passive matrix lcd panel manufacturer

Established in 2007, Raystar Optronics., Inc. is the leading manufacturer of PMOLED display (Passive Matrix OLED) and modules in Central Taiwan Science Park. Taiwan.

Raystar built its reputation by offering advanced technology, design services and manufacturing efficiency in Character OLED modules, Graphic OLED modules, TFT LCM display modules, Monochrome Character LCD modules, Graphic LCM display modules products. Our products are for small and medium sizes and covered in industrial and consumer applications.

Alibaba.com offers 536 passive matrix lcd products. About 9% % of these are lcd modules, 1%% are digital signage and displays, and 1%% are mobile phone lcds.

For product design engineers and manufacturers, a custom display and touch solution is the best approach to meet their unique application needs. Turning to us to be your monochrome LCD manufacturer means you’ll gain the experience and expertise of our in-house engineering team. Our talented engineers can develop customized solutions using a wide range of LCD technologies:Custom TN LCD displays

New Vision Display is a custom LCD display manufacturer serving OEMs across diverse markets. One of the things that sets us apart from other LCD screen manufacturers is the diversity of products and customizations we offer. Our LCD portfolio ranges from low-cost monochrome LCDs to high-resolution, high-brightness color TFT LCDs – and pretty much everything in between. We also have extensive experience integrating LCD screen displays into complete assemblies with touch and cover lens.

Sunlight readable, ultra-low power, bistable (“paper-like”) LCDs. Automotive grade, wide operating/storage temperatures, and wide viewing angles. Low tooling costs.

Among the many advantages of working with NVD as your LCD screen manufacturer is the extensive technical expertise of our engineering team. From concept to product, our sales and technical staff provide expert recommendations and attentive support to ensure the right solution for your project.

As a leading LCD panel manufacturer, NVD manufactures custom LCD display solutions for a variety of end-user applications: Medical devices, industrial equipment, household appliances, consumer electronics, and many others. Our state-of-the-art LCD factories are equipped to build custom LCDs for optimal performance in even the most challenging environments. Whether your product will be used in the great outdoors or a hospital operating room, we can build the right custom LCD solution for your needs. Learn more about the markets we serve below.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

This is another story just like those, except this one involves the very screen you’re probably looking at, especially if it’s based on LCD technology.

In the 1970s, a pair of engineers that worked for Westinghouse, T. Peter Brody and Fang-Chen Luo, came to develop the first active-matrix LCD screen. Brody, born in Hungary, had gained an interest in the fledgling technology of thin film transistors, an experimental technology that had come to be seen as a potential avenue for visually displaying content in a more compact form than a cathode-ray tube.

“It has been apparent for some time that a solid-state flat panel display is conceptually achievable,” the patent filing stated. “Efforts to utilize silicon technology to this end are limited by the size limitation problems of the silicon wafer, which negates achievement of large area displays.”

But it was the starting point of the technology that stuck. By the mid-1990s, active-matrix displays that relied on color became the norm in laptops, thanks to their combination of vivid color and thinness. But despite the concept coming from an American company’s R&D department and improved by other American R&D departments, nearly all panels were developed by Japanese manufacturers even at the beginning of their mainstream use cases.

In fact, Westinghouse’s efforts with the flat-panel LCD display ended way back in the 1970s, as did similar efforts at other large U.S. companies. “Both large corporations and venture capital-backed start-ups have quit the field, usually after hitting production difficulties,” authors Richard Florida and David Browdy wrote.

Japanese LCD designer and manufacturer Optrex Corp. and Optrex America Inc., its sales and marketing channel in the Americas, have introduced what Optrex is calling the first passive matrix LCD with Advanced Black Nematic (ABN) technology.

LCDs with ABN technology provide higher contrast ratios and wider viewing angles than conventional passive matrix displays, with true black levels, no performance shift over wide temperature ranges, and virtually no color shift, the company says.

According to Optrex, conventional passive matrix displays offer limited performance, such as brightness of less than 100 cd/m2 and contrast ratio of less than 80:1, which are not acceptable for some applications. As a result, Vacuum Florescent Display (VFD) technology has been prevalent in many automotive and certain industrial applications. However, LCDs utilizing ABN technology can achieve performance equal to or better than VFD. They provide a true black level by reducing the light leakage, resulting in contrast ratios of up to 1000:1, super wide viewing angles and no performance shift over a wide temperature range. Because LCDs with ABN technology exhibit practically no color shift, any backlight color can be used without compromising the contrast ratio, the company says.

![]()

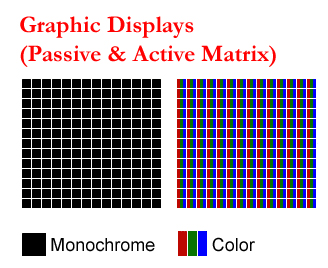

1. Passive Matrix LCD: It uses a grid of vertical and horizontal conductors comprised of Indium Tin Oxide to create an image. Each pixel is controlled by an intersection of two conductors. It represents the off state of LCD i.e the pixel is OFF.

2. Active Matrix LCD: It uses thin-film transistors that are arranged in a matrix on a glass surface. To control the voltage tiny switching transistors and capacitors are used at each pixel location. The active pixel is called so because it has the ability to control the individual pixels and switch them quickly. thin-filmwhich

Difference between Active Matrix LCD and Passive Matrix LCD:Active Matrix LCDPassive Matrix LCDIt uses thin film transistors that are arranged in a matrix on a glass surface. To control the voltage tiny switching transistors and capacitors are used at each pixel location.It uses grid of vertical and horizontal conductors such that the intersection of two of those conductors allows for controlling a single pixel.

Active matrix LCDs are used in full-color LCD TVs monitors, cell phones etc.They are used in calculators display or a digital wrist watches where the display contains a limited number of segment and does not require full color. They are often created for custom applications.

On an elaborative note, passive and active displays also have several types which run down their very own category. For example, passive LCDs may be of the following types:Monochrome TN (Twisted Nematic) – here the liquid crystal cells do not require any current to flow past them and automatically work with lower voltages provided by the batteries.

It uses thin film transistors that are arranged in a matrix on a glass surface. To control the voltage tiny switching transistors and capacitors are used at each pixel location.

OLEDs are made from organic light-emitting materials that emit light when electricity is applied. OLED displays are emissive. That is the reason that OLED displays do not require backlight or filtering that are used in LCDs. As a result, OLEDs can be made flexible and transparent while providing the best images and great contrast and view angles.

Similar to LCD displays having two types: Passive Matrix LCD and Active-Matrix LCD, OLED displays also has two types: PMOLED and AMOLED. The difference is in the driving electronics – it can be either Passive Matrix (PM) or Active Matrix (AM).

Similar to passive matrix LCD, a PMOLED display uses a simple control scheme in which you control each row (or line) in the display sequentially (one at a time). PMOLED electronics do not contain a storage capacitor and so the pixels in each line are actually off most of the time. Because of this ,more voltage is needed to make PMOLED brighter. If you have 10 lines, for example, you have to make the one line that is on 10 times as bright (the real number is less than 10, but that’s the general idea).

The company is also showcasing new microLED displays at Opto Taiwan 2021, which started today. The most interesting display is a 1.58" 256x256 Passive Matrix display. The company collaborated with Solomon Systech to develop the IC for this display.PlayNitride says that this display could be commercialization in 2022. PlayNitride have demonstrated PM-MicroLED displays before, together with RiTDisplay.

This article will look at the entire microLED display, and also compare it to current LCD and OLED displays. After all one of the main advantages of microLED displays is the increased efficiency (and brightness) compared to current displays. Most people assume that indeed microLEDs are much more efficient than OLEDs and LCDs.

MicroLED microdisplay developer Plessey Semiconductor announced that it has developed new passive-matrix monochrome microLED microdisplays. Plessey says it can customize the resolution and color of its PM displays to the customer requirements.

Plessey demonstrated its first such PM microdisplays with the 48x36 blue panel you see above. The company says it plans to introduce 384x128 monochrome and 128x128 RGB passive matrix microdisplays by the end of 2020.

Three-Five Systems today introduced a new high-quality, color liquid crystal display (LCD) technology for use in personal communications products. The announcement is significant because the Tempe, Arizona, firm is one of the few U.S. companies to both develop and manufacture LCDs.

The new proprietary technology, called Liquid Crystal activeDrive, or LCaD, allows passive-matrix LCDs to offer many of the benefits of high-quality active-matrix LCDs by using customized semiconductors to scan multiple lines in the display at the same time. In typical passive-matrix LCD screens, scanning is slow since it is done only one line at a time,

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey