passive matrix lcd panel free sample

It uses thin film transistors that are arranged in a matrix on a glass surface. To control the voltage tiny switching transistors and capacitors are used at each pixel location.

OLEDs are made from organic light-emitting materials that emit light when electricity is applied. OLED displays are emissive. That is the reason that OLED displays do not require backlight or filtering that are used in LCDs. As a result, OLEDs can be made flexible and transparent while providing the best images and great contrast and view angles.

Similar to LCD displays having two types: Passive Matrix LCD and Active-Matrix LCD, OLED displays also has two types: PMOLED and AMOLED. The difference is in the driving electronics – it can be either Passive Matrix (PM) or Active Matrix (AM).

Similar to passive matrix LCD, a PMOLED display uses a simple control scheme in which you control each row (or line) in the display sequentially (one at a time). PMOLED electronics do not contain a storage capacitor and so the pixels in each line are actually off most of the time. Because of this ,more voltage is needed to make PMOLED brighter. If you have 10 lines, for example, you have to make the one line that is on 10 times as bright (the real number is less than 10, but that’s the general idea).

Outlined in this section are TFT LCD (Thin Film Transistor Liquid Crystal Display) basic knowledge, including structures, driving methods (Passive Matrix / PMLCD, Active Matrix / AMLCD) and comparison, RGB filters, display mode, generations and production process.

As our society progresses into an overwhelmingly technological state, screens seem to pop up almost everywhere. Behind those glass displays, or flat panel displays, lie hundreds of thousands of complex, tiny devices, controlling the pixels that comprise the overall image we see. Those devices are known as Thin Film Transistors, or abbreviated, TFTs.

A TFT LCD, or a thin film transistor liquid crystal display, is one of the fastest growing forms of display technology today. The thin film transistor (TFT) is a type of semiconductor device used in display technology to enhance efficiency, compactness, and cost of the product.

LCD has a genetic disadvantage compared to other display technologies: Narrow Viewing Angles. For the last 40 years, scientists and engineers put a lot of effort to improve LCD viewing angles and made great progress. In this section we will introduce O-Film TFT, MVA (Multi-domain Vertical Alignment) TFT, IPS (In Plane Switching)and AFFS (Advanced Fringe Field Switching) TFT.

Most of TFT LCDs are hard to read under the sunlight. Orient Display offer Sunlight Readable TFT with these approaches: Transflective TFT, Surface Treatment, Optical Bonding.

The company is also showcasing new microLED displays at Opto Taiwan 2021, which started today. The most interesting display is a 1.58" 256x256 Passive Matrix display. The company collaborated with Solomon Systech to develop the IC for this display.PlayNitride says that this display could be commercialization in 2022. PlayNitride have demonstrated PM-MicroLED displays before, together with RiTDisplay.

This article will look at the entire microLED display, and also compare it to current LCD and OLED displays. After all one of the main advantages of microLED displays is the increased efficiency (and brightness) compared to current displays. Most people assume that indeed microLEDs are much more efficient than OLEDs and LCDs.

MicroLED microdisplay developer Plessey Semiconductor announced that it has developed new passive-matrix monochrome microLED microdisplays. Plessey says it can customize the resolution and color of its PM displays to the customer requirements.

Plessey demonstrated its first such PM microdisplays with the 48x36 blue panel you see above. The company says it plans to introduce 384x128 monochrome and 128x128 RGB passive matrix microdisplays by the end of 2020.

The transmission (luminance) versus the applied voltage characteristic is shown in Fig. 11. The shown characteristic is for normal viewing angle and indicates that grayscale levels can be achieved by varying the voltage across the LCD. Unfortunately, the transmission – voltage curve is viewing angle dependent, leading to grayscale errors and color shift in a display when it is viewed from significant angles to the display normal.

The equivalent circuit with the parasitic elements of a pixel cell and a typical TFT-LCD pixel layout are shown in fig. 12. The pixel consists of a switch TFT device, with the gate electrode connected to the row driver lines and the source electrode connected to the column driver lines. Furthermore, a storage capacitor is connected in parallel to the LC pixel capacitance.

The crosstalk effect is caused due to the column-line video-signal coupling during one frame and a DC component is being added to the AC data voltage. The DC component can not be entirely eliminated for all gray across the entire pixels matrix, resulting to slight difference in the pixel transmittance between the odd and even frames. A solution to this problem is the polarity inversion method. Apart from elimination of the DC component, the influence of the flicker on the display image quality is also eliminated with the use of a polarity inversion method. Four different polarity inversion methods have been widely used. Figure 13 shows the configuration of the four polarity inversion methods. The type of the polarity inversion method has an impact on the power consumption of the display. In the frame inversion method, all the pixels are driven to + Vp polarity in one frame period and then all of them are driven to – Vp polarity during the next frame period. This method is the most power-efficient method. However, this method is sensitive to the flicker and to vertical and horizontal crosstalk, meaning that this method can not be used in high image quality displays.

A full color LCD display can be generated by incorporating red, green and blue color filters at the pixels. In order to produce the desirable color tone, the pixel is divided into three sub-pixels each one having red, green and blue color filter, respectively. The three sub-pixels have the same dimensions and the proper combination of each color tone; by applying the right voltages to the liquid crystals, the desired pixel emissive colour will be produced. The width of each sub-pixel is three times smaller than the sub-pixel length and when the three sub-pixels are very closely placed in parallel, a square full color pixel is produced. Figure 14 shows a full colour square pixel.

LCD connected to this controller will adjust itself to the memory map of this DDRAM controller; each location on the LCD will take 1 DDRAM address on the controller. Because we use 2 × 16 type LCD, the first line of the LCD will take the location of the 00H-0FH addresses and the second line will take the 40H-4FH addresses of the controller DDRAM; so neither the addresses of the 10H-27H on the first line or the addresses of the 50H-67H on the second line on DDRAM is used.

To be able to display a character on the first line of the LCD, we must provide written instructions (80h + DDRAM address where our character is to be displayed on the first line) in the Instruction Register-IR and then followed by writing the ASCII code of the character or address of the character stored on the CGROM or CGRAM on the LCD controller data register, as well as to display characters in the second row we must provide written instructions (C0H + DDRAM address where our character to be displayed on the second line) in the Instructions Register-IR and then followed by writing the ASCII code or address of the character on CGROM or CGRAM on the LCD controller data register.

As mentioned above, to display a character (ASCII) you want to show on the LCD, you need to send the ASCII code to the LCD controller data register-DR. For characters from CGROM and CGRAM we only need to send the address of the character where the character is stored; unlike the character of the ASCII code, we must write the ASCII code of the character we want to display on the LCD controller data register to display it. For special characters stored on CGRAM, one must first save the special character at the CGRAM address (prepared 64 addresses, namely addresses 0–63); A special character with a size of 5 × 8 (5 columns × 8 lines) requires eight consecutive addresses to store it, so the total special characters that can be saved or stored on the CGRAM addresses are only eight (8) characters. To be able to save a special character at the first CGRAM address we must send or write 40H instruction to the Instruction Register-IR followed by writing eight consecutive bytes of the data in the Data Register-DR to save the pattern/image of a special character that you want to display on the LCD [9, 10].

We can easily connect this LCD module (LCD + controller) with MCS51, and we do not need any additional electronic equipment as the interface between MCS51 and it; This is because this LCD works with the TTL logic level voltage—Transistor-Transistor Logic.

Pins 7–14 (8 Pins) of the display function as a channel to transmit either data or instruction with a channel width of 1 byte (D0-D7) between the display and MCS51. In Figure 6, it can be seen that each Pin connected to the data bus (D0-D7) of MCS51 in this case P0 (80h); P0.0-P0.7 MCS-51 connected to D0-D7 of the LCD.

Pins 4–6 are used to control the performance of the display. Pin 4 (Register Select-RS) is in charge of selecting one of the 2 display registers. If RS is given logic 0 then the selected register is the Instruction Register-IR, otherwise, if RS is given logic 1 then the selected register is the Data Register-DR. The implication of this selection is the meaning of the signal sent down through the data bus (D0-D7), if RS = 0, then the signal sent from the MCS-51 to the LCD is an instruction; usually used to configure the LCD, otherwise if RS = 1 then the data sent from the MCS-51 to the LCD (D0-D7) is the data (object or character) you want to display on the LCD. From Figure 6 Pin 4 (RS) is connected to Pin 16 (P3.6/W¯) of MCS-51 with the address (B6H).

Pin 5 (R/W¯)) of the LCD does not appear in Figure 6 is used for read/write operations. If Pin 5 is given logic 1, the operation is a read operation; reading the data from the LCD. Data will be copied from the LCD data register to MCS-51 via the data bus (D0-D7), namely Pins 7–14 of the LCD. Conversely, if Pin 5 is given a voltage with logical 0 then the operation is a write operation; the signal will be sent from the MCS51 to LCD through the LCD Pins (Pins 7–14); The signal sent can be in the form of data or instructions depending on the logic level input to the Register Select-RS Pin, as described above before if RS = 0 then the signal sent is an instruction, vice versa if the RS = 1 then the signal sent/written is the data you want to display. Usually, Pin 5 of the LCD is connected with the power supply GND, because we will never read data from the LCD data register, but only send instructions for the LCD work configuration or the data you want to display on the LCD.

Pin 6 of the LCD (EN¯) is a Pin used to enable the LCD. The LCD will be enabled with the entry of changes in the signal level from high (1) to low (0) on Pin 6. If Pin 6 gets the voltage of logic level either 1 or 0 then the LCD will be disabled; it will only be enabled when there is a change of the voltage level in Pin 6 from high logic level to low logic level for more than 1000 microseconds (1 millisecond), and we can send either instruction or data to processed during that enable time of Pin 6.

Pin 3 and Pin 15 are used to regulate the brightness of the BPL (Back Plane Light). As mentioned above before the LCD operates on the principle of continuing or inhibiting the light passing through it; instead of producing light by itself. The light source comes from LED behind this LCD called BPL. Light brightness from BPL can be set by using a potentiometer or a trimpot. From Figure 6 Pin 3 (VEE) is used to regulate the brightness of BPL (by changing the current that enters BPL by using a potentiometers/a trimpot). While Pin 15 (BPL) is a Pin used for the sink of BPL LED.

4RSRegister selector on the LCD, if RS = 0 then the selected register is an instruction register (the operation to be performed is a write operation/LCD configuration if Pin 5 (R/W¯) is given a logic 0), if RS = 1 then the selected register is a data register; if (R/W¯) = 0 then the operation performed is a data write operation to the LCD, otherwise if (R/W¯) = 1 then the operation performed is a read operation (data will be sent from the LCD to μC (microcontroller); it is usually used to read the busy bit/Busy Flag- BF of the LCD (bit 7/D7).

5(R/W¯)Sets the operating mode, logic 1 for reading operations and logic 0 for write operations, the information read from the LCD to μC is data, while information written to the LCD from μC can be data to be displayed or instructions used to configure the LCD. Usually, this Pin is connected to the GND of the power supply because we will never read data from the LCD but only write instructions to configure it or write data to the LCD register to be displayed.

6Enable¯The LCD is not active when Enable Pin is either 1 or 0 logic. The LCD will be active if there is a change from logic 1 to logic 0; information can be read or written at the time the change occurs.

Liquid crystal display (LCD), a popular display type found in laptops for many years, is now a popular choice for desktop computers and TV display. LCDs also are popular on watches and other electrical devices.

An LCD has two sheets of material, surrounding a liquid that contains crystals that act as pixels for the display. Each crystal has a red, green, and blue cell that is illuminated by an electrical charge hitting the crystal, which then creates the image you see onscreen.

Color: The two forms of color display are active matrix and passive matrix:Active matrix: An active matrix display, the most popular type of display today, uses at least one transistor per pixel, or crystal, which allows the electrical charge to be held longer on the crystal. This helps to create very crisp images with high resolution. With active matrix displays, the images are clear and easy to view, even from an angle. Because it uses transistors, an active matrix display uses more power than a passive matrix display. Active matrix displays are also known as thin-film transistor (TFT) displays.

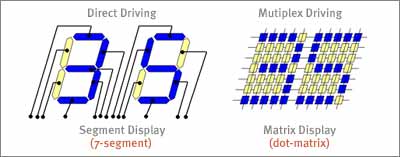

1. Passive Matrix LCD: It uses a grid of vertical and horizontal conductors comprised of Indium Tin Oxide to create an image. Each pixel is controlled by an intersection of two conductors. It represents the off state of LCD i.e the pixel is OFF.

2. Active Matrix LCD: It uses thin-film transistors that are arranged in a matrix on a glass surface. To control the voltage tiny switching transistors and capacitors are used at each pixel location. The active pixel is called so because it has the ability to control the individual pixels and switch them quickly. thin-filmwhich

Difference between Active Matrix LCD and Passive Matrix LCD:Active Matrix LCDPassive Matrix LCDIt uses thin film transistors that are arranged in a matrix on a glass surface. To control the voltage tiny switching transistors and capacitors are used at each pixel location.It uses grid of vertical and horizontal conductors such that the intersection of two of those conductors allows for controlling a single pixel.

Active matrix LCDs are used in full-color LCD TVs monitors, cell phones etc.They are used in calculators display or a digital wrist watches where the display contains a limited number of segment and does not require full color. They are often created for custom applications.

On an elaborative note, passive and active displays also have several types which run down their very own category. For example, passive LCDs may be of the following types:Monochrome TN (Twisted Nematic) – here the liquid crystal cells do not require any current to flow past them and automatically work with lower voltages provided by the batteries.

An AMLCD) is a type of flat-panel display, the only viable technology for high-resolution TVs, computer monitors, notebook computers, tablet computers and smartphones with an LCD screen, due to low weight, very good image quality, wide color gamut and response time.

The concept of active-matrix LCDs was proposed by Bernard J. Lechner at the RCA Laboratories in 1968.thin-film transistors was made by T. Peter Brody, Fang-Chen Luo and their team at Westinghouse Electric Corporation in 1972.

The most common type of AMLCD contains, besides the polarizing sheets and cells of liquid crystal, a matrix of thin-film transistors to make a thin-film-transistor liquid-crystal display.pixel on the display while all the other pixels are being updated. This method provides a much brighter, sharper display than a passive matrix of the same size. An important specification for these displays is their viewing-angle.

Thin-film transistors are usually used for constructing an active matrix so that the two terms are often interchanged, even though a thin-film transistor is just one component in an active matrix and some active-matrix designs have used other components such as diodes. Whereas a passive matrix display uses a simple conductive grid to apply a voltage to the liquid crystals in the target area, an active-matrix display uses a grid of transistors and capacitors with the ability to hold a charge for a limited period of time. Because of the switching action of transistors, only the desired pixel receives a charge, and the pixel acts as a capacitor to hold the charge until the next refresh cycle, improving image quality over a passive matrix. This is a special version of a sample-and-hold circuit.

Brody, T. P.; Fang Chen Luo; Szepesi, Z. P.; Davies, D. H. (1975). "A 6 x 6-in 20-lpi electroluminescent display panel". IEEE Transactions on Electron Devices. 22 (9): 739. doi:10.1109/T-ED.1975.18214. S2CID 1378753.

"History of TFT LCD". Archived from the original on 2013-08-23. Retrieved 2011-02-22. There are many kinds of AMLCD. For their integrated switching devices most use transistors made of deposited thin films, which are therefore called thin-film transistors (TFTs).

This type of LCD was invented at the Brown Boveri Research Center, Baden, Switzerland, in 1983.twisted nematic (TN) LCDs with a 90 degrees twisted structure of the molecules have a contrast vs. voltage characteristic unfavorable for passive-matrix addressing as there is no distinct threshold voltage. STN displays, with the molecules twisted from 180 to 270 degrees, have superior characteristics.

The main advantage of STN LCDs is their more pronounced electro-optical threshold allowing for passive-matrix addressing with many more lines and columns. For the first time, a prototype STN matrix display with 540x270 pixels was made by Brown Boveri (today ABB) in 1984, which was considered a breakthrough for the industry.

STN LCDs require less power and are less expensive to manufacture than TFT LCDs, another popular type of LCD that has largely superseded STN for mainstream laptops. STN displays typically suffer from lower image quality and slower response time than TFT displays. However, STN LCDs can be made purely reflective for viewing under direct sunlight. STN displays are used in some inexpensive mobile phones and informational screens of some digital products. In the early 1990s, they had been used in some portable computers such as Amstrad"s PPC512 and PPC640, and in Nintendo"s Game Boy.

CSTN (color super-twist nematic) is a color form for electronic display screens originally developed by Sharp Electronics. The CSTN uses red, green and blue filters to display color. The original CSTN displays developed in the early 1990s suffered from slow response times and ghosting (where text or graphic changes are blurred because the pixels cannot turn off and on fast enough). Recent advances in the technology, however, have made CSTN a viable alternative to active matrix displays. New CSTN displays offer 100ms response times (for comparison TFT displays offer 8ms or less), a 140 degree viewing angle and high-quality color rivaling TFT displays – all at about half the cost. A newer passive-matrix technology called High-Performance Addressing (HPA) offers even better response times and contrast than CSTN.

Samsung had two proprietary technologies for STN LCDs, Ultra Fine & Bright (UFB), which delivered wide viewing angle (about 120 degrees), faster response time (about 60 ms) and less power consumption, while Ultra Fine & High Speed (UFS), delivered almost same color depths as TFT LCDs, greater color purity, much faster response time (about 14 ms) and same contrast ratio as TFT LCDs.

Dual Scan STN: An enhanced STN passive matrix LCD. The screen is divided into halves, and each half is scanned simultaneously, thereby doubling the number of lines refreshed per second and providing a sharper appearance. DSTN was widely used on earlier laptops. See STN and LCD.

FSTN: Film compensated STN, Formulated STN or Filtered STN. A passive matrix LCD technology that uses a film compensating layer between the STN display and rear polarizer for added sharpness and contrast. It was used in laptops before the DSTN method became popular and many early 21st Century cellphones.

CCSTN: Color Coded Super Twist Nematic. An LCD capable of displaying a limited range of colours, used in some digital organisers and graphic calculators in the 1990s

Shenzhen SLS Industrial Co.,ltd established in 2003, is a professional LCD module manufacturer and solution provider. We have 1 full-auto COG assembly line, 2 semi-auto assembly line, backlight assembly line, no dust TP bonding line and manufacturing tech support, we can provide unique, innovative and cost effective LCD module development and manufacturing. Our product range includes: middle-small size TFT LCD, industrial capacitive touch panel... Our LCD products have been widely used in communications, GPS, Equipment, electronic audio-visual, instrumentation, household appliances, PDA and other industries.

Global Passive Matrix Liquid Crystal Display Market, By Product (Manual, Automatic), Screen Size (Less Than 5, 5-10, >10), Type (Instrument Cluster Displays, Head-up Display, Centre Stack Display, Driver Information Display, Advanced Instrument Cluster Display, Rear- Seat Entertainment Touch Screen Display, Camera Information Display), Vehicle Type (Premium Passenger Cars, Compact Passenger Cars, Luxury Passenger Cars, Mid-Sized Passenger Cars, Heavy Commercial Vehicles, Light Commercial Vehicles), Application (Navigation, Telematics, Infotainment, Blind Spot Detection) – Industry Trends and Forecast to 2029.

Liquid Crystal Displays (LCDs) are widely used in various industries, including entertainment, corporate, transportation, retail, hospitality, education, and healthcare. These enable organizations to reach a larger audience. They also aid in the establishment of a centralized network for digital communications. Passive matrix liquid crystal displays are in high demand for displaying content.

Data Bridge Market Research analyses that the passive matrix liquid crystal display market which was growing at a value of 7.08 billion in 2021 and is expected to reach the value of USD 18.23 billion by 2029, at a CAGR of 12.55% during the forecast period of 2022-2029. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand.

A flat-panel display composed of a grid of horizontal and vertical wires. At the intersection of each grid is an LCD element representing a single pixel, allowing or blocking light. An active-matrix display, which is more expensive and of higher quality, uses a transistor to control each pixel. These lighting solutions are highly energy-efficient, have a longer lifespan than traditional lighting solutions, and have a lower environmental impact.

Passive matrix liquid crystal displays have several built-in advantages, including exceptional readability, light in a much narrower spectrum than other illumination sources, energy efficiency, low operating costs, and long life. These will be expected to reduce electronic power losses and increase market usage of competently used outdoor displays. Furthermore, using passive matrix liquid crystal displays for advertising, promoting sporting events and brands, and other types of events is a highly innovative and cost-effective method of promoting these types of events.

The increasing reliance on navigation systems is a critical factor driving market growth, as is continuous innovation in driver assistance solutions and enhancement of driver experience and safety features, among other factors driving the passive-matrix liquid crystal display market. Furthermore, significant technological advances and developments in the market will create new opportunities for the passive-matrix liquid crystal display market during the forecast period.

This increasing reliance on navigation systems is an important factor driving market growth, as is continuous innovation in driver assistance solutions and enhancement of driver experience and safety features, among other factors driving the passive-matrix liquid crystal display market.

Furthermore, significant technological advances and developments in the market will create new opportunities for the passive-matrix liquid crystal display market during the forecast period.

However, a lack of adoption and preference for implementing high-cost automotive displays, as well as rising concerns about the mobility functionality of touch screen displays in comparison to mechanical controls, are among the major factors that will limit market growth and further challenge the passive-matrix liquid crystal display market during the forecast period.

This passive matrix liquid crystal display market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the passive matrix liquid crystal display market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

The COVID-19 has had an impact on the digital liquid crystal display (LCD) market. Limited investment costs and a lack of employees hampered sales and production of liquid crystal display (LCD) technology. However, the government and key market players adopted new safety measures in order to develop the practices. As technology advanced, the sales rate of the li liquid crystal display (LCD) digital increased because it targeted the right audience. Increased device sales across the globe are expected to drive market growth in the post-pandemic scenario.

The passive matrix liquid crystal display market is segmented on the basis of product, screen size, type, vehicle type and application. The growth amongst these segments will help you analyse meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

The passive matrix liquid crystal display market is analysed and market size insights and trends are provided by country, product, screen size, type, vehicle type and application as referenced above.

The countries covered in the passive matrix liquid crystal display market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

The passive matrix liquid crystal display market competitive landscape provides details by competitor. details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, Global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies" focus related to passive matrix liquid crystal display market.

M2 PRESSWIRE-August 29, 2019-: TFT LCD Display Modules Market To Show Extensive Growth Due To The Increasing Popularity Of LCD Displays Till 2023 | Million Insights

Kaohsiung Opto-Electronics (KOE), a wholly owned subsidiary of Japan Display Inc (JDI), was formed in 2012 to advance the design, development and manufacture of market leading TFT LCD display modules previously established by Hitachi.

However, the R&D team of the Chinese firm has developed an algorithm-based approach which uses deep learning and neural networks to optimise and recognise fingerprints on a LCD display. The breakthrough could result in a big development in the prominence of in-display fingerprint sensors on smartphones.

Greensburg, PA, March 02, 2019 --(PR.com)-- AGDisplays, an advanced LCD display solutions company, announces the release of a new line of powerful IPS LCD modules for use in Marine electronic applications.

LCD Display Technology to Represent Robust Growth Compared to TFT-LCD technology, LCD display technology is anticipated to witness strong growth in the global automotive smart display market.

NEC Display Solutions of America, Inc., a provider of commercial LCD display and projector solutions, is pleased to announce that Richard Ventura, Vice President of Strategy, NEC Display Solutions of America, has been selected as a 2018 inductee to System Contract News" Hall of Fame, the company said.

(http://www.ibtimes.com/apple-reportedly-going-big-6-inch-lcd-iphone-8-successor-2593796) IBT previously reported that that Apple is planning to put a 6-inch LCD display on the iPhone 8 successor and Japan Display would be supplying those LCD panels.

One 5.5-inch version will have an LCD display, while a premium version will pack an OLED display for the first time in the iPhone"s history, according to the supply chain analyst (via Apple Insider).

- Japanese IT company NEC"s NEC Display Solutions of America commercial LCD display and projector solutions unit has launched the MultiSync MDC212C2 monitor, a clinical review display with a built-in calibration timer so technicians can schedule calibrations of displays during off hours, the company said.

Tokyo, Oct 7, 2014 - (JCN Newswire) - Sharp"s "8K full-spec LCD display" exhibited at CEATEC Japan, a comprehensive annual exhibition showcasing the latest in IT and electronics from October 7 to 11, has received "Minister of Internal Affairs and Communications Award of CEATEC AWARD 2014".

Leaked photos of a gadget claimed to be the next Apple iPad appear to show a bonded LCD display, which would allow either a thinner next-gen model or a larger battery, according to a report from UK-based tech site The Register.

"The new Micro820 controller, LCD display, plug-in modules and Connected Components Workbench software Release 6.0 have the features and options that help them differentiate their offerings and be more competitive." Connected Components Workbench software simplifies the configuration, design and maintenance of the Micro820 controller.

Fact.MR has announced the addition of the "LCD Panel Market Forecast, Trend Analysis & Competition Tracking - Global Review 2018 to 2028"report to their offering.

IMARC"s latest study "TFT LCD Panel Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Machinery, Raw Materials, Cost and Revenue" provides a techno-commercial roadmap for setting up a TFT LCD panel manufacturing plant.

Sharp has LCD panel factories in Kameyama and Sakai in Japan and produces small- and medium-sized panels for smartphones as well as large panels for TVs.

Sharp said yesterday it has agreed to pay Dell and two other companies US$198.5 million to settle a lawsuit for fixing LCD panel prices in Europe and North America.

Samsung Electronics Co Ltd (Korea:005930) (OTCOTHER: SSNLF) announced today that it is expanding the transparent display market with the production of a 46-inch transparent LCD panel, beginning this month.

The LCD panel business alliance still continues in a form, in order to "respond to such challenging conditions and to strengthen their respective market competitiveness," according to the statement released by Samsung.

As LCD panel prices continue to slide due to a supply glut, Sony is increasingly relying on other manufacturers for the key TV component as part of its cost-cutting efforts, the daily said.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey