ito lcd panel quotation

Many LCD technologies, such as monochrome character, dot matrix and segment displays, make use of ITO glass. Even though ITO glass has been in existence for some time, it is still an important aspect in LCD designs and will be covered in the article below.

The article about ITO glass was written by Barbara Dutra, an exchange engineering student from Brazil, who is currently an intern at Focus Display Solutions. Her current job responsibilities include ISO certification, Test and quality insurance of inbound LCD displays and writing technical articles.

The Indium tin oxide is a material used in modern devices that manipulates ambient light. ITO is a good material, because it has a good response time to conduct electricity and an appropriate transparency for the emission of light.

It is also used in flat panel TVs where each pixel is turned ON or OFF by a pair of transparent electrodes ITO. Touch screen displays are the latest innovations using that material.

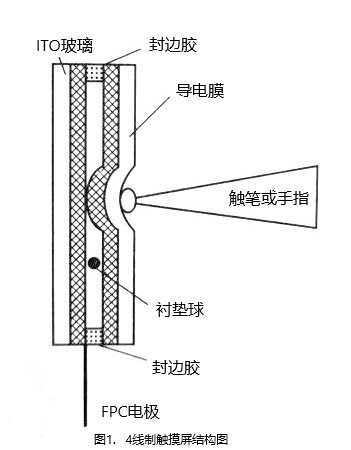

The first touchscreen devices were sold with a pen and were manufactured with two layers of ITO glass separated by a small gap. When the resistive screens were touched with a pen, the two layers came into contact, creating a short circuit and allowing a current to pass and be detected by the device.

New devices, implementing newer technology, use the finger to allow the short circuit that identifies the position without the need of a pen. The touch in the screen changes its capacitance at that location and this change is perceived by a single layer of ITO.

The ITO glass is a thin transparent film similar to common glass, but unlike glass, it is a conductor of electricity because it is a kind of transparent conductive oxide (TCO). So it has the property of reflecting electromagnetic radiation in the infrared region (spectrum) and having a low electrical resistivity.

The ITO is the best TCO because it is a good combination of transparency and conductivity. Because of its transparency, ITO glass does not absorb light photons. Absorption occurs when the photon energy corresponds to what is necessary to let the electron in an excited state.

To produce the thin films of ITO glass, it is common to use sputtering techniques with radio frequency assisted by constant magnetic field (RF magnetron sputtering). The sputtering technique involves the transport of molecules or atoms ejected from a source (also called the target) to a substrate.

The ITO glass is an expensive material because of the indium mineral, but this is not the biggest problem. The biggest challenge is the shortage expected to take place in a few years because indium is a rare mineral.

This is bad news because the market of touch screen devices is in an expansion mode and every day the demand increases since bigger and bigger screens are created using a larger amount of ITO.

Some hypotheses are the cadmium oxide, silver nanowires and graphene (carbon nanomaterial). The first is almost as transparent as ITO glass and has a greater capacity of conduct electricity, but it is very unstable and deteriorates quickly (half-life).

One solution to this problem is to apply 20% of ITO in the cadmium oxide just to create a film of protection on the material. Another problem, an environmental one, is that this oxide is more toxic and demands care in the manipulation and disposal of waste. This could be a future environmental problem.

Silver is very similar to high quality ITO, but it is quite flexible. Unfortunately silver nanowires are ten times more expensive to produce than the already expensive ITO and cheaper metals seem to not work.

The graphene can be used for touch screen displays because of the characteristics but is an expensive technology today. In the future the price between ITO glass and carbon nanotubes will be equivalent because of the lack of indium and carbon segment growth cheapening their cost. So, the graphene looks a promising option.

But that does not rule out this option because the processing power is in expansion. Anyway these free indium techniques do not solve a fundamental problem: with or without touch, the electrodes that provide power to the pixels on the LCD screen depend on the ITO glass. This will be solved only with the development of new materials that emulate the highly desirable ability of the ITO glass to combine transparency and conductivity.

It is safe to say that the cost of LCD displays does not look to be decreasing any time soon, if at all. Part of the reason for higher cost displays is not only the potential cost increase due to an ITO shortage. But a labor shortage that is taking place in many LCD manufacturing locations.

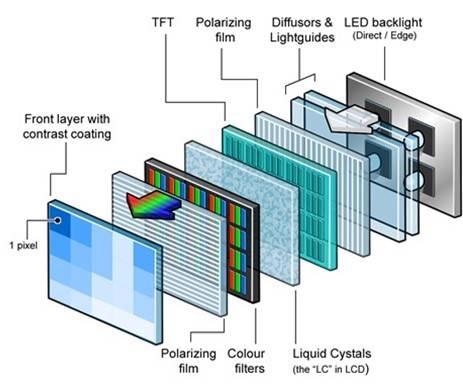

From its structure, LCD is a flat display device. It looks like a sandwich that consists of a layer of liquid crystal, front and back ITO glasses, and front and back polarizer films. A liquid crystal cell is composed of front and back ITO glasses and is filled with liquid crystal and surrounded by the sealing glue (typically epoxy resin), only a liquid crystal entrance is left. There is a tiny gap between two glasses, only about a few um, which is filled by liquid crystal in vacuum conditions through the entrance. When the gap is full, the entrance will be sealed with epoxy resin, and the liquid crystal cell is done. And the front and back polarizer films are attached to the surface of the liquid crystal cell. There is an ITO conductive film between the liquid crystal and the glass. The function of the film is to bring the signal from the outside to the liquid crystal. The liquid crystal is arrayed systematically and orderly in the cell when the power is off. When the power is on, it will rearrange according to the rules we have predesigned, so it has special optical properties and electrical properties at the same time.

And let us see what ITO glass is. We only add a layer of Indium Tin Oxide conductive film to the surface of normal glass, and it becomes the ITO glass. It is very simple, isn’t it?

By the way, if the ITO glass is very small, say 8*20 mm, it will definitely increase the cost of labour. If is very large, say 150*200 mm, it will increase the cost of material loss because it will be a great loss if we accidentally break a piece of glass.

One of my German clients told me there was an unexpected segment on 6321 LCD screen. That was because we haven’t completely cleaned the useless parts of ITO film. I have to protect my client’s privacy, so I can’t reveal the blueprint of 6321 LCD screen in this post.

Two, we need additional production processes and labour costs to make the view direction. Please see my post to learn more about view direction. In other words, the view direction of LCD screen is achieved and controlled by ITO glass.

As we talk about the tooling fee, we have to refer to the quantity of the first batch. We usually send 5~20 pieces of LCD screen samples to our customers. If you have received our samples, and you want a small batch of order like 100 pieces or 500 pieces, I am sorry to inform you that we can’t make it because the quantity you demand is below the MOQ (Minimum Order Quantity) and the wastage of starting up the machine is great. Only in mass production will the machine which makes ITO glass begin to operate. Therefore, if you want a small batch of orders, I strongly suggest that it goes with the sample order.

See the picture above. It has a black background and 3 colors, hasn’t it? The background is purely black, so it is a VA LCD screen. But LED backlight for this LCD screen has only one color (white), all the other three colors (blue, green and red) are silver printed on the front of ITO glass.

Polarizer film is composed of a series of plastic films (PVA, TAC, PSA film, Release film and Protective film) which are coated with a layer of optical adhesive film which can be attached to the surface of the ITO glass.

If one polarizer film is missing, we can see nothing. When the power is turned off, the color we see on the surface of LCD screen is the color of the polarizer film; when the power is turned on, the light we see is the color of the LED backlight.

9. Positive and Negative displays of LCD screens depend on the front polarizer film while Transmissive, Reflective and Transflective displays of LCD screens rely on the back polarizer film.

There are three different kinds of back polarizer film: transmissive back polarizer film, reflective back polarizer film and transflective back polarizer film. But there is only one kind of front polarizer film. If a LCD screen is a positive display, as long as we flip over the front polarizer film and attach it to the surface of the ITO glass, it’ll become a negative display LCD screen.

All the features of LCD screens are achieved by ITO glasses, polarizer films and other optical films. But the switch function of liquid crystal is extremely important for LCD displays. Otherwise, it can’t display any image.

3. Temperature testing of LCD screen is under certain conditions and we can’t guarantee the testing results if you don’t follow the temperature testing rules.

Do you have any questions about ITO glass, polarizer film and liquid crystal? You are welcome to email me and leave some comments. I also would love for the comments of those who are experienced in the LCD industry to comment as well.

ITO conductive glass is based on the sodium-calcium or silicon-boron sheet glass, then using the magnetron sputtering method to coat with a layer of indium tin oxide films (commonly known as ITO). The main ingredient of the ITO film is indium tin oxide. In the case of only a few thousand angstroms thickness, the indium tin oxide has high light transmission and high conductive ability. The ITO used in the LCD display is a conductive glass with high transmittance.

It is widely used in TN , STN , HTN ,LCD monitor as well as touch panel ,with minimum resistance of 2 . conventional products 30 /500 as well as specific products 2 /30 etc. both of them are produced under strict and durable quality criteria with a monthly capacity of 36,0000 sheet .

ITO plating glass is made from extra thin float glass after it goes through slicing ,filing polishing and cleaning .Under the circumstances of vacuum and extreme heat , through magnetron shedding splashing , a plate of transparent Indium tin oxide is precipitated on glass surface which is used as conductive board of LCD

Using: Liquid -crystal display (LCD) ,touch panel(TP ),electro luminescence display (ELD ),solar energy battery , car rear-view mirror , glass screens of MP3 and cell phones and other transparent conductive plating .etc.afely export wooden packing

ITO Glass is manufactured through coating ITO transparent conductive layer on single side or double sides of glass according to the advanced technology of vacuum magnetron sputtering. It is the critical material for producing resistive or capacitive touch screens. When used on LCD, a SiO2 layer should be added before coating ITO layer on glass to prevent the ions of glass substrate from penetrating into the conductive layer. If it is requested for higher transmittance, one or multiple AR (anti-reflective) layers can be added before coating ITO layer on glass, thus making it the high-transmittance ITO conductive glass.

ITO Glass used for TN-LCD/HTN-LCD/STN-LCD/TFT-LCD/PDP/OLED/VFD/LCOS in the application of vehicle, consumer electronics, industrial products, LCD (liquid crystal display):

PRODUCT DESCRIPTIONThe display is a 20.1 inch LCD panel providing 1600 x 1200 resolution. It is an active type digital to digital which connects to the onboard conversion board. The display offers a 20.1" diagonal LCD with a 300nit brightness and 1000:1 contrast ratio. It has a Pixel Pitch of only 0.255mm and will display 16.7 million colors (True color). The industrial monitor comes with a standard 15-pin VGA connector on the back of the rackmount monitor for your pc system connection. The OSD function lets you adjust the monitor for the contrast, balance, horizontal position, vertical position, phase, and brightness. All the power on/off switch and OSD buttons are located on the front of the LCD monitor for easy access. The construction of the rugged monitor is of heavy-duty steel. It features all-steel construction with a rack-mountable aluminum bezel. The monitor comes with a metal ruggedized housing to fit into the standard 19" rack cabinet. The AR glass is mounted in front of the panel to protect against the impact on the industrial monitor panel and dust. The systems are designed to meet military shock, vibration, and environmental standards. The 100/240VAC power supply is provided. Option for 24V DC power supply. The rackmount monitor is ready to mount into the standard 19" rack cabinet. It occupies a 9U rack unit.

Our indium tin oxide coatings are a perfect choice whenever glass with an electrically conductive surface and high optical transmission is required. We achieve these properties by applying a thin conductive ITO film to high-quality substrates using sputter coating technology.

Our company supplies the ITO-coated slides and coverslips listed in the table on this page in any standard laboratory size for scientific applications. So whether you use the formats, such as typical in microscopy, or whether you need ITO glass sheets with particular dimensions for photovoltaic research, all this is possible. Our ITO-coated products have also proven to be an excellent solution for micro-structuring and patterning applications. You can structure our ITO with a laser or by using etching technology. On request, we are pleased to share the etching recommendations for our indium tin oxide materials.

All TCO coatings (TCO = transparent conductive oxide) of our CEC-S and CEC-P series feature SiO2 passivation layer. This quartz barrier is only a few nanometers thick. It is located between the substrate and the indium tin oxide thin film, so the ITO film remains on top and is only in direct contact with the high-purity quartz layer and not with the substrate glasses. This passivation prevents the otherwise occurring leaching of alkali oxides from a soda-lime glass into liquid crystals. It is a crucial feature for the longevity of liquid crystal displays (LCD) and a great advantage not only for displays and electronics. The SiO2 layer increases product performance without increasing cost, as it is integrated efficiently into the process. The perfect alkali-ion shielding performance achieved with the SiO2 barrier is superior to any other technology.

Besides the popular S- and P-series, we fabricate many other indium tin oxide coated products based on more exotic glasses. ITO-coated optical quartz glass (CEC-Q), ITO-coated borosilicate glass (CEC-B), 1737F ITO-glass (CEC-A), EAGLE2000 ITO-glass (CEC-E), ITO-coated thin glass (CEC-T), and our double side ITO-coated CEC-SD are also part of our manufacturing program. This wide range of our standard indium tin oxide materials is usually always in stock. (see table on this website for specifications and deliverable thicknesses)

However, if you search for an ITO coating with customized film thicknesses based on other materials or surface resistivities not listed in the table, we also coat according to your requirements in a dedicated run. The same applies to index-matched ITO and backside anti-reflective coatings, which are optional for some materials. Please use our inquiry formto contact us with your specifications and get a custom ITO quote.

Whether you search for a small ITO-coated glass, as often used for organic LED displays (OLED), whether you require larger dimensions for organic solar cells, or if you want a typical microscope slides size used in science. All these sizes are possible.

The recovery of ITO and the glass substrate from discarded TFT-LCDs, without crushing the glass substrate, was done by using an electrochemical method and acid treatments. Anodic conditions did not show any redox reaction of the ITO except oxygen evolution. The oxygen evolution lifted the ITO layer off the glass substrate with the remaining colour filer and black matrix. Recovery of the ITO was 75%, but it showed an In–Sn ratio of 15.9 : 1. The recovered ITO was not suitable for reuse directly. It may be that it needed the addition of extra Sn. However, this work presented a new process for the resource circulation of the indium from discarded LCD panels. The free glass substrate was then recovered after removing the colour filter and black matrix by using an acid solution. The optical transmittance of the recovered glass substrate was about 90% in the visible region, and the average roughness was 0.96 nm.

The TFT-LCD (Flat Panel) Antitrust Litigationclass-action lawsuit regarding the worldwide conspiracy to coordinate the prices of Thin-Film Transistor-Liquid Crystal Display (TFT-LCD) panels, which are used to make laptop computers, computer monitors and televisions, between 1999 and 2006. In March 2010, Judge Susan Illston certified two nationwide classes of persons and entities that directly and indirectly purchased TFT-LCDs – for panel purchasers and purchasers of TFT-LCD integrated products; the litigation was followed by multiple suits.

TFT-LCDs are used in flat-panel televisions, laptop and computer monitors, mobile phones, personal digital assistants, semiconductors and other devices;

In mid-2006, the U.S. Department of Justice (DOJ) Antitrust Division requested FBI assistance in investigating LCD price-fixing. In December 2006, authorities in Japan, Korea, the European Union and the United States revealed a probe into alleged anti-competitive activity among LCD panel manufacturers.

The companies involved, which later became the Defendants, were Taiwanese companies AU Optronics (AUO), Chi Mei, Chunghwa Picture Tubes (Chunghwa), and HannStar; Korean companies LG Display and Samsung; and Japanese companies Hitachi, Sharp and Toshiba.cartel which took place between January 1, 1999, through December 31, 2006, and which was designed to illegally reduce competition and thus inflate prices for LCD panels. The companies exchanged information on future production planning, capacity use, pricing and other commercial conditions.European Commission concluded that the companies were aware they were violating competition rules, and took steps to conceal the venue and results of the meetings; a document by the conspirators requested everybody involved "to take care of security/confidentiality matters and to limit written communication".

Companies directly affected by the LCD price-fixing conspiracy, as direct victims of the cartel, were some of the largest computer, television and cellular telephone manufacturers in the world. These direct action plaintiffs included AT&T Mobility, Best Buy,Costco Wholesale Corporation, Good Guys, Kmart Corp, Motorola Mobility, Newegg, Sears, and Target Corp.Clayton Act (15 U.S.C. § 26) to prevent Defendants from violating Section 1 of the Sherman Act (15 U.S.C. § 1), as well as (b) 23 separate state-wide classes based on each state"s antitrust/consumer protection class action law.

In November 2008, LG, Chunghwa, Hitachi, Epson, and Chi Mei pleaded guilty to criminal charges of fixing prices of TFT-LCD panels sold in the U.S. and agreed to pay criminal fines (see chart).

The South Korea Fair Trade Commission launched legal proceedings as well. It concluded that the companies involved met more than once a month and more than 200 times from September 2001 to December 2006, and imposed fines on the LCD manufacturers.

Sharp Corp. pleaded guilty to three separate conspiracies to fix the prices of TFT-LCD panels sold to Dell Inc., Apple Computer Inc. and Motorola Inc., and was sentenced to pay a $120 million criminal fine,

Seven executives from Japanese and South Korean LCD companies were indicted in the U.S. Four were charged with participating as co-conspirators in the conspiracy and sentenced to prison terms – including LG"s Vice President of Monitor Sales, Chunghwa"s chairman, its chief executive officer, and its Vice President of LCD Sales – for "participating in meetings, conversations and communications in Taiwan, South Korea and the United States to discuss the prices of TFT-LCD panels; agreeing during these meetings, conversations and communications to charge prices of TFT-LCD panels at certain predetermined levels; issuing price quotations in accordance with the agreements reached; exchanging information on sales of TFT-LCD panels for the purpose of monitoring and enforcing adherence to the agreed-upon prices; and authorizing, ordering and consenting to the participation of subordinate employees in the conspiracy."

On December 8, 2010, the European Commission announced it had fined six of the LCD companies involved in a total of €648 million (Samsung Electronics received full immunity under the commission"s 2002 Leniency Notice) – LG Display, AU Optronics, Chimei, Chunghwa Picture and HannStar Display Corporation.

On July 3, 2012, a U.S. federal jury ruled that the remaining defendant, Toshiba Corporation, which denied any wrongdoing, participated in the conspiracy to fix prices of TFT-LCDs and returned a verdict in favor of the plaintiff class. Following the trial, Toshiba agreed to resolve the case by paying the class $30 million.

7~10 Ohm/sq (<10 Ohm/sq), ITO Glass Substrate, Indium Doped Tin Oxide (In-SnO2 or ITO) coated glass, 1.1 mm, can customize conductive film patterns as required

Applications:Indium tin oxide (ITO) is one of the most widely used transparent conducting oxides (TCO) because of its two main properties, its electrical conductivity and optical transparency. ITO can also be easily deposited on a substrate as a thin film. High quality sputtered Indium Doped Tin Oxide (ITO) films can be used as electrodes for photovoltaic/solar cells, LCD display, electrochemical deposition, capacitors, Infrared detection applications.

Carlos Biaou, a PhD student at UC Berkeley worked with MSE Supplies to fabricate several hundred customized ITO and FTO substrates for his thesis research, and he had a very positive feedback on the products and services he received from MSE Supplies.

Dr. Selma Duhovi from MIT has used the ITO and FTO substratesprovided byMSE Supplies for smart glass application, and has been very satisfied with the products and services provided by MSE Supplies.

(Reuters) - Samsung Electronics Co, Sharp Corp and five other makers of liquid crystal displays agreed to pay more than $553 million to settle consumer and state regulatory claims that they conspired to fix prices for LCD panels in televisions, notebook computers and monitors.A worker prepares a display of Sharp flat panel televisions for the 2009 International Consumer Electronics Show (CES) at the Las Vegas Convention Center in Las Vegas, Nevada, January 7, 2009. REUTERS/Steve Marcus

The settlement is the latest arising from lawsuits alleging the creation of an international cartel designed to illegally inflate prices and stifle competition in LCD panels between 1999 and 2006, affecting billions of dollars of U.S. commerce.

In December 2006, authorities in Japan, Korea, the European Union and the United States revealed a probe into alleged anti-competitive activity among LCD panel manufacturers. Many companies and executives have since pleaded guilty to criminal antitrust violations and paid more than $890 million in fines.

The latest payout includes $538.6 million to resolve claims by “indirect” purchasers that bought televisions and computers with thin film transistor LCDs, as well as claims by eight states: Arkansas, California, Florida, Michigan, Missouri, New York, West Virginia and Wisconsin.

Other defendants have yet to settle, including Taiwan-based AU Optronics Corp, one of the largest LCD panel manufacturers; South Korea’s LG Display Co and Toshiba Corp.

The accord follows a settlement this month by eight companies, including Samsung and Sharp, to pay $388 million to settle litigation by direct purchasers of the LCD panels.

Liquid crystal display (LCD) panels are the most widespread type of display panels in use today. They are found in a plethora of electronic devices including wristwatches, smartphones, handheld gaming consoles, laptop computers, televisions, gasoline pumps, etc.

A liquid crystal is a substance which is liquid in form, but with properties akin to solid crystals. Liquid crystal substances were purportedly discovered as early as 1888, but their commercialization in making display panels did not occur until the 1970s, when the digital wristwatch was introduced.

Since their commercialization, some electronic devices with LCD panels have had a profound negative impact on certain traditional industries. For example, the Swiss mechanical wristwatch industry suffered severe losses in the 1970s as a result of the commercialization of low-priced digital wristwatches. Moreover, the reduction in price of LCD monitors and TVs in the early to mid-2000s caused the end the seven decade long production of cathode ray tube (CRT) TVs in the U.S.

However, will LCD panel technology survive with the slow but gradually expanding application of light emitting diode (LED) panels? LED panels are now incorporated in various electronic devices such as smart watches, smartphones, TVs, etc.

These statistics indicate that approximately 2920 U.S. patent applications were filed in 2014 for technological improvements in the field of LCD devices (e.g., computer monitors, smartphone displays, TVs, etc.), followed by approximately 3040 in 2015, approximately 2400 in 2016 and approximately 2240 in 2017. On the other hand, about 2920 U.S. patents were filed in 2014 for technological improvements in the field of LED devices, followed by about 2900 in 2015, about 2750 in 2016 and about 2660 in 2017. Since patent applications are generally maintained secret until 18 months after filing of a patent application, the filing data for 2018 and 2019 is not yet available.

These statistics indicate that patent applications for both the LED and LCD devices are being filed in large numbers. However, the number of annual filings for LCD panels is somewhat lower than that of LED panels for 2016 and 2017.

Statistics gathered from the U.S. Patent and Trademark Office concerning the number of patents granted in both technological fields in recent years indicate that approximately 2600 U.S. patents were issued in 2015 for improvements in the field of LCD devices, followed by approximately 2400 in 2016, approximately 2520 in 2017 and approximately 2320 in 2018. On the other hand, about 2400 U.S. patents were issued in 2015 for improvements in the field of LED devices, about 2410 in 2016, about 2560 in 2017 and about 2440 in 2018.

The statistics provided above illustrate that the number of applications and patents granted for LCD displays in recent years is somewhat lower than of LED displays, but this fact alone may not be enough to conclude that LCD displays are headed into obsolescence.

In order to form a rational prediction as to which type of display panel will ultimately prevail in the future, additional factors must be considered. These factors include the complication involved with the manufacturing process and the manufacturing costs associated with each type of display panel, how thin can each type of display panel be manufactured, and any unique features or attributes associated with each type of display panel.

LCD panels have a backlight assembly that directs white light into a liquid crystal layer. The liquid crystal layer acts like a shutter in order to allow only a desired quantity of light to pass through at each pixel of the panel. Having passed through the liquid crystal layer, the light then passes through a color filter in order to become colored light. The colored light forms the image on the panel.

Other structural arrangements of LCD panels exist, but the above example is intended to illustrate the three main structural components of an LCD panel.

An LED panel, on the other hand, is composed of a large number of individual LEDs arranged in rows and columns, similar to the arrangement of the pixels in an LCD panel. However, this is where the similarities between the two types of display panels end.

Each individual LED in the panel is configured to emit light of a predetermined color toward the user. A large number of LEDs which emit light of different colors form a desired image on the screen. However, in order to form the image, and to change it as needed (e.g., to view a video), the brightness of the individual LEDs must be varied up and down. This can be accomplished by changing the voltage applied to each individual LED in the panel.

As can be gleaned, because the LEDs emit colored light, LED panels do not need a separate light source (e.g., a backlight) for generating light, and they do not need a separate color filter placed over the light source in order to generate colored light. In addition, because the LEDs themselves can produce the desired brightness of light, LED panels do not need an additional shutter mechanism. Thus, LED panels have a simpler structure than LCD displays.

In addition, LED displays can be curved to a much smaller radius than LCD panels, and can be manufactured to be foldable or bendable. For example, the SAMSUNG Galaxy Fold is a smartphone with a foldable LED display panel. LCD panels cannot be made to bend (beyond a minimal degree) or fold.

While the image quality is very good on both types of displays, LED panels have a larger contrast ratio due to the deeper black color that they can render. This is because the LED pixels which are responsible for generating black are simply turned off in order to avoid emitting any light at all. This feature is unique to LED panels.

LCD panels generate black by attempting to block the transmission of light emitted from the backlight. However, the shutter mechanism of LCD panels is not perfect and allows a small quantity of light to escape (or leak) toward the user. The leakage of light causes the black areas of an image to appear dark gray on the screen.

In addition, LED panels can be made thinner than LCD panels since they omit the backlight assembly, the liquid crystal layer, and the color filer layer.

In conclusion, with all the pros of LED panels over LCDs, it seems that the answer to the question posed above hinges on manufacturing/retail costs. LCD panels still exist because they can produce good quality images at a low cost. If LED panels can be produced and sold at a cost comparative to that of LCD panels, the LCD panel technology may well become history.

Our company specializes in developing solutions that arerenowned across the globe and meet expectations of the most demanding customers. Orient Display can boast incredibly fast order processing - usually it takes us only 4-5 weeks to produce LCD panels and we do our best to deliver your custom display modules, touch screens or TFT and IPS LCD displays within 5-8 weeks. Thanks to being in the business for such a noteworthy period of time, experts working at our display store have gained valuable experience in the automotive, appliances, industrial, marine, medical and consumer electronics industries. We’ve been able to create top-notch, specialized factories that allow us to manufacture quality custom display solutions at attractive prices. Our products comply with standards such as ISO 9001, ISO 14001, QC 080000, ISO/TS 16949 and PPM Process Control. All of this makes us the finest display manufacturer in the market.

ITO high-light transmission and high-conductivity are great for Liquid Crystal Displays (LCD). ITO films exhibit excellent transmittance and high-conductivity characteristics. These properties make ITO the best choice for transparent electrodes in Liquid Crystal displays.

However, ITO isn"t without its problems. Alternative solutions are currently being developed and finding success in the market, which is lowering the cost of ITO and increasing its adoption. As a result, Nanomarkets predicts that sales will continue to increase in the next few years before declining.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey