tft lcd de mode quotation

Texas Instruments has been making progress possible for decades. We are a global semiconductor company that designs, manufactures, tests and sells analog and embedded processing chips. Our products help our customers efficiently manage power, accurately sense and transmit data and provide the core control or processing in their designs.

Some of my customers have sent me inquiries about LCD panels and asked for quote. They only gave me the information about the screen size, for example, segment LCD screen 36 x 22 mm & 57 x 22 mm & 77 x 25 mm or 128 * 32 pixel. I had to explain to them why we cannot give a quote. Here is a summary of the necessary information that we need before we can offer quotes:

Do you only need a LCD screen or LCD module (including LCD screen, LED backlight, IC, PCB, Plastic shell)? If you only need a LCD screen, is it a segment LCD or a dot matrix LCD? We have a lot of experience in the LED and LCD industries and give the best quote.

Please give me the quantity you want before you ask me for a quote. There is definitely a difference between purchasing 100,000 and 1,000 pieces. The more you order each buy, the cheaper the unit price and shipping cost will be.

Does 36 x 22 mm & 57 x 22 mm & 77 x 25 mm mean outer dimension or view area? As for 128*32 pixel, we don’t know the size of LCD screen, so we are unable to give a quote.

I have been asked this question by my customers many times: what is your MOQ (minimum order quantity)? There are different MOQ for different sizes of LCD screens. For example: The MOQ of 36 x 22 mm segment LCD is 5000 pieces, and the MOQ of 113.5 x 62mm segment LCD is 1,000 pieces. So please tell me the size of your LCD first before you ask me for the MOQ.

Dot matrix LCD can display any graphic, so it doesn’t need it. But segment LCD does and we are going to need it for the official blueprint we are about to make.

If we make a 17 segment LCD display that adopts static drive mode, there will be 18 feet (each segment has one foot and one common foot). If it adopts a dynamic drive mode whose duty is one-third, there will be 9 feet (17/3=6 feet and 3 common feet).

Static drive mode needs more feet, so it costs a little more than dynamic drive, but the display effect of static drive is a little better. If it is a dot matrix LCD, it must adopt dynamic drive, otherwise, the feet will be too many. For example, 128 * 32 pixel LCD screen adopts static drive, it will be (128 * 32+1) 4097 feet. If the duty of 128 * 32 pixel LCD screen is 32, there will be (128 * 32/32+32) 160 feet.

There are many kinds of LCD interfaces, with wide range of applications. The classification criteria mainly depends on the driving mode and control mode of the LCD. At present, there are generally several connection modes for color LCDs on mobile phones: MCU mode, RGB mode, SPI mode, VSYNC mode, MDDI mode, DSI mode, etc. and only the TFT module has RGB interface.

It is mainly used in the field of single-chip microcomputers. Later, it is widely used in low-end mobile phones, and its main feature is that it is cheap. The standard term for the MCU-LCD interface is the 8080 bus standard proposed by Intel.

Therefore, 8080 is used to refer to the MCU-LCD screen in many documents. It can be mainly divided into 8080 mode and 6800 mode, and the difference between the two is mainly the timing. There are 8 bits, 9 bits, 16 bits, 18 bits, and 24 bits for data bit transfer. Connections are divided into: CS/, RS (register selection), RD/, WR/, and data lines. The advantages are: the control is simple and convenient, no clock and synchronization signals are required. The disadvantage is: it consumes GRAM, so it is difficult to achieve a large screen (above 3.8). For LCM with MCU interface, the internal chip is called LCD driver. The main function is to transform the data/command sent by the host into the RGB data of each pixel, so that it can be displayed on the screen. This process does not require point, line, frame clocks.

The LCD Driver IC of the MCU interface is equipped with GRAM. As a co-processor of the MCU, it accepts the Command/Data sent by the MCU and can work relatively independently. Pay attention to, the internal chip of LCD Module (LCM) is called the LCD driver. The main function is to transform the data/commands sent by the host computer into the RGB data of each pixel, so that it can be displayed on the screen. This process also does not require point, line, frame clocks.

In fact, this mode is to add a VSYNC signal to the MCU mode and applied to the update of the moving picture, which is very different from the above interface. This mode supports the function of direct animation display. It provides a solution for animation display with minimal changes to the MCU interface. In this mode, the internal display operation is synchronized with the external VSYNC signal. Animation display at a higher rate than internal operations can be achieved. However, due to the difference in its operation mode, this mode has a limit on the speed, that is, the write speed to the internal SRAM must be greater than the speed of the display read internal SRAM.

The M6800 mode supports selectable bus widths of 8/9/16/18-bit (the default is 8 bits). The actual design idea is the same as that of Intel 8080. The main difference is the bus control read and write signals in this mode. Combined on one pin (with a latch signal (E) data bit transmission has 8, 9, 16 and 18 bits).

The large screen adopts more modes, and the data bit transmission also has the 6-, 16- and 18-, 24-bit. The connections are generally: VSYNC, HSYNC, DOTCLK, CS, RESET, some also need RS, and the rest is the data line. Its advantages and disadvantages are just the opposite of MCU mode. The main difference between the MCU-LCD screen and the RGB-LCD screen is the location of the video memory. The video memory of RGB-LCD is acted by system memory, so its size is only limited by the size of system memory. Where RGB-LCD can be made larger, such as 4.3" can only be regarded as entry-level, and 7" in MID, 10" screens have begun to be widely used. At the beginning of the design of MCU-LCD, it was only necessary to consider that the memory of the single-chip microcomputer was small, so the video memory was built into the LCD module, and then the software updated the video memory through special display commands with small MCU screen. At the same time, the display update speed is slower than RGB-LCD. The display data transmission mode is also different. RGB screen only needs to organize the data in the video memory. After starting the display, the LCD-DMA will automatically transfer the data in the video memory through the RGB interface to the LCM, while the MCU screen needs to send a drawing command to modify the internal RAM of the MCU (that is, the RAM of the MCU screen cannot be directly written).

Therefore, the RGB display speed is significantly faster than that of the MCU, and the MCU-LCD is also slower in terms of video playback. For the LCM of the RGB interface, the host directly outputs the RGB data of each pixel without conversion (except for GAMMA correction, etc.). For this interface, an LCD controller is required in the host part to generate RGB data and sync signals.

Here gives a note. The color TFT LCD screen mainly has 2 kinds of interfaces: TTL interface (RGB color interface), and LVDS interface (differential signal transmission). The TTL interface is mainly used for small-sized TFT screens below 12.1 inches, and the LVDS interface is mainly used for large-sized TFT screens above 8 inches. The TTL interface has many lines and the transmission distance is short, while the LVDS interface has a long transmission distance and a small number of lines. The large screen adopts more modes, the control pins are VSYNC, HSYNC, VDEN, VCLK, S3C2440 supports up to 24 data pins, and the data pin is VD[23-0].

The image data sent by the CPU or graphics card is a TTL signal (0-5V, 0-3.3V, 0-2.5V, or 0-1.8V), and the LCD itself also receives a TTL signal, which is transmitted at a high rate over long distances. However, its performance is poor, and the anti-interference ability is relatively poor. With the time goes by, a variety of transmission modes were proposed, such as LVDS, TDMS, GVIF, P&D, DVI and DFP. They actually just encode the TTL signal sent by the CPU or graphics card into various signals for transmission, and decode the received signal on the LCD side to obtain the TTL signal. No matter what transmission mode is used, the essential TTL signal is the same. Note: TTL/LVDS are two signal transmission modes: TTL is a mode in which high level means 1, and low level means 0; LVDS is the difference of a positive and negative corresponding waveform used to indicate the 1 or 0.

Qualcomm"s MDDI, which can improve the reliability of mobile phones and reduce power consumption by reducing wiring. It will replace SPI mode as a high-speed serial interface in the mobile field.

2) When using the MCU mode, since the data can be stored in the IC"s internal GRAM first and then written to the screen, the LCD in this mode can be directly connected to the memory bus. It is different when using RGB mode, and has no internal RAM, HSYNC, VSYNC, ENABLE, CS, RESET, RS can be directly connected to the GPIO port of memory, and use the GPIO port to simulate waveforms.

RGB interface mode: The display data is not written into DDRAM, but directly written to the screen, which is fast and often used to display video or animation.

The commonly used interfaces of TFT-LCD, including TTL (RGB), LVDS, EDP, and MIPI. Here roughly talk about the basic principles of the signal composition of these interfaces.

TTL is transistor-transistor logic, and TTL level signals are generated by TTL devices. TTL devices are a large category of digital integrated circuits. They are manufactured by bipolar technology and have the characteristics of high speed, low power consumption and many varieties.

The TTL interface is an interface for transmitting data in parallel. When using it, it is not necessary to use a dedicated interface circuit at the driver board end and the LCD panel end of the liquid crystal display, but the TTL data signal output by the main control chip of the driver board is transmitted through the cable. It is directly transmitted to the input interface of the LCD panel. Due to the high signal voltage, many connections and long transmission cables of the TTL interface, the anti-interference ability of the circuit is relatively poor, and it is easy to generate electromagnetic interference (EMI). In practical applications, TTL interface circuits are mostly used to drive small-size (below 15in) or low-resolution LCD panels. The highest pixel clock of TTL is only 28MHz.

The TTL output interface of the driver board generally includes three types of signals: RGB data signal, clock signal and control signal. As shown below:

Dual channels, that is, two sets of RGB data, which are divided into odd channels and even channels. Some clocks are also divided into OCLK/ECLK, and some share one. The following figure has two, as shown below:

It refers to the pixel clock signal, which is the benchmark for transmitting data and reading the data signal. When using odd/even pixel dual way to transmit RGB data, different output interfaces use different methods of pixel clock. Some output interface odd/even pixel dual data share a pixel clock signal, and the others set odd pixel data clock and even pixel two clock signals to meet the needs of different LCD panels.

The control signals include a data enable signal (or an effective display data strobe signal) DE, a horizontal sync signal HS, and a vertical sync signal VS.

LVDS is a low-voltage differential signaling technology interface. A digital video signal transmission method developed to overcome the shortcomings of large power consumption and large EMI electromagnetic interference when transmitting broadband high bit rate data in TTL level mode. The LVDS output interface uses a very low voltage swing (about 350mV) to transmit data differentially on two PCB traces or a pair of balanced cables, that is, low-voltage differential signaling. Using the LVDS output interface, the signal can be transmitted at a rate of several hundred Mbit/s on the differential PCB line or balanced cable. Due to the low-voltage and low-current driving method, low noise and low power consumption are achieved.

In a liquid crystal display, the LVDS interface circuit includes two parts, the LVDS output interface circuit (LVDS transmitter) on the motherboard side and the LVDS input interface circuit (LVDS receiver) on the LCD panel side. The LVDS emitter converts the TTL signal into an LVDS signal, and then transmits the signal to the LVDS decoding IC on the receiving end through the flexible cable (line) between the driver board and the LCD panel, and the LVDS receiver then serializes the serial signal which is converted into a parallel signal of TTL level, and sent to the LCD screen timing control and row and column drive circuit. In other words, TFT only recognizes TTL (RGB) signals.

EDP is a communication interface of the computer display screen. The resolution of the computer using the EDP display interface will be higher than that of the LVDS interface. Generally, high-definition screens use this communication interface. It is a fully digital interface based on the DisplayPort architecture and protocol. It can transmit high-resolution signals with simpler connectors and fewer pins, and can achieve simultaneous transmission of multiple data, so the transmission rate is much higher than LVDS.

Compared with the LVDS interface, the MIPI interface is rare, but in fact, it has many advantages. The MIPI interface module has the advantages of high speed, large amount of data transmission, low power consumption, and good anti-interference when compared with the parallel port. It is more and more favored by customers and is growing rapidly. For example, an 8M module with both MIPI and parallel port transmission requires at least 11 transmission lines and an output clock of up to 96M to achieve a full pixel output of 12FPS when using an 8-bit parallel port. Channel 6 transmission lines can achieve a frame rate of 12FPS at full pixels, and the current consumption will be about 20MA lower than that of parallel port transmission. Since MIPI uses differential signal transmission, the design needs to be strictly designed according to the general rules of differential design. The key is to achieve differential impedance matching. The MIPI protocol stipulates that the differential impedance of the transmission line is 80-125 ohms.

16x2 LCD means that there are two rows in which 16 characters can be displayed per line, and each character takes 5X7 matrix space on LCD. ... In this tutorial we are going to connect 16X2 LCD module to the 8051 microcontroller (AT89S52).

LCD Displays that use a parallel interface include Character, Graphic and TFT. ... The initial step is to energize the LCD. Reads and Writes are sent via 8 data lines and 3 control lines. These control lines are Read/Write (R/W), Enable (E) and Register Select (RS).

A TFT LCD display module consists of a TFT LCD panel, one or more COG (chip-on-glass) or COB (chip-on-board) driver ICs, a backlight, and an interface. Several TFT display interface technologies exist today. Picking the right interface depends on specific end-product concerns.

These interfaces communicate through read, write and chip-select signals to address registers or display RAM. Depending on color depth (8, 9, 16 or 18-bit), MCU sends RGB signals directly to LCM"s display memory.

TFT is a kind of LCD. The TFT(Thin Film Field-effect Transistor) is a video in which every single pixel in the liquid crystal display is actuated by a Thin Film Transistor embedded in the rear. Thus can achieve high speed, high brightness, high contrast display screen information.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

In-plane switching was developed by Hitachi Ltd. in 1996 to improve on the poor viewing angle and the poor color reproduction of TN panels at that time.

Initial iterations of IPS technology were characterised by slow response time and a low contrast ratio but later revisions have made marked improvements to these shortcomings. Because of its wide viewing angle and accurate color reproduction (with almost no off-angle color shift), IPS is widely employed in high-end monitors aimed at professional graphic artists, although with the recent fall in price it has been seen in the mainstream market as well. IPS technology was sold to Panasonic by Hitachi.

IPS has since been superseded by S-IPS (Super-IPS, Hitachi Ltd. in 1998), which has all the benefits of IPS technology with the addition of improved pixel refresh timing.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

It achieved pixel response which was fast for its time, wide viewing angles, and high contrast at the cost of brightness and color reproduction.Response Time Compensation) technologies.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

When the field is on, the liquid crystal molecules start to tilt towards the center of the sub-pixels because of the electric field; as a result, a continuous pinwheel alignment (CPA) is formed; the azimuthal angle rotates 360 degrees continuously resulting in an excellent viewing angle. The ASV mode is also called CPA mode.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

The statements are applicable to Merck KGaA as well as its competitors JNC Corporation (formerly Chisso Corporation) and DIC (formerly Dainippon Ink & Chemicals). All three manufacturers have agreed not to introduce any acutely toxic or mutagenic liquid crystals to the market. They cover more than 90 percent of the global liquid crystal market. The remaining market share of liquid crystals, produced primarily in China, consists of older, patent-free substances from the three leading world producers and have already been tested for toxicity by them. As a result, they can also be considered non-toxic.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

※Price Increase NotificationThe TFT glass cell makers such as Tianma,Hanstar,BOE,Innolux has reduced or stopped the production of small and medium-sized tft glass cell from August-2020 due to the low profit and focus on the size of LCD TV,Tablet PC and Smart Phone .It results the glass cell price in the market is extremely high,and the same situation happens in IC industry.We deeply regret that rapidly rising costs for glass cell and controller IC necessitate our raising the price of tft display.We have made every attempt to avoid the increase, we could accept no profit from the beginning,but the price is going up frequently ,we"re now losing a lot of money. We have no choice if we want to survive. There is no certain answer for when the price would go back to the normal.We guess it will take at least 6 months until these glass cell and semiconductor manufacturing companies recover the production schedule. (Mar-03-2021)

Impact: ER-TFT043-7 is the same with ER-TFT043A1-7 in mechanical dimension and electrical spec in our testing.As old customer,we recommend you test samples before mass order.

ER-TFT043A1-7 is 4.3 inch IPS TFT LCD 800x480 dots display, with driver IC ST7262E43 and optional capacitive touch panel or resistive touch panel,superior display quality,full view angle and easily controlled by MCU such as PIC, AVR, ARDUINO,ARM and Raspberry portable or handheld device.PI.

It can be used in any embedded systems,car,mp4,gps,industrial device,security and hand-held equipment which requires display in high quality and colorful image.It supports rgb interface. FPC with zif connector is easily to assemble or remove.Of course, we wouldn"t just leave you with a datasheet and a "good luck!".Here is the link for 4.3"TFT Touch Shield with Libraries, Examples.Schematic Diagram for Arduino Due,Mega 2560,Uno and 8051 Microcontroller Development Board&Kit.

IPS, also known as In-Plane Switching, is a type of monitor display and screen technology that uses a voltage to control the alignment of liquid crystals, similar to TN technology. However, IPS displays use a different crystal orientation where the crystals are parallel to the glass substrates, hence the term ‘in-plane’. Rather than ‘twisting’ the crystals to modify the amount of light let through, IPS crystals are essentially rotated, which has a range of benefits. IPS displays offer the best color reproduction as well as the widest viewing angles compared to other LCD technologies.

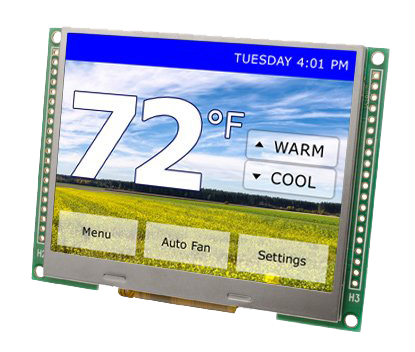

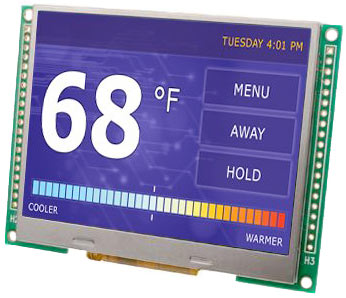

While TN LCD’s support high refresh rates with low response times, they do come with sub-optimal viewing angles, and slightly diminished color reproduction. IPS panels address these downfalls with 80 degree viewing angles that eliminate color inversion and contrast diminishment. IPS technology is ideal for a wide array of applications such as medical, industrial, HVAC, Pool/Spa due to the ability to use the displays in both landscape and portrait mode while maintaining uniform viewing angles. This also allows for displays to be seen from different angles and heights, ideal for jacuzzi controls and thermostats that tend to require consideration of dynamic user parameters.

Le service des pièces jointes, CJoint.com est un service de partage de fichier gratuit pour partager vos documents dans vos courriels, sur les forums ou dans vos petites annonces.

Color LCD module PS302-04043-00 is composed of the amorphous silicon thin film transistor liquid crystal display (a-Si TFT LCD) panel structure with driver LSIs for driving the TFT (Thin Film Transistor) array and a dual mode backlight. The a-Si TFT LCD panel structure is injected liquid crystal material into a narrow gap between the TFT array glass substrate and a color-filter glass substrate. Color (Red, Green, Blue) data signals from a host system (e.g. signal generator, etc.) are modulated into best form for active matrix system by a signal processing board, and sent to the driver LSIs which drive the individual TFT arrays. The TFT array as an electro-optical switch regulates the amount of transmitted light from the backlight assembly, when it is controlled by data signals. Color images are created by regulating the amount of transmitted light through the TFT array of red, green and blue dots.

The “gamut” of a display refers to the range of colours it can display, and for LCD monitors this is normally related to the backlight type that is used to light the screen from behind the LCD panel. There are several common reference colour spaces that you will no doubt have heard of, including the long-standing “sRGB” reference space and more recently adopted standards in the monitor market like DCI-P3 or Adobe RGB. This article will provide a hopefully simple overview of what colour gamut is, then take a top level look at the different ways to measure and quote this spec, without delving in to loads of overly technical or complicated information that might bore you too much. We will also talk about our newly improved testing methodology and equipment we will start to use for future reviews to enhance our accuracy and data we can report.

If you enjoy our work and want to say thanks, donations to the site are very welcome. If you would like to get early access to future reviews and articles please consider becoming a TFT Central supporter.

Check Availability and Pricing – Affiliate LinksTFTCentral is a participant in the Amazon Services LLC Associates Programme, an affiliate advertising programme designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com, Amazon.co.uk, Amazon.de, Amazon.ca and other Amazon stores worldwide. We also participate in a similar scheme for Overclockers.co.uk.

Experiments at the beginning of the last century into the human eye eventually led in 1931 to the creation of a system that encompassed all the range of colours our eyes can perceive. Its graphical representation is called a CIE diagram as shown in the image above. All the colours perceived by the eye are within the collared area. This standard is called CIE-1931 and is widely used throughout the world to be able to measure and compare colours for printed documents as well as displays. The CIE-1931 standard maps colours to a 2 dimensional x,y space as shown above. It is sometimes referred to as a “CIE-1931 xy chromaticity diagram”

The CIE-1931 color space has worked well to enable accurate color reproduction in print and displays. Unfortunately, further study revealed that the severity of color differences, as perceived by humans, were non-uniform in the CIE-1931 color space. What that means is that for example two blue colours at a certain distance ‘v’ in the CIE-1931 color space will look more different to humans than two green colours at the same distance ‘v’. In 1976 a new color space, called CIE-1976, was introduced to fix this issue. The CIE-1976 color space, as shown above, was specifically designed to align uniformly with human perception. This is sometimes referred to as a “CIE-1976 u’v’ chromaticity diagram”. The CIE-1931 color space should no longer really be used, but today’s reality is that it is still prevalent throughout the industry.

Within this overall CIE area there are various standard colour spaces that have been defined over the years. In the display market these define a certain range of colours that the screen can produce and is related to the backlight of the screen, as opposed to the panel itself.

The most common colour space that has been around for a long time and is widely used is sRGB. This is the default for Windows, the internet, most games, movies and for SDR (Standard Dynamic Range) content. It is widely used across different devices and content.

You may be familiar with images like the above which shows the sRGB colour space triangle within the CIE-1931 chromaticity diagram (left), or less commonly within the CIE-1976 diagram (right). The sRGB gamut triangle defines a certain range of colours based on the primaries of red, green and blue (RGB).

When discussing monitor colour gamut many manufacturers will quote how much of this sRGB space the screen can cover, with modern “standard gamut” LED backlights normally covering 97 – 100% of this reference space quite easily. It’s important for a screen to have good coverage of sRGB at least to ensure accurate colour reproduction and so that it can display the full range of colours it is supposed to, when viewing common sRGB-based content.

Many modern displays are now promoted as featuring “wide colour gamut” (WCG), being able to produce colours that are beyond the range of traditional “standard gamut” sRGB displays. This is achieved in a number of ways by enhancing the backlight with special treatments or films (e.g. Quantum Dot coating), or using certain backlight types in some cases such as RGB LED. The result is a screen that can offer more vivid and saturated colours that stretch beyond sRGB and try to confirm to other colour space standards, supporting content created and intended to be displayed in these wider colour spaces. Some common wide gamut reference spaces include:

One of the most popular colour space standards quoted today is DCI-P3 which was defined by Digital Cinema Initiatives, and is associated commonly with cinema and movie content. It has become closely linked with modern HDR promotion also and so has become more widespread in recent years with modern TV’s, monitors and content.

In simplistic terms where high coverage of DCI-P3 is achieved, a user knows that it can offer wider colour range than a standard sRGB gamut screen, and will allow them to better display content that has been produced based on this standard. Modern HDR movies, videos and games are good examples of where DCI-P3 is used for creation, and where you ideally therefore need a DCI-P3 supporting screen to show them properly.

Many modern displays will therefore quote a DCI-P3 coverage %. Again you need to be careful of whether this is relative to CIE-1931 or 1976 and ideally you’d want it to be as close to 100% coverage as possible if you want to be able to accurately produce the intended colours from DCI-P3 content. Nowadays this DCI-P3 coverage provides a fairly useful comparison spec when comparing wide gamut screens, since sRGB is no longer wide enough unless you refer to over-coverage figures, which can sometimes be misleading or can get a bit silly.

The Adobe RGB (1998) color space was developed by Adobe Systems Inc. to improve upon the gamut of the sRGB color space in primarily cyan-green hues, for better conversion to the subtractive CMYK color model used by printers. It uses the same red and blue primaries as the sRGB color space, but the green primary is more saturated and also of a much deeper hue of green (sRGB uses a rather yellowish hue of green). This colour space is more commonly referred to with the more professional-orientated monitors aimed at printing, colour critical work etc. It doesn’t carry the “multimedia” connotations that DCI-P3 does and so is less widely used nowadays for many gaming and movie focused wide gamut screens.

The Rec. 2020 standard is actually more than just a color space. It is the standard for Ultra High Definition Television (UHD-TV), which also includes resolution, refresh rate and colour depth considerations. Focusing on the colour gamut side of things for the purposes of this article, the Rec. 2020 offers significant improvement over the Rec. 709 standard when it comes to the color gamut: nearly twice the size of its predecessor. It stretches considerably beyond Adobe RGB and DCI-P3 as well. This is not commonly used as a monitor spec at the moment, but expect this to become more widely quoted in the future as manufacturers reach beyond the now popular DCI-P3 reference, and look for new ways to promote and compare their wide gamut production.

One thing you will often see in specs and marketing is a colour gamut spec relative to sRGB, but quoted beyond 100%. We also currently provide this in our reviews as we feel it’s quite a useful comparison figure between different displays. For a wide gamut screen this basically shows how far beyond sRGB the colour space extends, so you will see figures such as 130% sRGB and so on quoted.

This is a reasonable spec to include for comparison as you could have one screen which has 120% sRGB for instance, compared with another that can do 160% sRGB. This tells you that the latter will have a wider colour range, and should offer more vivid and saturated colours. Some people like that added boost to colours, regardless of whether they are conforming to certain colour spaces or standard, or whether they are “accurate” for the content they are viewing. Some people just like the boosted and accentuated colours.

Quoting an over-coverage of sRGB is technically possible only if the sRGB gamut is fully covered at 100% on it’s own. We will continue to provide some measurements and context in our reviews in this area in the future anyway as it can be a useful reference point to compare different screens.

Most manufacturer websites and marketing brochures will list the colour gamut of the display nowadays. We’ve already mentioned earlier about being careful whether they are quoting CIE-1931 (the most common still) or CIE-1976 coverage specs. You need to compare like for like at least. Some of the specs they quote might be based on their own internal testing at the factory which should be reliable but probably still needs validating by third parties or reviewers. This factory measurement is especially likely to have happened if you see rather specific specs like “97.6% DCI-P3” for example. Other times it might be a more generic figure based on the intended panel/backlight spec of the part they are using, which is often just quoted broadly by panel manufacturers as something like “~95% DCI-P3” or “>90% DCI-P3” or similar. Take marketing specs with a pinch of salt as ever.

It is possible to get some information about a monitors colour gamut from the display’s EDID information too. Extended Display Identification Data (EDID) is a metadata format for display devices to describe their capabilities to a video source (e.g. graphics card or set-top box). The data format is defined by a standard published by the Video Electronics Standards Association (VESA).

The free VESA DisplayHDR test tool is a useful tool for some testing elements, but also provides some information read from the monitor EDID. Below for example is the report from the LG 38GL950G (a Native G-sync screen):

In this section in the middle it reports the RGB primary xy numbers and from there it accurately calculates the gamut coverage for several popular and common colour spaces (relative to CIE-1976) including sRGB, Adobe RGB, DCI-P3 and Rec.2020. We have validated that these calculations are correct incidentally using the tools discussed later in this article. This could in theory be a useful and quick way to establish the colour gamut capabilities of the display, although the crucial thing here is to consider whether you can trust the EDID information or not?

The EDID information is provided by the display manufacturer so in one sense you might want to put as much faith in to that spec as you might in to any other spec they market for the display! This information could potentially be very hit and miss from display to display and from one manufacturer to another. It is always a good idea to test the gamut independently if you can, or refer to review sites like TFTCentral who will measure it as well independently.

In some cases you might be able to put more faith in this information contained within the EDID. For instance we know that Native NVIDIA G-sync screens are factory colour calibrated as part of the strict NVIDIA process with highly accurate equipment and processes, and the information recorded in detail in the EDID. It is likely that many other non-G-sync screens might not update this EDID information accurately in the factory in this same way. There is a high chance some values could be average figures, desired/expected, or even just made up. As a result it’s always better to independently verify the results if you can with a highly accurate method, or refer to review sites who can do that for you in their testing.

It’s worth also keeping in mind that this EDID information is only available for a single colour space mode, usually the native backlight colour space and so even if this was highly accurate information based on real testing in the factory that you could believe in, it’s not possible to know how it might perform in other modes like specific sRGB emulation modes etc. We will continue to test monitor gamut independently in various modes (using our new more accurate method described below) rather than rely on manufacturer EDID information, although we may well cross-refer from time to time to see how accurate this EDID information tends to be.

Getting the accurate gamut coverage number for a monitor is challenging. It requires both high end measurement equipment and a careful measurement procedure. In the past we have used an X-rite i1 Pro 2 spectrophotometer combined with ChromaPure’s software to measure colour gamut in sRGB, DCI-P3 and Rec.2020. This provides a pretty decent measurement of colour gamut, but we believe we can improve it and be more thorough.

We have now updated our testing methodology to include tests with a new spectroradiometer device, the UPRtek MK550T spectroradiometer. This helps increase our accuracy and provide further measurements in our reviews. Check out the linked article where we look at this new device, its software and the various other useful and new things it will allow us to do. Here we will just talk about how it can help improve our colour gamut measurements and accuracy. This is an expensive but well regarded device and should provide improved levels of accuracy when measuring colour spaces.

By measuring the x,y primaries of RGB produced by the monitor with the high levels of accuracy that this spectroradiometer device can provide (in various modes if necessary), we can use a special calculation tool to work out the true gamut coverage for both CIE-1931 and CIE-1976, considering absolute and relative figures. Combining the super high accuracy of the UPRtek device with this new method produces the most accurate measurements of the monitors true gamut coverage.

We carried out the tests on the LG 38GL950Gwhich offers a wide colour gamut Nano IPS panel. It also has a working sRGB emulation mode. This is a Native G-sync module screen which also gives us a chance to sanity check the EDID information against our measurements which we believe should be accurate given the factory calibration and measurement process NVIDIA perform. We measured the screen with our new UPRtek device and gamut calculation tool as described above. The following results were obtained:

sRGB coverage – Firstly the manufacturer quotes a 135% sRGB coverage in an effort to provide a comparison point against other screens quoted in a similar way, so you can tell that it has an even wider colour space coverage than a screen that might be 120% sRGB for example. It also highlights the fact that it is a decent way beyond a normal “standard gamut” sRGB screen (typically quoted as 97 – 100% sRGB). We’ve talked earlier about whether or not quoting over-coverage in this way is appropriate or can lead to errors, but our view is that it’s a useful additional spec. In our original review we were able to confirm using our i1 Pro 2 device and ChromaPure software a 130.9% sRGB coverage so this was close to the spec. Measurement with the UPRtek spectroradiometer device and gamut calculation software will not allow over-coverage calculation in the same way, so we only confirm here that 100% coverage of the sRGB space is achieved regardless of whether you are considering CIE 1931 or 1976. This was not checked with our old method, as only an over-coverage spec was calculated, without consideration for if the sRGB gamut was covered exactly and fully. The UPRtek device allows us to confirm this more thoroughly. So in this instance, given 100% is covered, the 130.9% over-coverage spec is valid too. So we can summarise that the 38GL950G in its native wide gamut mode can successfully cover 100% of the sRGB reference, and extends beyond that to around 130.9% for comparison purposes with other screens.

Adobe RGB coverage– this isn’t quoted by the manufacturer or measured with our old i1 Pro 2 device/ChromaPure process, but using the new device and method we can confirm that the native gamut covers 89.5% (CIE-1931) or 94.8% (CIE-1976) of the Adobe RGB reference. This is a useful additional measurement now possible and relevant to those doing colour critical work/photo work/printing.

DCI-P3 coverage– The manufacturer quotes 98% coverage. Using the UPRtek device we can confirm that 98.1% of the CIE-1976 DCI-P3 space is covered. It looks like LG spec is based on CIE-1976 although they don’t stipulate, perhaps because this gives you the higher number? This means that there is a small portion of the reference space that is not produced, so it can’t cover 100% of DCI-P3. Our i1 Pro/ChromaPure tests measured a smaller 96.5% which must be down to small inaccuracies in the i1 Pro device relative to the UPRtek spectroradiometer

Rec.2020 coverage– LG don’t provide a spec for this. Our original method calculated 69.2% coverage and we saw similar results from the UPRtek device as well, although a bit higher at 75.9% relative to CIE-1976.

The screen has an sRGB emulation mode as well which is designed to restrict the full backlight gamma and provide a more “standard gamut” appearance for those who might want to work with sRGB content, or avoid oversaturation or unrealistic colour tones for certain uses.

sRGB coverage– using our original method we recorded a 97.7% coverage in this mode. With the new method this was more accurately recorded 100% coverage regardless of if you are referring to CIE-1931 or 1976. This is is a more accurate method of measurement thanks to the new more advanced device which confirms a slightly more accurate sRGB emulation than we had originally measured.

DCI-P3 coverage– In this sRGB emulation mode this greatly reduced the colour gamut of the screen. Our original method recorded 72.0% coverage, now more accurately calculated at 75.21% (CIE-1931 comparison) or 81.9% (CIE-1976). You can see why it’s important to know whether CIE-1931 or 1976 are being used in specs and measurements as the figures are very different. Again the new device offers improved accuracy.

We won’t provide all these measurements in our future reviews, we will think of a simpler and easier way to present figures that you can easily refer to and rely on.

Below this is the information reported from the EDID in the VESA Display HDR tool which provides CIE-1976 coverage calculations. This is listed as the Native gamut as well:

The EDID information being reported by the screen is based on the native wide gamut mode based on the figures listed, and our own measurements. There is a very good correlation between the manufacturer provided stats in the EDID and our own measurements which is great news.

We carried out the same tests on the recently reviewed Asus ROG Swift PG329Q which had a particularly wide colour gamut. This is an adaptive-sync screen (i.e. not a Native G-sync module screen like the LG 38GL950G is) which also gives us a chance to sanity check the EDID information again and see whether that is accurate, or is less reliable than the NVIDIA calibrated EDID information from Native G-sync screens.

sRGB coverage – Firstly the manufacturer quotes a 160% sRGB coverage in an effort to provide a comparison point against other screens quoted in a similar way, so you can tell that it has an even wider colour space coverage than a screen that might be 130% sRGB for example. It also highlights the fact that it is a long way beyond a normal “standard gamut” sRGB screen (typically quoted as 97 – 100% sRGB). We’ve talked earlier about whether or not quoting over-coverage in this way is appropriate or can lead to errors, but our view is that it’s a useful additional spec. In our original review we were able to confirm using our i1 Pro 2 device and ChromaPure software a 157.4% sRGB coverage so this was close to the spec. Measurement with the UPRtek spectroradiometer device and gamut calculation software will not allow over-coverage calculation in the same way, so we only confirm here that 100% coverage of the sRGB space is achieved regardless of whether you are considering CIE 1931 or 1976. This was not checked with our old method, as only an over-coverage spec was calculated. The UPRtek device allows us to confirm this more thoroughly. So in this instance, given 100% is covered, the 157.4% over-coverage spec is valid too. So we can summarise that the PG329Q in its native wide gamut mode can successfully cover 100% of the sRGB reference, and extends beyond that to around 157.4%.

Adobe RGB coverage– this isn’t quoted by the manufacturer or measured with our old i1 Pro 2 device/ChromaPure process, but using the new device and method we can confirm that the native gamut covers 100% of the Adobe RGB reference too (again regardless of whether we consider CIE-1931 or 1976). This is a useful additional measurement now possible and relevant to those doing colour critical work/photo work/printing.

DCI-P3 coverage– The manufacturer quotes 98% coverage, and this is one area where it is a little more tricky. Using the UPRtek device we can confirm that 98.1% of the CIE-1976 DCI-P3 space is covered. It looks like Asus’ spec is based on CIE-1976 although they don’t stipulate, perhaps because this gives you the higher number? This means that there is a small portion of the reference space that is not produced, so it can’t cover 100% of DCI-P3. Our i1 Pro/ChromaPure tests confirm that the gamut extends beyond that reference area to around 116.0%. If we are being strict, this isn’t quite true as it can’t cover the full 100%, being only 98.1% covered. The 116.0% shows it reaches beyond the DCI-P3 space a fair bit, but doesn’t tell the full picture. So we would summarise here that 98.1% of the DCI-P3 reference is covered, but if we were to consider over-coverage area it extends to approx 116.0%. The new method allows us to more accurately confirm DCI-P3 coverage, including with higher levels of accuracy.

Rec.2020 coverage– Asus don’t provide a spec for this. Our original method calculated 83.3% coverage and we saw similar results from the UPRtek device as well.

The screen has an sRGB emulation mode as well which is designed to restrict the full backlight gamma and provide a more “standard gamut” appearance for those who might want to work with sRGB content, or avoid oversaturation or unrealistic colour tones for certain uses.

sRGB coverage– using our original method we recorded a 95.2% coverage in this mode. With the new method this was more accurately recorded at 97.1 / 97.0% depending on if you are referring to CIE-1931 or 1976. Either way this is a more accurate method of measurement thanks to the new more advanced device.

DCI-P3 coverage– In this sRGB emulation mode this greatly reduced the colour gamut of the screen. Our original method recorded 70.2% coverage, now more accurately calculated at 73.1% (CIE-1931 comparison) or 79.9% (CIE-1976). You can see why it’s important to know whether CIE-1931 or 1976 are being used in specs and measurements as the figures are very different. Again the new device offers improved accuracy.

We won’t provide all these measurements in our future reviews, we will think of a simpler and easier way to present figures that you can easily refer to and rely on.

Below this is the information reported from the EDID in the VESA Display HDR tool which provides CIE-1976 coverage calculations. This is listed as the Native gamut as well:

The EDID information being reported by the screen appears to be based on the sRGB mode based on the figures listed, and our own measurements. This is fair enough, although it means it can’t confirm the full native gamut figures for you which is probably the more common usage scenario than sRGB mode. There is however a pretty good correlation, within 2 – 3%) between the manufacturer provided stats in the EDID and our own measurements which is good news.

The improved accuracy of the new method means we can provide better colour gamut results in our future reviews. We will provide colour gamut results as in the following example:

The table will confirm the colour space absolute coverage and also the relative coverage (which includes any extension beyond the reference) relative to common reference spaces of sRGB, DCI-P3, Adobe RGB and Rec.2020. These measurements are relative to CIE-1976 by the way. We will also be able to provide CIE-1976 chromaticity diagrams like the example shown, where the monitors gamut is plotted with the white triangle, compared to a selected reference space, in this instance sRGB.

While modern wide gamut screens have their place when you consider modern HDR multimedia, games and professional content, they do present some challenges for the user. The problem is that a huge portion of the content we consume is still based on the sRGB standard, including Windows, the internet, most games, movies and normal SDR (Standard Dynamic Range) content. If you use a wide gamut screen with sRGB content then the colours get “stretched” and end up looking unnatural and inaccurate. Some people prefer the boosted vividness and more saturated colours anyway even for their day to day general SDR use, enjoying the “pop” of the colours and the bright and colourful appearance. Your average consumer may well not care about the accuracy and will be perfectly happy with the screen looking more colourful than others.

However the wider the colour gamut of the backlight is, the more potential this has to cause problems when viewing standard sRGB gamut content. Skin tones can look too red and sun-burnt, the sky can be artificially blue and plants and foliage can look too neon green and unrealistic. If you’re doing colour critical work, photo editing or are just concerned about the accuracy of the image then this is not good. What we need is a way to view sRGB content on a wide gamut screen without the wide colour gamut being forced.

One way to overcome this challenge in some cases is through correct calibration and profiling of the screen. Through the use of a calibration device and appropriate software you can profile the screen relative to the sRGB colour space and create an ICC profile. This profile is activated at the graphics card level and provides mapping corrections that can be read by “colour aware” applications such as leading photo editing software. This profile can tell the screen how to map the colour gamut of the backlight back to the sRGB reference space so that you can view sRGB content as intended.

This is a common and reasonable method but unfortunately has its drawbacks. You really need to have your own calibration device and software to do this profiling, and relying on third party ICC profiles and settings from other people can lead to too many variables and errors. ICC profiles are also not widely supported and while some photo editing software packages will accept them, the profiles get discarded in games and movies and are generally a bit of a pain to implement at a system level. So you can improve the accuracy in some places but not everywhere.

Finally when you carry out this calibration ideally you want to be making as many changes and corrections to the screen itself at a hardware level, so that the graphics card ICC profile has as few corrections as possible to make. The more corrections you have to make at the graphics card level, the more risk there is of introducing issues like colour banding, tone crushing and loss of detail. Where a monitor provides plenty of options to change things like gamma, colour channels etc this is usually ok as you can get “most of the way there” with the OSD settings, before the profile completes the final corrections and the sRGB gamut mapping. If the screen is inflexible in OSD settings, you end up having to do more of the correction from the ICC profile and this can often lead to issues.

A better option is if you can hardware calibrate the display itself. This feature is usually reserved for high end colour critical and professional monitors, where access to the monitors Look Up Table (LUT) is available. You need a calibration tool and software of your own for this, but you can actually calibrate the screen at a hardware level as opposed to needing to use an ICC profile at the graphics card level. Generally the calibration software will automatically correct all the settings of the monitor and make all corrections to the hardware LUT, which ensures all the changes are being made to the monitor itself. When you carry out this process you can usually define the colour space you want to calibrate to, and so you can hardware calibrate the screen specifically to sRGB if you want.

This is more accurate and flexible than a software based ICC profile, helping ensure that tonal values are retained and there are no introduced issues like banding or loss of detail. The other major benefit with hardware calibration is that because the settings are saved to the monitor itself, this is active for all applications and uses. You don’t need to mess around with ICC profile usage, and the settings apply for games, movies and all software because its all being done from the display itself. Unfortunately this feature is reserved at the moment for higher end and professional grade screens so is not widely available to your average user.

Another useful way to overcome this challenge is by using a so-called “sRGB emulation mode”. This is provided on many wide gamut screens as a preset mode where the screen itself deliberately reduces or “clamps” the native wide gamut back to the sRGB reference space, or as close to it as possible. You will see us check the availability and performance of any sRGB emulation mode in our reviews.

This can often work well, helping reduce the colour gamut and providing a preset mode the user can easily swit

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey