2.4 inch tft lcd touch screen module for arduino code made in china

Arduino library for 8-bit TFT LCDs such as ILI9325, ILI9328, etc - GitHub - adafruit/TFTLCD-Library: Arduino library for 8-bit TFT LCDs such as ILI9325, ILI9328, etc

Adafruit GFX graphics core Arduino library, this is the "core" class that all our other graphics libraries derive from - GitHub - adafruit/Adafruit-GFX-Library: Adafruit GFX graphics core A...

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

After trying for several days trying the solutions I found on the web, and none works 100%. So I decided to do an library specific to this controller.

I changed the Adafruit libraries for TFT: GFX , TFTLCD and TouchScreen. I join all in this one library, the library SPFD5408, to avoid problems with duplicate libraries and enables also have the original library Adafruit ready for use in other projects with another TFT hardware.

Arduino has always helped to build projects easily and make them look more attractive. Programming an LCD screen with touch screen option might sound as a complicated task, but the Arduino libraries and shields had made it really easy. In this project we will use a 2.4” Arduino TFT LCD screen to build our own Arduino Touch Screen calculator that could perform all basic calculations like Addition, Subtraction, Division and Multiplication.

Before we actually dive into the project it is important to know, how this 2.4” TFT LCD Module works and what are the types present in it. Let us take a look at the pinouts of this 2.4” TFT LCD screen module.

As you can see there are 28 pins which will perfectly fit into any Arduino Uno / Arduino Mega Board. A small classification of these pins is given in the table below.

As you can see the pins can be classified in to four main classifications such as LCD Command Pins, LCD Data Pins, SD Card Pins and Power Pins, We need not know much about the detailed working of these pins since they will be take care by our Arduino Library.

You can also find an SD card slot at the bottom of the module shown above, which can be used to load an SD card with bmp image files, and these images can be displayed in our TFT LCD screen using the Arduino Program.

Another important thing to note is your Interface IC. There are many types of TFT modules available in the market starting from the original Adafruit TFT LCD module to cheap Chinese clones. A program which works perfectly for your Adafruit shield might not work the same for Chinese breakout boards. So, it is very important to know which types of LCD display your are holding in hand. This detail has to be obtained from the vendor. If you are having a cheap clone like mine then it is most probably using the ili9341 driver IC.You can follow this TFT LCD interfacing with Arduino tutorial to try out some basic example programs and get comfortable with the LCD screen. Also check out our other TFT LCD projects with Arduino here:

If you planning to use the touch screen function of your TFT LCD module, then you have to calibrate it to make it work properly. A LCD screen without calibration might work unlikely, for instance you might touch at one place and the TFT might respond for a touch at some other place. These calibrations results will not be similar for all boards and hence you are left on your own to do this.

The best way to calibrate is to use the calibration example program (comes with library) or use the serial monitor to detect your error. However for this project since the size of buttons is large calibration should not be a big problem and I will also explain how you can calibrate your screen under the programming section below.

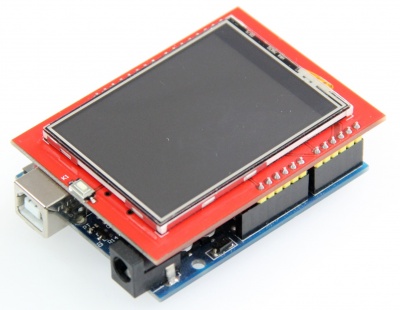

The 2.4” TFT LCD screen is a perfect Arduino Shield. You can directly push the LCD screen on top of the Arduino Uno and it will perfectly match with the pins and slid in through. However, as matters of safety cover the Programming terminal of your Arduino UNO with a small insulation tape, just in case if the terminal comes in contact with your TFT LCD screen. The LCD assembled on UNO will look something like this below.

We are using the SPFD5408 Library to get this arduino calculator code working. This is a modified library of Adafruit and can work seamlessly with our LCD TFT Module. You can check the complete program at the end of this Article.

Now, open Arduino IDE and select Sketch -> Include Librarey -> Add .ZIP library. A browser window will open navigate to the ZIP file and click “OK”. You should notice “Library added to your Libraries” on the bottom-left corner of Arduino, if successful. A detailed guide to do the same is given in the Interfacing Tutorial.

Now, you can use the code below in your Arduino IDE and upload it to your Arduino UNO for the Touch Screen Calculator to work. Further down, I have explained the code into small segments.

We need three libraries for this program to work; all these three libraries were given in the ZIP file you downloaded from the above provided link. I have simply included them in the code as shown below.

As said earlier we need to calibrate the LCD screen to make it work as expected, but don’t worry the values given here are almost universal. The variables TS_MINX, TS_MINY, TS_MAXX, and TS_MAXY decide the calibration of the Screen. You can toy around them if you feel the calibration is not satisfactory.

As we know the TFT LCD screen can display a lot of colours, all these colours have to be entered in hex value. To make it more human readable we assign these values to a variable as shown below.

Okay now, we can get into the programming part. There are three sections involved in this program. One is creating a UI of a calculator with buttons and display. Then, detecting the buttons based on the users touch and finally calculating the results and display them. Let us get through them one by one.

Another challenging task is detecting the user touch. Every time the user touches somewhere we will able to how where the X and Y position of the pixel he touched. This value can be displayed on the serial monitor using the println as shown below.

Since we have designed the box with width and height of 60 pixel each and have four Rows and for columns starting from (0,0). The position of each box can be predicted as shown in below picture.

Now, since we know the position of all the boxes. When a user touches anywhere we can predict where he has touched by comparing his (X,Y) values with the value for each box as shown below.

The final step is to calculate the result and display them on TFT LCD Screen. This arduino calculator can perform operation with 2 numbers only. These two numbers are named as variables “Num1” and “Num2”. The variable “Number” gives and takes value from Num1 and Num2 and also bears the result.

When a use presses a button, one digit is added to number. When another button is pressed, the previous one digit is multiplied with 10 and the new number is added with it. For example, if we press 8 and then press 5 and then press 7. Then first the variable will hold 8 then (8*10)+5=85 then (85*10)+7 = 857. So finally the variable will have the value 857 with it.

When we perform any operation like addition, when the users presses the addition button the value from Number will be transferred to Num1 and then Number will be made zero so that it gets ready to take the input for second number.

The working of this Arduino Touch Screen Calculator is simple. You have to upload the below given code on your Arduino and fire it up. You get the calculator displayed on your LCD screen.

Now, you can enter any number and perform your calculations. It is limited to only two operand and only operator for now. But, you can tweak the code to make it have lots of option.

You have to press the “C” to clear the value on screen each time after performing a calculation. Hope you understood the project and enjoyed building something similar. If you have any doubts feel free to post them on forums or on the comment section below. See you next time with another interesting project until then happy computing!!

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This module is a 2.4-inch TFT LCD module with “320X240” resolution and 65K color display. It is suitable for Arduino Uno and Mega2560 development boards, and also supports SD card expansion function. It uses 8-bit parallel port communication, and the driver IC is ILI9341.

The 2.4-inch display is a ready-made shield for Arduino Uno, which can also be placed on the Arduino Mega. The pins of this shield are designed to be easily installed on the Arduino. The bad point about these modules is that they use all Arduino Uno pins.

Open the downloaded file and upload the main.ino code on your Arduino Board. This code is for testing the display module and comes with full screen calibration.

Kuongshun Electronic, one of the international well-known manufacturers and suppliers of 2.4 inch tft touch screen module for uno r3 red which is situated in China, now has quality products for sale. We are equipped with a group of professional and experienced workers, as well as advanced equipment. You can rest assured to buy discount and low price 2.4 inch tft touch screen module for uno r3 red made in China from us and check the pricelist with us.

Note: The following picture is the connection diagram of the 2.8-inch TFT screen and Arduino uno, but this product is connected in exactly the same way.

If the Arduino board has an ICSP interface, set the SPI Config switch on the display module to the ICSP direction (by default) (the company"s Arduino UNO motherboard has an ICSP interface, just plug it in directly.).

This product uses the same LCD control chip and touch panel control chip as the 3.5-inch TFT screen of the same series of our company, so the code is completely compatible. The following takes 3.5-inch TFT as an example to introduce.

LCD_Show can display colorful patterns with different shapes and times. LCD_ShowBMP is for displaying the picture in BMP, and LCD_Touch is for using the touching function.

The display controller used in this product is ILI9486, and we need to initialize the controller through the SPI communication protocol, and the initialization functions are written in LCD_Driver.cpp.

The function functions related to the screen display are written in LCD_GUI.cpp. The function of each function and the parameters passed are explained in the source code. You can call it directly when you need to use it.

Before using LCD_ShowBMP to display pictures, first copy the pictures in the PIC folder in the data to the root directory of the SD card (you should understand that in the root directory, that is to save the pictures directly to the SD card, do not put them in any subfolders folder.).

Here is an explanation. This demo shows that the BMP picture first reads the picture data in the BMP format in the SD card through the SPI protocol, and then displays the data as an image.

These functions are all written in LCD_Bmp.cpp. In fact, the image data in BMP format with a specific file name is read from the SD card, and then the display function written by us is called to re-express the data as an image.

No matter which platform this method is on, the principle is similar. Interested friends can check the relevant information and study the relevant code carefully.

After running this demo, there are five colors on the right side of the screen. Black is the default color in the system, and you can touch it to choose the brush color. Click AD button, and click the red "+" to calibrate the screen with the prompts. Click the right corner "CLEAR" to clear the drawing board.

In fact, you can also use Image2Lcd image modulo software to convert images of different sizes and formats into array data, and then use the functions we wrote to display them.

The data sheets of all control chips are given in the information for your reference. If you want to know more about why the underlying functions are written like this, go to the data sheets and look at them!

Note: The following picture is the connection diagram of the 2.8-inch TFT screen and XNUCLEO-F103RB, but this product is connected in exactly the same way.

The demos are developed based on the HAL library. Download the program, find the STM32 program file directory, and open STM32\XNUCLEO-F103RB\lcd4in-demo\MDK-ARM\ lcd4in-demo.uvprojx.

This product uses the same LCD control chip and touch panel control chip as the 3.5-inch TFT screen of the same series of our company, so the code is completely compatible. The following takes 3.5-inch TFT as an example to introduce.

After running the demo, it displays some characters and patterns at first, then displays four pictures, and finally displays the touch sketchpad function. Actually, three projects in the Arduino platform code are integrated in the main function, we place the three main functions in sequence and place TP_DrawBoard(); in an infinite loop to achieve the above functions.

Before using LCD_ShowBMP to display pictures, copy the pictures in the PIC folder in the data to the root directory of the SD card, and then insert the SD card into the SD card slot on the back of the screen to start the download program verification.

It should be noted here that the SD card should be in the FAT format, and the picture should be 480*320 pixels with 24-bit color depth and BMP format.

In fact, you can also use Image2Lcd image modulo software to convert images of different sizes and formats into array data, and then use the functions we wrote to display them.

The data sheets of all control chips are given in the information for your reference. If you want to know more about why the underlying functions are written like this, go to the data sheets and look at them!

In this tutorial, you will learn how to use and set up 2.4″ Touch LCD Shield for Arduino. First, you’ll see some general information about this shield. And after learning how to set the shield up, you’ll see 3 practical projects.

The role of screens in electronic projects is very important. Screens can be of very simple types such as 7 Segment or character LCDs or more advanced models like OLEDs and TFT LCDs.

One of the most important features of this LCD is including a touch panel. If you are about to use the LCD, you need to know the coordinates of the point you touch. To do so, you should upload the following code on your Arduino board and open the serial monitor. Then touch your desired location and write the coordinates displayed on the serial monitor. You can use this coordination in any other project./*TFT LCD - TFT Touch CoordinateBased on Librery Examplemodified on 21 Feb 2019by Saeed Hosseinihttps://electropeak.com/learn/*/#include

Displaying Text and Shapes on Arduino 2.4 LCD/*TFT LCD - TFT Simple drivingmodified on 21 Feb 2019by Saeed Hosseinihttps://electropeak.com/learn/*/#include

Displaying BMP pictures/*This code is TFTLCD Library Example*/#include

To display pictures on this LCD you should save the picture in 24bit BMP colored format and size of 240*320. Then move them to SD card and put the SD card in the LCD shield. we use the following function to display pictures. This function has 3 arguments; the first one stands for the pictures name, and the second and third arguments are for length and width coordinates of the top left corner of the picture.bmpdraw(“filename.bmp”,x,y);

Create A Paint App w/ Arduino 2.4 Touchscreen/*This code is TFTLCD Library Example*/#include

Final NotesIf you want to display pictures without using an SD card, you can convert it to code and then display it. You can display even several photos sequentially without delay to create an animation. (Check this)But be aware that in this case, Arduino UNO may not be suitable (because of low processor speed). We recommend using the Arduino Mega or Arduino DUE.

This post is an introduction to the Nextion display with the Arduino. We’re going to show you how to configure the display for the first time, download the needed resources, and how to integrate it with the Arduino UNO board. We’ll also make a simple graphical user interface to control the Arduino pins.

Nextion is a Human Machine Interface (HMI) solution. Nextion displays are resistive touchscreens that makes it easy to build a Graphical User Interface (GUI). It is a great solution to monitor and control processes, being mainly applied to IoT applications.

The Nextion has a built-in ARM microcontroller that controls the display, for example it takes care of generating the buttons, creating text, store images or change the background. The Nextion communicates with any microcontroller using serial communication at a 9600 baud rate.

The best model for you, will depend on your needs. If you’re just getting started with Nextion, we recommend getting the 3.2” size which is the one used in the Nextion Editor examples (the examples also work with other sizes, but you need to make some changes). Additionally, this is the most used size, which means more open-source examples and resources for this size.

Connecting the Nextion display to the Arduino is very straightforward. You just need to make four connections: GND, RX, TX, and +5V. These pins are labeled at the back of your display, as shown in the figure below.

You can power up the Nextion display directly from the Arduino 5V pin, but it is not recommended. Working with insufficient power supply may damage the display. So, you should use an external power source. You should use a 5V/1A power adaptor with a micro USB cable. Along with your Nextion display, you’ll also receive a USB to 2 pin connector, useful to connect the power adaptor to the display.

The best way to get familiar with a new software and a new device is to make a project example. Here we’re going to create a user interface in the Nextion display to control the Arduino pins, and display data.

The user interface has two pages: one controls two LEDs connected to the Arduino pins, and the other shows data gathered from the DHT11 temperature and humidity sensor;

At this moment, you can start adding components to the display area. For our project, drag three buttons, two labels and one slider, as shown in the figure below. Edit their looks as you like.

All components have an attribute called objname. This is the name of the component. Give good names to your components because you’ll need them later for the Arduino code. Also note that each component has one id number that is unique to that component in that page. The figure below shows the objname and id for the slider.

You should trigger an event for the touchable components (the buttons and the slider) so that the Arduino knows that a component was touched. You can trigger events when you press or when you release a component.

To do that, select one of the buttons, and in the event window, select the Touch Release Event tab, and put a tick on the Send Component ID option. Repeat this process for the other button, and the slider.

Notice that we have labels to hold the units like “ºC”, “ºF” and “%”, and empty labels that will be filled with the readings when we have our Arduino code running.

Once the GUI is ready, you need to write the Arduino code so that the Nextion can interact with the Arduino and vice-versa. Writing code to interact with the Nextion display is not straightforward for beginners, but it also isn’t as complicated as it may seem.

A good way to learn how to write code for the Arduino to interact with the Nextion display is to go to the examples folder in the Nextion library folder and explore. You should be able to copy and paste code to make the Arduino do what you want.

The first thing you should do is to take note of your components in the GUI that will interact with the Arduino and take note of their ID, names and page. Here’s a table of all the components the code will interact to (your components may have a different ID depending on the order you’ve added them to the GUI).

Here you use the page ID, the component ID and their name – just check the table above with all the components. To define a text you use NexText, to define a button you use NexButton, for a slider you use NexSlider and for the progress bar you use NexProgressBar.

For the slider (h0), you have the following function that writes the current slider position on the tSlider label and sets led2 brightness accordingly:

Finally, you need a function for the bUpdate (the update button). When you click this button the DHT temperature and humidity sensor reads temperature and humidity and displays them on the corresponding labels, as well as the humidity on the progress bar. That is the bUpdatePopCallback() function.

In the setup(), you need to attach the functions created to the corresponding events. For example, when you click on the bOn button, the bOnPopCallback function will be triggered.

In this post we’ve introduced you to the Nextion display. We’ve also created a simple application user interface in the Nextion display to control the Arduino pins. The application built is just an example for you to understand how to interface different components with the Arduino – we hope you’ve found the instructions as well as the example provided useful.

In our opinion, Nextion is a great display that makes the process of creating user interfaces simple and easy. Although the Nextion Editor has some issues and limitations it is a great choice for building interfaces for your electronics projects. We have a project on how to create a Node-RED physical interface with the Nextion display and an ESP8266 to control outputs. Feel free to take a look.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey