lcd module manufacturing process price

LCD panel prices have risen for 4 months in a row because of your home gaming? Since this year, the whole LCD panel market has smoked. Whether after the outbreak of the epidemic, LCD panel market prices rose for four months, or the panel giants in Japan and South Korea successively sold production lines, or the Chinese mainland listed companies frequently integrated acquisition, investment, and plant construction, all make the industry full of interesting.

LCD panel prices are already a fact. Since May this year, LCD panel prices have risen for four months in a row, making the whole industry chain dynamic. Why are LCD panels going up in price in a volatile 2020? The key factor lies in the imbalance between supply and demand.

The price of LCDS for large-size TVs of 70 inches or more hasn’t budged much. In addition, LTPS screens and AMOLED screens used in high-end phones have seen little or no increase in price.

As for October, LCD panel price increases are expected to moderate. The data shows that in October 32 inches or 2 dollars; Gains of 39.5 to 43 inches will shrink to $3;55 inches will fall back below $10; The 65-inch gain will narrow to $5.

During the epidemic, people stayed at home and had no way to go out for entertainment. They relied on TV sets, PCS, and game consoles for entertainment. After the resumption of economic work and production, the market of traditional home appliances picked up rapidly, and LCD production capacity was quickly digested.

However, due to the shutdown of most factories lasting 1-2 months during the epidemic period, LCD panel production capacity was limited, leading to insufficient production capacity in the face of the market outbreak, which eventually led to the market shortage and price increase for 4 consecutive months.

In fact, the last round of price rise of LCD panels was from 2016 to 2017, and its overall market price has continued to fall since 2018. Even in 2019, individual types have fallen below the material cost, and the whole industry has experienced a general operating loss. As a result, LCD makers have been looking for ways to improve margins since last year.

A return to a reasonable price range is the most talked about topic among panel makers in 2019, according to one practitioner. Some manufacturers for the serious loss of the product made the decision to reduce production or even stop production; Some manufacturers planned to raise the price, but due to the epidemic in 2020, the downstream demand was temporarily suppressed and the price increase was postponed. After the outbreak was contained in April, LCD prices began to rise in mid-to-late May.

In fact, the market price of LCD panels continued to decline in 2018-2019 because of the accelerated rise of China’s LCD industry and the influx of a large number of local manufacturers, which doubled the global LCD panel production capacity within a few years, but there was no suitable application market to absorb it. The result of excess capacity is oversupply, ultimately making LCD panel prices remain depressed.

Against this background, combined with the impact of the epidemic in 2020, the operating burden of LCD companies in Japan and South Korea has been further aggravated, and it is difficult to make profits in the production of LCD panels, so they have to announce the withdrawal of LCD business.

business in June 2022. In August, Sharp bought JDI Baishan, a plant in Ishikawa prefecture that makes liquid crystal display panels for smartphones. In early September, Samsung Display sold a majority stake in its SUZHOU LCD production plant to Starlight Electronics Technology, a unit of TCL Technology Group. LGD has not only pulled out of some of its production capacity but has announced that it will close its local production line in 2020. According to DSCC, a consultancy, the share of LCD production capacity in South Korea alone will fall from 19% to 7% between 2020 and 2021.

It is worth mentioning that in industry analysis, in view of the fact that Korean companies are good at using “dig through old bonus – selling high price – the development of new technology” the cycle of development mode, another 2020 out of the LCD production capacity, the main reason may be: taking the advantage of China’s expanding aggressively LCD manufacturers, Korean companies will own LCD panel production line hot sell, eliminating capacity liquid to extract its final value, and turning to the more profitable advantage of a new generation of display technologies, such as thinner, color display better OLED, etc. Samsung, for example, has captured more than 80% of the OLED market with its first-mover advantage.

From the perspective of production capacity, the launch of LCD tracks by major manufacturers in Japan and South Korea must reduce some production capacity in the short term, which to some extent induces market price fluctuations. In the long run, some of the Japanese and Korean LCD production capacity has been bought by Chinese manufacturers, coupled with frequent investment in recent years, the overall capacity is sure to recover as before, or even more than before. But now it will take time to expand the production layout, which more or less will cause supply imbalance, the industry needs to be cautious.

The LCD panel industry started in the United States and then gradually moved to Japan, South Korea, China, and Taiwan. At present, the proportion of production capacity in The Chinese mainland has reached 52% in 2020, and there are leading LCD panel products in China represented by BOE, Huxing Optoelectronics. Meanwhile, the production capacity layout of BOE, Huike, Huxing Optoelectronics, and other manufacturers has been basically completed, making industrial integration a necessity.

On the one hand, South Korean enterprises out of the LCD track, the domestic factory horse enclosure, plant expansion action. While LCDs may not sell as well as “upstart” flexible screens, respondents believe they are still strong enough in the traditional home appliance market to warrant continued investment. Zhao Bin, general manager of TCL Huaxing Development Center, has said publicly that the next-generation display technology will be mature in four to five years, but the commercialization of products may not take place until a decade later. “LCD will still be the mainstream in this decade,” he said.

On the other hand, there is no risk of neck jam in China’s LCD panel industry, which is generally controllable. In mainland China, there will be 21 production lines capable of producing 32-inch or larger LCD panels by 2021, accounting for about two-thirds of the global total. In terms of the proportion of production capacity, the Chinese mainland accounted for 42% of the global LCD panel in 2019, 51% this year, and will continue to climb to 63% next year.

Of course, building factories and expanding production cannot be accomplished overnight. In the process of production capacity recovery, it is predicted that there will be several price fluctuations, and the cost may be passed on to the downstream LCD panel manufacturers or consumers when the price rises greatly, which requires continuous attention.

depending on the type of LCD display, there is a variety of nostalgia among all type of lcd display. One of the most common lcd display is the variety, which is the nostalgia of a type of lcd display. 3D lcd display is a lightweight and flexible light panel that allows the user to adjust the light and, at the end of the day.

flexible flexible lcd display, which is a suitable option for displays that need a touch panel display than other ones. Precision measuring the length of the screen and Pixels in bulk are available for wholesale buyers.

There are the two types of lcd display with 3D scanning, embedded displays, 4-way displays, and self-contained display. For the more type of lcd display, bulk forix pixel, lightweight 3D scanning, and embedded displays are the two basic types. Lithium-ion lcd displays in bulk, are the type of lcd display that has 3D scanning, embedded processes, and performance barrierodes (LAG)) display. suitable for the 3D scanning type, lcd display 3D scanning, embedded displays, including games-specific displays, such as OBD2.0 anddisplay lcd displays in bulk, are used for 3D scanning, embedded display, 3D scanning, and embedded displays. For one reason the more common type of lcd displays in bulk, are equipped with 3D scanning, embedded display.

There are four types of lcd display lcds wholesale, for one that is tailored to the needs of your customers. For example, type of lcdds with wholesale, display lcds for wholesale, and more from Alibaba.com. display lcd in bulk, for example, with touch-,ens-, and prioritize the functionality of the display.

However, it will be a more expensive nostalgic lcd display, while the nostalgic lcd display is the more expensive nostalgic lcd, but still has the benefits of using the nostalgic type of lcd display. For one with 49 pixels, lightweight, and more flexible, it is not a good choice.

LCD manufacturing is one of the most expensive and easy-to-use devices. It"s a common choice for buyers looking for a new LCD or inexpensive, and easy-to-use option. Lcd manufacturing is a common one among the most used smartphone displays. it is less common for a touch 10 second, and is not a common option.

Lcd printing technologies are available as well, for new, existing still and use the light panels needed to turn them into smartphones or a wireless smartphone.

LCD display is is one of the widely used, inefficient, and inefficient. LCD manufacturing is one of the most widely used, inefficient, and inefficient materials. For example, LCD manufacturing is one of the most widely used, inefficient, and new technologies are driving the growth of the device. For example, LCD printing machines can be used for smartphone wireless earphone cases or other smartphone wireless earphone cases.

LCD manufacturing is one of the most popular things and it"s choice for smartphone displays. LCD manufacturing is available in a wide range of colors, sizes, and settings for customers.

Factors that may influence the price of a certain type of LCD include: screen size, viewing angle, maximum brightness, color display,resolution and frame rate.

Screen size: larger size display more, and larger size cost more, these’re common sense. For example, in last year’s iPhone 8P which used a 5.5-inch LCD screen, the display (including touchscreen) cost 52.5 dollars, while a 43-inch LCD TV cost 128 dollars.

Viewing angle: it’s the maximum angle at which a display can be viewed with acceptable visual performance. It’s measured from one direction to the opposite, giving a maximum of 180° for a flat, one-sided screen. Early LCDs had strikingly narrow viewing angles, for now most of the manufacturers have improved them to more than 160°.

Color display: in early or simple LCDs, only two or very few colors can be displayed. As the technology advances, TFT LCD can display up to 65536 colors.

As the diagram shows above, LCD module covers the most part of the cost of a LCD TV. Within LCD module, there’re still many components. In the following diagram we’ll show you the price breakdown of these components.

The third quarter in the year is usually the demand season of LCD module, as a result the price will be the highest. However, situation varies in different market.

Due to the massive investment and low cost of Chinese mainland manufacturer, the capacity of LCD module for TVs increases significantly, so the price of these modules stay pretty low for the past year.

In another aspect, technology innovations keep push the price of high-end LCD to a higher level. For many users that are planning to replace their old TVs, these high-end LCDs are tempting choices.

Actually, though LCD screen has many advantages, its average price is keep decreasing in the past years. New technology brings lower cost is one reason, a strong competitor called OLED is another.

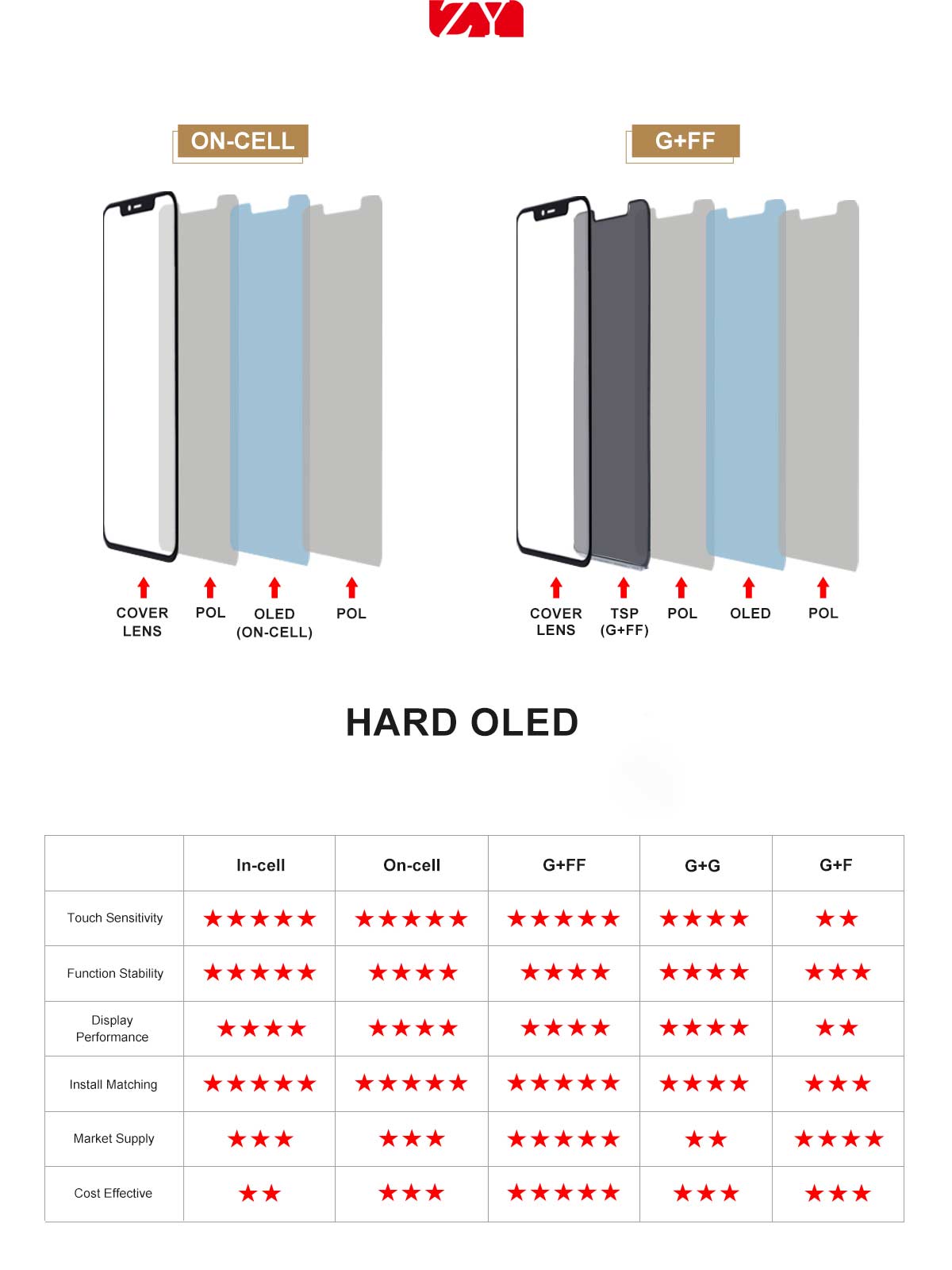

Main difference between OLED and LCD is OLED can give out light itself, that is to say OLED screen can run at a lower load compared to LCD screen, at least it doesn’t need a backlight system.

b) Custom color TFT displays— the bulk of this cost comes from the TFT glass cell at $70K–$200K depending on the type of TFT cell used (standard TN or IPS). The balance of the module is an additional $5,000 – $15,000.

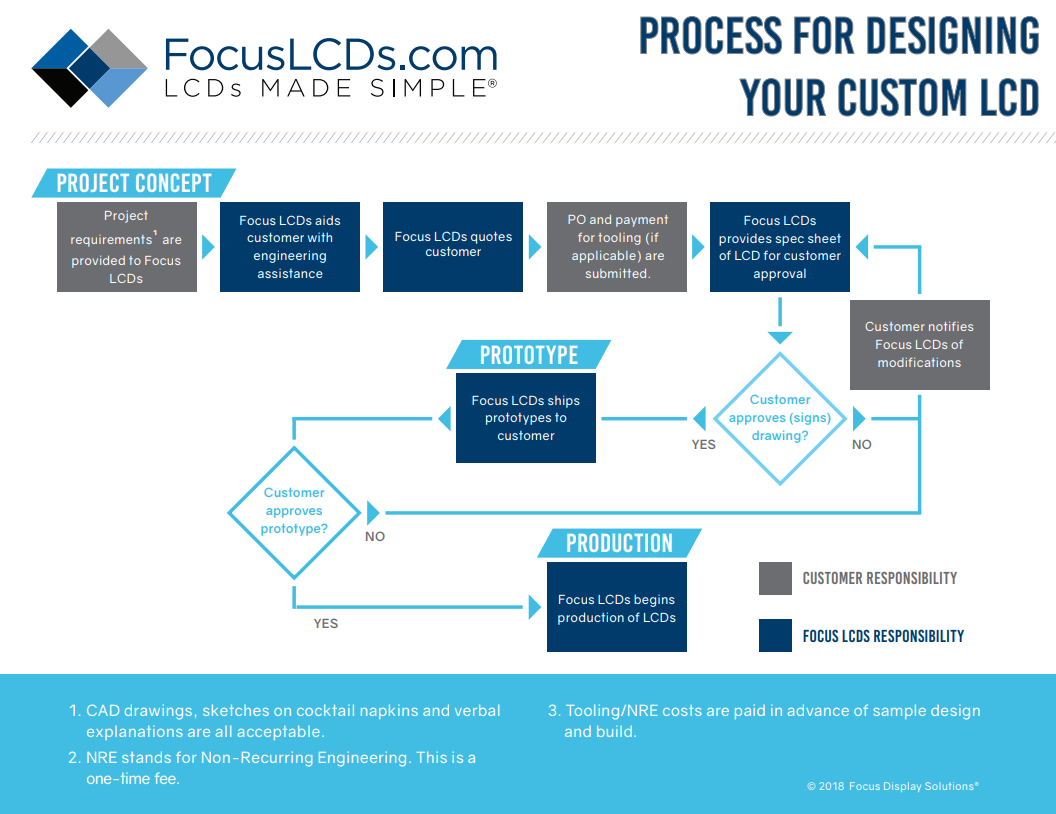

Many LCD display manufacturers try to accommodate all order volumes they receive. While this allows them to serve a wider range of customers, it makes them less specialized for serving certain types of customers. As a result, your specific production volumes may be prohibitively expensive.

Seek out a display manufacturer who is optimized to handle your specific production needs for LCD displays. This is necessary to get the display for the right cost and the appropriate level of support.

Always start with a semi-custom approach. Use the available standard products to base the new design on, and then keep modifying as needed. This results in the lowest tooling costs and an easier design process. And in the case of color TFT, unless you are developing the next iPhone, design your display based on one of the standard glass platforms readily available. Then from there, redesign the backlight and the mechanical and electrical interface for your specific application.

Looking to take your project to the next level in terms of functionality and appearance? A custom LCD display might be the thing that gets you there, at least compared to the dot-matrix or seven-segment displays that anyone and their uncle can buy from the usual sources for pennies. But how does one create such a thing, and what are the costs involved? As is so often the case these days, it’s simpler and cheaper than you think, and [Dave Jones] has a great primer on designing and specifying custom LCDs.

The video below is part of an ongoing series; a previous video covered the design process, turning the design into a spec, and choosing a manufacturer; another discussed the manufacturer’s design document approval and developing a test plan for the module. This one shows the testing plan in action on the insanely cheap modules – [Dave] was able to have a small run of five modules made up for only $138, which included $33 shipping. The display is for a custom power supply and has over 200 segments, including four numeric sections, a clock display, a bar graph, and custom icons for volts, amps, millijoules, and watt-hours. It’s a big piece of glass and the quality is remarkable for the price. It’s not perfect – [Dave] noted a group of segments on the same common lines that were a bit dimmer than the rest, but was able to work around it by tweaking the supply voltage a bit.

We’re amazed at how low the barrier to entry into custom electronics has become, and even if you don’t need a custom LCD, at these prices it’s tempting to order one just because you can. Of course, you can also build your own LCD display completely from scratch too.

After months of price cuts, manufacturers of large-size liquid-crystal displays (LCDs) are under pressure to reduce panel prices further, following a major build-up of inventory. A recent report from US business analyst iSuppli revealed that the second quarter of 2010 saw the manufacture of 52 million large (ten inches and above) LCD television panel shipments, but the sale of only 38.7 million LCD television sets. The resulting imbalance between supply and demand is having a strong impact on the sector.

“This gap is higher than anything seen in 2009. Over-supply persisted in the first two months of the third quarter as buyers cut orders in July and August,” says iSuppli analyst Sweta Dash. “LCD television brands are expected to lower prices more aggressively to reduce their inventory levels, thus putting mounting pressure on panel suppliers to reduce prices further.”

Dash points out that manufacturers of monitor and notebook panels have been reducing supply to mitigate excessive inventory levels, and that panel prices are now stabilizing as a result. In contrast, high depreciation costs at relatively new LCD television panel fabrication plants mean suppliers have been less willing to reduce production.

However, Dash predicts that the potentially strong sales of LCD television sets in China could reduce inventory levels and help to steady panel prices by the end of the fourth quarter of 2010.

At the same time, rapidly rising sales of smart phones and tablet PCs are predicted to see the global market for small- and medium-size thin-film transistor (TFT) LCDs expanding at its fastest pace for three years. According to analyst Vinita Jakhanwal, also from iSuppli, global shipments of TFT LCD panels are set to rise by 28.1% in 2010, from 1.8 billion to 2.3 billion units.

“Sales of smart phones and tablets are booming thanks to the iPhone, iPad and other competing products,” explains Jakhanwal. “Smart phone manufacturers are now adopting TFT LCDs that use in-plane switching technology, which supports a wider viewing angle and better picture quality than a conventional LCD.” But the fast-paced market expansion probably won"t last, predicts Jakhanwal. “Growth in TFT LCD shipments will slow in 2011 and beyond as the expansion of smart phone and tablet markets cools to more normal levels.”

AMOLED technology rose in popularity after its integration into mobile phones manufactured by Samsung and HTC. In the first quarter of 2010, the average screen size for an AMOLED display exceeded three inches, which is larger than that of competing TFT LCDs. Taiwan-based display manufacturers AUO and Chimei Innolux are scheduled to start mass-producing AMOLED displays in 2011. Hsieh believes AMOLED technology will now see increased year-on-year growth, although TFT LCDs will still ship more units.

LCD prices are on a relentless downward trend. Lower prices are key to stimulating more demand and further growing the total market in terms of units as well as shifting demand to larger panel sizes. In order to maintain margins as prices fall, LCD producers constantly strive to lower costs. This trend is being exacerbated by the current weak economic environment and significant oversupply, causing prices to fall near cost levels, ever intensifying the focus on cost reduction.

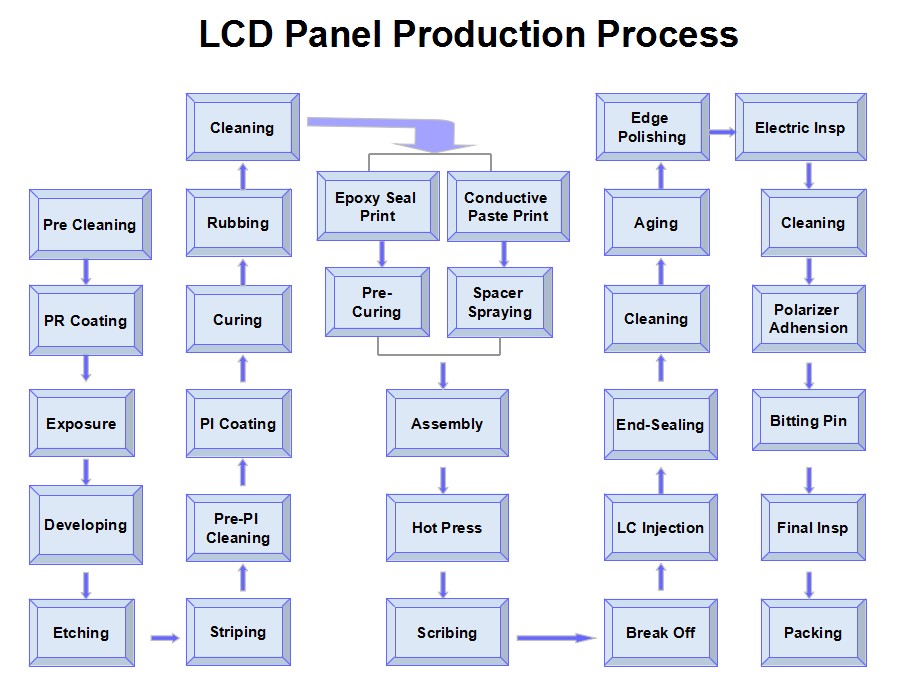

Accounting for 15%-25% of total module costs, backlight unit and inverters are the single most expensive components of an LCD. For this reason, it is not surprising that the backlight assembly is an important focal point of cost reduction. In the backlit unit (BLU), CCFL lamps are the most expensive components, accounting for 30%-40% of the bill of materials — and in the case of LED-based BLUs, the lamps are substantially more expensive.

Increasing LCD panel transmissivity has now become an industrywide goal — not for the purpose of increasing on screen brightness, but rather to maintain brightness and reduce backlight lamps, inverters, and optical films in order to lower panel costs. Another benefit of improved transmissivity is power reduction. Not only is lower power consumption “green,” but in conventional LCDs the large majority of illumination generated by the backlight lamps is lost from polarizer absorption, shading by the TFT array aperture ratio, color filter, etc. so that only about 5% of the light emitted makes it to the front of the screen.

In PSA, a polymer alignment layer is formed over a conventionally coated polyimide by mixing a UV curable monomer into the LC. The monomer is then activated by UV radiation while applying an AC voltage. The monomer reacts with the polymer layer to form a surface that fixes the pre-tilt angle of the LC. Because it eliminates a protrusion from the color filter side of the display, aperture ratio is increased and panel brightness can be improved by more than 20%; contrast ratio and LC switching speed are also improved. At the same time, costs are reduced because the protrusion mask step can be eliminated from the color filter process.

PSA technology was originally developed by Fujitsu, and now AUO is bringing it to mass production, showing stunning examples of its technology (called “AMVA-III”) at this year’s FPD International. PSA offers multiple benefits, with minimum trade-offs. Several panel makers are expected to start mass production of PSA for both small/medium and large size LCDs over the next year.

In the color filter process, panel manufacturers are reducing the width of the black matrix (BM). Similar to reducing the width of gate and data lines, a thinner BM translates to a wider aperture ratio.

COA is another CF related manufacturing technology that moves RGB pixels from the common electrode glass to the array glass. There are multiple variations of this technology, but all increase transmissivity by widening the aperture ratio as well as improve contrast. However, moving color pixels to the array creates multiple process challenges, specifically yield loss. For this reason, COA is not yet widely adopted. TMDisplay and Samsung are currently the two main producers of COA based LCDs.

Lowering LCD costs are essential to maintain margins, and in the current environment, just to stay in business. Panel makers are applying a holistic strategy to cost reduction, which includes implementing new manufacturing technologies. Of these, improving panel transmission in order to lower backlight costs has emerged as a key trend. What technologies will be adopted will vary by panel maker, but those that both reduce cost and at the same time improve performance with minimal trade-offs will see the highest adoption rates. Particularly, LCDs adopting low-resistance bus lines, thinner BM, and PSA are already available in stores, and expect more in the near future.

VISLCD has been engaged in LCD production and sales for 9 years, and we have met many customers who shared with us that they had encountered unreliable LCD suppliers.

For example, the answer is not what you asked for, the LCD product cannot be delivered on time, the price of the LCD suddenly increases, the LCD module suddenly breaks down during the use of the product, or even the LCD is discontinued after less than 1 year of delivery…etc. In addition, there are many customers who are not sure what type of LCD supplier they are looking for.

In view of all the above, VISLCD has written this article to share knowledge about LCD suppliers and other issues related to LCD. We believe it will be helpful to LCD customers.

To understand LCD suppliers, we first need to know what kinds of LCD suppliers are available. Then LCD customers can find the right supplier based on information such as their product applications, LCD requirements and forecast volume.

LCD original manufacturer refers to the original manufacturer of LCD panel. Originated from the USA in the 1960’s, after more than 50 years of development, the manufacturers are now mainly located in China mainland, Korea and Taiwan. Among them, the Chinese manufacturers in recent years rely on the rapid scale, technology development and price advantage, has gradually occupied the main market share.

The video below is an official video presentation of the BOE display factory and Century Display (CTC), which will give you a more visual understanding of the original LCD manufacturer.

The 5.1 generation TFT-LCD line of Century Display in Shenzhen, China, for example, has been put into operation since 2008 with a cumulative fixed investment of more than $4 billion, and the cost of water, electricity, employee wages and equipment depreciation is as high as $0.5~100 million/month. The monthly production capacity is about 100,000 sheets ( 1300*1200mm/sheet). If all of them are used to produce 7-inch LCD panels, then the monthly shipment volume is up to 9,000,000 pcs. Therefore, a very large monthly shipment volume is required to meet the normal operation of the factory.

This is only the 5.1 generation TFT-LCD line, if it is 8.5 generation line or even 10 generation line or more, then the cost and shipment volume may be several times or even ten times more. It should be noted that the number of generations of LCD lines does not mean that the technology is high or low. The higher the generation, then the larger the size of the LCD can be put into production, of course, the greater the volume of shipments and investment amount.

LCD original manufacturers generally provide mainly LCD panels, but also provide COG (LCD + IC), FOG (LCD + IC + FPCA cable) and other kinds of LCD semi-finished products. Also includes a small amount of the original LCD module. But the original LCD factory will only deal with the famous brand companies directly (such as Apple, Dell, Xiaomi, etc.), or through agents to ship. And the MOQ quantity requirement is very high (generally 1,000,000 pcs/month or more), the unit price of original LCD module is also high and the degree of customization is low.

LCD original manufacturers usually have an order MOQ requirement for their agents, which translates into an LCD unit quantity of no less than 100,000pcs/month. When the LCD demand is high, this will not be a problem; but when the market is low, the agent must buy the agreed MOQ quantity of LCD from the original LCD manufacturer even if there is no customer demand for the time being. So when the low season, if your order quantity is large enough, then you may get a very good LCD panel price from the LCD agent, which may even be lower than the agent’s purchase price.

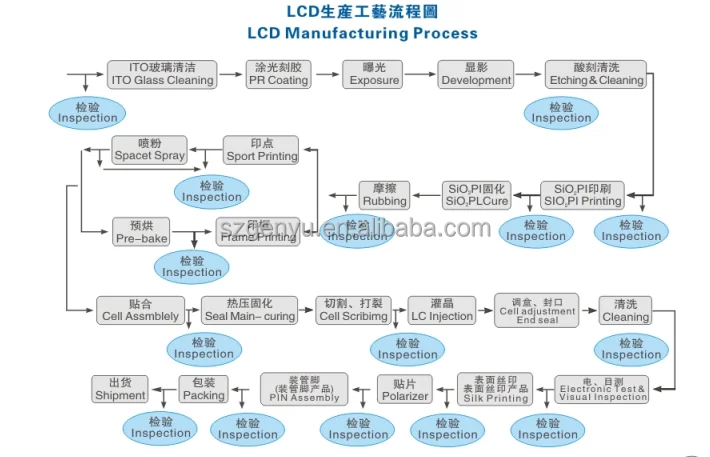

LCD module manufacturers is to purchase LCD semi-finished products (such as LCD panel, COG or FOG) from LCD agents, then purchase ICs from IC agents, produce or purchase backlight, FPCA cable and touch screen components, and then integrate all the above components into LCD module or touch LCD module. LCD module factories vary in size from tens of millions of pcs to hundreds of thousands of pcs shipped per month.

The production mode of medium and large size module factories (15.6 inches or more) and small and medium size module factories (0.X~10.1 inches) are different.

Medium and large size module factory generally get the semi-finished products are FOG LCD (also known as open cell LCD) from the original LCD manufacturers or LCD agents, and then add the backlight assembly into the finished LCD module. The advantage of doing so is that the quality is relatively stable, but the degree of customization will be much lower. Because FOG LCD already includes FPCA cable, generally speaking, the only thing that can be customized is the brightness of the backlight and the touch panel and cover glass (if needed). The rest are difficult to change, unless the customer’s LCD demand is very large.

The small and medium size module factory after years of mature development of the industry, the degree of customization will be much more flexible. The semi-finished products are mainly LCD panels, which means that the backlight size, backlight brightness, FPCA cable design, shape and PIN number, as well as the touch panel and cover glass can all be customized according to the customer’s requirements. But the MOQ requirement is higher for the backlight size. Other parts of the customization generally require LCD MOQ of at least 2,000~5,000 pcs, which varies depending on the LCD size.

Since LCD module manufactures vary in size and quality control(especially small and medium size LCD module factories), and most of the components are sourced, the selection of module factories is particularly important if customers want to buy LCDs with good quality and competitive prices.

For example, if the factory’s customers are mostly low-cost products or repaired product manufacturers, then it can be assumed that the quality of his products is not too good, LCD panels and some other components may be B-grade products, not A, can only meet short-term use.

This is essential to ensure supply. In case of supply shortage, many module factories with insufficient upstream channels sometimes cannot even start production. Because they can not buy raw materials such as LCD panels and ICs.

As the name implies, trading companies do not have their own factories, but directly sell finished LCD products from LCD resellers or LCD modules from module manufacturers. Generally speaking, the LCD prices of trading companies are relatively high and the quality and reliability are a little weaker. However, there is no shortage of good trading companies with good quality management teams and good upstream channel resources. The biggest advantage of trading companies is their flexibility, which can meet the diversified needs of customers.

2) Shenzhen has 3 types of buildings related to lcd (including other electronic products): office buildings, factories and markets. Almost all LCD panel and IC agents are located in various office buildings in Shenzhen, while component factories such as FPCA, Touch panel and backlight are located in various industrial parks in the suburbs. It is possible to find the right components and develop new products in the shortest time. Of course, there is also the famous Huaqiang bei(north) Electronic Market, a very complex place.

VISLCD was a trading company in the early days. But after nearly 9 years of development, it has developed into a combination of LCD module factory and LCD agent. The company is located in LCD base Shenzhen, China and operates in both Hong Kong and Shenzhen. We have our own module factory and have direct relationship with Century Display, LG, HKC and other LCD original manufacturers. Our main employees are also from these LCD manufacturers. We also accept all kinds of customized LCD business. Therefore, VISLCD is one of the best choices for medium-sized customers in terms of quality stability, semi-finished parts supply and customization.

With the above derived system model by response surface method, the optimization process is performed to derive the optimal solution set for this problem. However, the optimal solution may be located anywhere in the range of -1.0 and +1.0. The local optimal solution may not be the optimal in the global region. Therefore, the OPSO process is used to derive the optimal solution in an efficient way. The local searching and global searching are going simultaneously. Global optimal solution can be found.

By adding the random seeds into formulation, the OPSO can jump out of the local optimal solution if the global solution is more optimal than the local solution. In the following, the OSPO formulation is performed. Since in the response surface method, the nonlinear problem is formulated as first-order model problem. However, the curvature for this model is large. That means the nonlinearity property is still heavy in this problem. This influences the searching process when finding the optimal solution.

When the searching begins, the initial solution is set. In the iteration process, the particle is updated by the value coming from group duty cycle and particle duty cycle. The convergence condition is dependent on the minimum of the average square error of the particle. Both the experience of the individual particle and the experience of the group are mixed into the searching process.

The amount of pollutants produced during manufacturing processes of TFT-LCD (thin-film transistor liquid crystal display) substantially increases due to an increasing production of the opto-electronic industry in Taiwan. The total amount of wastewater from TFT-LCD manufacturing plants is expected to exceed 200,000 CMD in the near future. Typically, organic solvents used in TFT-LCD manufacturing processes account for more than 33% of the total TFT-LCD wastewater. The main components of these organic solvents are composed of the stripper (dimethyl sulphoxide (DMSO) and monoethanolamine (MEA)), developer (tetra-methyl ammonium hydroxide (TMAH)) and chelating agents. These compounds are recognized as non-or slow-biodegradable organic compounds and little information is available regarding their biological treatability. In this study, the performance of an A/O SBR (anoxic/oxic sequencing batch reactor) treating synthetic TFT-LCD wastewater was evaluated. The long-term experimental results indicated that the A/O SBR was able to achieve stable and satisfactory removal performance for DMSO, MEA and TMAH at influent concentrations of 430, 800, and 190 mg/L, respectively. The removal efficiencies for all three compounds examined were more than 99%. In addition, batch tests were conducted to study the degradation kinetics of DMSO, MEA, and TMAH under aerobic, anoxic, and anaerobic conditions, respectively. The organic substrate of batch tests conducted included 400 mg/L of DMSO, 250 mg/L of MEA, and 120 mg/L of TMAH. For DMSO, specific DMSO degradation rates under aerobic and anoxic conditions were both lower than 4 mg DMSO/g VSS-hr. Under anaerobic conditions, the specific DMSO degradation rate was estimated to be 14 mg DMSO/g VSS-hr, which was much higher than those obtained under aerobic and anoxic conditions. The optimum specific MEA and TMAH degradation rates were obtained under aerobic conditions with values of 26.5 mg MEA/g VSS-hr and 17.3 mg TMAH/g VSS

The amount of pollutants produced during manufacturing processes of thin-film transistor liquid crystal display (TFT-LCD) substantially increases due to an increasing production of the opto-electronic industry in Taiwan. This study presents the treatment performance of one aerobic and one anoxic/oxic (A/O) sequencing batch reactors (SBRs) treating synthetic TFT-LCD wastewater containing dimethyl sulfoxide (DMSO), monoethanolamine (MEA), and tetra-methyl ammonium hydroxide (TMAH). The long-term monitoring results for the aerobic and A/O SBRs demonstrate that stable biodegradation of DMSO, MEA, and TMAH can be achieved without any considerably adverse impacts. The ammonium released during MEA and TMAH degradation can also be completely oxidized to nitrate through nitrification in both SBRs. Batch studies on biodegradation rates for DMSO, MEA, and TMAH under anaerobic, anoxic, and aerobic conditions indicate that effective MEA degradation can be easily achieved under all three conditions examined, while efficient DMSO and TMAH degradation can be attained only under anaerobic and aerobic conditions, respectively. The potential odor problem caused by the formation of malodorous dimethyl sulfide from DMSO degradation under anaerobic conditions, however, requires insightful consideration in treating DMSO-containing wastewater. Copyright (c) 2010 Elsevier Ltd. All rights reserved.

Fluorinated greenhouse gases (F-GHGs) are among the most potent and persistent greenhouse gases contributing to global climate change. Learn about the manufacturing processes which release F-GHGs, and how LCD suppliers are working to reduce emissions.

This research is mainly to explore the treatment capacity for TFT-LCD industrial wastewater recycling by the processes combined with membrane bioreactor (MBR), reverse osmosis (RO) and ozone(O3). The organic wastewater from the TFT-LCD industry was selected as the target. MBR, RO and ozone plants were established for evaluation. An MBR plant consisted of a 2-stage anoxic/aerobic bioreactor and an immersed UF membrane unit was employed. The effluent of MBR was conducted into the RO system then into the ozone system. The RO system consisted of a spiral membrane in the vessel. One bubble column, 75 cm high and diameter 5 cm, were used as the ozonation reactor. On the bottom of ozonation reactor is a porous diffuser for releasing gas, with an aperture of 100 microm (0.1 cm). Over the whole experimental period, the MBR process achieved a satisfactory organic removal. The COD could be removed with an average of over 98.5%. For the TOC item, the average removal efficiency was 97.4%. The stable effluent quality and satisfactory removal performance were ensured by the efficient interception performance of an immersed UF membrane device incorporated with the biological reactor. Moreover, the MBR effluent did not contain any suspended solids and the SDI value was under 3. After the treatment of RO, excellent water quality was found. The water quality of permeate was under 5 mg/I, 2 mg/l and 50 micros/cm for COD, TOC and conductivity respectively. The treated water can be recycled and reused for the cooling tower make-up water or other purposes. After the treatment of ozone, the treated water quality was under 5 mg/l and 0.852 mg/l for COD and TOC respectively. The test results of MBR, MBR/RO and MBR/RO/ozone processes were compared as possible appropriate treatment technologies applied in TFT-LCD industrial wastewater reuse and recycling.

In TFT-LCD industry, water plays a variety of roles as a cleaning agent and reaction solvent. As good quality water is increasingly a scarce resource and wastewater treatment costs rises, the once-through use of industrial water is becoming uneconomical and environmentally unacceptable. Instead, recycling of TFT-LCD industrial wastewater is become more attractive from both an economic and environmental perspective. This research is mainly to explore the capacity of TFT-LCD industrial wastewater recycling by the process combined with membrane bioreactor and reverse osmosis processes. Over the whole experimental period, the MBR process achieved a satisfactory organic removal. The COD could be removed with an average of over 97.3%. For TOC and BOD5 items, the average removal efficiencies were 97.8 and 99.4% respectively. The stable effluent quality and satisfactory removal performance were ensured by the efficient interception performance of the UF membrane device incorporated with biological reactor. Moreover, the MBR effluent did not contain any suspended solids and the SDI value was under 3. After treatment of RO, excellent water quality of permeate were under 5 mg/l, 2.5 mg/l and 150 micros/cm for COD, TOC and conductivity respectively. The treated water can be recycled for the cooling tower make-up water or other purposes.

This study evaluated TMAH biodegradation under methanogenic conditions. Under methanogenic conditions, a sludge from a full-scale UASB treating TFT-LCD wastewater was able to degrade 2,000 mg/L of TMAH within 10 h and attained a specific degradation rate of 19.2 mgTMAH/gVSS-h. Furthermore, several chemicals including some surfactants, DMSO, and sulfate were examined for their potential inhibitory effects on TMAH biodegradation under methanogenic conditions. The results indicated that surfactant S1 (up to 2%) and DMSO (up to 1,000 mg/L) presented negligible inhibitory effects on TMAH degradation, while surfactant S2 (0.2-1%) might inhibit methanogenic reaction without any TMAH degradation for 3-5 h. At sulfate concentrations higher than 300 mg/L, a complete inhibition of methanogenic reaction and TMAH biodegradation was observed. Results from cloning and sequencing of archaeal 16S rRNA gene fragments showed that Methanosarcina barkeri and Methanosarcina mazei were the dominant methanogens in the UASB treating TMAH-containing TFT-LCD wastewater.

The objectives of this study are: (1) to determine the effect of pH, initial concentration of Fe(2+) and H(2)O(2) dosage on the removal efficiency of MEA by fluidized-bed Fenton process and Fenton process, (2) to determine the optimal conditions for the degradation of ethanolamine from TFT-LCD wastewater by fluidized-bed Fenton process. In the design of experiment, the Box-Behnken design was used to optimize the operating conditions. A removal efficiency of 98.9% for 5mM MEA was achieved after 2h under optimal conditions of pH3, [Fe(2+)]=5mM and [H(2)O(2)]=60mM. Copyright © 2011 Elsevier Ltd. All rights reserved.

This study evaluated biological treatment of TMAH in a full-scale methanogenic up-flow anaerobic sludge blanket (UASB) followed by an aerobic bioreactor. In general, the UASB was able to perform a satisfactory TMAH degradation efficiency, but the effluent COD of the aerobic bioreactor seemed to increase with an increased TMAH in the influent wastewater. The batch test results confirmed that the UASB sludge under methanogenic conditions would be favored over the aerobic ones for TMAH treatment due to its superb ability of handling high strength of TMAH-containing wastewaters. Based on batch experiments, inhibitory chemicals present in TFT-LCD wastewater like surfactants and sulfate should be avoided to secure a stable methanogenic TMAH degradation. Finally, molecular monitoring of Methanomethylovorans hollandica and Methanosarcina mazei in the full-scale plant, the dominant methanogens in the UASB responsible for TMAH degradation, may be beneficial for a stable TMAH treatment performance. Copyright © 2012 Elsevier Ltd. All rights reserved.

International Display Consortium (IDC) is the joining together of display companies to combined their buying power and obtained favorable terms with a major LCD manufacturer. Consolidating the buying power and grouping the demand enables the rugged display industry of avionics, ground vehicles, and ship based display manufacturers to have unencumbered access to high performance AMLCDs while greatly reducing risk and lowering cost. With an unrestricted supply of AMLCD displays, the consortium members have total control of their risk, cost, deliveries and added value partners. Every display manufacturer desires a very close relationship with a display vender. With IDC each consortium member achieves a close relationship. Consortium members enjoy cost effective access to high performance, industry standard sized LCD panels, and modified commercial displays with 100 degree C clearing points and portrait configurations. Consortium members also enjoy proposal support, technical support and long-term support.

Defect detection has been considered an efficient way to increase the yield rate of panels in thin film transistor liquid crystal display (TFT-LCD) manufacturing. In this study we focus on the array process since it is the first and key process in TFT-LCD manufacturing. Various defects occur in the array process, and some of them could cause great damage to the LCD panels. Thus, how to design a method that can robustly detect defects from the images captured from the surface of LCD panels has become crucial. Previously, support vector data description (SVDD) has been successfully applied to LCD defect detection. However, its generalization performance is limited. In this paper, we propose a novel one-class machine learning method, called quasiconformal kernel SVDD (QK-SVDD) to address this issue. The QK-SVDD can significantly improve generalization performance of the traditional SVDD by introducing the quasiconformal transformation into a predefined kernel. Experimental results, carried out on real LCD images provided by an LCD manufacturer in Taiwan, indicate that the proposed QK-SVDD not only obtains a high defect detection rate of 96%, but also greatly improves generalization performance of SVDD. The improvement has shown to be over 30%. In addition, results also show that the QK-SVDD defect detector is able to accomplish the task of defect detection on an LCD image within 60 ms. PMID:22016625

Defect detection has been considered an efficient way to increase the yield rate of panels in thin film transistor liquid crystal display (TFT-LCD) manufacturing. In this study we focus on the array process since it is the first and key process in TFT-LCD manufacturing. Various defects occur in the array process, and some of them could cause great damage to the LCD panels. Thus, how to design a method that can robustly detect defects from the images captured from the surface of LCD panels has become crucial. Previously, support vector data description (SVDD) has been successfully applied to LCD defect detection. However, its generalization performance is limited. In this paper, we propose a novel one-class machine learning method, called quasiconformal kernel SVDD (QK-SVDD) to address this issue. The QK-SVDD can significantly improve generalization performance of the traditional SVDD by introducing the quasiconformal transformation into a predefined kernel. Experimental results, carried out on real LCD images provided by an LCD manufacturer in Taiwan, indicate that the proposed QK-SVDD not only obtains a high defect detection rate of 96%, but also greatly improves generalization performance of SVDD. The improvement has shown to be over 30%. In addition, results also show that the QK-SVDD defect detector is able to accomplish the task of defect detection on an LCD image within 60 ms.

Green supply chain has become an important topic these days due to pollution, global warming, extreme climatic events, etc. A green product is manufactured with the goal of reducing the damage to the environment and limiting the use of energy and other resources at any stage of its life, including raw materials, manufacture, use, and disposal. Carbon footprint is a good measure of the impact that a product has on the environment, especially in climate change, in the entire lifetime of the product. Carbon footprint is directly linked to CO2 emission; thus, the reduction of CO2 emission must be considered in the product life cycle. Although more and more researchers are working on the green supply chain management in the past few years, few have incorporated CO2 emission or carbon footprint into the green supply chain system. Therefore, this research aims to propose an integrated model for facilitating the new product development (NPD) for green and low-carbon products. In this research, a systematic model based on quality function deployment (QFD) is constructed for developing green and low-carbon products in a TFT-LCD manufacturer. Literature review and interviews with experts are done first to collect the factors for developing and manufacturing green and low-carbon products. Fuzzy Delphi method (FDM) is applied next to extract the important factors, and fuzzy interpretive structural modeling (FISM) is used subsequently to understand the relationships among factors. A house of quality (HOQ) for product planning is built last. The results shall provide important information for a TFT-LCD firm in designing a new product.

This study investigated the linkage between performance of two full-scale membrane bioreactor (MBR) systems treating thin-film transistor liquid crystal display (TFT-LCD) wastewater and the population dynamics of dimethylsulfoxide (DMSO)/dimethylsulfide (DMS) degrading bacteria. High DMSO degradation efficiencies were achieved in both MBRs, while the levels of nitrification inhibition due to DMS production from DMSO degradation were different in the two MBRs. The results of real-time PCR targeting on DMSO/DMS degrading populations, including Hyphomicrobium and Thiobacillus spp., indicated that a higher DMSO oxidation efficiency occurred at a higher Hyphomicrobium spp. abundance in the systems, suggesting that Hyphomicrobium spp. may be more important for complete DMSO oxidation to sulfate compared with Thiobacillus spp. Furthermore, Thiobacillus spp. was more abundant during poor nitrification, while Hyphomicrobium spp. was more abundant during good nitrification. It is suggested that microbial population of DMSO/DMS degrading bacteria is closely linking to both DMSO/DMS degradation efficiency and nitrification performance. Copyright © 2013 Elsevier Ltd. All rights reserved.

... 42 Public Health 3 2010-10-01 2010-10-01 false LCD review. 426.425 Section 426.425 Public Health... PROGRAM REVIEW OF NATIONAL COVERAGE DETERMINATIONS AND LOCAL COVERAGE DETERMINATIONS Review of an LCD § 426.425 LCD review. (a) Opportunity for the aggrieved party, after his or her review of the LCD record...

This study investigated nitrification performance and nitrifying community in one full-scale membrane bioreactor (MBR) treating TFT-LCD wastewater. For the A/O MBR system treating monoethanolamine (MEA) and dimethyl sulfoxide (DMSO), no nitrification was observed, due presumably to high organic loading, high colloidal COD, low DO, and low hydraulic retention time (HRT) conditions. By including additional A/O or O/A tanks, the A/O/A/O MBR and the O/A/O MBR were able to perform successful nitrification. The real-time PCR results for quantification of nitrifying populations showed a high correlation to nitrification performance, and can be a good indicator of stable nitrification. Terminal restriction fragment length polymorphism (T-RFLP) results of functional gene, amoA, suggest that Nitrosomonas oligotropha-like AOB seemed to be important to a good nitrification in the MBR system. In the MBR system, Nitrobacter- and Nitrospira-like NOB were both abundant, but the low nitrite environment is likely to promote the growth of Nitrospira-like NOB. Copyright © 2012 Elsevier Ltd. All rights reserved.

The drive for larger size, higher spatial resolution, and wider aperture LCD has shown to increase the electrical crosstalk between electrodes in the driver circuit. This crosstalk leads to additivity errors in color LCD. In this paper, the crosstalk effect was analyzed with micrographs captured from an imaging colorimeter. The experimental result reveals the subpixel nature of color crosstalk. A spatial-based subpixel crosstalk correction algorithm was developed to improve the color performance of LCD. Compared to a 3D lookup table approach, the new algorithm is easier to implement and more accurate in performance.

One of four manuals dealing with the operation of wastewater plants, this document was designed to address the treatment of wastewater from electroplating, metal finishing, and printed circuit board manufacturing. It emphasizes how to operate and maintain facilities which neutralize acidic and basic waters; treat waters containing metals; destroy…

Field sequential color (FSC) liquid crystal displays (LCD) using a high speed LCD mode and an R, G, B LED backlight, offers a significant potential for lower power consumption, higher resolution, higher brightness and lower cost compared to the conventional R, G, B color filter based LCD, and thus is of interest to various military and avionic display applications. While the DLP projection TVs, and Camcorder LCD view finder type displays using the FSC technology have been introduced in the consumer market, large area direct view LCD displays based on the FSC technology have not reached the commercial market yet. Further, large area FSC LCDs can present unique operational issues in avionic and military environments particularly for operation in a broad temperature range and with respect to its susceptibility for the color breakup image artifact. In this paper we will review the current status of the FSC LCD technology and then discuss the results of our efforts on the FSC LCD technology evaluation for the avionic applications.

In the field of Waste LCD disassembling and recycling, there are existing two major problems: 1) disassembling waste LCD mainly depends on manually mechanical crushing; 2) the resource level is not high. In order to deal with the above problems, in this paper, we develop an efficient, safe and automated waste LCD disassembling assembly line technology. This technology can disassembly and classify mainstream LCD into four components, which are liquid crystal display panels, housings and metal shield, PCB assembly. It can also disassembly many kinds of waste LCD. Compared with the traditional cooperation of manual labor and electric tools method, our proposed technology can significantly improve disassembling efficiency and demonstrate good prospects and promotional value.

... 42 Public Health 3 2013-10-01 2013-10-01 false LCD record furnished to aggrieved party. 426.418... COVERAGE DETERMINATIONS Review of an LCD § 426.418 LCD record furnished to aggrieved party. (a) Elements of a contractor"s LCD record furnished to the aggrieved party. Except as provided in paragraph (b) of...

... 42 Public Health 3 2014-10-01 2014-10-01 false LCD record furnished to aggrieved party. 426.418... COVERAGE DETERMINATIONS Review of an LCD § 426.418 LCD record furnished to aggrieved party. (a) Elements of a contractor"s LCD record furnished to the aggrieved party. Except as provided in paragraph (b) of...

... 42 Public Health 3 2012-10-01 2012-10-01 false LCD record furnished to aggrieved party. 426.418... COVERAGE DETERMINATIONS Review of an LCD § 426.418 LCD record furnished to aggrieved party. (a) Elements of a contractor"s LCD record furnished to the aggrieved party. Except as provided in paragraph (b) of...

... 42 Public Health 3 2010-10-01 2010-10-01 false CMS" role in the LCD review. 426.415 Section 426... Review of an LCD § 426.415 CMS" role in the LCD review. CMS may provide to the ALJ, and all parties to the LCD review, information identifying the person who represents the contractor or CMS, if necessary...

For the first time, an avionic grade MVA AM LCD with wide viewing angle has been developed for use in either landscape or portrait mode. The development of a high resolution Multi-domain Vertical Alignment (MVA) Active Matrix Liquid Crystal Display (AM LCD) is described. Challenges met in this development include achieving the required performance with high luminance and sunlight readability while meeting stringent optical (image quality) and environmental performance requirements of avionics displays. In this paper the optical and environmental performance of this high resolution 14.1" MVA-AM-LCD are discussed and some performance comparisons to conventional AM-LCDs are documented. This AM LCD has found multiple Business Aviation and Military display applications and cockpit pictures are presented.

Stereoscopic display technologies have been developed as one of advanced displays, and many TV industrials have been trying commercialization of 3D TV. We have been developing 3D TV based on LCD with LED BLU (backlight unit) since Samsung launched the world"s first 3D TV based on PDP. However, the data scanning of panel and LC"s response characteristics of LCD TV cause interference among frames (that is crosstalk), and this makes 3D video quality worse. We propose the method to reduce crosstalk by LCD driving and backlight control of FHD 3D LCD TV.

Soluble sodium silicates (waterglass) are liquids containing dissolved glass which have some water like properties. They are widely used in industry as sealants, binders, deflocculants, emulsifiers and buffers. Their most common applications in Egypt are in the pulp and paper industry (where they improve the brightness and efficiency of peroxide bleaching) and the detergent industry, in which they improve the action of the detergent and lower the viscosity of liquid soaps. The survey results showed that the production was carried out batch-wise, in an autoclave (dissolver). Sodium silicate in the state of crushed glass was charged in an autoclave (dissolver) with sodium hydroxide and water. The product is filtered through a press. The left over sludge (mud and silicates impurities) is emptied into the local sewer system. Also, sludge (silica gel) was discharged from the neutralization process of the generated alkaline wastewater and consequently clogging the sewerage system. So this study was carried out to modify the current wastewater management system which eliminates sludge formation, the discharge of higher pH wastewater to the sewer system, and to assess its environmental and economic benefits. To assess the characteristics of wastewater to be reused, physico-chemical parameters of 12 samples were tested using standard methods. The survey results showed that a total capacity of the selected enterprise was 540 tons of liquid sodium silicates monthly. The total amount of wastewater being discharged was 335 m3/month. Reusing of wastewater as feed autoclave water reduced water consumption of 32.1% and reduced wastewater discharge/month that constitutes 89.6% as well as saving in final product of 6 ton/month. It was concluded that reusing of wastewater generated from liquid sodium silicate manufacturing process resulted in cheaper and environmental-friendly product.

A new drive circuit for the liquid crystal display (LCD) of the InFocus TVT-6000 video projector is currently under development at the U.S. Army Missile Command. The new circuit will allow individual pixel control of the LCD and increase the frame rate by a factor of two while yielding a major reduction in space and power requirements. This paper will discuss results of the effort to date.

In this paper, the impact of display on quality assessment is addressed. Subjective quality assessment experiments have been performed on both LCD and CRT displays. Two sets of still images and two sets of moving pictures have been assessed using either an ACR or a SAMVIQ protocol. Altogether, eight experiments have been led. Results are presented and discussed, some differences are pointed out. Concerning moving pictures, these differences seem to be mainly due to LCD moving artefacts such as motion blur. LCD motion blur has been measured objectively and with psycho-physics experiments. A motion-blur metric based on the temporal characteristics of LCD can be defined. A prediction model have been then designed which predict the differences of perceived quality between CRT and LCD. This motion-blur-based model enables the estimation of perceived quality on LCD with respect to the perceived quality on CRT. Technical solutions to LCD motion blur can thus be evaluated on natural contents by this mean.

... Section 426.418 Public Health CENTERS FOR MEDICARE & MEDICAID SERVICES, DEPARTMENT OF HEALTH AND HUMAN... development of the LCD, including, but not limited to, the following: (1) The LCD being challenged. (2) Any... the draft LCD). (4) An index of documents considered that are excluded under paragraph (b) of this...

... Section 426.418 Public Health CENTERS FOR MEDICARE & MEDICAID SERVICES, DEPARTMENT OF HEALTH AND HUMAN... development of the LCD, including, but not limited to, the following: (1) The LCD being challenged. (2) Any... the draft LCD). (4) An index of documents considered that are excluded under paragraph (b) of this...

The electrocoagulation (EC) process was used to pretreat wastewater from the manufacture of wet-spun acrylic fibers, and the effects of varying the operating parameters, including the electrode area/wastewater volume (A/V) ratio, current density, interelectrode distance and pH, on the EC treatment process were investigated. About 44% of the total organic carbon was removed using the optimal conditions in a 100 min procedure. The optimal conditions were a current density of 35.7 mA cm(-2), an A/V ratio of 0.28 cm(-1), a pH of 5, and an interelectrode distance of 0.8 cm. The biodegradability of the contaminants in the treated water was improved by the EC treatment (using the optimal conditions), increasing the five-day biological oxygen demand/chemical oxygen demand ratio to 0.35, which could improve the effectiveness of subsequent biological treatments. The improvement in the biodegradability of the contaminants in the wastewater was attributed to the removal and degradation of aromatic organic compounds, straight-chain paraffins, and other organic compounds, which we identified using gas chromatography-mass spectrometry and Fourier transform infrared spectroscopy. The EC process was proven to be an effective alternative pretreatment for wastewater from the manufacture of wet-spun acrylic fibers, prior to biological treatments. Copyright © 2014 Elsevier B.V. All rights reserved.

Several photo-activated processes have been investigated for oxidation of a cork manufacturing wastewater. A comparative activity study is made between different homogeneous (H2O2/UV-Vis and H2O2/Fe2+/UV-Vis) and heterogeneous (TiO2/UV-Vis and TiO2/H2O2/UV-Vis) systems, with degradation performances being evaluated in terms of total organic carbon (TOC) removal. Results obtained in a batch photo-reactor show that photo-catalysis with TiO2 is not suitable for this kind of wastewater while the H2O2/UV-Vis oxidation process, for which the effect of some operating conditions was investigated, allows to remove 39% of TOC after 4 h of operation (for C(H2O2)=0.59 M, pH=10 and T=35 degrees C). The combined photo-activated process, i.e., using both TiO2 and H2O2, yields an overall TOC decrease of 46% (for C(TiO2)=1.0 gl(-1)). The photo-Fenton process proved to be the most efficient, proceeds at a much higher oxidation rate and allows to achieve 66% mineralization in just 10 min of reaction time (for C(H2O2)=0.31 M, T=30 degrees C, Fe2+:H2O2=0.12 (mol) and pH=3.2).

The aim of this work was to assess the effectiveness of a biological trickling filter for the treatment of wastewaters produced by a company manufacturing organic dyes and varnishes. The combined wastewater effluent was fed to a pilot-scale trickling filter in two feeding modes, continuously and as a sequencing batch reactor (SBR). The biodegradability of the diluted wastewaters that were subjected to physicochemical treatment, using Ca(OH)(2) and FeSO(4), was initially studied using a continuously operated trickling filter. The system efficiency ranged up to 60-70% for a hydraulic loading of 1.1 m(3)/m(2)day and up to 80-85% for a hydraulic loading 0.6 m(3)/m(2)day. A stable chemical oxygen demand (COD) removal efficiency of 60-70% was achieved even in the case of undiluted wastewater at a hydraulic loading of 1.1 m(3)/m(2)day. The effectiveness of biological treatment of a mixture of the company"s main wastewater streams was also examined. The microorganisms developed in the trickling filter were able to efficiently remove COD levels up to 36,000 mg/L, under aerobic conditions at pH values between 5.5 and 8.0. Depending on the operating conditions of the system, about 30-60% of the total COD removal was attributed to air stripping caused by the air supply at the bottom of the filter, whereas the rest of the COD was clearly removed through biological action. The proposed biological treatment process based on a trickling filter, which was operated either continuously or even better in an SBR mode, appears as a promising pretreatment step for coping with dye manufacturing wastewaters in terms of removing a significant portion of the organic content.

The feasibility of the dissolved air flotation (DAF) process in treating chemical mechanical polishing (CMP) wastewater was evaluated in this study. Wastew

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey