, an O-film enhancement polarizer will widen the viewing angle to 75 degree in each direction. However, these enhancements bring along contrast reduction. Adjusting LCD contrast is necessary.

Using a liquid crystal display with proper viewing angle is very important to your product"s success. And we should keep in mind that optimized contrast is crucial, too. Both parameters define the visual appearance of the LCD display and the appeal of your product. Choices are based on cost performance trade offs.

For example, if your project requires a wide viewing angle 2.4" TFT LCD. TN TFT panel with O-film solution might be better than using IPS LCD. Topway engineers are here to help you making those design decisions.

.jpg)

Let us start with the basics first; refresh the knowledge about TN and LCD displays in general, later we will talk about TFTs (Thin Film Transistors), how they differ from regular monochrome LCD displays. Then we will go on to the ghosting effect, so we will not only discuss the technology behind the construction of the TFT, but also some phenomena, like the ghosting effect, or grayscale inversion, that are important to understand when using an LCD TFT display.

Next, we will look at different technologies of the TFT LCD displays like TN, IPS, VA, and of course about transmissive and transflective LCD displays, because TFT displays also can be transmissive and transflective. In the last part we will talk about backlight.

Let us start with a short review of the most basic liquid crystal cell, which is the TN (twisted nematic) display. On the picture above, we can see that the light can be transmit through the cell or blocked by the liquid crystal cell using voltage. If you want to learn more about monochrome LCD displays and the basics of LCD displays, follow this link.

What is a TFT LCD display and how it is different from a monochrome LCD display? TFT is called an active display. Active, means we have one or more transistors in every cell, in every pixel and in every subpixel. TFT stands for Thin Film Transistor, transistors that are very small and very thin and are built into the pixel, so they are not somewhere outside in a controller, but they are in the pixel itself. For example, in a 55-inch TV set, the TFT display contains millions of transistors in the pixels. We do not see them, because they are very small and hidden, if we zoom in, however, we can see them in every corner of each pixel, like on the picture below.

On the picture above we can see subpixels, that are basic RGB (Red, Green, Blue) colors and a black part, with the transistors and electronic circuits. We just need to know that we have pixels, and subpixels, and each subpixel has transistors. This makes the display active, and thus is called the TFT display. TFT displays are usually color displays, but there are also monochrome TFT displays, that are active, and have transistors, but have no colors. The colors in the TFT LCD display are typically added by color filters on each subpixel. Usually the filters are RGB, but we also have RGBW (Red, Green, Blue, White) LCD displays with added subpixels without the filter (White) to make the display brighter.

Going a little bit deeper, into the TFT cell, there is a part inside well known to us from the monochrome LCD display Riverdi University lecture. We have a cell, liquid crystal, polarizers, an ITO (Indium Tin Oxide) layer for the electrodes, and additionally an electronic circuit. Usually, the electronic circuit consists of one transistor and some capacitors to sustain the pixel state when we switch the pixel OFF and ON. In a TFT LCD display the pixels are much more complicated because apart from building the liquid crystal part, we also need to build an electronic part.

That is why TFT LCD display technologies are very expensive to manufacture. If you are familiar with electronics, you know that the transistor is a kind of switch, and it allows us to switch the pixel ON and OFF. Because it is built into the pixel itself, it can be done very quickly and be very well controlled. We can control the exact state of every pixel not only the ON and OFF states, but also all the states in between. We can switch the light of the cells ON and OFF in several steps. Usually for TFT LCD displays it will be 8-bit steps per color, so we have 256 steps of brightness for every color, and every subpixel. Because we have three subpixels, we have a 24-bit color range, that means over 16 million combinations, we can, at least theoretically, show on our TFT LCD display over 16 million distinct colors using RGB pixels.

Now that we know how the TFT LCD display works, we can now learn some practical things one of which is LCD TFT ghosting. We know how the image is created, but what happens when we have the image on the screen for a prolonged time, and how to prevent it. In LCD displays we have something called LCD ghosting. We do not see it very often, but in some displays this phenomenon still exists.

You may have seen this phenomenon already as it is common in every display technology, and even companies like Apple put information on their websites, that users may encounter this phenomenon and how to fix it. It is called image ghosting or image persistence, and even Retina displays are not free of it.

Another issue present in TFT displays, especially TN LCD displays, is grayscale inversion. This is a phenomenon that changes the colors of the screen according to the viewing angle, and it is only one-sided. When buying a TFT LCD display, first we need to check what kind of technology it is. If it is an IPS display, like the Riverdi IPS display line, then we do not need to worry about the grayscale inversion because all the viewing angles will be the same and all of them will be very high, like 80, 85, or 89 degrees. But if you buy a more common or older display technology type, like the TN (twisted nematic) display, you need to think where it will be used, because one viewing angle will be out. It may be sometimes confusing, and you need to be careful as most factories define viewing direction of the screen and mistake this with the greyscale inversion side.

On the picture above, you can see further explanation of the grayscale inversion from Wikipedia. It says that some early panels and also nowadays TN displays, have grayscale inversion not necessary up-down, but it can be any angle, you need to check in the datasheet. The reason technologies like IPS (In-Plane Switching), used in the latest Riverdi displays, or VA, were developed, was to avoid this phenomenon. Also, we do not want to brag, but the Wikipedia definition references our website.

We know already that TN (twisted nematic) displays, suffer from grayscale inversion, which means the display has one viewing side, where the image color suddenly changes. It is tricky, and you need to be careful. On the picture above there is a part of the LCD TFT specification of a TN (twisted nematic) display, that has grayscale inversion, and if we go to this table, we can see the viewing angles. They are defined at 70, 70, 60 and 70 degrees, that is the maximum viewing angle, at which the user can see the image. Normally we may think that 70 degrees is better, so we will choose left and right side to be 70 degrees, and then up and down, and if we do not know the grayscale inversion phenomena, we may put our user on the bottom side which is also 70 degrees. The viewing direction will be then like a 6 o’clock direction, so we call it a 6 o’clock display. But you need to be careful! Looking at the specification, we can see that this display was defined as a 12 o’clock display, so it is best for it to be seen from a 12 o’clock direction. But we can find that the 12 o’clock has a lower viewing angle – 60 degrees. What does it mean? It means that on this side there will be no grayscale inversion. If we go to 40, 50, 60 degrees and even a little bit more, probably we will still see the image properly. Maybe with lower contrast, but the colors will not change. If we go from the bottom, from a 6 o’clock direction where we have the grayscale inversion, after 70 degrees or lower we will see a sudden color change, and of course this is something we want to avoid.

To summarize, when you buy older technology like TN and displays, which are still very popular, and Riverdi is selling them as well, you need to be careful where you put your display. If it is a handheld device, you will see the display from the bottom, but if you put it on a wall, you will see the display from the top, so you need to define it during the design phase, because later it is usually impossible or expensive to change the direction.

We will talk now about the other TFT technologies, that allow us to have wider viewing angles and more vivid colors. The most basic technology for monochrome and TFT LCD displays is twisted nematic (TN). As we already know, this kind of displays have a problem with grayscale inversion. On one side we have a higher retardation and will not get a clear image. That is why we have other technologies like VA (Vertical Alignment), where the liquid crystal is differently organized, and another variation of the TFT technology – IPS which is In-Plane Switching. The VA and IPS LCD displays do not have a problem with the viewing angles, you can see a clear image from all sides.

Nowadays all TV sets, tablets and of course mobile phones are IPS or VA. You can turn them around and see the image clear from all sides. But, for monitor applications the TN technology is still widely used, because the monitor usually is in front of you and most of the time you look directly at it, from top, left or right side, but very rarely from the bottom, so the grayscale inversion viewing angle can be placed there. This technology still is very practical because it is affordable and has some advantages for gamers because it is very fast.

Apart from the different organization of the liquid crystals, we also organize subpixels a little bit differently in a VA and IPS LCD displays. When we look closer at the TN display, we will just see the subpixels with color filters. If we look at the VA or IPS display they will have subpixels of subpixels. The subpixels are divided into smaller parts. In this way we can achieve even wider viewing angles and better colors for the user, but of course, it is more complicated and more expensive to do.

The picture above presents the TN display and grayscale inversion. For IPS or VA technology there is no such effect. The picture will be the same from all the sides we look so these technologies are popular where we need wide viewing angles, and TN is popular where we don’t need that, like in monitors. Other advantages of IPS LCD displays are they give accurate colors, and wide viewing angles. What is also important in practice, in our projects, is that the IPS LCD displays are less susceptible to mechanical force. When we apply mechanical force to the screen, and have an optically bonded touch screen, we push the display as well as squeeze the cells. When we have a TN display, every push on the cell changes the image suddenly, with the IPS LCD displays with in-plane switching, different liquid crystals organization, this effect is lesser. It is not completely removed but it is much less distinct. That is another reason IPS displays are very popular for smartphones, tablets, when we have the touchscreens usually optically bonded.

If we wanted to talk about disadvantages, there is a question mark over it, as some of them may be true, some of them do not rely on real cases, what kind of display, what kind of technology is it. Sometimes the IPS displays can have higher power consumption than others, in many cases however, not. They can be more expensive, but not necessarily. The new IPS panels can cost like TN panels, but IPS panels definitely have a longer response time. Again, it is not a rule, you can make IPS panels that are very fast, faster than TN panels, but if you want the fastest possible display, probably the TN panel will be the fastest. That is why the TN technology is still popular on the gaming market. Of course, you can find a lot of discussions on the internet, which technology is better, but it really depends on what you want to achieve.

Now, let us look at the backlight types. As we see here, on the picture above, we have four distinct types of backlight possible. The most common, 95 or 99 per cent of the TFT LCD displays on the market are the transmissive LCD display type, where we need the backlight from the back. If you remember from our Monochrome LCD Displays lecture, for transmissive LCD displays you need the backlight to be always on. If you switch the backlight off, you will not see anything. The same as for monochrome LCD displays, but less popular for TFT displays, we have the transflective LCD display type. They are not popular because usually for transflective TFT displays, the colors lack in brightness, and the displays are not very practical to use. You can see the screen, but the application is limited. Some transflective LCD displays are used by military, in applications where power consumption is paramount; where you can switch the backlight off and you agree to have lower image quality but still see the image. Power consumption and saving energy is most important in some kind of applications and you can use transflective LCD displays there. The reflective type of LCD displays are almost never used in TFT. There is one technology called Low Power Reflective Displays (LPRD) that is used in TFT but it is not popular. Lastly, we have a variation of reflective displays with frontlight, where we add frontlight to the reflective display and have the image even without external light.

Just a few words about Low Power Reflective Displays (LPRD). This kind of display uses environmental light, ambient light to reflect, and produce some colors. The colors are not perfect, not perfectly clear, but this technology is becoming increasingly popular because it allows to have color displays in battery powered applications. For example, a smartwatch would be a case for that technology, or an electrical bike or scooter, where we can not only have a standard monochrome LCD display but also a TFT LCD color display without the backlight; we can see the image even in

strong sunlight and not need backlight at all. So, this kind of TFL LCD display technology is getting more and more popular when we have outdoor LCD displays and need a low power consumption.

On the picture above, we have some examples of how transmissive and reflective LCD displays work in the sunlight. If we have a simple image, like a black and white pattern, then on a transmissive LCD display, even with 1000 candela brightness, the image probably will be lower quality than for a reflective LCD display; if we have sunlight, we have very strong light reflections on the surface of the screen. We have talked about contrast in more detail in the lecture Sunlight Readable Displays. So, reflective LCD displays are a better solution for outdoor applications than transmissive LCD displays, where you need a really strong backlight, 1000 candela or more, to be really seen outdoors.

To show you how the backlight of LCD displays is built, we took the picture above. You can see the edge backlight there, where we have LEDs here on the small PCB on the edge, and we have a diffuser that distributes the light to the whole surface of LCD screen.

In addition to the backlight, we have something that is called a frontlight. It is similar to backlight, it also uses the LEDs to put the light into it, but the frontlight needs to be transparent as we have the display behind. On the example on the picture above we can see an e-paper display. The e-paper display is also a TFT display variation, but it is not LCD (liquid crystal), it is a different technology, but the back of the display is the same and it is reflective. The example you see is the Kindle 4 eBook reader. It uses an e-paper display and a frontlight as well, so you can read eBooks even during the night.

For many years, TFT displays have been the dominating technology in visualization. TFT LCDs are all around in our daily lives — in consumer and automotive applications, in our business environments, in healthcare, and within communication devices, home appliances, and factory automation products. While there are many LCD products available today, they’re not all suitable for every application. This is especially the case for industrial LCD monitors. To determine the best LCD display for your application, it’s important to understand your target market and its unique design issues.

The vast majority of LCD displays are designed for consumer devices such as smartphones, cameras, tablet computers, and gaming devices. But they have very different requirements than those for industrial applications. Due to very competitive pricing and quick production cycles, consumer display modules don’t always incorporate the durability, reliability, and advanced features required to survive in an industrial environment. Product life cycles are also typically much shorter in consumer applications. Screens manufactured for these applications are generally only available for one, in best case two years.

The ability to withstand temperature variations as well as shock and vibration is also a key consideration when selecting displays for today’s industrial applications. They must be resilient enough to withstand frequent bumps or jiggles by machine operators and surrounding equipment, and also must be able to handle various operating temperatures.

Industrial displays are typically housed in an enclosure as part of a larger piece of equipment. In these situations, the heat generated by the surrounding equipment gets trapped within the enclosure, which can be detrimental to many displays. Therefore, it’s important to keep the real storage and operating temperature requirements in mind when choosing a display. While measures can be taken to dissipate the generated heat — such as using fans within the enclosure — the most efficient way to ensure compliance with the storage and operating temperature requirements is to select a display that is optimized for these types of environments. Fortunately, improvements in liquid-crystal materials have made it possible to extend the operating temperature ranges of LCDs from –30 to 80°C presently.

It’s important that displays used in industrial applications support clear and precise viewing from multiple angles under a variety of ambient light conditions. The brighter the environment, the more difficult it can be to read a standard transmissive LCD display with a typical brightness of 250 to 300 cd/m2. NVD has developed displays that can perform in the 800-cd/m2-and-higher range by implementing high-efficiency LEDs for the backlight unit– if necessary, in combination with special brightness enhancement films.

Increasing the display’s contrast ratio is another effective way that display manufacturers can improve display readability in bright environments. Typical contrast ratios for non-industrial displays are in the range of 200:1 to 300:1, which may not be sufficient when a machine operator is viewing the display from a distance. Displays with contrast ratios around 500:1 or greater are better suited for industrial environments. Another benefit of this method is that it doesn’t increase power consumption.

Transflective LCDs are a good solution for environments with variable lighting. Having both transmissive and reflective characteristics, transflective LCDs have the option of using a backlight in dim lighting (transmissive mode), as well as using reflective properties in bright lighting (reflective mode). This reduces power consumption and heat production in reflective mode since the backlight isn’t used.

Multi-angle readability is another key selection factor. In a typical industrial environment, a machine operator is more likely to be positioned at an off-angle rather than right in front of the screen. Implementing a display designed for consumer applications typically doesn’t work well in this situation, as there is image distortion and color shifting when viewed at an angle. But, a number of technologies have been employed to improve off-angle viewing in displays, making them suitable for industrial applications. Some film-based technologies yield viewing angles of 160º horizontally and 140º vertically, but in some cases, this is still not sufficient. In-plane switching technology (IPS), multi-domain vertical alignment (MVA), and fringe field switching (FFS)offer alternatives. These proprietary technologies are able to achieve viewing angles of almost 90-degrees into all four directions without any color shift.

Size and resolution also play a role in overall readability. Displays between 2 and 15-inch diagonal sizes are used most often in industrial applications. These sizes provide sufficient area to view figures, waveforms, and other graphical data without taking up too much real estate on a piece of equipment.

From an aspect ratio 4:3 initially, industrial displays are now shifting to wide formats with WVGA to WXGA resolutions. The wide-aspect format enables users to view longer waveforms and more data on a single display. These display modules can also be designed to incorporate touch-key functions, allowing equipment manufacturers to skip physical switches and buttons and design HMIs based more on software than hardware.

.jpg)

4. The Product Displays The Image Outside The Door Clearly On The Screen Of The Host Inside The Door, Allowing The Master To See The Visitors Outside The Door At Home, And Supports Taking Pictures Manually.

Technology can be confusing because it evolves quickly, and there are complex acronyms for almost everything. If you are thinking ofbuildinga monitor or want to learn about the technology, you will encounter the term TFT Monitor at some point.

A lot goes on behind the glass surface, and we will look at this in comparison to other technologies to paint a clear picture of what TFT is and how it evolved.

TFT is an acronym for Thin Film Transistor, and it is a technology used in Liquid Crystal Display screens. It came about as an improvement to passive-matrix LCDs because it introduced a tiny, separate transistor for each pixel. The result? Such displays could keep up with quick-moving images, which passive-matrix LCDs could not do.

Also, because the transistors are tiny, they have a low power consumption and require a small charge to control each one. Therefore, it is easy to maintain a high refresh rate, resulting in quick image repainting, making a TFT screen the ideal gaming monitor.

The technology improved on the TN (Twisted Nematic) LCD monitor because the shifting pattern of the parallel, horizontal liquid crystals gives wide viewing angles. Therefore, IPS delivers color accuracy and consistency when viewed at different angles.

Both TFT and IPS monitors are active-matrix displays and utilize liquid crystals to paint the images. Technically, the two are intertwined because IPS is a type of TFT LCD. IPS is an improvement of the old TFT model (Twisted Nematic) and was a product of Hitachi displays, which introduced the technology in 1990.

The monitors can create several colors using the different brightness levels and on/off switches. But unlike OLED, both TFT and IPS do not emit light, so most have bright fluorescent lamps or LED backlights to illuminate the picture. Also, neither of them can produce color, so they have an RGB color filter layer.

Easy to Integrate and Update: By combining large-scale semiconductor IC and light source technology, TFTs have the potential for easy integration and updating/development.

Wide Application Range: TFTs are suitable for mobile, desktop screens, and large-screen TVs. Additionally, the technology can operate at a temperature range of -20°C to +50°C, while the temperature-hardened design can remain functional at temperatures not exceeding -80°C.

Impressive Display Effect: TFT displays use flat glass plates that create an effect of flat right angles. Combine this with the ability of LCDs to achieve high resolutions on small screen types, and you get a refreshing display quality.

Good Environmental Protection: The raw materials used to make TFT displays produce zero radiation and scintillation. Thus, the technology does not harm the user or the environment.

Mature Manufacturing Technology: TFT technology came into existence in the 60s. Over time, its manufacturing technology has matured to have a high degree of automation, leading to cheaper, large-scale industrial production.

Wide View Angle: One of the main advantages of IPS screens is their wide viewing angle due to the horizontal liquid crystals. They do not create halo effects, grayscale, or blurriness, but these are common flaws with TFTs.

Better Color Reproduction and Representation: The pixels in TFTs function perpendicularly after activation with the help of electrodes. However, IPS technology makes the pixels function while parallel horizontally. Thus, they reflect light better and create a more original and pristine image color.

Faster Frequency Transmittance: Compared to TFT, IPS screens transmit frequencies at about 25ms, which is 25x faster. This high speed is necessary to achieve wide viewing angles.

Liquid Crystal Display (LCD) is a front panel display that utilizes liquid crystals held between two layers of polarized glass to adjust the amount of blocked light. The technology does not produce light on its own, so it needs fluorescent lamps or white LEDs.

As explained earlier, TFT improved on the passive-matrix LCD design because it introduces a thin film transistor for each pixel. The technology reducescrosstalkbetween the pixels because each one is independent and does not affect the adjacent pixels.

LED screens are like the new kids on the block in the display market, and they operate very differently from LCDs. Instead of blocking light, LEDs emit light and are thinner, provide a faster response rate, and are more energy-efficient.

Since IPS is a type of TFT, when comparing the two, we are essentially looking at the old Thin-Film Transistor technology (Twisted Nematic) vs. the new (IPS). Even though TN is relatively old, this digital display type has its advantages, a vital one being the fast refresh rate. This feature makes such screens the preferred option by competitive gamers. If you have any inquiries about the technology,contact usfor more information.

Over the last 15 years we have been industry leaders in the design and manufacturing of display products. DLC offers monochrome TN/STN, TFT and OLED displays including all other ancillary components related to displays. Our transflective TFT displays enable viewing under direct sunlight, which provides tremendous value and is appealing to customers worldwide. IPS and LTPS panels provide a wide viewing angle, another favorable aspect in the electronic display market.

Our product portfolio contains more than 200 different models of TN, STN, DSTN monochrome and TFT color displays, as well as many monochrome OLED displays, all available in sizes ranging from 0.49 to 15 inch, and working temperatures between -40℃ and 90℃. Our products are widely used in automotive, medical and military applications.

The DLC factory area and offices combine for over 2000m2, and is run by our dedicated and hardworking employees of over 370 people. Our main production equipment includes: Two Toray CL2000 automatic COG bonding machines, which support a maximum size of 12-inch LCD panel bonding with capacity of 600-800 pieces per hour per machine; Two semi-automatic COG bonding machines; and several ACF and FPC bonding machines. We also have three end assembly lines with capacity of 1kk units per month. In addition, we added a new touch panel production line last year, which focuses on the design and manufacturing of various types of resistive and capacitive touch panels to seamlessly meet the growing demands for customized solutions.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey