lcd panel layers free sample

![]()

Layers is a free orchestral VST instrument, and an easy way to add orchestral sounds to your compositions and productions. Draw from the finest recordings of strings, woodwinds, and brass. Generate full chords with one-touch simplicity. And seamlessly blend layers of tonal colors and dynamics with your MIDI controller.

3D technology is getting more advanced, but many systems force the viewer into a single perspective quite unlike the way we view actual 3D images. MIT Media Lab is trying to develop a glasses-free screen called a Tensor Display that uses multiple layered LCDs to create an illusion that can be viewed from multiple perspectives. First announced for SIGGRAPH"s Emerging Technologies showcase, the technology has now been explained in much more detail at the MIT news office. Basically, a different portion of each video frame is displayed on one of the three LCDs, and pattern-calculating algorithms cause the screen to flicker as it displays multiple images that appear to change the picture based on perspective.

A web map is a map stored as an item in ArcGIS Online. A web map item contains all of the configuration settings for the map (in JSON format) such as the basemap layer, data layers, layer styles, and pop-up settings. Applications can access and display a web map using its item ID.

Use the Legend and ScaleBar widgets to add more context to the application. The Legend widget displays labels and symbols for layers visible in the view. The ScaleBar can display units in either metric or non-metric values.Create a ScaleBar. Add the scalebar to the bottom-left of the view.

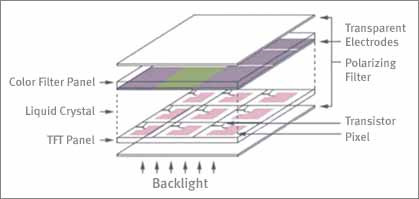

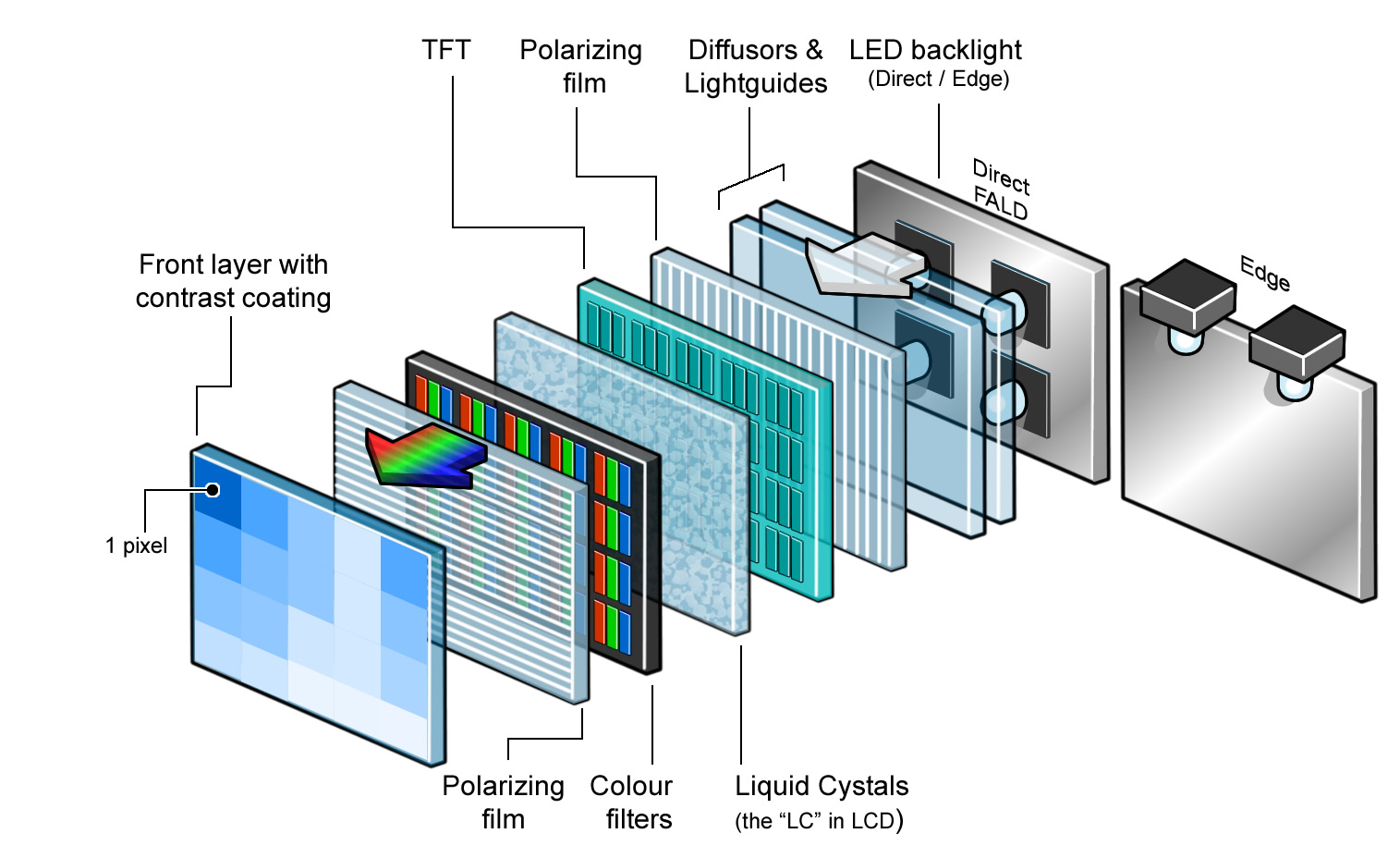

Liquid crystal displays (LCDs) are comprised of tiny elements of color called pixels. Pixels have dimensions of a few microns or less and consist of three subpixels colored red, green, and blue. The popular acronym, RGB, is often used to delineate the color of a specific pixel within 16.7 million different color combinations. These tiny pixels are densely packed into television screens, computer monitors, tablets, and phones that utilize backlighting to illuminate each pixels and create the complex patterns we recognize as graphics and images today.

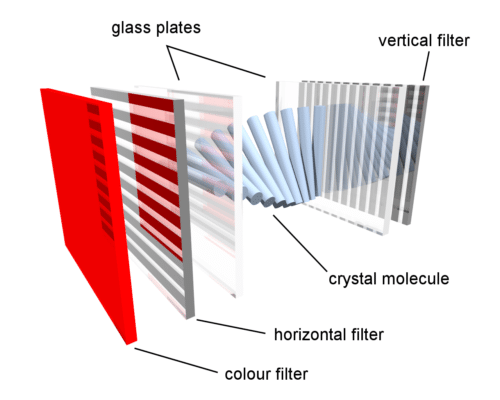

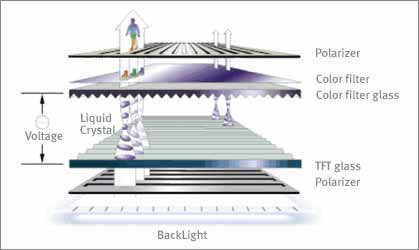

The most important concept in LCD technology is the behavior of liquid crystals. A twisted nematic liquid crystal layer acts to rotate (twist) the plane of polarization to align or misalign with the second polarizer. This means that if the polarizers are 90 degrees apart (see Figure 3, 4), then the twisted crystals will align with the second polarizer and permit light to pass through. Conversely, if the crystal layer did not exist, light would not pass through because the polarizers are oriented in such a way that the second polarizer blocks the light from the first polarizer.

Electrodes in LCDs function as on and off switches. The electrodes tune their voltage from on to off in 256 increments for each RGB subpixel. This is what gives 16.7 million different colors for each pixel (3 pixels, each with 256 shades; 2 raised to the 24th power).

In more primitive LCDs like those in digital watches or calculators, mirrors are used to reflect natural light to produce the digits we see on the displays. For more modern, high-power screens like TVs and laptops, backlights are used to illuminate the pixels. The backlights are often rectangles or strips of flourescent lamps or light emitting diodes (LEDs).

The most elementary concept of a computer screen lies in the manipulation of light. The goal here was to provide a simple overview of the primary components of a liquid crystal display (LCD) and its deceptive mechanics. Often, LCDs are thought of as complex systems not worth understanding, when in reality, an LCD consists most primitively of six parts: two polarizers, two electrodes, a liquid crystal layer, and a backlight or mirror. Once these mechanisms are understood, the complexity of a LCD remains in the deception of the human eye - not in the nature of its physics.

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

This sample shows how to customize the rendering of the drawing shapes in the drawing manager by accessing the rendering layers using the drawingManager.getLayers() function.

Liquid Crystal Display or LCD is a flat, electronic device generally used as a screen in televisions, computers, smartphones and display signs for producing still and movable images.

As the name goes, LCD is composed of liquid crystal particles. Liquid crystals generally do not emit light on their own rather they are illuminated by a fluorescent backlight.

Since liquid crystals do not produce light of their own, they need an external light source to work. An LCD panel has sets of polarised glass consisting of liquid crystal materials in between them. When the external light passes through one of the polarised glasses and electric current is applied on the liquid crystal molecules, they align themselves in such a way that polarised light travels from the first layer to the second polarised glass, causing an image to appear on the screen.

Here the LCD has a backlight, which passes through the LCD polarised glass to produce visible pattern. But because it uses backlight for working, the images displayed in such LCD types appear very dim when used under bright sunlight.

This LCD type has a reflective mirror layer and a backlight. It uses both outside light and backlight, making it suitable for indoor and outdoor conditions.

LCDs or Liquid Crystal Displays are flat, thin and lightweight, making them more usable and user friendly compared to CRTs. It uses liquid crystals and layers of polarised glass to produce images while consuming less power than CRT.

OLEDs or Organic Light Emitting Displays use a single glass with plastic panel and need no external light to work. Every pixel of this display is an LED light and an image is formed by controlling each of these LEDs. It is much thinner and lighter but expensive as compared to an Liquid Crystal Displays.

The PCB is designed and formed as a stack of layers. In the early days of printed circuit board (PCB) manufacturing, the board was simply an insulating core layer, clad with a thin layer of copper on one or both sides. Connections are formed in the copper layer(s) as conductive traces by etching away (removing) unwanted copper.

Fast forward to today, where almost all PCB designs have multiple copper layers. Technological innovation and refinements in the processing technology have led to a number of revolutionary concepts in PCB fabrication, including the ability to design and manufacture flexible PCBs. By joining rigid sections of PCB together via flexible sections, complex, hybrid PCBs can be designed that can be folded to fit into unusually shaped enclosures.

In printed circuit board design, the layer stack defines how the layers are arranged in the vertical direction, or Z plane. Since it is fabricated as a single entity, any type of board, including a rigid-flex board, must be designed as a single entity. To do this, the designer must be able to define multiple PCB layer stacks and assign different layer stacks to different zones of the rigid-flex design.

The Stackuptab details the fabrication layers. Layers are added, removed and configured in this tab. For a rigid-flex design, layers are also enabled and disabled in this tab.

The Delete Layer command is not available when: the Top Layer or Bottom Bayer is chosen, or the chosen layer is a dielectric layer, and removing it would result in two copper layers being next to each other.

Right-click in the layer grid then choose Move layer up / Move layer down or use the Edit » Layer Up / Edit » Layer Downcommand from the main menus to move the selected layer up or down in the Layer Stack, within the layers of the same type.

If the Stack Symmetry option is enabled in the Boardsection of the Properties panel, layers are added in matching pairs, centered around the mid-dielectric layer.

Internal copper layers include a Copper Orientation option which defines the direction that the copper is bonded to the core (and then etched from). Configure this to ensure the impedance calculations are accurate.

Copper layers also include an Orientation option. Configure this when a rigid-flex design has an internal/flex layer with components mounted on it, or when the design uses embedded components, to indicate the direction the component is oriented relative to that copper layer.

The next step is to define which layers the currently selected profile is to be available on. The grid is divided into two zones: the layers in the stackup are displayed on the left, on the right are the layers that the currently selected impedance profile will be available on. Use the layer checkbox in the Impedance Profile region to enable that layer to be available for the selected impedance profile.

When you select an enabled layer in the Impedance Profile region, all layers in the layer stack are faded, except those being used to calculate the impedance for that selected signal layer (show image

The Layer Stack for a new board includes a single, thruhole via span definition in the Via Types tab of the Layer Stack Manager. For a two-layer board, the default via is named Thru 1:2, the naming reflecting the via type, and the First and Last layers that the via spans. The default thruhole span cannot be deleted.

If a µVia is required, enable the µVia checkbox. This option will be only available when the via spans adjacent layers, or adjacent +1 (referred to as a Skip via).

If the Layer Stack has the Stack Symmetry option enabled, the Mirror option will become available. When Mirror is enabled a mirror of the current via, spanning the symmetrical layers in the layer stack, is automatically created.

In a high-speed design, when the barrel of a via extends beyond the signal layers that the signal is routed on, signal reflections can occur. This can lead to signal degradation and signal integrity issues. One approach used to resolve this is to drill out the unused via barrels using controlled depth drilling, which is a technique also referred to as back drilling.

If the Substack Properties has the Stack Symmetry option enabled in the Properties panel, the Mirror option will become available in the Back Drill section of the panel. When this is enabled, a mirror of the current Back Drill is created, for example, BD 1:3 | 6:4.

Using modern printing technology, it is possible to print conductive and non-conductive layers directly onto a substrate material, building up an electronic circuit. This is referred to as printed electronics.

Traditional dielectric layers are not used in printed electronics. Instead, local dielectric patches are printed where routing must cross over. When the Printed Electronicsoption is enabled in the Featuresdrop-down, all dielectric layers are removed from the layer stack and instead, the dielectric patches are defined by placing suitably shaped region objects on non-conductive layers.

Add Substacks. Additional substacks can be quickly created from an existing substack using the Shift+Click shortcut to select the required layers, and then dragging the selection horizontally to position it in the set of substacks.

Configure the relationships between layers in adjacent Substacks - do they share layers (Common), or are the layers unique in that Substack (Individual).

The Layer Stack Manager presents the layer properties in a spreadsheet-like grid. The properties can be edited directly in the grid or they can be edited in the Properties panel. The panel can be used in each of the Layer Stack Manager tabs, for example, giving access to the impedance profile and transmission line properties in the Impedance tab, or the µVia settings in the Via Types tab.

Process – displays the copper plating process that is applied to the base copper that makes up the outer signal layers of the PCB (the Top Layer and Bottom Layer).

Orientation – this defines which way the components point (orient) on that layer. For the top and bottom sides, this is set automatically in a new board. For other signal layers, it is used for:

The Copper Orientation can also be chosen using the drop-down in the Copper Orientation column of the Layer Stack. To enable the column, right-click in the header, choose Select columns then enable the Copper Orientation entry in the Select columns dialog. Also, the Trace Inverted option in the Impedance Profile mode of the panel can be used to configure the copper orientation.

The orientation can be configured using the Copper Orientation drop-down in the Stackup mode of the Properties panel in the Copper Orientation column (if it is currently displayed), or by the Trace Inverted checkbox in the Impedance Profile mode of the Properties panel.

Constructions – for dielectric layers, this displays the constructions of the layer. The numerical reference relates to the structure of the woven glass fabric used in the dielectric layer material; these are standard references used by PCB fabricators.

Stack Symmetry – enable to add layers in matching pairs, centered around the mid-dielectric layer. When enabled, the layer stack is immediately checked for symmetry around the central dielectric layer. If any pair of layers that are equidistant from the central dielectric reference layer are not identical, the Stack is not symmetric dialog opens.

Substack – this information is for the currently selected substack (layers, dielectric, thicknesses, etc.,). As you switch from one substack to another, this information will update accordingly (for the currently selected substack).

Model Type – preferred model for calculating the impact of surface roughness (refer to the articles below for more information on the various models). Applies to all copper layers in the stack (should it be the substack?).

Applied to the exposed outer copper layers. Has two functions: to prevent oxidization of the copper, and provide a good surface for solder adhesion. Different pros and cons for each type of finish, the most popular is ENIG, offering high quality, good solderability and low cost.

If you require the board layer stack to be symmetrical, enable the Stack Symmetry checkbox in the Boardregion of the Properties panel. When this is done, the layer stack is immediately checked for symmetry around the central dielectric layer. If any pair of layers that are equidistant from the central dielectric reference layer are not identical, the Stack is not symmetric dialog opens.

Mirror whole stack down - an additional dielectric layer is inserted after the last copper (Surface Finish) layer, then all of the signal and dielectric layers are replicated and mirrored below this new dielectric layer.

Mirror whole stack up - an additional dielectric layer is inserted before the first copper (Surface Finish) layer, then all of the signal and dielectric layers are replicated and mirrored above this new dielectric layer.

Use the Stack Symmetryoption as a quick way of defining a symmetric board - define half of the layer stack, enable the Stack Symmetry option, then use one of the mirror whole stack options to replicate that set of layers.

Each separate zone or region of a rigid-flex design can be made up of a different number of layers. To achieve that you need to be able to define multiple stacks, referred to as substacks.

Using the Substack Selector, select each Substack in turn and use the checkboxes to enable/disable layers, to give the layer-set required for that Substack.

For flex Substacks, enable the Is Flex option in the Properties panel. Flex-specific coverlay layers can only be added in a Substack that has the Is Flex option enabled and does not include a Soldermask layer.

There must be a unique substack defined for each unique set of layers needed in the rigid and flex regions of the overall board. Board mode is used to configure the different substacks required in an Advanced rigid-flex design.

Additional substacks can be quickly created from an existing substack using the Shift+Click shortcut to select the required layers, and then dragging the selection horizontally to position it in the set of substacks, as shown in the image below.

Configure the relationships between layers in adjacent Substacks - do they share layers (Common), or are the layers unique in that Substack (Individual).

For flex Substacks, enable the Is Flex option in the Properties panel. Flex-specific coverlay layers can only be added in a Substack that has the Is Flex option enabled and does not include a Soldermask layer.

The layers in the layer stack form the space on which you build up the design. There are a number of design tasks that are related to the layers that are not performed in the Layer Stack Manager. These tasks are summarized below, with links to more information.

The panel lists all plane layers. When a layer is selected in the Layers section, the section below will list all of the split plane zones on that layer (there will only be one if the plane is continuous with no splits defined). Double-click on a split plane zone to open the Split Plane dialog, where you can assign a net. You can also double-click on the layer in the workspace (when the plane layer is the active layer) to open the dialog.

The software needs to know which way components are oriented for each layer they are mounted on so that it knows when the component primitives must be mirrored. For the Top and Bottom Layers, this is configured automatically; for other layers, the setting is configured by the designer.

If the Orientation column is not visible, enable it by right-clicking on an existing heading in the layers grid then selecting Select columns from the context menu.

The Layer Stack Table is an intelligent design object, meaning it can be placed and updated as the design progresses. Double-click on the Layer Stack Table to edit it in the Properties panel.

Altium Designer also provides a dedicated documentation editor - Draftsman. Draftsman has been built from the ground up as an environment for creating high-quality documentation that can include dimensions, notes, layers stack tables, and drill tables. Based on a dedicated file format and set of drawing tools, Draftsman provides an interactive approach to bringing together fabrication and assembly drawings with custom templates, annotations, dimensions, callouts, and notes.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey