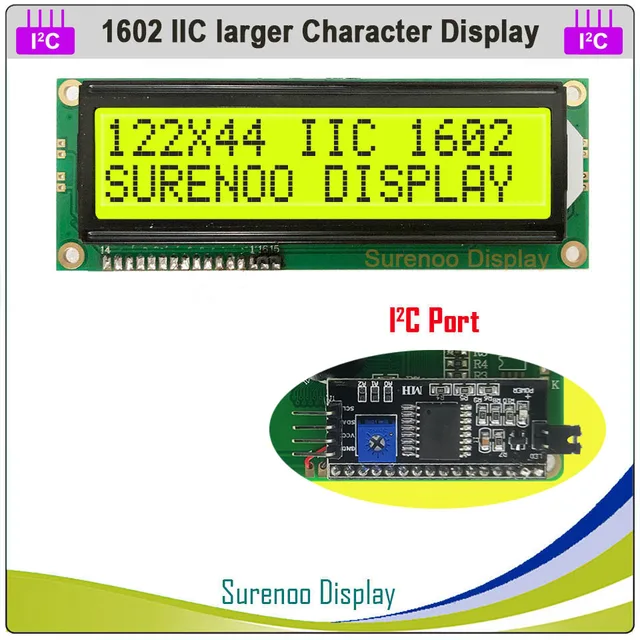

i2c 1602 serial lcd module datasheet made in china

With IIC/I2C interface, it only takes two I/O port thus saving more for other usages. You can adjust the contrast by the potentiometer at its back. If you dont want the backlight, you can also unplug the jumper cap at the LCD back.

As we all know, though LCD and some other displays greatly enrich the man-machine interaction, they share a common weakness. When they are connected to a controller, multiple IOs will be occupied of the controller which has no so many outer ports. Also it restricts other functions of the controller. Therefore, LCD1602 with an I2C port is developed to solve the problem. It is also simple to handle. It has only two bidirectional data lines, a serial data line and a serial clock one.

With IIC/I2C interface, it only takes two I/O port thus saving more for other usages. You can adjust the contrast by the potentiometer at its back. If you don’t want the backlight, you can also unplug the jumper cap at the LCD back.

With the LCD shield, you can display whatever you want by programming the code compatible with Arduino, Raspberry Pi board. Therefore, this is a perfect choice to make your project more interesting and vivid!

Holding the serial module with the I2C interface at the left hand end, there are 16 pins at the lower edge. The first of these is ground, and the second of these is +5v. Another option is to use the lower two pins on the I2C interface for power, but I found it more convenient to use the pins as described above.

I2C interface. On the serial module, the top pin is SCL (clock) and it goes to the Arduino A5. The second pin down is SDA (data) and it goes to the Arduino A4.

LCD print interface. There are 6 connections between the serial module and the LCD Keypad shield, all of them between pins with no labels. I will identify them on the LCD module by counting from Right to Left, with the first pin as 1. There are 2 blocks of 8, so they go from 1 to 16. I identify them on the I2C serial module by counting from Left to Right, there are also 16 of these. In addition I give each wire a label, which is the equivalent pin on the Arduino that is normally associated with that function, in the case of a direct connection without the serial module.

Keypad interface: This uses a single wire from the LCD module pin on the lower side labelled "A0", to pin A0 on the Arduino. At least that was pretty easy!

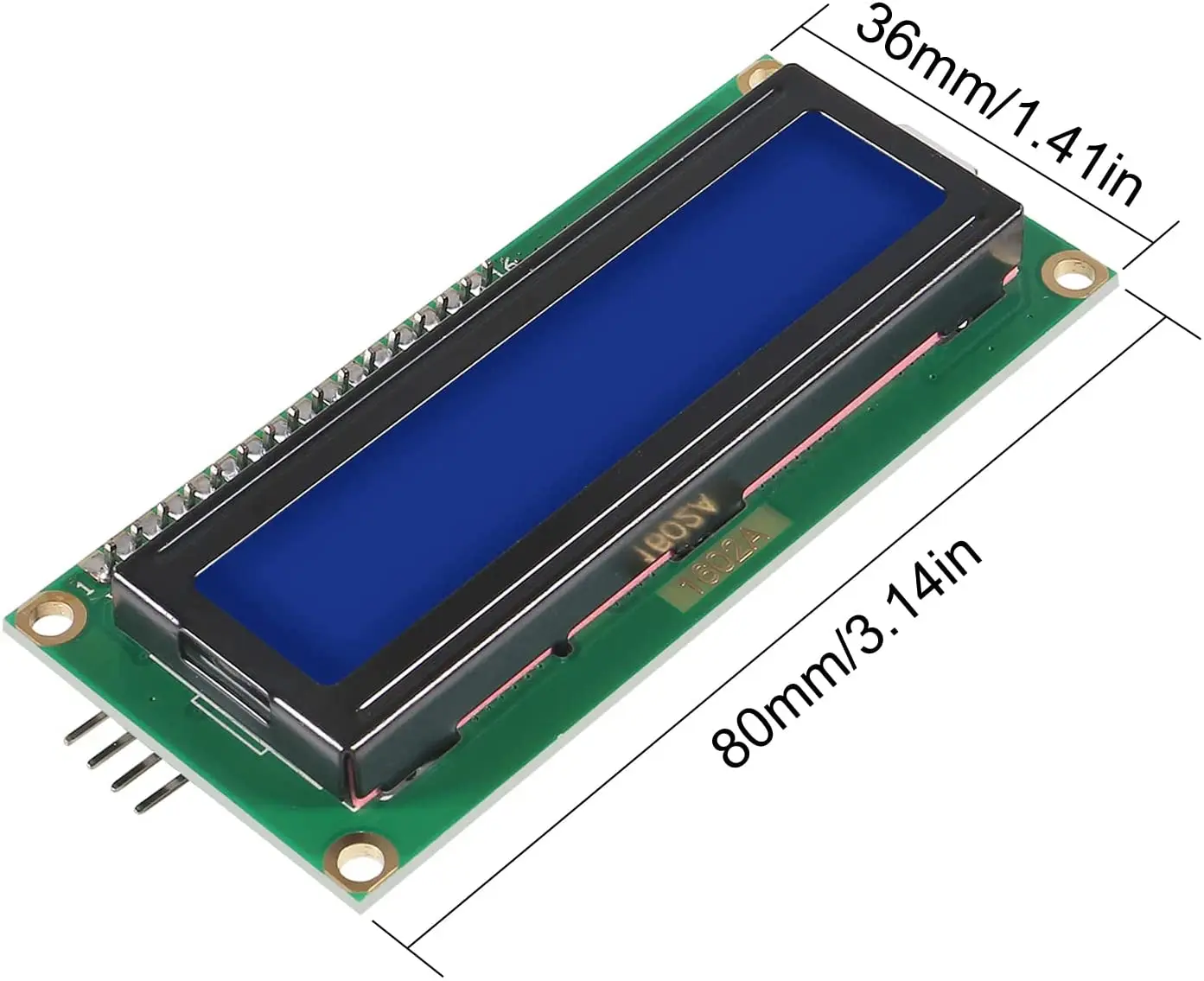

The 16×2 character LCD has two rows with the ability to display 16 ASCII characters on each row. Normal 16×2 character LCDs use 7 digital pins, while this module with I2C interface has reduced this number to 2 pins. A potentiometer is also included to adjust the display contrast. These LCDs have many applications and are used in cases such as: copiers and fax machines, laser printers, industrial testing tools, etc.

The required libraries must be included first. Next, we enter the I2C address that we obtained in the previous section. Then, the program waits for the user to write a phrase. When the user enters a phrase in the Serial Monitor field, the same phrase appears on the LCD.

The two images below are the results of displaying the phrase “1602 LCD” on the screen. This phrase is first written in the Serial Monitor. It then appears on the LCD when you send it.

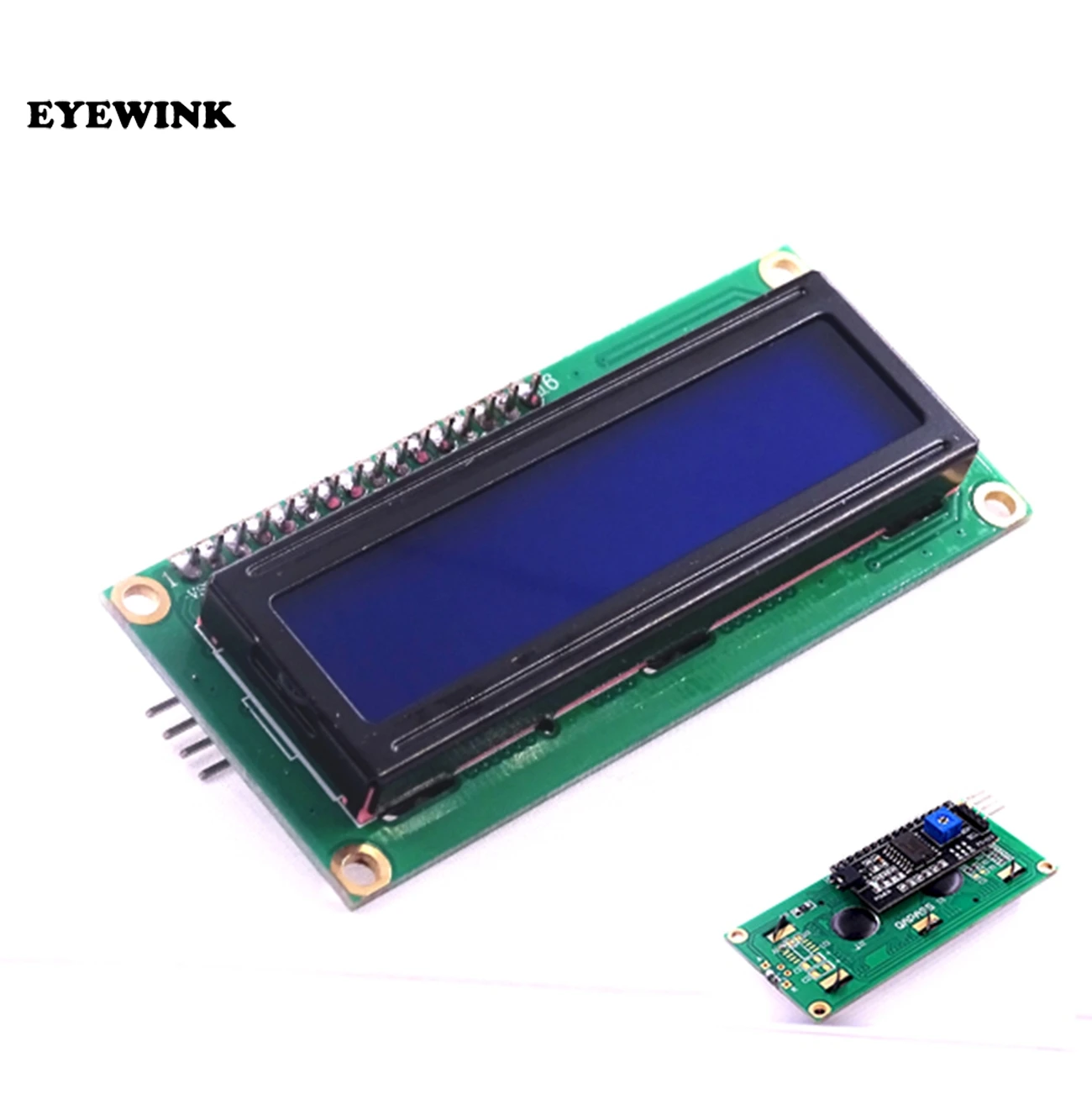

This is another great blue/yellow backlight LCD display. As the pin resources of Arduino controller is limited, your project may be not able to use normal LCD shield after connected with a certain quantity of sensors or SD card. However, with this I2C interface LCD module, you will be able to realize data display via only 2 wires. If you already has I2C devices in your project, this LCD module actually cost no more resources at all. It is fantastic for Arduino based project.

Here is pic shows how to connect an Arduino 1602 I2C module.The following is a table describing which pins on the Arduino should be connected to 1602 I2C LCD module.

As the maker movement has increasingly grown, we’d like to share the way to use Arduino and begin with controlling the LCD module. Yes, we’d like to start from LCD module instead of installation since makers can find lots of related information from the Internet. So we’ll have less basic introduction here.

After reading this article and manipulating, you will have the basic understanding of I2C bus and LCD, and learn the way to connect modules with Arduino, use basic program to control your LCD module, and think about the applications. The advanced control techniques will be explained in the future articles.

I2C Bus enables 2 devices to communicate with each other in a stable, high-speed, bidirectional way and with the least I/O pins. I2C Bus utilizes 2 lines to communicate, Serial Data Line (SDA) and Serial Clock Line (SCL), so that the protocol I2C uses is also called “bidirectional” protocol.

What’s more special is I2C Bus allows multiple devices to share the common communication lines. Thus, I2C Bus could control the communication function.

Here we use Arduino as the main board to control; pin A4 and A5 on the board are SDA and SCL pins respectively. To use I2C function, you would need to use Wire Library, which is the built-in library of Arduino IDE.

LCD is the abbreviation of liquid-crystal display; it’s a commonly-used display device and utilized everywhere in our daily life, from watches, calculators, TV to bulletin board.

This LCD module is the basic one and the most commonly-used character display; The voltage is 5V. The voltage level Arduino I/O Port uses is 5V so that we choose the LCD module. Besides, the LCD module can display 16 characters per line and there are 2 such lines. Also, the module uses I2C protocol. Thus, there are 4 pins on the module, including Vcc, GND, SDA, and SCL.

It is also easy to connect the wires. Firstly, you need to connect pin Vcc of the module to Arduino pin 5V, connect pin GND to Arduino pin GND, and connect pin SDA to Arduino pin A4. Lastly, connect pin SCL to Arduino pin A5 to complete the wiring.

Before introducing the sample, we’d like you to download the 3rd party libraries of I2C_LCD first. You can download the files here, decompress, and install. In this sample, the version we use is NewliquidCrystal_1.3.4. The followings are the codes we use for this sample.

Then, at the setting of initialization, LCD backlight will be controlled to blink 3 times. The first line will display “ICshop&MakerPRO” for one second, and the second line will display “Hello, Maker!” for 8 seconds. Then all the display will be cleared.

Hope all of you successfully complete the I2C_1602_LCD module display with the description mentioned above. If you failed, please check the wiring or you bought a defective device.

So next, you could think of if you can use the module to make a clock or environment sensors. You might have tons of ideas now! Why don’t you connect a LCD module in your next project?

I2C_LCD is an easy-to-use display module, It can make display easier. Using it can reduce the difficulty of make, so that makers can focus on the core of the work.

We developed the Arduino library for I2C_LCD, user just need a few lines of the code can achieve complex graphics and text display features. It can replace the serial monitor of Arduino in some place, you can get running informations without a computer.

More than that, we also develop the dedicated picture data convert software (bitmap converter)now is available to support PC platform of windows, Linux, Mac OS. Through the bitmap convert software you can get your favorite picture displayed on I2C_LCD, without the need for complex programming.

ERMC1602SBS-2 is 16 characters wide,2 rows character lcd module,SPLC780C controller (Industry-standard HD44780 compatible controller),6800 4/8-bit parallel interface,single led backlight with white color included can be dimmed easily with a resistor or PWM,stn- blue lcd negative,white text on the blue color,wide operating temperature range,rohs compliant,built in character set supports English/Japanese text, see the SPLC780C datasheet for the full character set. It"s optional for pin header connection,5V or 3.3V power supply and I2C adapter board for arduino.

Of course, we wouldn"t just leave you with a datasheet and a "good luck!".For 8051 microcontroller user,we prepared the detailed tutorial such as interfacing, demo code and Development Kit at the bottom of this page.

Connecting an LCD to your Raspberry Pi will spice up almost any project, but what if your pins are tied up with connections to other modules? No problem, just connect your LCD with I2C, it only uses two pins (well, four if you count the ground and power).

In this tutorial, I’ll show you everything you need to set up an LCD using I2C, but if you want to learn more about I2C and the details of how it works, check out our article Basics of the I2C Communication Protocol.

There are a couple ways to use I2C to connect an LCD to the Raspberry Pi. The simplest is to get an LCD with an I2C backpack. But the hardcore DIY way is to use a standard HD44780 LCD and connect it to the Pi via a chip called the PCF8574.

The PCF8574 converts the I2C signal sent from the Pi into a parallel signal that can be used by the LCD. Most I2C LCDs use the PCF8574 anyway. I’ll explain how to connect it both ways in a minute.

I’ll also show you how to program the LCD using Python, and provide examples for how to print and position the text, clear the screen, scroll text, print data from a sensor, print the date and time, and print the IP address of your Pi.

I2C (inter-integrated circuit) is also known as the two-wire interface since it only uses two wires to send and receive data. Actually it takes four if you count the Vcc and ground wires, but the power could always come from another source.

Connecting an LCD with an I2C backpack is pretty self-explanatory. Connect the SDA pin on the Pi to the SDA pin on the LCD, and the SCL pin on the Pi to the SCL pin on the LCD. The ground and Vcc pins will also need to be connected. Most LCDs can operate with 3.3V, but they’re meant to be run on 5V, so connect it to the 5V pin of the Pi if possible.

If you have an LCD without I2C and have a PCF8574 chip lying around, you can use it to connect your LCD with a little extra wiring. The PCF8574 is an 8 bit I/O expander which converts a parallel signal into I2C and vice-versa. The Raspberry Pi sends data to the PCF8574 via I2C. The PCF8574 then converts the I2C signal into a 4 bit parallel signal, which is relayed to the LCD.

Before we get into the programming, we need to make sure the I2C module is enabled on the Pi and install a couple tools that will make it easier to use I2C.

Now we need to install a program called I2C-tools, which will tell us the I2C address of the LCD when it’s connected to the Pi. So at the command prompt, enter sudo apt-get install i2c-tools.

Next we need to install SMBUS, which gives the Python library we’re going to use access to the I2C bus on the Pi. At the command prompt, enter sudo apt-get install python-smbus.

Now reboot the Pi and log in again. With your LCD connected, enter i2cdetect -y 1 at the command prompt. This will show you a table of addresses for each I2C device connected to your Pi:

We’ll be using Python to program the LCD, so if this is your first time writing/running a Python program, you may want to check out How to Write and Run a Python Program on the Raspberry Pi before proceeding.

I found a Python I2C library that has a good set of functions and works pretty well. This library was originally posted here, then expanded and improved by GitHub user DenisFromHR.

There are a couple things you may need to change in the code above, depending on your set up. On line 19 there is a function that defines the port for the I2C bus (I2CBUS = 0). Older Raspberry Pi’s used port 0, but newer models use port 1. So depending on which RPi model you have, you might need to change this from 0 to 1.

The function mylcd.lcd_display_string() prints text to the screen and also lets you chose where to position it. The function is used as mylcd.lcd_display_string("TEXT TO PRINT", ROW, COLUMN). For example, the following code prints “Hello World!” to row 2, column 3:

On a 16×2 LCD, the rows are numbered 1 – 2, while the columns are numbered 0 – 15. So to print “Hello World!” at the first column of the top row, you would use mylcd.lcd_display_string("Hello World!", 1, 0).

You can create any pattern you want and print it to the display as a custom character. Each character is an array of 5 x 8 pixels. Up to 8 custom characters can be defined and stored in the LCD’s memory. This custom character generator will help you create the bit array needed to define the characters in the LCD memory.

By inserting the variable from your sensor into the mylcd.lcd_display_string() function (line 22 in the code above) you can print the sensor data just like any other text string.

These programs are just basic examples of ways you can control text on your LCD. Try changing things around and combining the code to get some interesting effects. For example, you can make some fun animations by scrolling with custom characters. Don’t have enough screen space to output all of your sensor data? Just print and clear each reading for a couple seconds in a loop.

Winstar WO1602G is 16 characters x 2 lines COG Character LCD module with metal pin connection. This display is built in with ST7032I controller IC and it supports I2C interface. This series of module can be operating at temperatures from -20℃ to +70℃; its storage temperatures range from -30℃ to +80℃.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey