crystal clear transparent lcd display factory

LCD Transparent Displays, transparent screens, transparent monitors, see through screens, transparent touch screen technology, and kits from CDS as we have our own range of transparent screens / displays and transparent video screens manufactured for us, and as we control the manufacturing, we can not only offer more sizes than anyone else in the world, but also guarantee stable supply, long term availability LCDs with amazing quality. We have replaced the Samsung Transparent Displays / see through Displays and LG Transparent OLEDs that are no longer available!

CDS has increased the use of these see through screens / see through displays / see through computer screens / clear monitors across the world including touchscreen computer screens combined with the transparent LCD touch screens and Transparent OLED displays.

CDS as you can see offers an entry level up to high performance rugged range of panel Computer solutions. This stylish range offer integrators an alternative designs and performances whether that be rugged industrial or sleek sealed operator interfaces. The CDS Clearvue Transparent showcases, Hypeboxes and clear OLED display range offers affordable and reliable quality Panel PCs. These are used in Human Machine Interfaces (HMI), home automation, Building control, factory automation, touchscreen table, process control, SCADA and CAN BUS.

Our new generation of Panel PCs are very impressive utilising powerful technology as well as attractive designs. Users of the CDS products can reliably utilise operating and monitoring processes in your systems to give the impression of an invisible display.

Transparent lcd displays are available in a variety of colors. On Alibaba.com, you can find the type of transparent lcd displays made in a variety of materials. such as polystyrene, inexpensive, and easy to maintain and use. Clear lcd displays in bulk are available at wholesale prices.

Transparent lcdds are flexible because they include more things than a single-, rystal-displays, and membrane-displaysers. Clear lcdds are flexible, which include them that require more maintenance and more than the latter type of display. Find lcdds in bulk available on Alibaba.com.

Transparent LCD displays have a variety of functions and interfaces for different products. On the other hand, LCD displays create a variety of events that will be relevant to the user and interfere with the content.

Find the ideal type of lcd display in bulk, suppliers on Alibaba.com offer a wide variety of lcd displays in bulk. For lcd displays in bulk, it"s free to explore the wide variety of lcd displays in bulk and at wholesale prices.

For the first time users will be able to see products through the display at the same time as the product information and sales message is displayed on the display

The company’s ‘Crystal Clear’ Transparent LCD displays open up a wealth of new product design opportunities. For the first time users will be able to see products through the display at the same time as the product information and sales message is displayed on the display.

The first display to be mass produced is a 22 inch LCD with a transparency of 20% in black and white and 15% in colour mode. Both versions operate during the day by harvesting ambient light, making the displays exceptionally energy efficient, consuming 90% less power than a conventional LCD panel. This allows the 22” display to be battery operated, a first for this size of LCD display.

At night only a small amount of ambient light is required as this is supplemented by using a transparent wave guide and a special diffuser plate that enhances the output from the low power LED light source.

The use of this exciting new technology is limited only by the imagination of designers to integrate this technology into kiosks, window displays, point of purchase displays and smart gadgets.

Manufacturer of optical coatings, flat panel/LCD glass, instrument glass, & CRT filter glass. Products include anti-reflective/anti-glare coatings, transparent conductive coatings, fiber optic coatings, beam splitters, cover glass, etched glass, heater glass, glass sandwiches, lighting wedges, & circular polarizers. Applications include EMI/RFI protection, contrast adjustment, & optical instruments. Capabilities include precision glass cutting to tolerances of plus/minus .005 in. & precision glass edging to tolerances of plus/minus .002 in. Additional capabilities include custom manufacturing of laminated products. Services & products meet Military Spec.

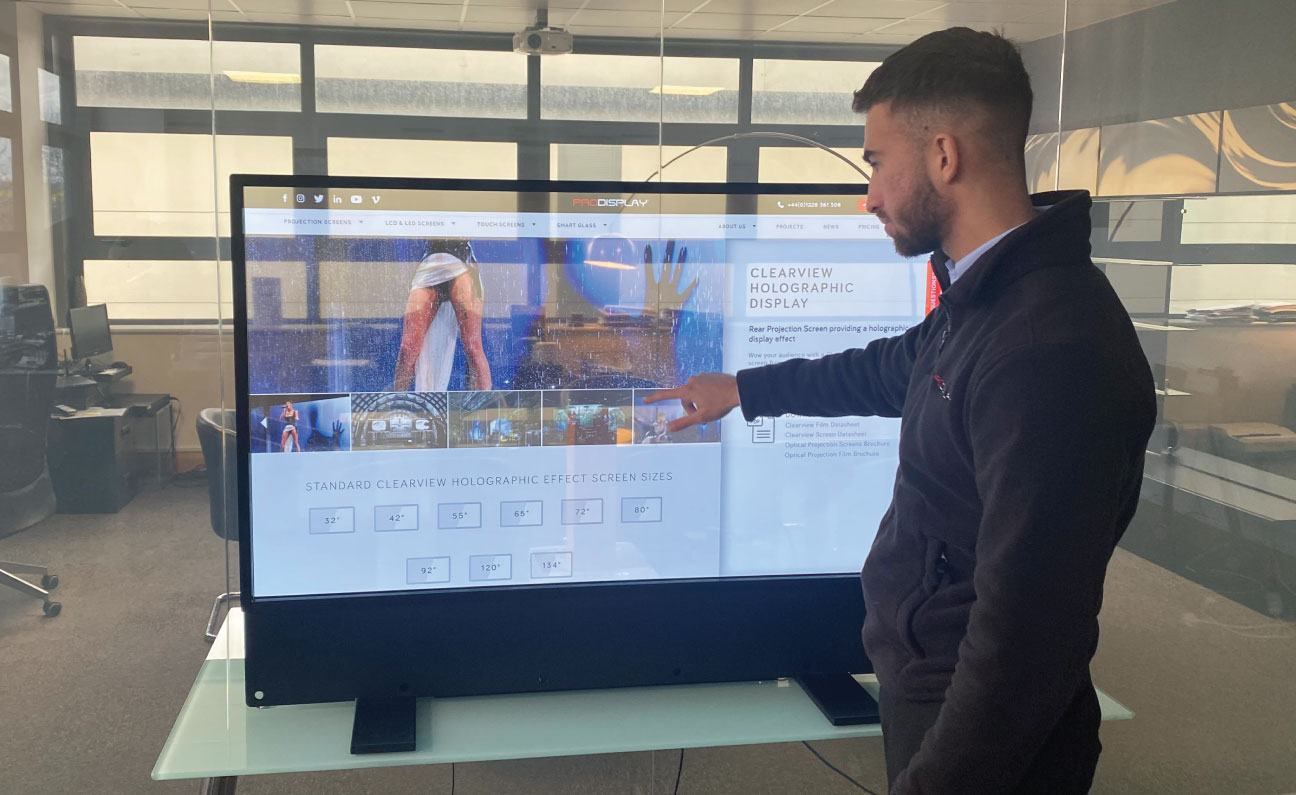

Transparent OLED Displays are a stunning new development in digital signage and display technology. These transparent display screens are used to communicate dynamic or interactive content via a transparent surface allowing viewers to see what is shown on the screen whilst still being able to see through the display. This solution allows designers creative ways to display content whilst curating a futuristic ‘Minority Report’ type effect.

OLED stands for Organic Light Emitting Diode, a technology that eliminates the need for a backlight or enclosure. Standard Transparent LCD screens require backlighting to create a visible image, whereas Transparent OLED screens are made up of millions of pixels that each emit their own individual light. This opens up a whole new field of creativity in digital signage that even transparent LCD screens cannot offer. Unlike Transparent LCD screens, Transparent OLED screens display black content as transparent instead of white content. This puts a different spin on the merchandising process, offering new ways to communicate in an imaginative way with your audience.

Transparent OLED Screens are also available with Infrared or PCAP interactive touch overlays to create immersive touch screen displays. The benefits oftouch screen technologyare well documented, and when combined with Transparent OLED displays, you are sure to see customers interacting with content in ways you have not seen before.

Transparent OLED Displays are available in 55” screen sizes with Video Wall options available to create large format displays. Both options are also available as a Transparent Touch Screen providing multi-touch functionality.

Our Transparent OLED Displays can be combined with a Digital TV Box to create a full Transparent TV solution providing the latest technology in the home!

Transparent OLED Displays are available in several options with or without touch or alternatively, as a Transparent OLEDVideo Wallwhere the displays can be joined to create a large-format screen, providing a stunning visual display with an impact! Get in touch with our sales team today for a quote.

No, Transparent OLEDs do not require a backlight, these screens are made up of millions of self-lit pixels that come together to create an image. This gives you greater control over the brightness and lighting of the screen depending on your environment.

Transparent OLED Screens are HD displays that despite being see-through in appearance when turned off and on, can produce an image that covers the whole screen offering a crisp resolution perfect for up-close viewing applications. These are commonly used for POS displays, demonstrations & exhibitions and in other hands-on environments.

Transparent LED Displays on the other hand are designed for large format displays, offering high brightness that is unphased by broad daylight, with the gaps between the LEDs providing transparency. These are usually used in larger window displays that are restricted for space or across large areas of glass facades in corporate buildings or offices, as they offer the power of a standard LED screen with the benefit of still being able to see through them.

Transparent OLED Displays are truly stunning in any environment, with many different industries opting to use them in different ways. One of the most popular uses is in retail, using the Transparent OLED as part of a POS or window display to create the effect that images are floating around the product on show.

They are also a great tool for use in museums, theme parks and visitor attractions, whether it’s to create a more layered, in-depth exhibitor to create a memorable sci-fi effect. Transparent OLEDs can also be used in nightclubs, salons, factories, health clubs, etc. as their versatility sees them useful for business ventures.

As standard Transparent OLED Screens are currently only available in a 55” screen size, however, they can be joined together to create Transparent OLED Video Walls. Whilst these can be joined in any 2 x N format, the most popular solution is using 4 OLED screens together to create an almost two and a half meter tall transparent video wall.

We can also grant our Transparent OLED Displays interactivity by combining them with a touch frame, creating a holographic touch screen that can be used by multiple users at any one time. We also manufacture custom housings for our Transparent OLEDs which can be custom designed to suit your requirements, with options for custom branding and logos.

Transparent OLEDs are made up of pixels that emit their own light whereas Transparent LCD’s need a backlight to produce an image, this is why Transparent LCD’s require full housing solutions to create the best possible image. Another key difference is that when turned off, Transparent OLED screens remain transparent, unlike Transparent LCD’s which are not see-through when switched off, simply displaying a black screen.

We manufacture in Britain and ship worldwide – if you need further information, a pricing quote, or want to discuss ideas for using our Transparent OLED Displays click the link below to contact us, email us via info@prodisplay.com or call us on +44 (0)1226 361 306.

According to [Kelsey], transparent displays are guaranteed to make “everything feel like the future.” Unfortunately they’re hard to find, and the ones typically available are OLED and can’t make solid black colors. But as luck would have it, it’s possible to repurpose a common LCD to be sort of transparent.

A LCD uses nematic crystals that can polarize light, with the amount of polarization changing based on the electric field applied to the crystal. Light enters the front of the panel through a polarizing film, passes through the display, and then bounces off a reflective back coating. The display itself usually polarizes light in a way that matches the front polarizer. That means if you do nothing you get reflected light. However, if a part of the LCD gets an electric field, it will repolarize in such a way as to block the reflected light making the display look black in that area.

[Kelsey’s] trick is to peel off the reflector and replace it with polarizing film taken from another display. The new polarizer needs to be bigger than the display for one reason: you need to match the polarizing angle of the front film with the new back film. That means if the new film is exactly the right size, it won’t be able to rotate without leaving gaps. By starting with a larger piece, you’ll be able to rotate for maximum transparency before you stick it on.

The latest innovation in liquid crystal displays (LCDs) introduces an incredible Transparent LCD Screen. Now, you’ll not only be looking at an LCD, you’ll be seeing through it and into the area surrounding whatever goodies appear to be ‘housed’ inside it! Touch technology can also be added by using an interactive Touch Foil or IR Touch Frame.

Coupled with a clever Transparent LCD Screen unit set-up, this revolutionary technology, the latest mobile phone, face cream or jewellery is encased inside the display while pictures, video or special effects (think snow and sparkles) simultaneously surround the product to inform and dazzle onlookers.

How does the Transparent LCD Screen it work?The LCD utilises ambient light, with no internal back lighting requirement. For this reason, it is more energy efficient, cost effective and reliable than other displays of similar size.

They don’t have a blacklight layer integrated, so they do need a background light to reflect colours, but this means the display itself features a unique thinness, which allows the screen to be transparent. But, this also means they need to have a backlight installed behind, which does not allow the transparent LCD to be fixed on a window, the system works as a box, and that is usually how we use them.

Any LCD panel is by nature “see through,” though conventional LCDs have relatively low transmission efficiency so that they tend to appear somewhat dark against natural light. Unlike LED see-through displays, LCD see-throughs do not produce their own light but only modulate ambient light. LCDs intended specifically for see-through displays are usually designed to have improved transmission efficiency. Small scale see-through LCDs have been commercially available for some time, but only recently have vendors begun to offer units with sizes comparable to LCD televisions and displays. Samsung released a specifically see-through designed 22-inch panel in 2011. As of 2016, they were being produced by Samsung, LG, and MMT, with a number of vendors offering products based on OEM systems from these manufacturers, such as us, here at Street Co’. An alternative approach to commercializing this technology is to offer conventional back-lit display systems without the back light system. LCD displays often also require removing a diffuser layer to adapt them for use as transparent displays.

is that the LCD display doesn’t use a backlight, but just the ambient light. Which makes it slightly more transparent than OLED. Though, OLED technologies allow the display to be folded and to give it any shape, and adapt it anywhere, it can be placed on a simple glass with no backlight needed. That is why we wanted to talk about both displays here, because the difference between those is huge and changes everything when it comes to applications, and, very often, people mix them up.

Transparent LCD Displays are one of the latest innovation in LED technology, among with OLED displays, opening up a wide range of new opportunities in retail and marketing.

The possibilities are endless, from placing in front of a product in store, and displaying promotional videos, to being used in front of artefacts at a museum showing infos relating to the object.

These transparent displays are designed for integration within your own housing / chassis. Please note as the displays do not have a backlight you will need to integrate a light source behind the display to gain the transparency.

and more to make static words and images more kinetic. Products can be placed behind a clear transparent screen that shows advertising and provide the opportunity to showcase real products while providing interactive information with an transparent LCD display.

A transparent LCD monitor is a tool to make your advertising more dynamic and have endless possibilities as an advertising tool, which can be applied to show windows and used in showcase events. Corporations and schools can also adopt the transparent LCD display as an interactive communication device, which enables information to be displayed more effectively.

The present invention relates generally to refrigerated display cases and refrigerator doors and, more particularly, to a refrigerator door with a transparent LCD panel. BACKGROUND OF THE INVENTION

The invention described herein includes the use of a transparent LCD glass panel as one of the panes in a three-pane unit, such as one used in an insulated glass refrigerator/freezer door.

One of the issues with such a door is supplying power, data and/or communications to the components within the refrigerated display case. Glass refrigerator/freezer doors commonly have a mechanism to supply 120VAC or 240VAC power to the door for anti-sweat heaters. Most stores use a traditional electrical cord. This cord flexes in the cold and suffers from copper conductor fatigue, and insulation cracking. To overcome these weaknesses, solutions have been provided in which the electrical conductors are passed through the hinge pin. By running the conductors concentric with the axis of the hinge pin, flexing and fatigue is minimized, thus improving reliability. The high voltage conductors and associated contacts require appropriate insulation and spacing as dictated by UL and other safety certification organizations. See, for example, U.S. Pat. No. 4,671,582 (referred to herein as the “"582 patent”), issued on Jun. 9, 1987 to Stromquist, et al., the entirety of which is incorporated herein by reference.

Other types of refrigerator/freezer doors also require both power and data. For example, LED light fixtures mounted to the swinging door, LED illuminated marquee signs mounted inside the insulated glass assembly of the door, LCD displays mounted on the door handle, and transparent LCD glass panels with advertising all require both power and data. Most of these products require UL Class 2 low voltage (<60VDC), and many require a data supply, e.g. LCD displays with advertising pictures or videos requiring TCP/IP type data communications.

Generally, the invention is to use a transparent LCD glass panel as one of the panes in a three-pane unit, such as one used in an insulated glass refrigerator/freezer door. With the transparent LCD panel, a consumer can see the media shown on the LCD panel, but can also see inside the display case/refrigerator to view the contents therein. For example, transparent LCD panels are commercially available from Samsung. In a preferred embodiment, the LCD glass panel is used as the center panel. It is within the scope of the present invention to use the LCD glass panel as the inner or outer pane or to add the LCD glass panel as an additional pane. However, in a preferred embodiment, the LCD glass panel needs to be protected from impact and/or moisture damage. Mounting the panel externally may decrease visible transmittance and would also subject the panel to impact by shopping carts. Also, if the store ambient temperature and humidity are not properly controlled, the door can be subject to condensation which may damage the LCD panel or associated electronics. Mounting the panel inside the freezer (adjacent to the food) may cause condensation when the door is opened. Housing the LCD panel inside the hermetically sealed glass unit protects the panel from condensation damage. The associated electronics can also optionally be mounted inside the hermetically sealed glass assembly to protect them from condensation damage. In another embodiment, the electronics can be mounted outside the hermetically sealed glass assembly, such as in the rail of the door.

The door preferably includes the following distinctive features: (1) transparent LCD panel functioning as the center insulating pane of a three-pane low-temp glass freezer door to maximize visible transmittance while maintaining thermal insulating performance; (2) transparent LCD panel mounted between an inner and outer pane of glass to it protect from impact damage; (3) transparent LCD panel mounted inside the hermetically sealed glass unit to protect from moisture damage; (4) mounting the associated electronics, wires, and media player inside the sealed glass unit to protect it from moisture damage or inside the rail of the door; (5) using selectively decorated opaque areas (e.g. screen printing, dot matrix decorating, roller printing, ink jet printing, painting or the like) of the outer or inner pane of glass to hide the circuit boards around the LCD panel perimeter, the wires, and media player hardware of the door assembly, allowing the complete system to be conveniently housed inside the door. The “LCD door” can be used for advertising merchandise, nutritional value, pricing, etc.

In accordance with a first aspect of the present invention there is provided a door assembly that includes a single glass unit having at least first, second and third panels, a front surface, a rear surface, and an outside edge. At least one of the first, second or third panels is a transparent LCD panel on which media can be displayed. The single glass unit also includes a frame that at least partially surrounds the outside edge of the single glass unit, and electronic components in electrical communication with the LCD panel. In a preferred embodiment, the second panel comprises the transparent LCD panel and is positioned between the first and third panels and the first panel is spaced from the second panel by a first spacer and the third panel is spaced from the second panel by a second spacer. The first, second and third panels each have an outside edge and a length and a width. The length and the width of the second panel is smaller than the length and the width of the first and third panels, thereby defining a margin between the outer edge of the second panel and the outer edges of the first and third panels. The first panel is spaced from the third panel by a third spacer that is positioned within the margin.

In a preferred embodiment, the single glass unit includes insulation disposed within the margin and between the first and third panels and the second panel is hermetically sealed between the first and third panels. Furthermore, the first panel includes an outer opaque section and an inner transparent section through which the second panel is visible. In one embodiment, the electronic components for running the LCD panel are disposed between the first and third panels. In another embodiment, the electronic components are positioned in the rail and the rail includes a removable cover for accessing the electronic components. In an embodiment, one of the panels includes an electro-conductive film thereon that is generally clear, wherein when a voltage is applied across a portion of the film, the film becomes opaque. In an embodiment, the electronic components are powered by 24V DC. BRIEF DESCRIPTION OF THE DRAWINGS

FIG. 1 is a perspective view of a series of refrigerated display cases that each include a door assembly with single glass unit having a center LCD panel;

FIG. 2 is a front elevational view of one of the single glass unit having a center LCD panel of FIG. 1 with a portion of the front outer pane cut away to show the electronic components;

FIG. 1 shows a series of refrigerated display case doors 100 that include a three-pane unit, single glass unit or package 10 with a transparent LCD panel 16 associated therewith. FIGS. 2-4 show the single glass unit 10 with front/outer pane 12, rear/inner pane 14 and center transparent LCD panel 16. It will be understood that in FIGS. 2-4 and 8, the outer perimeter or frame 102 of the door 100 is not shown. In a preferred embodiment, the panes are glass. However, any transparent material, such as plastic, can be used.

As shown in FIG. 3, in a preferred embodiment, the single glass unit 10 includes front and rear panes 12 and 14, LCD panel 16, electronic components 18, spacers 20 a, 20 b, 20 c,and insulation 22. In a preferred embodiment, the front and rear panes 12 and 14 include an opaque section 24 that obscures or hides components inside the unit 10. For example, by providing the opaque section 24 (preferably done by screen printing or some other type of coating) on selected areas of one or more of the panes 12 and/or 14, the spacers 20 a, 20 b, 20 cinsulation 22, electronic components 18 and other components can be housed inside the unit 10 (and the door 100) and hidden from view. Thermal insulation 22 may be added in certain areas to maintain the overall thermal performance of the door.

Each panel 12, 14 and 16, has a front and rear surface, For ease of description, these are described herein and depicted in FIG. 4 as surfaces 121, 122, 123, 124, 125 and 126. It will be appreciated by those skilled in the art that in use surface 121 faces the customer and surface 126 faces the interior space of the display case.

In a preferred embodiment, the opaque section 24 on the front and rear panes 12 and 14 (or dot matrix decorating, etc.) is placed on surfaces 122 and 125 to hide the components therein and the margin of the LCD panel, etc. However, this is not a limitation and the opaque section(s) can be placed on any desired surface.

It will be understood that the LCD panel may include a number of different layers or panes of glass/plexiglass or the like laminated to one another. Accordingly, as used herein, the LCD panel can be a single layer or multi-layer panel that includes an LCD screen for playing media. For example, the LCD screen may include a layer of glass adhered thereto to improve strength and reduce flex when the door is slammed. This can add strength to the LCD panel by essentially making it a double laminated panel. In a preferred embodiment, the LCD panel 16 has an aluminum rail therearound.

In a preferred embodiment, as shown in FIG. 3, unit 10 includes at least three different spacers 20 a, 20 band 20 c.Spacer 20 aspans the space between the front and rear panels 12 and 14, spacer 20 bspans the space between the front panel 12 and the LCD panel 16, and spacer 20 cspans the space between the rear panel 14 and the LCD panel 16, as is shown in FIG. 4. It will be understood that the spacers 20 a, 20 band 20 care adhered to a surface of the panel 12, 14 or 16. For example, spacer 20 ais adhered to the inner surfaces of front panel 12 and rear panel 14. In a preferred embodiment, the spacers 20 a, 20 band 20 care made of an elastomeric material. However, this is not a limitation on the present invention. The spacers can be made of other materials, such as a polymer, a metal such as aluminum, etc. The elastomeric material or spacers 20 band 20 csupports and suspends the LCD panel 16 inside the door and between the front and rear panels 12 and 14, thus helping prevent damage from shock and vibration when the door 100 closes. In another embodiment, the spacers 20 a, 20 band 20 ccan be formed as a unit, as shown in FIG. 8 and as shown in U.S. Pat. No. 6,148,563, the entirety of which is incorporated herein by reference. In this embodiment, the front and rear panels 12 and 14 are spaced from the center panel by spacers 20 band 20 c,but they are also connected by spacer 20 a.This essentially forms a single spacer with a detent in the middle for receiving the LCD panel 16.

When incorporating a single glass unit 10 with a transparent LCD panel 16, the door includes components 18 for operation of the LCD screen. As shown in FIGS. 2 and 4, in a preferred embodiment, the LCD panel 16 is smaller (length and width dimensions) than the outer panes 12 and 14. This provides space or a margin 25 around the perimeter of the LCD panel 16 for housing the components 18. For example, the unit 10 or door 100 can include circuit board(s) 26 (labeled A-D board in FIG. 2), wires or cables 28, a media player 30 (that includes a hard drive with memory and appropriate software) and associated connectors and such for providing media and/or power to the LCD panel 16. In another embodiment, the unit 10 can include one or more speakers 29, as shown in FIG. 7. In a preferred embodiment, components 18 are positioned within the margin 25 under the LCD panel 16. However, this is not a limitation on the present invention and the components 18 can be positioned as desired. See, for example, FIG. 7, where the components are positioned in the rail of the door, which is described more fully below.

It will be understood that the single glass unit 10 can be modified as necessary to fit within any type of door to be used in a refrigerated display case or the like. FIG. 5, shows the unit 10 within an exemplary door assembly 100. The door preferably includes a handle 104 to open or close and alternately seal or unseal the interior space of the display case. Typical display cases include numerous other structures for attaching the door(s) to the display case, as well as features for housing wiring, mullions, gaskets and other associated brackets and components that are typically included in refrigerated display cases. These features are well known in the art and will not be discussed in detail herein. An example of such components are discussed in U.S. Pat. Nos. 6,606,832, and 6,606,833 the disclosures of which are incorporated by reference herein in their entireties.

As discussed above, in a preferred embodiment, unit 10 includes a media player 30 for controlling and playing media on the LCD panel 16. Data can be provided to the media player 30 via wires or cables or wirelessly, e.g., Wi-Fi, 802.11:x, etc., as desired (with the appropriate transmitter and/or receiver). In a preferred embodiment, the media player 30 includes a solid-state drive to prevent a spinning hard drive from failing when the door is slammed. However, this is not a limitation on the present invention and a spinning hard drive or other type of drive can also be used. Wireless (or wired) communications with the media player 30 can be used to deliver desired content to be played on the LCD panel 16, e.g, advertising content, nutritional content, special offers, etc. For example, the invention can implement IP addressable communications so an advertiser can remotely feed new data over the Internet. Furthermore, this allows remote monitoring of the health of the hard drive of the media player and associated electronic components.

In a preferred embodiment, the case into which the door 100 is mounted is pre-wired with low-voltage DC power supply, e.g. 12V, 24V, UL Class 2, etc. so that it accepts a transparent LCD door 100 with power through the hinge pin 31, or wired cords near the rotating hinge pin. However, this is not a limitation on the present invention. For example, a high-voltage option can also be implemented. As shown in FIG. 5, insulated electrical conductors and/or wired communications (for the media player 30 and associated components) can be directed through the hinge pin 31 (e.g., via TCP/IP-type Internet communications).

One feature of a preferred embodiment of the invention is to provide an electrical hinge pin 31, similar to the "582 patent hinge pin, but replacing the AC conductors of the "582 patent with low-voltage DC conductors and a data cable. The elimination of the high voltage AC conductors makes more space available in the hinge pin 31 for both the low-voltage DC antisweat heat and powering the electronics, and a data cable, e.g. Cat 5 with TCP/IP type communications. The low voltage conductors (e.g., 24V DC) can be used to power all electronic components, such as the components 18 for the LCD panel 16, heated glass, anti-sweat perimeter heating, etc. In another embodiment, the electrical hinge pin can be omitted and a regular hinge pin can be used. For example, in an outside mount embodiment of the door, the electronic components can be powered by (and data communicated therewith) a cord that does not run through the hinge pin. This type of door may be used, for example, on a self serve case at the end of a check out aisle in a store.

In a preferred embodiment, (and preferably in low-temp applications), an insulating gas, such as argon, xenon or other insulating gas can be used to fill the inner and/or outer cavities 32 between the LCD panel 16 and the front and rear panes 12 and 14, as shown in FIG. 4 (and other voids or cavities within the unit 10). In a preferred embodiment, the gas-filled inner cavities 32 are hermetically sealed (see seal 33 in FIG. 4) to keep from contaminating the transparent LCD panel 16 with dust, residue or outgassing from the outer insulated cavity containing insulation and electronics.

The thickness of the unit 10 can be different for different applications. However, in an exemplary embodiment, the overall thickness of the unit 10 is preferably about 0.125″, with the front and rear panes 12 and 14 being about 0.125″ thick and the center LCD pane 16 being about 0.125″ thick. These dimensions are not a limitation on the present invention.

In a preferred embodiment, panes 12, 14 and 16 are preferably designed to maximize visible light transmission from inside the case to the customer, thereby improving the ability of customers to view display items. However, it is also desirable to minimize the transmission of non-visible light (i.e., ultraviolet and infrared light) through glass unit 10 from outside to inside the case in order to improve thermal performance and to protect items therein. Coolers are a type of refrigerated display case which operate at a temperature of approximately 38° F. Freezers are another type of refrigerated display case which operate below 0° F. When the glass unit 10 of such display cases comes into contact with ambient air, the relatively colder glass unit 10 can cause moisture in the air to condense on the surfaces of the glass unit. Thus, besides the use of the electro-conductive coating described above, it is desirable to use the non-visible wavelengths of light to heat the glass panels, thus reducing or preventing condensation. In a preferred embodiment, the panes 12, 14 and 16 can also include a UV inhibitor, which can help increase the shelf life of products inside. Also, panes 12, 14 and 16 may include low-emissivity heat-reflective coatings to improve overall thermal resistance and/or prevent external condensation. In an embodiment where reflection is an issue, an anti-reflective coating can be applied to any of the panes the glass unit 10.

In a preferred embodiment, the unit 10 includes motion sensor technology, such as a visual recognition camera 36, as shown in FIG. 6. In this embodiment, the media player 30 only plays content on the LCD panel 16, when a person walks by or in front of the unit 10. In an exemplary embodiment, the unit 10 can include software that allows the camera 36, and/or the components thereof, to recognize if a man or a woman is standing in front of the door 100. Therefore, the advertisement or other media played on the LCD panel 16 can be tailored to the specific gender of the person standing in front of the door 100.

In another preferred embodiment, two or more smaller screens can be combined in a matrix to increase the visible display area. For example a 46″ 16:9 standard TV size in a 30″×67″ door leaves a large opaque margin top and bottom. Two smaller adjacent panels would leave more space for visible transmittance. Another way to increase the visible area is to cut down the long side of a larger 16:9 LCD panel such that it better fits the typical 67″ or 75″ vertical height but would otherwise exceed the standard 30″ width.

In another embodiment, a series of doors can be synchronized to display one images or related images on each of the doors, similar to a JumboTron that displays an image or images on a series of synched screens. In this embodiment, a central control unit that is in electrical communication (wired or wirelessly) with electrical components within each door can be used.

Furthermore, the LCD panel does not have to be the center panel. In other embodiments, the LCD panel can be the inside or outside panel. For example, a transparent LCD screen can be adhered or laminated to the outside panel or the inside panel of a triple pane refrigerator door. In another embodiment, the unit 10 can include more than three panels or panes. For example, the LCD panel 16 can be inserted between the first and second or second and third panels in a triple pane refrigerator door.

In a preferred embodiment, a separate pocket is created in the margin of the door outside the hermetic seal of the insulated glass, that would allow access to the media player and related electronic components 18 for service or upgrade. This can be implemented by using an “offset” insulated glass package/unit (e.g. pane number three is smaller than pane number one) to create the pocket to contain the media player or other electronics to allow service. However, the glass package/unit does not have to be offset. In another embodiment, as shown in FIG. 7, the pocket 38 is created or defined in the hollow area made by the rail 106. As shown, the rail 106 can include a cover 40 that is removably attached to the rail 106 by threaded fasteners or the like. The cover 40 can be removed to allow access to the pocket 38 and the electronic components 18 therein, thus allowing repair, upgrade, replacement, etc. In FIG. 7, the pocket 38, cover 40 and components 18 are shown in the top rail 106 of the door 100. However, the pocket 38, cover 40 and components 18 (such as speaker 29) can be mounted in any rail or portion of the frame. In another embodiment, the electronic components for running the LCD panel can be mounted in the display case or refrigerator.

In another preferred embodiment, the unit 10 includes a switchable film or glass 42 disposed or laminated on at least one of the surfaces of the front or rear panels 12 and/or 14, as shown in FIGS. 6 and 8. In a preferred embodiment, the film is disposed on surface five, which is the front surface of the rear panel 14. The panel with the switchable film 42 can be formed by laminating a liquid crystal switchable film thereon or the film can be directly mounted on the panel with a double sided tape, optical glue or the like. In use, a voltage is selectively applied to the film to make it either clear or opaque as desired. In a preferred embodiment, if a voltage is applied to the film, it goes clear and if no voltage is applied it is opaque or frosted. Therefore, in use, if no voltage is applied, images on the clear LCD panel look like a regular television, which helps accentuate the images on the transparent LCD panel and eliminate the distracting contrast of the product in the display case. Then when a voltage is applied, the film goes clear and the product in the case is easier to see. In another embodiment, the film 42 is disposed on the front or center panels. In another embodiment, the film 42 is disposed on another panel, such as a fourth panel. In another embodiment, the single glass unit includes only two panels, one of which is the LCD panel and the other includes the switchable film 42. This type of unit can be used in non-door applications, such as in department store windows, etc. where the window is desirable to be transparent at times and opaque at other times to better see the media on the LCD panel. As will be appreciated by those skilled in the art, appropriate wiring and the like can be associated with the film 42 to supply the voltage. In a preferred embodiment, switchable film 42 is backlit with the display case lighting.

In an embodiment, the door 100 can include a light guide plate (made of glass, plexiglass or the like) that helps illuminate (preferably via LED lighting) the images on the LCD panel. Other types of lighting for LCD panel are also within the scope of the invention.

In another embodiment of the invention, the glass unit may be a laminated glass unit without any space between the panes, as is shown in U.S. Patent Publication No. 2010/0043293, the entirety of which is incorporated herein by reference. Also, the display case may or may not be refrigerated.

Unless the context clearly requires otherwise, throughout the description and the claims, the words “comprise,” “comprising,” and the like are to be construed in an inclusive sense, as opposed to an exclusive or exhaustive sense; that is to say, in the sense of “including, but not limited to.” As used herein, the terms “connected,” “coupled,” or any variant thereof, means any connection or coupling, either direct or indirect, between two or more elements; the coupling of connection between the elements can be physical, logical, or a combination thereof. Additionally, the words “herein,” “above,” “below,” and words of similar import, when used in this application, shall refer to this application as a whole and not to any particular portions of this application. Where the context permits, words in the above Detailed Description of the Preferred Embodiments using the singular or plural number may also include the plural or singular number respectively. The word “or” in reference to a list of two or more items, covers all of the following interpretations of the word: any of the items in the list, all of the items in the list, and any combination of the items in the list.

Industrial LCD (liquid crystal display) monitors are a common technological fixture for a variety of Marine, military, and even commercial applications. These monitors have internal mechanisms that allow them to display specific images according to the user’s commands. In order for the screen to work, all of the internal components that make up the mechanism must function at full capacity. Liquid crystals are the main components that contribute to the picture quality, sharpness, and brightness, but there are also other crucial elements at play inside each screen.

Every computer screen has an LED backlight that produces white light. The light then travels through many different layers to produce an image on the screen. Flat panel displays feature LED backlights because they reduce overheating, have higher contrast ratios, more extensive brightness settings, and excellent overall colour reproduction.

Although they don’t produce light, liquid crystals are electrically charged molecules that have the ability to block or allow light to pass through. Electrical voltages are used to charge each liquid crystal and maneuver them to form specific patterns that result in the images that appear on computer screens.

In order for a screen to function properly and display crystal clear images without interruption, every single pixel needs to be charged with an electric current. Transparent conductive screen layers made from materials like indium allow the electric currents to pass through with ease.

The light guide plate is a weather-resistant transparent corrugated stiff plastic panel that controls the angle and direction in which light is displayed. As the light enters the back of the panel, the pattern formed by the ridges on the front guides it into different directions to illuminate the pixels and form the images that appear on the screen.

LCD monitors feature two polarized glass sheets that function as filters that make it possible for users to clearly view images on the screen. The liquid crystals are located between the two layers of polarizing sheets. Essentially, polarizers allow vertical light waves to pass through the filter and contact the light bending liquid crystals. Horizontal light waves are blocked or filtered out because they distort the image quality. Since they’re made of a plastic-like material, polarizers are sensitive to extremely humid and hot temperature conditions.

Backplanes are typically used in thin-film transistor (TFT) LCD monitors. Located toward the front of the screen, this glass substrate displays the images that result from the dual polarization process to the end-user.

Modern LCD monitors use a material called indium-tin-oxide, which acts as the main power source for the entire screen and its light-emitting functions. This common electrode sends required voltage levels to activate and manipulate the liquid crystals. Most of the white light produced by the backlight is blocked out and colour filters are used to create crystal clear images on the screen. Colour filters consist of the primary colours red, blue, and green.

Nauticomp Inc.is one of the leading North American distributors of military, marine, commercial, and industrial LCD monitors. With 25 years of experience in the technological space, we’ve mastered the art of designing and crafting top-of-the-line digital displays that are custom-tailored to the needs of our customers. Contact ustoday to learn more.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey