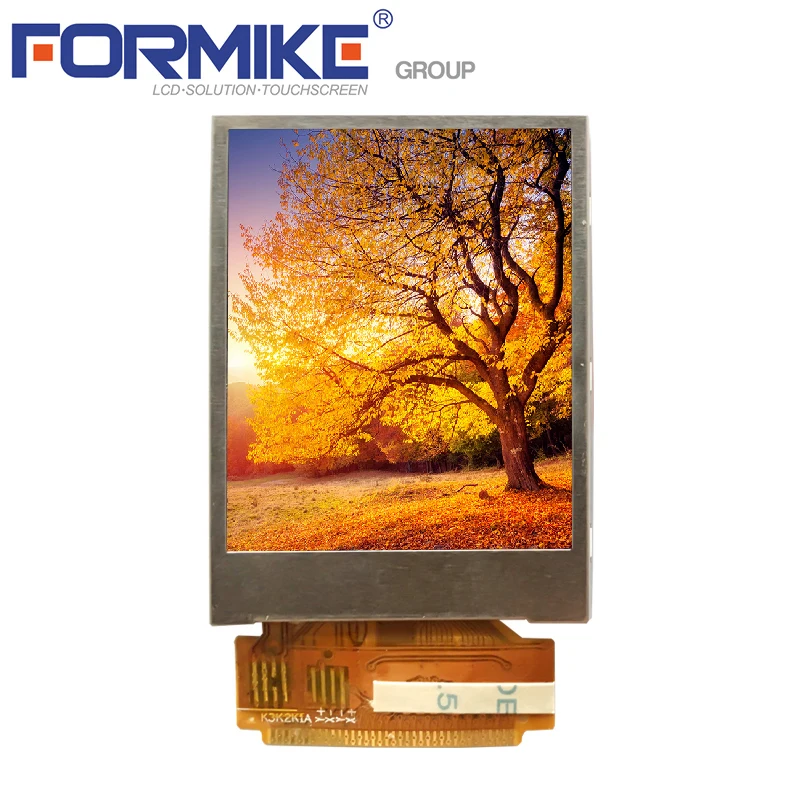

2 tft display factory

Check out the different functions in bulk at wholesale prices on Alibaba.com. Tft LCDs for more functionality and functional features in bulk are some of the manufacturers.

Yes, it is possible to use Tft lcd modules that require suitable components and are applied with the higher quality of the display. In bulk, wholesale Tft LCD displays are available in a variety of colors and designs.

Display screen is everywhere nowadays. Do you still remember the TVs or computer monitors 20 years ago? They were quadrate, huge and heavy. Now let’s look at the flat, thin and light screen in front of you, have you ever wondered why is there such a big difference?

Actually, the monitors 20 year ago were CRT (Cathode Ray Tube) displays, which requires a large space to run the inner component. And now the screen here in your presence is the LCD (Liquid Crystal Display) screen.

As mentioned above, LCD is the abbreviation of Liquid Crystal Display. It’s a new display technology making use of the optical-electrical characteristic of liquid crystal.

Liquid crystal is a state of substance that has both the characteristics of liquid and solid crystal. It don’t emit light itself, but it can let the light pass perfectly in specific direction. Meanwhile, liquid crystal molecule will rotate under the influence of a electric field, and then the light goes through it will rotate too. That said, liquid crystal can be a switch of light, which is the key in display technology.

STN LCD: STN is for Super-twisted Nematic. The liquid crystal in STN LCD rotate more angles than that in TN LCD, and have a different electrical feature, allowing STN LCD to display more information. There are many improved version of STN LCD like DSTN LCD (double layer) and CSTN LCD (color). This LCD is used in many early phones, computers and outdoor devices.

TFT LCD: TFT is for Thin Film Transistor. It’s the latest generation of LCD technology and has been applied in all the displaying scenario including electronic devices, motor cars, industrial machines, etc. When you see the word ‘transistor’, you may realize there’s integrated circuits in TFT LCD. That’s correct and the secret that TFT LCD has the advantage of high resolution and full color display.

In a simple way, we can divide TFT LCD into three parts, from bottom to top they are: light system, circuit system and light and color control system.In manufacturing process, we’ll start from inner light and color control system and then stretch out to whole module.

It’s accustomed to divide TFT LCD manufacturing process into three main part: array, cell and module. The former two steps are about the production of light and color control system, which contains TFT, CF (color filter) and LC (liquid crystal), named a cell. And the last step is the assembly of cell, circuit and light system.

Now let’s turn to the production of TFT and CF. Here is a common method called PR (photoresist) method. The whole process of PR method will be demonstrated in TFT production.

Assume full responsibility to meet all demands of our clients; achieve continuous advancements by promoting the growth of our clients; become the final permanent cooperative partner of clients and maximize the interests of clients for Industrial Tft-Lcd Panel, Wall Mounted Lcd Panel, Touch Screen Panel, Lcd In Computer Graphics,Multi Touch Display. We are willing to give you the lowest price in the market, best quality and very nice sales service.Welcome to do bussines with us,let"s be double win. The product will supply to all over the world, such as Europe, America, Australia,Indonesia, Sierra Leone,Norwegian, Los Angeles.We look forward to hearing from you, whether you are a returning customer or a new one. We hope you will find what you are looking for here, if not, please contact us immediately. We pride ourselves on top notch customer service and response. Thank you for your business and support!

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

Richard Ahrons (2012). "Industrial Research in Microcircuitry at RCA: The Early Years, 1953–1963". 12 (1). IEEE Annals of the History of Computing: 60–73. Cite journal requires |journal= (help)

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

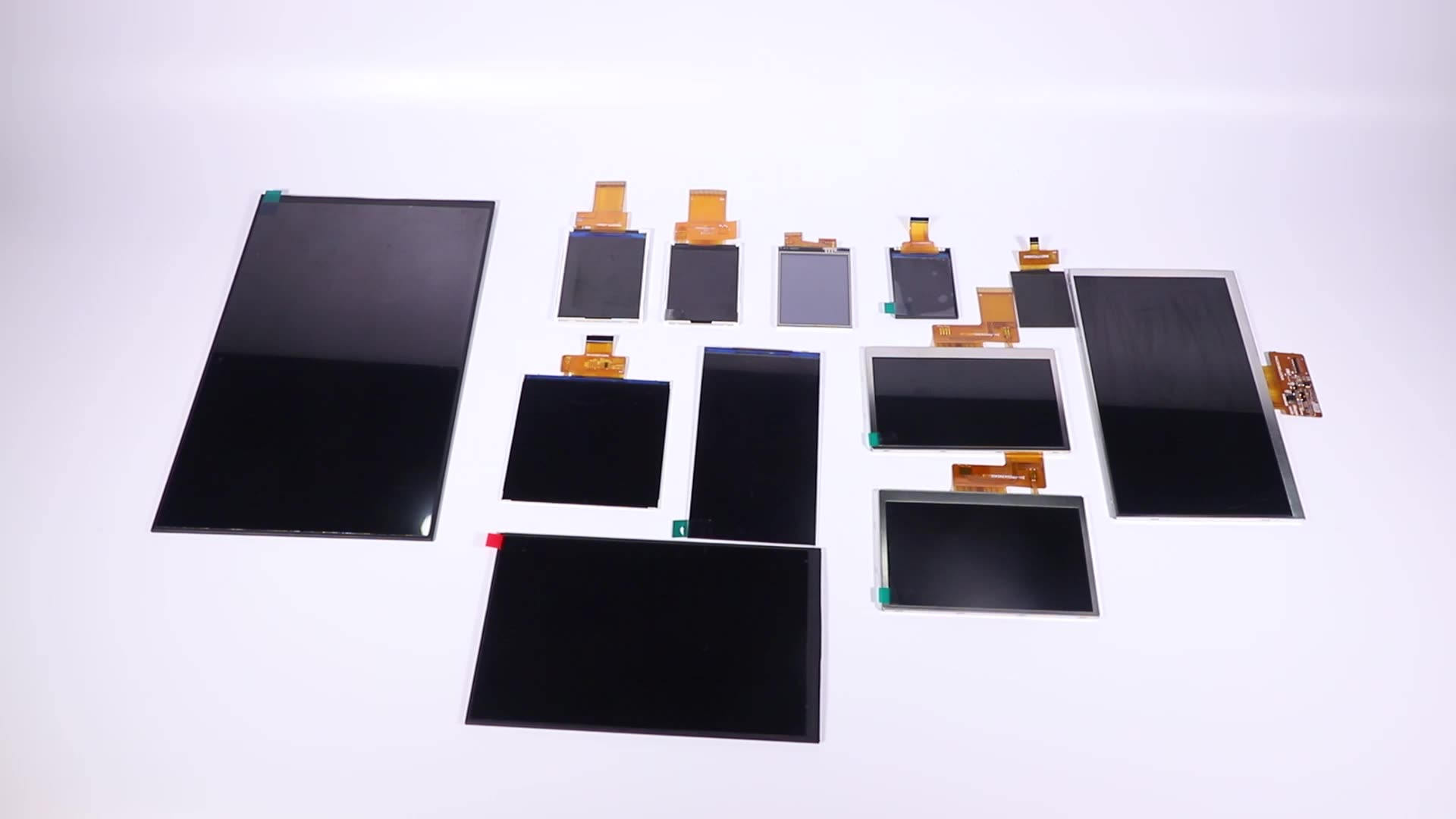

Raystar is a global leading LCD panel supplier and specialized in producing TFT LCD Panel, including Color TFT, Monochrome TFT Display and bar type TFT Display. Raystar Color TFT displays are available in various resolutions and offers a wide product range of small to medium-sized TFT-LCD modules from 0.96” to 12.3". The interface options are in MCU / RGB / SPI / UART / 8080 / LVDS. TFT Panel with control board or TFT LCD Panel with micro controller are also available.

These wide viewing angle Small Format TFT LCDs with optional touch are industrial grade and cost competitive. Therefore these products are a popular display choice to integrate in many projects.

Using only high-tech factories that we partner with, we provide clients with the service of designing liquid crystal display panel (LCD) and liquid crystal display module(LCM), and is committed to the customized service, R&D, sales, after-sales service of display products. Our factories have hundreds of engineers focusing on creating the highest quality displays including monochrome LCD (TN, STN), colour LCD (CSTN and TFT), Custom LCD’s, LCD module (both COG* and COB*) which are widely used in mobile phones and many other applications.

Our state of the art factory produces High Resolution TFT glass panel cells, has TN, HTN, STN and TFT technologies for LCD panels. The Factory has class 1000 clean rooms, high accuracy bonding, pre bonding and heat seal machinery, many production lines specifically for TFT production, OCA and OCF bonding machines, In-House LCD glass cleansing process, output thousands of pieces per month.

Touchscreen overlay cover glass only available (so you do not have to purchase the display)These displays can come with: touchscreen components, touchscreen overlays, industrial touch screen,Wide LCDs, LED TFTs, and TFT Colour displays.

Other options are: LCD drivers, LVDS Touchscreen displays, automotive LCD Display, TFT high resolution screens, TFT LCD capacitive touchscreens, TFT capacitive touchscreens, high brightness LCDs, Letterbox Displays, small VGA Displays, LCD panel without backlights,Variations of our Small Format TFT LCDs include: TFT Display touchscreens, TFT IPS Display, monochrome displays, TFT or LCD, embedded components, LCD components, TFT Drivers, industrial range of Displays,

CDS also offers industrial TFT LCDs,Our displays are used in: touch screen vending machines, automotive touch screen displays, vending machine display panel, Touch screen vending, TFT Automotive, LCD Dislay panel kits, Touch screen TFT monitors, LCD Display components, LCD Screen components, and POS LCD Displays.As you can see from the tables above we have sizes including: 8.8 inches, 4.3 inch LCD Display, 10.1″ TFT LCD, 3.5 inch LCD Display, 4.3 inch display, 3.5 inch TFT LCD Display, 4.3″ screen, 7 inch LCD panel, 3 inch LCD Displays, and 4.3″ TFT LCDs as well as other small LCD Display screens.We have options on and equivalents to the following displays and TFT panel manufacturers: Raystar, Kingtech LCD, Digital View, OLED modules, OLED products, Powertip LCD Displays, Data Vision LCD, LG TFT Display, Tianma NLT, Powertip Displays, Mitsubishi LCD Displays, DMC components, Kyocera LCDs, NLT Technologies Ltd, Sharp LCD TFT modules, LCD manufacturers in the USA, PMOLED Displays, innolux display corp, Industrial touchscreens, A Grade TFT LCD Displays, Panoramic TFT Displays, Samsung TFT Displays, Touchscreen components, Transparent TFT Displays, Touchscreen components, TFT LCD controllers, as well as other TFT LCD manufacturers and Liquid crystal Display manufacturers.

CDS offers the widest range of displays and touchscreens including Abon touchscreens, Ampire LCD distributor, alternative Prisma interface baord supplier including Prisma iiia, Solomon Goldentek, Panasonic TFT, Winmate display, USB IO, and Apollo monitors

Our range includes AMOLED, circular displays, circular monitors, circular screens, circular TFT screens, round displays, Round TFT LCD displays, TFT AMOLEDs, TFT and IPS, TFT display interface microcontroller, TFT LCD or AMOLED, TFT LCD super AMOLED, WXGA TFT Displays, and WXGA TFT screens

As well as large format displays CDS also offers DSI TFT Display, large monochrome LCD displays, mono displays, mono OLEDC displays, mono TFT LCDs, monochrome displays, PCT Touchscreens, projected capacitive touch PCT technology, sq monitors and squid IDS.

CDS added a number of additional controller boards nd accessories which include TFT adaptor boards, TFT boards, TFT display controller boards, USB c LCD controller, USB touch kit, resistive touch screen, TFT accessories com, LCD controller board, LCD controller board USB c, LCD controller board, HDMI to MiPi DSI board, HDMI to MiPi DSI bridge, HDMI to MiPi LCD controller board, EDP adaptor bard, elite C microcontroller, Displaylink DL 3000 .

Whether it be bar type LCDs or any of CDS display solutions or many TFT displays we can help with comparing mipi dsi vs lvds interfces or mipi to edp wch can include use on pos shelf displays and rgb epaper for example.

For many years, TFT displays have been the dominating technology in visualization. TFT LCDs are all around in our daily lives — in consumer and automotive applications, in our business environments, in healthcare, and within communication devices, home appliances, and factory automation products. While there are many LCD products available today, they’re not all suitable for every application. This is especially the case for industrial LCD monitors. To determine the best LCD display for your application, it’s important to understand your target market and its unique design issues.

The vast majority of LCD displays are designed for consumer devices such as smartphones, cameras, tablet computers, and gaming devices. But they have very different requirements than those for industrial applications. Due to very competitive pricing and quick production cycles, consumer display modules don’t always incorporate the durability, reliability, and advanced features required to survive in an industrial environment. Product life cycles are also typically much shorter in consumer applications. Screens manufactured for these applications are generally only available for one, in best case two years.

In contrast, display modules for industrial applications require Long product life cycles— often up to ten years or more. Plus, when an industrial module is discontinued by the manufacturer, a successor product should be backward-compatible so as to fit into the existing enclosure without requiring a redesign of the entire system.

The ability to withstand temperature variations as well as shock and vibration is also a key consideration when selecting displays for today’s industrial applications. They must be resilient enough to withstand frequent bumps or jiggles by machine operators and surrounding equipment, and also must be able to handle various operating temperatures.

Industrial displays are typically housed in an enclosure as part of a larger piece of equipment. In these situations, the heat generated by the surrounding equipment gets trapped within the enclosure, which can be detrimental to many displays. Therefore, it’s important to keep the real storage and operating temperature requirements in mind when choosing a display. While measures can be taken to dissipate the generated heat — such as using fans within the enclosure — the most efficient way to ensure compliance with the storage and operating temperature requirements is to select a display that is optimized for these types of environments. Fortunately, improvements in liquid-crystal materials have made it possible to extend the operating temperature ranges of LCDs from –30 to 80°C presently.

It’s important that displays used in industrial applications support clear and precise viewing from multiple angles under a variety of ambient light conditions. The brighter the environment, the more difficult it can be to read a standard transmissive LCD display with a typical brightness of 250 to 300 cd/m2. NVD has developed displays that can perform in the 800-cd/m2-and-higher range by implementing high-efficiency LEDs for the backlight unit– if necessary, in combination with special brightness enhancement films.

Increasing the display’s contrast ratio is another effective way that display manufacturers can improve display readability in bright environments. Typical contrast ratios for non-industrial displays are in the range of 200:1 to 300:1, which may not be sufficient when a machine operator is viewing the display from a distance. Displays with contrast ratios around 500:1 or greater are better suited for industrial environments. Another benefit of this method is that it doesn’t increase power consumption.

Multi-angle readability is another key selection factor. In a typical industrial environment, a machine operator is more likely to be positioned at an off-angle rather than right in front of the screen. Implementing a display designed for consumer applications typically doesn’t work well in this situation, as there is image distortion and color shifting when viewed at an angle. But, a number of technologies have been employed to improve off-angle viewing in displays, making them suitable for industrial applications. Some film-based technologies yield viewing angles of 160º horizontally and 140º vertically, but in some cases, this is still not sufficient. In-plane switching technology (IPS), multi-domain vertical alignment (MVA), and fringe field switching (FFS)offer alternatives. These proprietary technologies are able to achieve viewing angles of almost 90-degrees into all four directions without any color shift.

Size and resolution also play a role in overall readability. Displays between 2 and 15-inch diagonal sizes are used most often in industrial applications. These sizes provide sufficient area to view figures, waveforms, and other graphical data without taking up too much real estate on a piece of equipment.

From an aspect ratio 4:3 initially, industrial displays are now shifting to wide formats with WVGA to WXGA resolutions. The wide-aspect format enables users to view longer waveforms and more data on a single display. These display modules can also be designed to incorporate touch-key functions, allowing equipment manufacturers to skip physical switches and buttons and design HMIs based more on software than hardware.

New Vision Display’s experts are prepared to assist in defining appropriate solutions for all applications and in helping find the right balance between manufacturing cost and performance.

Ready to get started or learn more about how we can help your business? Call us at +1-855-848-1332 or fill out the form below and a company representative will be in touch within 1 business day.

... and dusty conditions. Plus, the protective glass serves to protect the display against sharp foreign objects, meaning the screen is still operable even with deep scratches on the surface.

VMD 3002 is a robust 10.4-inch TFT LCD monitor with enhanced brightness, projected capacitive touchscreen, and high performance loud speaker. It is designed with a single cable to consolidate ...

VMD 1001 is a 7-inch TFT LCD monitor with 4 wire resistant touch screen sensor. With the high brightness display and automatically brightness control, it is designed ...

VMD 2002 is an 8-inch TFT LCD monitor with 4 wire resistant touch screen sensor. With the high brightness display and automatically brightness control, it is designed ...

TOPWAY Color TFT Modules are designed to provide robust and easy to install display products for industrial applications. For many years in business, the broad design experience and the full range of iconic products made ...

Model Name:AMG-19OPDX01T7Screen Size:19"Active Display Area (mm):376.32(H)x301.06(V)Pixel Pitch (mm):0.294(H)x0.294(V)Display Mode:Normally whiteDisplay Resolution (pixel):1280x1024Contrast Ratio:1000:1Touch screen(optional):PCAP ...

... information systems(HIS) or electronic health record(EHR). It ranges from all-in-one computer, mobile tablets, diagnostic monitors, electronic paper display, and telemedicine. All our medical grade products are certified ...

The HANNspree HP248WJB is a 23.8-inch Full HD monitor featuring an integrated 5Mpixel webcam, microphone array and stereo speakers for video conferencing and live-streaming. The TFT panel delivers ultra-wide ...

... daisy chainable HS272PDB monitor has both a DisplayPort input and a DisplayPort output. The DisplayPort output connects to the next downstream display. This cabling arrangement, with one DisplayPort cable between each ...

... 17" touch monitor features 1280x 1024 resolutions which help you to have the photo images more clear. Furthermore the 4:3 ratio TFT is easy to work with your current applications.

Hengstar embedded open display products adopt industrial process, with standard DC 12V power input, 9 ~ 36V optional, working temperature support - 30 ~ ...

... . This compact display is less than 8” wide and weighs only 1 kg, and the same model is available in screen sizes up to 21.5". This touchscreen monitor can be connected to any computer including a rugged ...

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

Kingtech is one of the leading TFT LCD display OEM/ODM manufacturers in China since 2003. Customization is allowed for projects such as industrial devices, medical, POS, logistics devices, smart home applications and etc.

To provide a one-stop LCD display solution. During the last 17 years, based on LCD manufacturing as our center, we gradually expand to the TFT capacitive touchscreen, driving board, software hardware design, and complete industrial computer solution.

As a professional LCD screen supplier/ LCD display supplier/ LCD panel company/ LCD module manufacturer, Kingtech LCD aims to provide a one-stop service and solve your problems. With a strong LCD Display module R & D team and strict quality management of IS09001, IS01400ATF16949 certificates.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey