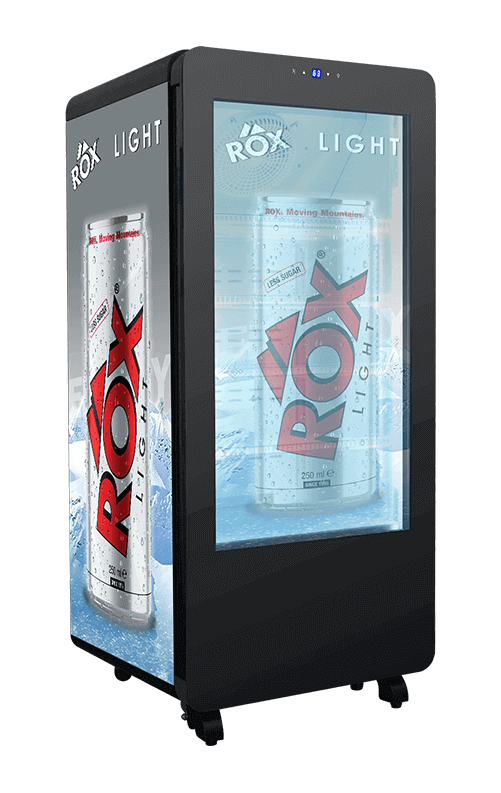

cooler with lcd display free sample

We think out of the box and spin it differently. Each of our LCD fridges is newly developed to fit with the screen size. The front glass door is a FULL-SIZE advertising screen.

So here’s the thing. As a CPU cooler, it is absolutely wonderful, running Doom Eternal on high keeps the CPU cores no higher than about 38’C, with some cores staying as low as 35’C. And for context, I live in Southern California, and it can get crazy hot sometimes, so when the average CPU temp during gaming is about 55-60’C, I cannot understate how ***GOOD*** this is.

However, the software, is an absolute hell. The iCue software that Corsair has developed, while slick and has a friendly UI, sometimes you just want to rip your hair out. For whatever reason, it conflicts with the LCD screen, which is meant to be the main feature of this product, meaning the majority of the time you won’t even get to use it. I got to only a couple times, and it’s really fun to have whatever gif or image you want playing, so it’s incredibly disappointing when it doesn’t work. I know it’s iCue itself, because whenever I reboot the PC or even click to Shut Down, the LCD will briefly spring back to life, it’s only once the computer seemingly detects the iCue software that it suddenly stops working. And now, after about a month of usage, I started getting the problem of iCue no longer detecting the cooler, which is something that I’d heard about, and so far any solution articles that Corsair has available don’t seem to work (it’s not very hopeful to see that on average only about 10-30% of people find the articles helpful). Thankfully, given the fact that I can see the error symbol that I’m all too familiar with at this point, and running high-demanding games while observing CPU temp, I’ve come to the conclusion that the cooler is indeed still working and receiving power (this alone is why I’m so happy to praise the hardware).

So that being said, do I recommend it? Well, if you believe yourself to have good luck with technology, then yes I’d say go for it. The product is incredible for its core purpose.

However, if you don’t want to deal with the software hellscape that is iCue, not the disappointment of paying extra for a feature that doesn’t seem to work, I’d say get the non-LCD model of this product. Just don’t forget that there is also a chance that it will lose detection.

Subject to underwriting approval. See Simple Financing Examples. Estimated monthly amount is based on the equivalent of 1% financing fee over a financing period of 6 months. Financing fee typical for business customers with exceptional creditworthiness and is calculated based on purchase amount and does not decline until satisfaction of the transaction. Assignment of purchasing limit occurs at Behalf enrollment. Financing request and approval occurs at the transaction checkpoint. Terms and Conditions subject to change at any time. The discount rate is expressed in a percentage as an example only for comparison purposes.

** Behalf’s Net is an alternative financing option offered by Select merchants and allows the Business Customer to pay no financing fees if the Order Request is satisfied in full and in accordance with terms and conditions within 30 days.

An all-in-one (AIO) liquid cooler not only ensures quieter cooling than a traditional air cooler, but it might even lower temperatures enough to let you overclock further. AIOs are a super simple way to water-cool your PC without any mess or the headache of choosing components. We also recommend investing in a liquid cooler if you have or are planning to buy a high-performance processor like the new Intel Core i9-13900K or AMD"s Ryzen 7950x.

Most builds call for a 240mm AIO. To that end, we recommend the Corsair iCUE H100i RGB Elite, thanks to its solid software integration, excellent included fans, and good price tag. You can jump up or down depending on your PC build size or cooling needs, too, with various options available.

Note: Before diving in, you"ll need to take note of your CPU socket before picking up an AIO water cooler. Every CPU cooler is a little different, so you"ll need to know what CPU socket your motherboard has to see if the cooler supports it.

The Corsair iCUE H100i RGB Elite is a minor update to the H100i RGB Pro XT, which has been our top recommendation for a while. It features an updated pump design with 16 RGB LEDs, and thanks to iCUE, you can sync up all of your various RGB accessories for a unified look inside your build. The software also allows you to check on your CPU and coolant temperature to make sure everything is running smoothly.

In addition to a 240mm radiator, the kit comes with Corsair"s new AF Elite fans. These are high-performance 120mm PWM fluid dynamic bearing fans that combine a low-noise design with the company"s "AirGuide" technology for powerful cooling, quiet operation, and exceptional durability. They also support Zero RPM and Variable Pump Speed specialized cooling modes in iCUE to keep noise to a minimum when your system is idle or under light loads.

The Corsair iCUE H100i RGB Elite is an easy AIO to recommend. The company is behind some of the best desktop CPU coolers, and the cooler clocks in at about $140. Socket support is excellent, too, with mounting options for all recent Intel and AMD processors, including Threadripper.

When it comes to raw thermal performance, the Arctic Liquid Freezer II is the best 360mm AIO cooler on the market. It reaches similar performance to competing coolers from NZXT and Corsair while being very inexpensive. Currently selling for about $130, the price is comparable to and in some cases lesser than most competitive 360mm AIO coolers out there.

The pump on the AIO is controlled by PWM, allowing it to modulate with the workload rather than run at full speed all the time. The Liquid Freezer II also includes a 40 mm fan next to the pump, set to sit over your motherboard"s VRM chips. In more extreme overclocking sessions, this may improve stability. Otherwise, it includes three Arctic 120 mm fans to keep air flowing.

This cooler is all about performance and price. It gets those two bits right, but not without some concessions. It doesn"t feature any sort of lighting, and the design may not be to everyone"s tastes. Still, the Arctic Liquid Freezer II hits a sweet spot that other coolers can"t compete with. Socket support is a little limited, but the Liquid Freezer still supports most recent chips. On AMD, it supports AM4 CPUs, and on Intel, it supports all LGA115x sockets, as well as 2011-3 and 2066 with a square Independent Loading Mechanism (ILM).

NZXT"s third-generation Kraken X coolers are well worth the asking prices. The cooler is now available in an all-white finish with two 120mm Aer RGB 2 fans making it perfect for your next white PC build. This 240mm model clocks in at around $145, which still isn"t too expensive. The design is much more appealing than Arctic"s offering while achieving similar levels of thermal performance.

For looks, the Kraken X"s infinity mirror pump cap is a showstopper. It bounces light around inside the cap to create the illusion of infinite LED rings. Like nearly all NZXT products, the Kraken X53 is fully integrated with CAM, allowing you to monitor temperatures and tweak your lighting settings. Over the X52, the X53 also includes an NZXT Hue 2 connection on the pump, offering power for up to six Hue 2 accessories. If you want to trick out your rig with synced-up RGB, the NZXT Kraken X53 is for you.

Socket support is excellent, with support for TR4 and AM4 on AMD, and LGA115X, 1700, and 1,200 on Intel. NZXT rates the Kraken X53 for six years of continuous use — 60,000 hours, technically — which is around what we"d expect for most AIO coolers. NZXT offers a six-year warranty, though, so you"re covered from any defects for the rated life of the cooler.

120 mm AIOs usually aren"t very good, but the Corsair H80i v2 is the best 120 mm AIO around. Without proper surface area on the radiator, most 120 mm coolers just aren"t up to snuff when it comes to cooling power. The Corsair H80i v2 solves that problem. The radiator is twice as thick, clocking in at 49mm compared to the standard 25mm. The H80i v2 doesn"t match the cooling performance of a 240mm radiator, but it gets a lot closer than a standard 120 mm one.

As for support, the Corsair H80i v2 comes with Intel mounting hardware for socket 1366 up to LGA1200 (Intel"s redesign of LGA1151, designed for Comet Lake CPUs). Basically, if you have an Intel processor introduced after 2008, you"re fine. AMD support is a little sparser. The cooler technically supports AM2 up to AM4, but the box only ships with mounting hardware for up to AM3. You"ll need a separate AM4 bracket. Thankfully, Corsair sells them for only a few dollars. There"s no RGB on this one, either, though you can control fan speed and monitor temperatures through Corsair"s iCUE software.

Cooler Master offers a range of "lite" AIOs, which are basically previous iterations of Cooler Master"s MasterLiquid line with increased socket support and double FEP tubing. At around $85, the Cooler Master ML240L v2 is the best budget AIO available. It comes with a 240mm radiator, two RGB fans, and a small RGB controller. Thermal performance isn"t great, and the noise level is higher than some more costly options. However, the ML240L clocks in around $50 cheaper than most competing 240mm AIOs. Plus, you can always swap the fans out later for more lighting options and slightly better noise levels.

The Cooler Master ML240L comes with nearly universal socket support, too. On Intel, it supports LGA1200, LGA20xx, LGA115x, and LGA1366, and on AMD, it supports AM2 to AM4, as well as FM2 and FM1. For the price, it"s hard to beat the ML240L.

If you want the best RGB AIO cooler, the EK-AIO 240 D-RGB goes off the deep end. Short of a small black strip where the tubes connect, the mounting block has a translucent, slightly diffused surface, washing out the lights inside into a beautiful display of color. EK is the place for custom water cooling, and the EK-AIO 240 shows why.

This is Corsair"s first all-in-one liquid cooler with a built-in LCD on the pump block. The iCUE H100i Elite LCD is a step beyond the older H100i RGB Pro XT and an excellent choice if you care about RGB lighting and customizations. The bright 2.1-inch panel comes with a 480x480 resolution making it sharper than most AIO LCD displays. It can be used to showcase a variety of things including system temperatures, custom artwork, GIFs, videos, and more. This can be done with Corsair"s iCUE software which also offers additional information about the cooler.

The AIO comes with two 120mm Corsair ML RGB ELITE magnetic levitation fans for great cooling performance while maintaining quiet operation. There is also support for a zero-RPM cooling profile that allows the fans to stop entirely at low temperatures thus eliminating any fan noise. Expect excellent thermal performance thanks to the custom cold plate that features a high-density stack of 128 micro-skived fins per inch providing highly efficient cooling.

Apart from the 240mm option, the Corsair Elite LCD AIO is also available in 360mm and 420mm configurations and there is support for all modern CPU sockets including the latest Intel LGA 1700 and AMD"s upcoming AM5.

The Alphacool Eisbaer Aurora is a CPU cooler that you can refill. Unlike other AIO liquid coolers, you can swap out the fluid, upgrade the hoses and fittings, and even expand the loop. The most recent model supports digital RGB on the fans and CPU block, too, allowing you to trick out your lighting however you want.

The looks are right, but Alphacool didn"t sacrifice thermals with the Eisbaer Aurora. The radiator is made out of copper for a little extra cooling potential, and the nickel-plated copper CPU block has been slightly enlarged compared to previous versions. For CPU support, the Eisbaer Aurora supports most modern processors, though it doesn"t officially support Threadripper chips.

The most important part of an AIO CPU cooler is the radiator size. A larger radiator offers better cooling performance, but you need to make sure it can fit inside your case. Otherwise, look at the socket support to make sure you can use the cooler with your motherboard and buy from a reputable brand.

Most AIO coolers have a lifespan of six years, regardless of if they have RGB or not. You can expect an AIO cooler from a reputable brand to run for six years without issues, but every cooler is a little different. We recommend looking up individual AIO cooler reviews to see if others have had issues with reliability.

Before buying an AIO cooler, you need to know about the risks it may pose to your PC. Although failures are few and far between, every AIO cooler is still putting water dangerously close to your precious PC components, so there"s always a risk that the cooler could leak or fail and damage your parts. The fact that AIO coolers are closed makes matters worse because you can"t open the loop to see if there are any problems.

The best way to mitigate risk is to keep an eye on your cooler to see if there are any signs of leaking and to monitor your CPU temperature to see if the pump is failing. As long as you keep an eye on both, you can find most problems before they do any catastrophic damage.

In a typical setup, yes, liquid cooling is simply better at capturing and dissipating heat than an air cooling system alone — however, they aren"t necessarily better than the best air coolers. AIO coolers are a popular option to add liquid cooling because they offer the whole cooling system in a premade package that"s relatively easy to set up, and they tend to be very quiet.

That being said, AIO coolers may not be the best choice for every gaming station. As we mentioned above, not all PC cases have a lot of room to add a radiator, pump, and tubing. If you aren"t interested in overclocking and your current system manages temperatures just fine, you may not see a lot of benefit from switching to an AIO cooler, either.

That depends on several factors. The pump that moves the liquid in the cooler is typically silent or at least inconsequential compared to other PC noises. AIO models usually have fans, which will get noisy if they operate at high speed or are dirty. You can decrease fan noise by keeping them free of dust and monitoring their settings via the BIOS if possible. The good news is that, with liquid cooling, fans usually don"t have to work as hard and are less likely to make lots of noise.

Another source of noise can be gurgling from the liquid as it flows, especially at higher pump speeds. If your AIO cooler is chilling your PC just fine at lower pump speeds, you can easily keep noise levels down this way. If annoying gurgling noises persist, there could be air cycling in the system. Proper installation and pump placement can often help avoid bubbling issues like this, so it may be time to take a look at your mounting choices. You can also run the cooler through a process to clear out air bubbles.

Ever since it was founded back in 2004, NZXT has been focused on the always-lucrative PC gaming market. The company started out with just a few PC cases, yet their unique aesthetics and features were more than enough to let the company establish a solid foothold in the advanced PC market. Several years later, NZXT slowly began diversifying their product portfolio by adding cooling and power products to it. Today, the company produces a large variety of PC cases, cooling, and power products, as well as PC peripherals and accessories.

NZXT entered the PC cooling market nearly a decade ago by releasing all-in-one (AIO) liquid cooling solutions and accessories for them, including GPU mounting brackets. However unlike other manufacturers who have opted to build large, diverse product lineups, NZXT never kept more than a handful of AIO coolers available in their product line-up. Instead, the company has focused on delivering a few quality and aesthetically-unique designs, rather than trying to take the competition down on raw performance alone.

Today we are taking a look at NZXT’s latest liquid coolers, the Kraken X-3 and Z-3 series. These are more of a refresh rather a total upgrade over last year’s X-2 series, but NZXT has made some notable tweaks. Between the two families there are five different coolers in three sizes, covering the usual 240/280/360mm configurations. Both the X and Z series utilize the same cooling hardware, but NZXT has positioned the Z series as a premium option with a novel aesthetic feature – while the X series has RGB lighting on top of the pump base, the Z series tops its base with a full-fledged (and full color) LCD screen.

For this review we"re checking out both the X73 and the Z63, giving us a full view of the performance and features we can expect from most coolers that NZXT currently offers.

The new Kraken Z-3 and X-3 coolers ship in relatively simple packaging, based on the same white/purple artistic theme that NZXT has used over the last few years. A picture of the cooler covers the otherwise plain front of the packaging. Inside the box we found the coolers and their parts well protected by custom cardboard inserts.

All of the coolers share practically the same bundle, which is limited to the basics. Inside the box we only found the required mounting hardware, the necessary wiring, and an installation manual. We should also note that NZXT does not include the TR4 socket mounting plate by default, but they do have one available as an optional part for Threadripper owners.

The NZXT Z63 and X73 come with two 140 mm and three 120 mm fans respectively. The company went with high quality fans, with fluid dynamic bearing (FDB) engines and anti-vibration mounting pads. They are not overly powerful, though with their flat-bladed, high-pressure design they shouldn"t have much trouble overcoming the resistance of the radiator. There is no lighting about the fans, with the company focusing their artistic enhancement efforts on the pump block instead.

Digging into our review samples, let"s start with deciphering NZXT’s cooler names. The first character denotes the series, the second the size, and the third is the version. For example, the Z63 and the Z73 coolers belong to the same series and share most features but their radiator size differs, while the X73 and Z73 are of the same size but belong to different series. Thus the Z63 and the X73 that we will be reviewing today check both of these boxes, allowing us to explore the differences between the Z and X series and measure the thermal performance of both the 280 mm and the 360 mm coolers.

So what sets apart NZXT"s X and Z series coolers? In short, it"s all about displays. For the Z series, NZXT has topped off the the main block assembly with a 2.36” LCD screen. The LCD can be programmed to showcase everything from images and GIFs to real-time data. And despite the low 320×320 px resolution, it is crisp and bright, with beautiful color reproduction.

Otherwise for the X model, NZXT dials things back just a tad and uses a mirrored top with LEDs placed under it. Once powered, the company logo and a ring appear, with the mirror creating an infinity effect about the ring. The LEDs are RGB and users can adjust the colors of the ring using NZXT’s CAM software. On the whole it is a relatively simple and attractive visual setup.

Other than the display topping the main block, the X and Z series coolers are all but identical. The rest of the main block is the same between the two, going right down to the contact plate and mini pumps. So at the base of NZXT"s LCD and LED handiwork lies a circular copper plate, secured on the plastic body with eight stainless steel screws. A layer of thermal paste is pre-applied onto the contact plate. It is not machined down to a mirror finish but it is smooth and entirely flat. The contact plate is not large enough to cover Ryzen Threadripper processors and, although it should work okay, we generally advise against using coolers that are not specifically developed for the TR4 socket on Threadripper processors.

Moving on, let"s talk about NZXT"s radiators. Their different sizes aside, the radiators of both the Z63 and X73 seem to be identical in terms of design. The subtle but significant difference is that the 120 mm fan radiator of the X73/Z73 is 26 mm thick, while the 140 mm fan radiator of the Z63/X63 is 30 mm thick. It"s just a few millimeters, but it"s something that should absolutely be considered confirming the cooler’s compatibility with a given case, as sometimes a few millimeters makes all the difference. Both radiators are typical dual-pass cross-flow designs, with tiny fins soldered on thin oblong tubes. This is by far the most dominant radiator design for AIO systems and rightfully so, as it offers the best efficiency within limited proportions and for the temperature differences that AIO coolers have to deal with.

The hose fixings on the radiator side are immovable, making them a bit less flexible during installation. In order to cope with long-term evaporation losses, NZXT is using what they are calling “ultra-low evaporation” high-density rubber tubing, with external nylon sleeve braiding for additional mechanical protection. NZXT also took the time to punch the company logo on the sides of the radiators.

We guarantee your satisfaction on every product we sell with a full refund — and you won’t even need a receipt.* We want you to be satisfied with your Micro Center purchase. However, if you need help or need to return an item, we’re here for you!

*If you are a Micro Center Insider or if you have provided us with validated contact information (name, address, email address), you won’t even need your receipt.

Computer cooling is required to remove the waste heat produced by computer components, to keep components within permissible operating temperature limits. Components that are susceptible to temporary malfunction or permanent failure if overheated include integrated circuits such as central processing units (CPUs), chipsets, graphics cards, and hard disk drives.

Components are often designed to generate as little heat as possible, and computers and operating systems may be designed to reduce power consumption and consequent heating according to workload, but more heat may still be produced than can be removed without attention to cooling. Use of heatsinks cooled by airflow reduces the temperature rise produced by a given amount of heat. Attention to patterns of airflow can prevent the development of hotspots. Computer fans are widely used along with heatsink fans to reduce temperature by actively exhausting hot air. There are also more exotic cooling techniques, such as liquid cooling. All modern day processors are designed to cut out or reduce their voltage or clock speed if the internal temperature of the processor exceeds a specified limit. This is generally known as Thermal Throttling, in the case of reduction of clock speeds or Thermal Shutdown in the case of a complete shutdown of the device or system.

Cooling may be designed to reduce the ambient temperature within the case of a computer, such as by exhausting hot air, or to cool a single component or small area (spot cooling). Components commonly individually cooled include the CPU, graphics processing unit (GPU) and the northbridge.

Poor airflow including turbulence due to friction against impeding components such as ribbon cables, or incorrect orientation of fans, can reduce the amount of air flowing through a case and even create localized whirlpools of hot air in the case. In some cases of equipment with bad thermal design, cooling air can easily flow out through "cooling" holes before passing over hot components; cooling in such cases can often be improved by blocking of selected holes.

Because high temperatures can significantly reduce life span or cause permanent damage to components, and the heat output of components can sometimes exceed the computer"s cooling capacity, manufacturers often take additional precautions to ensure that temperatures remain within safe limits. A computer with thermal sensors integrated in the CPU, motherboard, chipset, or GPU can shut itself down when high temperatures are detected to prevent permanent damage, although this may not completely guarantee long-term safe operation. Before an overheating component reaches this point, it may be "throttled" until temperatures fall below a safe point using dynamic frequency scaling technology. Throttling reduces the operating frequency and voltage of an integrated circuit or disables non-essential features of the chip to reduce heat output, often at the cost of slightly or significantly reduced performance. For desktop and notebook computers, throttling is often controlled at the BIOS level. Throttling is also commonly used to manage temperatures in smartphones and tablets, where components are packed tightly together with little to no active cooling, and with additional heat transferred from the hand of the user.

The user can also do a lot in order to preemptively prevent damage from happening. They can perform a visual inspection of the cooler and case fans. If any of them aren"t spinning correctly, it"s likely that they"ll need to be replaced. The user should also clean the fans thoroughly, since dust and debris can increase the ambient case temperature and impact fan performance. The best way to do so is with compressed air in an open space. Another preemptive technique to prevent damage is to replace the thermal paste regularly.

As electronic computers became larger and more complex, cooling of the active components became a critical factor for reliable operation. Early vacuum-tube computers, with relatively large cabinets, could rely on natural or forced air circulation for cooling. However, solid-state devices were packed much more densely and had lower allowable operating temperatures.

IBM developed three generations of the Thermal Conduction Module (TCM) which used a water-cooled cold plate in direct thermal contact with integrated circuit packages. Each package had a thermally conductive pin pressed onto it, and helium gas surrounded chips and heat-conducting pins. The design could remove up to 27 watts from a chip and up to 2000 watts per module, while maintaining chip package temperatures of around 50 °C (122 °F). Systems using TCMs were the 3081 family (1980), ES/3090 (1984) and some models of the ES/9000 (1990).

Heat removal was critical. Refrigerant was circulated through piping embedded in vertical cooling bars in twelve columnar sections of the machine. Each of the 1662 printed circuit modules of the machine had a copper core and was clamped to the cooling bar. The system was designed to maintain the cases of integrated circuits at no more than 54 °C (129 °F), with refrigerant circulating at 21 °C (70 °F). Final heat rejection was through a water-cooled condenser.

In the later Cray-2, with its more densely packed modules, Seymour Cray had trouble effectively cooling the machine using the metal conduction technique with mechanical refrigeration, so he switched to "liquid immersion" cooling. This method involved filling the chassis of the Cray-2 with a liquid called Fluorinert. Fluorinert, as its name implies, is an inert liquid that does not interfere with the operation of electronic components. As the components came to operating temperature, the heat would dissipate into the Fluorinert, which was pumped out of the machine to a chilled water heat exchanger.

Performance per watt of modern systems has greatly improved; many more computations can be carried out with a given power consumption than was possible with the integrated circuits of the 1980s and 1990s. Recent supercomputer projects such as Blue Gene rely on air cooling, which reduces cost, complexity, and size of systems compared to liquid cooling.

A computer has a certain resistance to air flowing through the chassis and components. This is the sum of all the smaller impediments to air flow, such as the inlet and outlet openings, air filters, internal chassis, and electronic components. Fans are simple air pumps that provide pressure to the air of the inlet side relative to the output side. That pressure difference moves air through the chassis, with air flowing to areas of lower pressure.

Fans generally have two published specifications: free air flow and maximum differential pressure. Free air flow is the amount of air a fan will move with zero back-pressure. Maximum differential pressure is the amount of pressure a fan can generate when completely blocked. In between these two extremes are a series of corresponding measurements of flow versus pressure which is usually presented as a graph. Each fan model will have a unique curve, like the dashed curves in the adjacent illustration.

Fans can be installed parallel to each other, in series, or a combination of both. Parallel installation would be fans mounted side by side. Series installation would be a second fan in line with another fan such as an inlet fan and an exhaust fan. To simplify the discussion, it is assumed the fans are the same model.

Parallel fans will provide double the free air flow but no additional driving pressure. Series installation, on the other hand, will double the available static pressure but not increase the free air flow rate. The adjacent illustration shows a single fan versus two fans in parallel with a maximum pressure of 0.15 inches (3.8 mm) of water and a doubled flow rate of about 72 cubic feet per minute (2.0 m3/min).

To determine flow rate through a chassis, the chassis impedance curve can be measured by imposing an arbitrary pressure at the inlet to the chassis and measuring the flow through the chassis. This requires fairly sophisticated equipment. With the chassis impedance curve (represented by the solid red and black lines on the adjacent curve) determined, the actual flow through the chassis as generated by a particular fan configuration is graphically shown where the chassis impedance curve crosses the fan curve. The slope of the chassis impedance curve is a square root function, where doubling the flow rate required four times the differential pressure.

In this particular example, adding a second fan provided marginal improvement with the flow for both configurations being approximately 27–28 cubic feet per minute (0.76–0.79 m3/min). While not shown on the plot, a second fan in series would provide slightly better performance than the parallel installation.

For example, a typical chassis with 500 watts of load, 130 °F (54 °C) maximum internal temperature in a 100 °F (38 °C) environment, i.e. a difference of 30 °F (17 °C):

This would be actual flow through the chassis and not the free air rating of the fan. It should also be noted that "Q", the heat transferred, is a function of the heat transfer efficiency of a CPU or GPU cooler to the airflow.

Mainboard of a NeXTcube computer (1990) with 32 bit microprocessor Motorola 68040 operated at 25 MHz. At the lower edge of the image and left from the middle, the heat sink mounted directly on the CPU can be seen. There was no dedicated fan for the CPU. The only other IC with a heat sink is the RAMDAC (right from CPU).

Passive heatsink cooling involves attaching a block of machined or extruded metal to the part that needs cooling. A thermal adhesive may be used. More commonly for a personal computer CPU, a clamp holds the heatsink directly over the chip, with a thermal grease or thermal pad spread between. This block has fins and ridges to increase its surface area. The heat conductivity of metal is much better than that of air, and it radiates heat better than the component that it is protecting (usually an integrated circuit or CPU). Fan-cooled aluminium heatsinks were originally the norm for desktop computers, but nowadays many heatsinks feature copper base-plates or are entirely made of copper.

Dust buildup between the metal fins of a heatsink gradually reduces efficiency, but can be countered with a gas duster by blowing away the dust along with any other unwanted excess material.

Usually a heatsink is attached to the integrated heat spreader (IHS), essentially a large, flat plate attached to the CPU, with conduction paste layered between. This dissipates or spreads the heat locally. Unlike a heatsink, a spreader is meant to redistribute heat, not to remove it. In addition, the IHS protects the fragile CPU.

Another growing trend due to the increasing heat density of computers, GPUs, FPGAs, and ASICs is to immerse the entire computer or select components in a thermally, but not electrically, conductive liquid. Although rarely used for the cooling of personal computers,transformers. It is also becoming popular with data centers.passive heat exchange between the computer hardware and the enclosure it is placed in.heater core or radiator) might still be needed though, and the piping also needs to be placed correctly.

The coolant used must have sufficiently low electrical conductivity not to interfere with the normal operation of the computer. If the liquid is somewhat electrically conductive, it may cause electrical shorts between components or traces and permanently damage them.dielectric) and not conduct electricity.

Where powerful computers with many features are not required, less powerful computers or ones with fewer features can be used. As of 2011VIA EPIA motherboard with CPU typically dissipates approximately 25 watts of heat, whereas a more capable Pentium 4 motherboard and CPU typically dissipates around 140 watts. Computers can be powered with direct current from an external power supply unit which does not generate heat inside the computer case. The replacement of cathode ray tube (CRT) displays by more efficient thin-screen liquid crystal display (LCD) ones in the early twenty-first century has reduced power consumption significantly.

A component may be fitted in good thermal contact with a heatsink, a passive device with large thermal capacity and with a large surface area relative to its volume. Heatsinks are usually made of a metal with high thermal conductivity such as aluminium or copper,thermal grease, a thermal pad, or thermal adhesive may be placed between the component and heatsink.

Heat is removed from the heatsink by convection, to some extent by radiation, and possibly by conduction if the heatsink is in thermal contact with, say, the metal case. Inexpensive fan-cooled aluminium heatsinks are often used on standard desktop computers. Heatsinks with copper base-plates, or made of copper, have better thermal characteristics than those made of aluminium. A copper heatsink is more effective than an aluminium unit of the same size, which is relevant with regard to the high-power-consumption components used in high-performance computers.

Passive heatsinks are commonly found on older CPUs, parts that do not dissipate much power (such as the chipset), computers with low-power processors, and equipment where silent operation is critical and fan noise unacceptable.

Several brands of DDR2, DDR3, DDR4 and DDR5 DRAM memory modules are fitted with a finned heatsink clipped onto the top edge of the module. The same technique is used for video cards that use a finned passive heatsink on the GPU.

Dust tends to build up in the crevices of finned heatsinks, particularly with the high airflow produced by fans. This keeps the air away from the hot component, reducing cooling effectiveness; however, removing the dust restores effectiveness.

Peltier junctions are generally only around 10-15% as efficient as the ideal refrigerator (Carnot cycle), compared with 40–60% achieved by conventional compression cycle systems (reverse Rankine systems using compression/expansion).moving parts, low maintenance, compact size, and orientation insensitivity) outweighs pure efficiency.

As active heat pumps which consume power, TECs can produce temperatures below ambient, impossible with passive heatsinks, radiator-cooled liquid cooling, and heatpipe HSFs. However, while pumping heat, a Peltier module will typically consume more electric power than the heat amount being pumped.

Liquid cooling is a highly effective method of removing excess heat, with the most common heat transfer fluid in desktop PCs being (distilled) water. The advantages of water cooling over air cooling include water"s higher specific heat capacity and thermal conductivity.

The principle used in a typical (active) liquid cooling system for computers is identical to that used in an automobile"s internal combustion engine, with the water being circulated by a water pump through a waterblock mounted on the CPU (and sometimes additional components as GPU and northbridge)heat exchanger, typically a radiator. The radiator is itself usually cooled additionally by means of a fan.

Disadvantages of liquid cooling include complexity and the potential for a coolant leak. Leaked water (and any additives in the water) can damage electronic components with which it comes into contact, and the need to test for and repair leaks makes for more complex and less reliable installations. (The first major foray into the field of liquid-cooled personal computers for general use, the high-end versions of Apple"s Power Mac G5, was ultimately doomed by a propensity for coolant leaks.

While originally limited to mainframe computers, liquid cooling has become a practice largely associated with overclocking in the form of either manufactured all-in-one (AIO) kits or do-it-yourself setups assembled from individually gathered parts.

A heat pipe is a hollow tube containing a heat transfer liquid. The liquid absorbs heat and evaporates at one end of the pipe. The vapor travels to the other (cooler) end of the tube, where it condenses, giving up its latent heat. The liquid returns to the hot end of the tube by gravity or capillary action and repeats the cycle. Heat pipes have a much higher effective thermal conductivity than solid materials. For use in computers, the heatsink on the CPU is attached to a larger radiator heatsink. Both heatsinks are hollow, as is the attachment between them, creating one large heat pipe that transfers heat from the CPU to the radiator, which is then cooled using some conventional method. This method is usually used when space is tight, as in small form-factor PCs and laptops, or where no fan noise can be tolerated, as in audio production. Because of the efficiency of this method of cooling, many desktop CPUs and GPUs, as well as high end chipsets, use heat pipes or vapor chambers in addition to active fan-based cooling and passive heatsinks to remain within safe operating temperatures. A vapor chamber operates on the same principles as a heat pipe but takes on the form of a slab or sheet instead of a pipe. Heat pipes may be placed vertically on top and form part of vapor chambers. Vapor chambers may also be used on high-end smartphones.

The corona discharge cooler developed by Kronos works in the following manner: A high electric field is created at the tip of the cathode, which is placed on one side of the CPU. The high energy potential causes the oxygen and nitrogen molecules in the air to become ionized (positively charged) and create a corona (a halo of charged particles). Placing a grounded anode at the opposite end of the CPU causes the charged ions in the corona to accelerate towards the anode, colliding with neutral air molecules on the way. During these collisions, momentum is transferred from the ionized gas to the neutral air molecules, resulting in movement of gas towards the anode.

The advantages of the corona-based cooler are its lack of moving parts, thereby eliminating certain reliability issues and operating with a near-zero noise level and moderate energy consumption.

Undervolting is a practice of running the CPU or any other component with voltages below the device specifications. An undervolted component draws less power and thus produces less heat. The ability to do this varies by manufacturer, product line, and even different production runs of the same product (as well as that of other components in the system), but processors are often specified to use voltages higher than strictly necessary. This tolerance ensures that the processor will have a higher chance of performing correctly under sub-optimal conditions, such as a lower-quality motherboard or low power supply voltages. Below a certain limit, the processor will not function correctly, although undervolting too far does not typically lead to permanent hardware damage (unlike overvolting).

Conventional cooling techniques all attach their "cooling" component to the outside of the computer chip package. This "attaching" technique will always exhibit some thermal resistance, reducing its effectiveness. The heat can be more efficiently and quickly removed by directly cooling the local hot spots of the chip, within the package. At these locations, power dissipation of over 300 W/cm2 (typical CPU is less than 100 W/cm2) can occur, although future systems are expected to exceed 1000 W/cm2.

In micro-channel heatsinks, channels are fabricated into the silicon chip (CPU), and coolant is pumped through them. The channels are designed with very large surface area which results in large heat transfers. Heat dissipation of 3000 W/cm2 has been reported with this technique.heat flux is lower with dielectric coolants used in electronic cooling.

Phase-change cooling is an extremely effective way to cool the processor. A vapor compression phase-change cooler is a unit that usually sits underneath the PC, with a tube leading to the processor. Inside the unit is a compressor of the same type as in an air conditioner. The compressor compresses a gas (or mixture of gases) which comes from the evaporator (CPU cooler discussed below). Then, the very hot high-pressure vapor is pushed into the condenser (heat dissipation device) where it condenses from a hot gas into a liquid, typically subcooled at the exit of the condenser then the liquid is fed to an expansion device (restriction in the system) to cause a drop in pressure a vaporize the fluid (cause it to reach a pressure where it can boil at the desired temperature); the expansion device used can be a simple capillary tube to a more elaborate thermal expansion valve. The liquid evaporates (changing phase), absorbing the heat from the processor as it draws extra energy from its environment to accommodate this change (see latent heat). The evaporation can produce temperatures reaching around −15 to −150 °C (5 to −238 °F). The liquid flows into the evaporator cooling the CPU, turning into a vapor at low pressure. At the end of the evaporator this gas flows down to the compressor and the cycle begins over again. This way, the processor can be cooled to temperatures ranging from −15 to −150 °C (5 to −238 °F), depending on the load, wattage of the processor, the refrigeration system (see refrigeration) and the gas mixture used. This type of system suffers from a number of issues (cost, weight, size, vibration, maintenance, cost of electricity, noise, need for a specialized computer tower) but, mainly, one must be concerned with dew point and the proper insulation of all sub-ambient surfaces that must be done (the pipes will sweat, dripping water on sensitive electronics).

A "thermosiphon" traditionally refers to a closed system consisting of several pipes and/or chambers, with a larger chamber containing a small reservoir of liquid (often having a boiling point just above ambient temperature, but not necessarily). The larger chamber is as close to the heat source and designed to conduct as much heat from it into the liquid as possible, for example, a CPU cold plate with the chamber inside it filled with the liquid. One or more pipes extend upward into some sort of radiator or similar heat dissipation area, and this is all set up such that the CPU heats the reservoir and liquid it contains, which begins boiling, and the vapor travels up the tube(s) into the radiator/heat dissipation area, and then after condensing, drips back down into the reservoir, or runs down the sides of the tube. This requires no moving parts, and is somewhat similar to a heat pump, except that capillary action is not used, making it potentially better in some sense (perhaps most importantly, better in that it is much easier to build, and much more customizable for specific use cases and the flow of coolant/vapor can be arranged in a much wider variety of positions and distances, and have far greater thermal mass and maximum capacity compared to heat pipes which are limited by the amount of coolant present and the speed and flow rate of coolant that capillary action can achieve with the wicking used, often sintered copper powder on the walls of the tube, which have a limited flow rate and capacity.)

Evaporation devices ranging from cut out heatsinks with pipes attached to custom milled copper containers are used to hold the nitrogen as well as to prevent large temperature changes. However, after the nitrogen evaporates, it has to be refilled. In the realm of personal computers, this method of cooling is seldom used in contexts other than overclocking trial-runs and record-setting attempts, as the CPU will usually expire within a relatively short period of time due to temperature stress caused by changes in internal temperature.

Thermal compound is commonly used to enhance the thermal conductivity from the CPU, GPU, or any heat-producing components to the heatsink cooler. (Counterclockwise from top left: Arctic MX-2, Arctic MX-4, Tuniq TX-4, Antec Formula 7, Noctua NT-H1)

Most older PCs use flat ribbon cables to connect storage drives (IDE or SCSI). These large flat cables greatly impede airflow by causing drag and turbulence. Overclockers and modders often replace these with rounded cables, with the conductive wires bunched together tightly to reduce surface area. Theoretically, the parallel strands of conductors in a ribbon cable serve to reduce crosstalk (signal carrying conductors inducing signals in nearby conductors), but there is no empirical evidence of rounding cables reducing performance. This may be because the length of the cable is short enough so that the effect of crosstalk is negligible. Problems usually arise when the cable is not electromagnetically protected and the length is considerable, a more frequent occurrence with older network cables.

Supply cool air to the hot components as directly as possible. Examples are air snorkels and tunnels that feed outside air directly and exclusively to the CPU or GPU cooler. For example, the BTX case design prescribes a CPU air tunnel.

Expel warm air as directly as possible. Examples are: Conventional PC (ATX) power supplies blow the warm air out the back of the case. Many dual-slot graphics card designs blow the warm air through the cover of the adjacent slot. There are also some aftermarket coolers that do this. Some CPU cooling designs blow the warm air directly towards the back of the case, where it can be ejected by a case fan.

Air that has already been used to spot-cool a component should not be reused to spot-cool a different component (this follows from the previous items). The BTX case design violates this rule, since it uses the CPU cooler"s exhaust to cool the chipset and often the graphics card. One may come across old or ultra-low-budget ATX cases which feature a PSU mount in the top. Most modern ATX cases do however have a PSU mount in the bottom of the case with a filtered air vent directly beneath the PSU.

Fewer fans but strategically placed will improve the airflow internally within the PC and thus lower the overall internal case temperature in relation to ambient conditions. The use of larger fans also improves efficiency and lowers the amount of waste heat along with the amount of noise generated by the fans while in operation.

There is little agreement on the effectiveness of different fan placement configurations, and little in the way of systematic testing has been done. For a rectangular PC (ATX) case, a fan in the front with a fan in the rear and one in the top has been found to be a suitable configuration. However, AMD"s (somewhat outdated) system cooling guidelines notes that "A front cooling fan does not seem to be essential. In fact, in some extreme situations, testing showed these fans to be recirculating hot air rather than introducing cool air."

Loosely speaking, positive pressure means intake into the case is stronger than exhaust from the case. This configuration results in pressure inside of the case being higher than in its environment. Negative pressure means exhaust is stronger than intake. This results in internal air pressure being lower than in the environment. Both configurations have benefits and drawbacks, with positive pressure being the more popular of the two configurations. Negative pressure results in the case pulling air through holes and vents separate from the fans, as the internal gases will attempt to reach an equilibrium pressure with the environment. Consequently, this results in dust entering the computer in all locations. Positive pressure in combination with filtered intake solves this issue, as air will only incline to be exhausted through these holes and vents in order to reach an equilibrium with its environment. Dust is then unable to enter the case except through the intake fans, which need to possess dust filters.

Desktop computers typically use one or more fans for cooling. While almost all desktop power supplies have at least one built-in fan, power supplies should never draw heated air from within the case, as this results in higher PSU operating temperatures which decrease the PSU"s energy efficiency, reliability and overall ability to provide a steady supply of power to the computer"s internal components. For this reason, all modern ATX cases (with some exceptions found in ultra-low-budget cases) feature a power supply mount in the bottom, with a dedicated PSU air intake (often with its own filter) beneath the mounting location, allowing the PSU to draw cool air from beneath the case.

Each server can have an independent internal cooler system; Server cooling fans in (1 U) enclosures are usually located in the middle of the enclosure, between the hard drives at the front and passive CPU heatsinks at the rear. Larger (higher) enclosures also have exhaust fans, and from approximately 4U they may have active heatsinks. Power supplies generally have their own rear-facing exhaust fans.

Rack cabinet is a typical enclosure for horizontally mounted servers. Air typically drawn in at the front of the rack and exhausted at the rear. Each cabinet can have additional cooling options; for example, they can have a Close Coupled Cooling attachable module or integrated with cabinet elements (like cooling doors in iDataPlex server rack).

"Cooling and Noise in Rugged Industrial Computers". Chassis Plans Rugged Computers and LCD Displays. Archived from the original on 7 January 2014. Retrieved 11 February 2016.

"GE"s "dual piezo cooling jet" could enable even cooler gadgets". gizmag.com. 14 December 2012. Archived from the original on 21 July 2013. Retrieved 20 April 2013.

Brackets [ ], parenthesis ( ), less than/greater than < > and ellipsis ... are used to describe, respectively, optional, required, positional and repeating elements. Example commands are prefixed with a number sign #, which also serves to indicate that on Linux root permissions (or suitable udev rules) may be required.

Note: in addition to --debug, setting the PYUSB_DEBUG=debug and LIBUSB_DEBUG=4 environment variables can be helpful with problems suspected to relate to PyUSB or LibUSB.

In case more than one supported device is found, one them can be selected with --match

Color arguments containing spaces, parenthesis or commas need to be quoted, as these characters can have special meaning on the command-line; the easiest way to do this on all supported platforms is with double quotes.

Make sure that liquidctl is available in the context where the batch file will run: in short, liquidctl --version should work within a normal Command Prompt window.

This can be temporarily solved by manually rebinding the device to the kernel usbhid driver. Replace

Alternatively to running liquidctl as root (or with sudo), you can install the udev rules provided in extra/linux/71-liquidctl.rules to allow unprivileged access to the devices supported by liquidctl.

This is a list of currently implemented G Codes in Prusa firmware as of 7th of May 2021. The description is only for Prusa Research-specific G-codes. The rest can be found on RepRap Wiki. With exception of M117, they are all shown in order of appearance in the code. There are reasons why some G Codes aren"t in numerical order.

SuperPINDA sensor has internal temperature compensation and no thermistor output. There is no point of doing temperature calibration in such case. If PINDA_THERMISTOR and SUPERPINDA_SUPPORT is defined during compilation, calibration is skipped with serial message "No PINDA thermistor". This can be caused also if PINDA thermistor connection is broken or PINDA temperature is lower than PINDA_MINTEMP.

WARNING! USE WITH CAUTION! If you"ll try to probe where is no leveling pad, nasty things can happen! In Prusa Firmware this G-code is deactivated by default, must be turned on in the source code.

It is used for setting the current position of each axis. The parameters are always absolute to the origin. If a parameter is omitted, that axis will not be affected. IfX, Y, or Z axis are specified, the move afterwards might stutter because of Mesh Bed Leveling. E axis is not affected if the target position is 0 (G92 E0). A G92 without coordinates will reset all axes to zero on some firmware. This is not the case for Prusa-Firmware!

This command can be used to set the stepper inactivity timeout (S) or to disable steppers (X,Y,Z,E) This command can be used without any additional parameters. In that case all steppers are disabled.

Print the firmware info and capabilities Without any arguments, prints Prusa firmware version number, machine type, extruder count and UUID.M115 U Checks the firmware version provided. If the firmware version provided by the U code is higher than the currently running firmware, it will pause the print for 30s and ask the user to upgrade the firmware.

This causes the given message to be shown in the status line on an attached LCD. It is processed early as to allow printing messages that contain G, M, N, or T.

This command asks the firmware to reply with the current print settings as set in memory. Settings will differ from EEPROM contents if changed since the last load / save. The reply output includes the G-Code commands to produce each setting. For example, Steps-Per-Unit values are displayed as an M92 command.

Sets the Z-probe Z offset. This offset is used to determine the actual Z position of the nozzle when using a probe to home Z with G28. This value may also be used by G81 (Prusa) / G29 (Marlin) to apply correction to the Z position. This value represents the distance from nozzle to the bed surface at the point where the probe is triggered. This value will be negative for typical switch probes, inductive probes, and setups where the nozzle makes a circuit with a raised metal contact. This setting will be greater than zero on machines where the nozzle itself is used as the probe, pressing down on the bed to press a switch. (This is a common setup on delta machines.)

Sets the printer IP address that is shown in the support menu. Designed to be used with the help of host software. If P is not specified nothing happens. If the structure of the IP address is invalid, 0.0.0.0 is assumed and nothing is shown on the screen in the Support menu.

Printers with TMC2130 drivers haveX, Y, Z and E as options. The steps-per-unit value is updated accordingly. Not all resolutions are valid! Printers without TMC2130 drivers also have B and S options. In this case, the steps-per-unit value in not changed!

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey