lcd panel layers pricelist

Our company specializes in developing solutions that arerenowned across the globe and meet expectations of the most demanding customers. Orient Display can boast incredibly fast order processing - usually it takes us only 4-5 weeks to produce LCD panels and we do our best to deliver your custom display modules, touch screens or TFT and IPS LCD displays within 5-8 weeks. Thanks to being in the business for such a noteworthy period of time, experts working at our display store have gained valuable experience in the automotive, appliances, industrial, marine, medical and consumer electronics industries. We’ve been able to create top-notch, specialized factories that allow us to manufacture quality custom display solutions at attractive prices. Our products comply with standards such as ISO 9001, ISO 14001, QC 080000, ISO/TS 16949 and PPM Process Control. All of this makes us the finest display manufacturer in the market.

Now, one more note before I start breaking down options and prices. When I talk about video walls, I’m not referring to buying four TVs from a big box store and hanging them together. TVs are problematic as video walls for a number of reasons. Their bezels are usually larger and have logos, they’re usually not bright enough to serve as commercial displays, and they can’t meet the demand of 24/7 usage. You’ll hear me discuss LCDs and LEDs, but when I do, I’ll be referring to monitors, not TVs. It’s an important distinction.

While blended front projections and rear projection cubes are viable options for video walls, LED and LCDs are the most common display technology used for video walls.

Generally, LEDs are more expensive than LCDs (for models that deliver the same image quality), making the latter the budget-friendly choice. The major tradeoff is the LCD’s bezel lines for the line-free LED array.

For simple video walls, a basic 2×2 high-quality LCD unit can cost as little as $4800, while larger, more elaborate setups with more advanced features (touchscreen capabilities) can go as high as $30,000.

A 1.2mm pixel pitch LED video wall costs approximately $2K sq./ft. This figure translates into $200K for a video wall with 160” x 90” outside dimensions. This includes the mounts, panels and installation costs without taking into account the cost of infrastructure, installation and programming and other ancillary costs (like tax and shipping).

While LEDs are more expensive than LCDs, they lend themselves to more customization in terms of size and shape, with the added benefit of being bezel-less.

It’s best not to scrimp on mounts. You should choose a mount that is sufficiently rigid to prevent sagging and able to provide alignment adjustments in all axes when needed. Most importantly, use mounts that permit front serviceability of individual panels. This prevents the need to remove other panels to service just one failed panel, thus reducing the cost of maintenance and repairs.

Video processors handle video rotation, layering, or windowing of content and other custom effects. Depending on the content to be displayed and how it will be displayed, video processors can easily become the most expensive component of the video wall. The cost depends largely on the number of simultaneous layers displayed on the wall at a given time and the number of physical inputs and outputs required. Processors can range from $15k to $80K, depending on complexity.

Also, custom content needs to be created (or scaled to fit) for video walls that don’t come in standard resolutions like 1080P, 2K,4K, etc. You might want to avoid such non-standard walls since it can be quite expensive to create such custom content. Instead, try to use a video wall layout that maintains standard aspect ratios. For LED walls, this means a 16:10, 16:9, or other cinema aspect ratios while LCD arrays should come in 2×2, 3×3, 4×4, and other standard array sizes.

If one LCD is good, two is better, right? I"m not talking about two layer LCD. No, that"s still not quite right. LCDs have lots of layers. How about Double Stuf LCD? Nailed it.

Double Stuf LCDs have the potential to improve the contrast ratio of a display with minimal additional power draw and without needing additional LEDs, like

The problem, and what has always been LCD"s problem, is this method doesn"t block all the light. There"s no such thing as a "black" LCD pixel. Some light always leaks through, which is why LCDs have always had worse black levels and contrast compared to other technologies, like

In Hisense"s prototypes and the current version of this TV (currently only available in China), the second layer was 1080p on a 4K display. Hisense promises that when this tech reaches US shores, both layers will be 4K. This means that essentially it"s an LCD TV with a 8 million zone backlight, far more than even mini-LED has. With two 4K modules, each pixel gets a far greater ability to block the light from the backlight, greatly improving this longstanding LCD issue and improving the contrast ratio.

Price-wise, Hisense is aiming to be cheaper than OLED, though probably similar-to or more than higher-end LCDs. For reference the HZ65U9E, its 65-inch model for sale in China now, is 17,999 yuan, which converts to about $2,500, £2,000, or AU$3,700.

Manufacturers have a lot of money in LCD, and that"s not changing any time soon. They"re always looking out for the next big thing, which is how we got OLED and how we"ll be getting MicroLED. Before we get to the next gen, there"s still a lot of improvement to be made with the current gen. Mini-LED is one aspect of that, and potentially so is dual-LCD. No doubt we"ll hear more about both at CES in January.

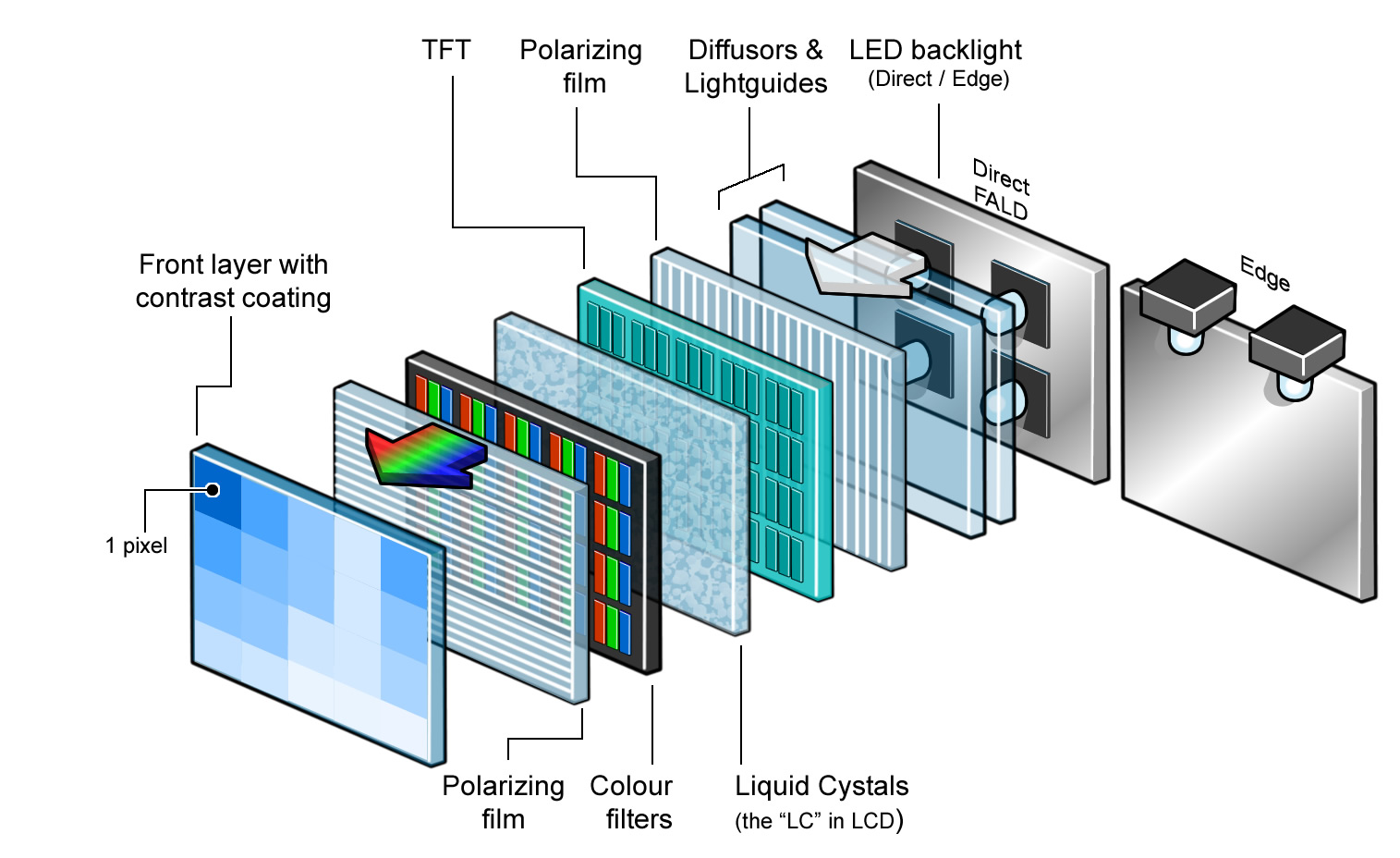

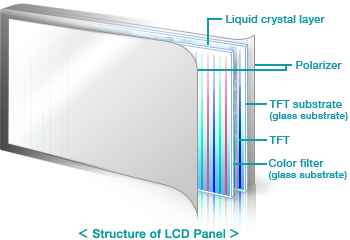

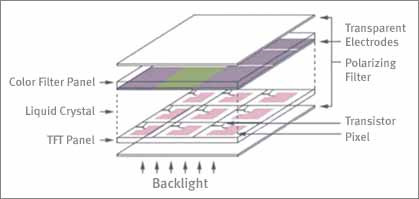

To create an LCD, you take two pieces ofpolarized glass. A special polymer that creates microscopic grooves in the surface is rubbed on the side of the glass that does not have the polarizing film on it. The grooves must be in the same direction as the polarizing film. You then add a coating of nematic liquid crystals to one of the filters. The grooves will cause the first layer of molecules to align with the filter"s orientation. Then add the second piece of glass with the polarizing film at a right angle to the first piece. Each successive layer of TN molecules will gradually twist until the uppermost layer is at a 90-degree angle to the bottom, matching the polarized glass filters.

As light strikes the first filter, it is polarized. The molecules in each layer then guide the light they receive to the next layer. As the light passes through the liquid crystal layers, the molecules also change the light"s plane of vibration to match their own angle. When the light reaches the far side of the liquid crystal substance, it vibrates at the same angle as the final layer of molecules. If the final layer is matched up with the second polarized glass filter, then the light will pass through.

If we apply an electric charge to liquid crystal molecules, they untwist. When they straighten out, they change the angle of the light passing through them so that it no longer matches the angle of the top polarizing filter. Consequently, no light can pass through that area of the LCD, which makes that area darker than the surrounding areas.

Building a simple LCD is easier than you think. Your start with the sandwich of glass and liquid crystals described above and add two transparent electrodes to it. For example, imagine that you want to create the simplest possible LCD with just a single rectangular electrode on it. The layers would look like this:

The LCD needed to do this job is very basic. It has a mirror (A) in back, which makes it reflective. Then, we add a piece of glass (B) with a polarizing film on the bottom side, and a common electrode plane (C) made of indium-tin oxide on top. A common electrode plane covers the entire area of the LCD. Above that is the layer of liquid crystal substance (D). Next comes another piece of glass (E) with an electrode in the shape of the rectangle on the bottom and, on top, another polarizing film (F), at a right angle to the first one.

The electrode is hooked up to a power source like a battery. When there is no current, light entering through the front of the LCD will simply hit the mirror and bounce right back out. But when the battery supplies current to the electrodes, the liquid crystals between the common-plane electrode and the electrode shaped like a rectangle untwist and block the light in that region from passing through. That makes the LCD show the rectangle as a black area.

Photo: Prove to yourself that an LCD display uses polarized light. Simply put on a pair of polarizing sunglasses and rotate your head (or the display). You"ll see the display at its brightest at one angle and at its darkest at exactly 90 degrees to that angle.

Prices for all TV panel sizes fluctuated and are forecast to fluctuate between 2020 and 2022. The period from March 2020 to July 2021 saw the biggest price increases, when a 65" UHD panel cost between 171 and 288 U.S. dollars. In the fourth quarter of 2021, such prices fell and are expected to drop to an even lower amount by March 2022.Read moreLCD TV panel prices worldwide from January 2020 to March 2022, by size(in U.S. dollars)Characteristic32" HD43" FHD49"/50" UHD55" UHD65" UHD------

DSCC. (January 10, 2022). LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars) [Graph]. In Statista. Retrieved December 19, 2022, from https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC. "LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars)." Chart. January 10, 2022. Statista. Accessed December 19, 2022. https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC. (2022). LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars). Statista. Statista Inc.. Accessed: December 19, 2022. https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC. "Lcd Tv Panel Prices Worldwide from January 2020 to March 2022, by Size (in U.S. Dollars)." Statista, Statista Inc., 10 Jan 2022, https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC, LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars) Statista, https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/ (last visited December 19, 2022)

Samsung Display will stop producing LCD panels by the end of the year. The display maker currently runs two LCD production lines in South Korea and two in China, according to Reuters. Samsung tells The Verge that the decision will accelerate the company’s move towards quantum dot displays, while ZDNetreports that its future quantum dot TVs will use OLED rather than LCD panels.

The decision comes as LCD panel prices are said to be falling worldwide. Last year, Nikkei reported that Chinese competitors are ramping up production of LCD screens, even as demand for TVs weakens globally. Samsung Display isn’t the only manufacturer to have closed down LCD production lines. LG Display announced it would be ending LCD production in South Korea by the end of the 2020 as well.

Last October Samsung Display announced a five-year 13.1 trillion won (around $10.7 billion) investment in quantum dot technology for its upcoming TVs, as it shifts production away from LCDs. However, Samsung’s existing quantum dot or QLED TVs still use LCD panels behind their quantum dot layer. Samsung is also working on developing self-emissive quantum-dot diodes, which would remove the need for a separate layer.

Samsung’s investment in OLED TVs has also been reported by The Elec. The company is no stranger to OLED technology for handhelds, but it exited the large OLED panel market half a decade ago, allowing rival LG Display to dominate ever since.

Although Samsung Display says that it will be able to continue supplying its existing LCD orders through the end of the year, there are questions about what Samsung Electronics, the largest TV manufacturer in the world, will use in its LCD TVs going forward. Samsung told The Vergethat it does not expect the shutdown to affect its LCD-based QLED TV lineup. So for the near-term, nothing changes.

One alternative is that Samsung buys its LCD panels from suppliers like TCL-owned CSOT and AUO, which already supply panels for Samsung TVs. Last year The Elec reported that Samsung could close all its South Korean LCD production lines, and make up the difference with panels bought from Chinese manufacturers like CSOT, which Samsung Display has invested in.

OLED displays have higher contrast ratios (1 million : 1 static compared with 1,000 : 1 for LCD screens), deeper blacks and lower power consumption compared with LCD displays. They also have greater color accuracy. However, they are more expensive, and blue OLEDs have a shorter lifetime.

OLED displays offer a much better viewing angle. In contrast, viewing angle is limited with LCD displays. And even inside the supported viewing angle, the quality of the picture on an LCD screen is not consistent; it varies in brightness, contrast, saturation and hue by variations in posture of the viewer.

There are no geographical constraints with OLED screens. LCD screens, on the other hand, lose contrast in high temperature environments, and lose brightness and speed in low temperature environments.

With current technology, OLED displays use more energy than backlit LCDs when displaying light colors. While OLED displays have deeper blacks compared with backlit LCD displays, they have dimmer whites.

LCDs use liquid crystals that twist and untwist in response to an electric charge and are lit by a backlight. When a current runs through them, they untwist to let through a specific amount of light. They are then paired with color filters to create the display.

AMOLED (Active-Matrix Organic Light-Emitting Diode) is a different form of OLED used in some mobile phones, media players and digital cameras. It offers higher refresh rates with OLEDs and consume a lot less power, making them good for portable electronics. However, they are difficult to view in direct sunlight. Products with AMOLED screens include Galaxy Nexus, Galaxy S II, HTC Legend and PlayStation Vita.

Are there still possibilities to improve the contrast of an LCD panel? In addition to the use of local dimming and a solid anti-reflection layer, not much has changed in LCD panels for a long time. That could change with the introduction of Dual Layer LCD technology for televisions. A new term, which we explain in detail in this article.

Dual layer LCD is another way to achieve the same result. If one LCD panel can create a contrast value of 1,000: 1, you can create a theoretical contrast of 1,000: 000: 1 by placing two LCD panels one behind the other. That is an idea that has been around for a long time and has already been used in some medical imaging monitors.

This is how it works. In the structure of the LCD TV, a second LCD panel is slid between the backlight and the original LCD panel. That extra panel determines how much light passes through to the original panel, it only works in grayscale. That is why it is often referred to as a light modulator or dimming panel. You can consider it as a special kind of local dimming. Each pixel of the dimming panel counts as a dimming zone. For example, a dual layer LCD TV can have millions of dimming zones.

Theoretically, you would naturally opt for a 4K dimming panel. You actually have about 8 million dimming zones, one per pixel, and you are at the same level as OLED. But we also see that a Full HD dimming panel is chosen, which provides approximately two million dimming zones (one zone per four pixels). The reasons for this are of a different nature. It will undoubtedly be cheaper to use a 2K dimming panel instead of a 4K version. In addition, there are probably also technical reasons: for example, impact on energy consumption. And the extra benefit of a 4K panel may be too small.

We also notice that Hisense still communicated with one million dimming zones at IFA, which would indicate a dimming panel with only the half of Full HD resolution. At CES Hisense spoke of two million dimming zones.

Dual layer LCD TV should be a cheaper alternative to OLED, just like mini-LED. Currently there are professional grading monitors for the film studio of Sony (BVM-HX310) and Panasonic (Megacon). Towards consumers, only Hisense (HZ65U9E) comes out with this technology.

The contrast values currently being claimed vary widely, varying between 1,000,000: 1 and 150,000: 1. This variation is large but not unexpected, since a small difference in black value has a huge impact on contrast. In any case, those values are considerably better than for a traditional LCD TV that is somewhere between 1,000: 1 and 3,000: 1 (without local dimming).

LCD panel manufacturers have another reason to look at dual layer solutions. So many LCD factories have been set up in China that there is considerable overcapacity. Excess capacity reduces the price, which is good for the consumer, but manufacturers prefer to reduce their output a bit. But an LCD factory can be compared to many other factories: if it is not running at full capacity, there is a risk of financial loss. A solution where you can use that overcapacity to make a better product (in this case with two LCD panels) is of course attractive.

Unfortunately there are a few important hurdles for this technology, and the most important ones seems to us the energy consumption. An LCD panel has a considerable loss because the light has to go through different optical layers. We often see a figure of around 6% light efficiency. If we place two LCD panels behind each other, that problem will of course be much worse. That energy consumption will not be underestimated, we could already more or less estimate at the show of the Panasonic Megacon at IFA last year. Even when we were standing a meter from the screen you could still feel the heat coming from the screen. This is of course no problem for a studio monitor, but for a consumer product it is different.

Hisense claims that their panel has an efficiency of 4%. That may not seem dramatically less, but still, that means that you have to generate 50% more light in the background lighting to achieve the same brightness as a traditional LCD TV. Such a TV therefore uses at least 50% more power. That could be a problem given the strict energy consumption standards that will come in 2021.

The construction of such a panel is also a challenge. After all, the two LCD panels must be perfectly aligned, or there will be a shadow effect. If the pixel grid of the dimming panel is not perfectly hidden behind the grid of the second LCD panel, it casts a shadow on the second LCD panel. This requires clarity, but also creates other visible image errors. If too many faulty panels roll off the belt (in other words, if the “yield” is low), then that is reflected in a higher price. It remains to be seen whether the result is still economically meaningful.

Finally, we all want slim televisions, but two LCD panels are obviously thicker than one panel. The manufacturer can compensate for this by working with an edge-LED backlight, but in combination with a FALD backlight, such a TV would clearly be a bit thicker, although we do not expect the step to be very large.

Of course, the possible breakthrough of this technology also revolves around cost. At the moment, the price of dual layer LCD seems to be somewhere between a classic FALD LCD TV and an OLED TV, according to Trendforce analysts (attention, indicated prices are only for the panel, not for the finished TV). They also estimate the price to be slightly lower than that of a mini LED TV.

Dual Layer LCD technology for televisions offers interesting prospects. By sticking two LCD panels behind each other with LCD technology you can raise the contrast to OLED level and the fact that professional grading monitors use it is a clear indicator that the technology has potential. But the consumer market also imposes other requirements on a TV, in particular on energy consumption, and there remains a doubt as to whether dual layer LCD will not consume too much energy.

The technology might also find its way to monitors and laptop computers. displays. BOE (the Chinese panel manufacturer that makes the panels for Hisense) has already announced that it has also developed a 31.5-inch gaming monitor.

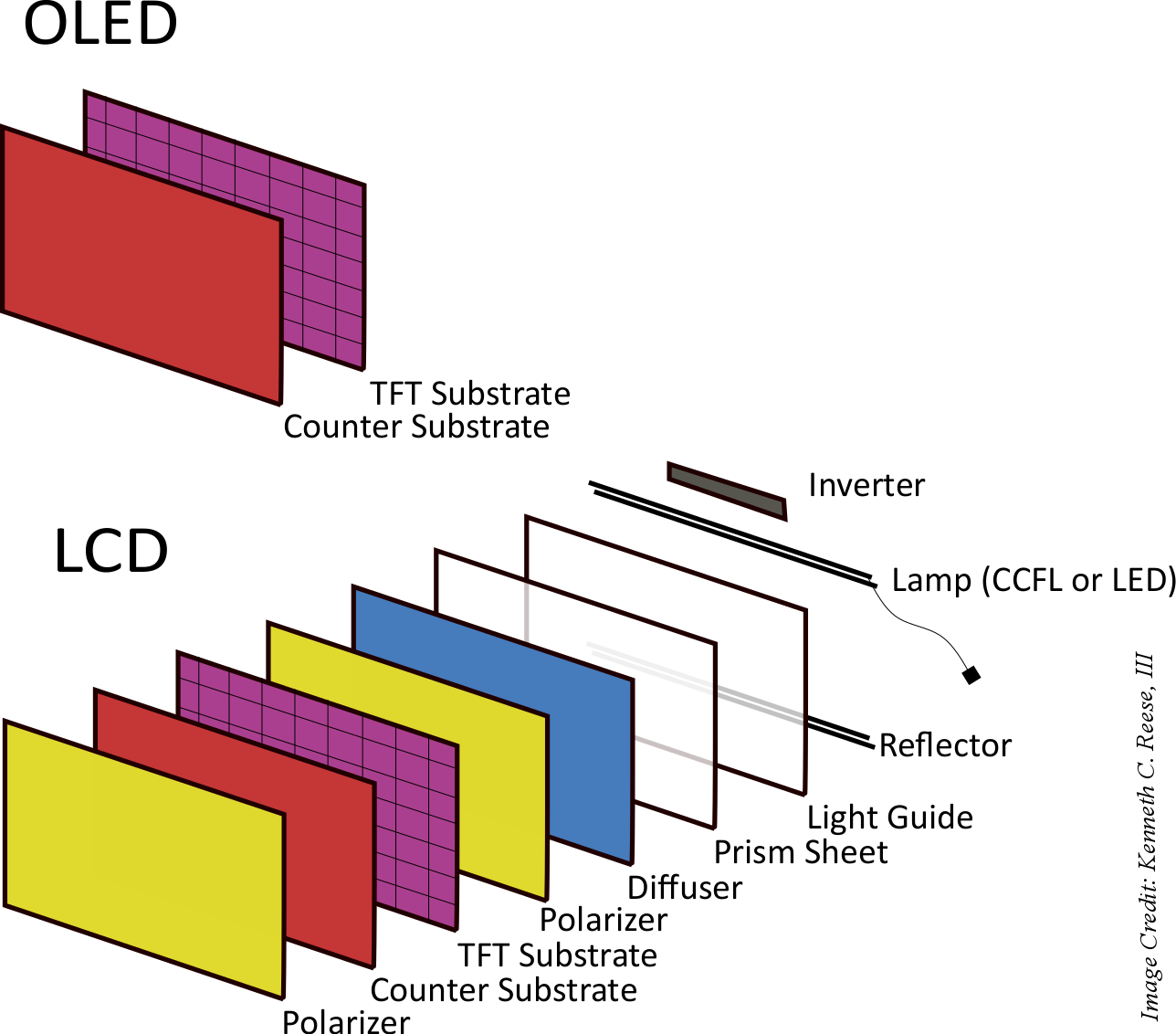

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

It may seem odd in the face of stalled economies and stalled AV projects, but the costs of LCD display products are on the rise, according to a report from Digital Supply Chain Consulting, or DSCC.

Demand for LCD products remains strong , says DSCC, at the same time as shortages are deepening for glass substrates and driver integrated circuits. Announcements by the Korean panel makers that they will maintain production of LCDs and delay their planned shutdown of LCD lines has not prevented prices from continuing to rise.

I assume, but absolutely don’t know for sure, that panel pricing that affects the much larger consumer market must have a similar impact on commercial displays, or what researchers seem to term public information displays.

Panel prices increased more than 20% for selected TV sizes in Q3 2020 compared to Q2, and by 27% in Q4 2020 compared to Q3, we now expect that average LCD TV panel prices in Q1 2021 will increase by another 12%.

The first chart shows our latest TV panel price update, with prices increasing across the board from a low in May 2020 to an expected peak in May/June of this year. Last month’s update predicted a peak in February/March. However, our forecast for the peak has been increased and pushed out after AGC reported a major accident at a glass plant in Korea and amid continuing problems with driver IC shortages.

Prices increased in Q4 for all sizes of TV panels, with massive percentage increases in sizes from 32” to 55” ranging from 28% to 38%. Prices for 65” and 75” increased at a slower rate, by 19% and 8% respectively, as capacity has continued to increase on those sizes with Gen 10.5 expansions.

Prices for every size of TV panel will increase in Q1 at a slower rate, ranging from 5% for 75” to 16% for 43”, and we now expect that prices will continue to increase in Q2, with the increases ranging from 3% to 6% on a Q/Q basis. We now expect that prices will peak in Q2 and will start to decline in Q3, but the situation remains fluid.

All that said, LCD panels are way less costly, way lighter and slimmer, and generally look way better than the ones being used 10 years ago, so prices is a relative problem.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey