low power lcd display module free sample

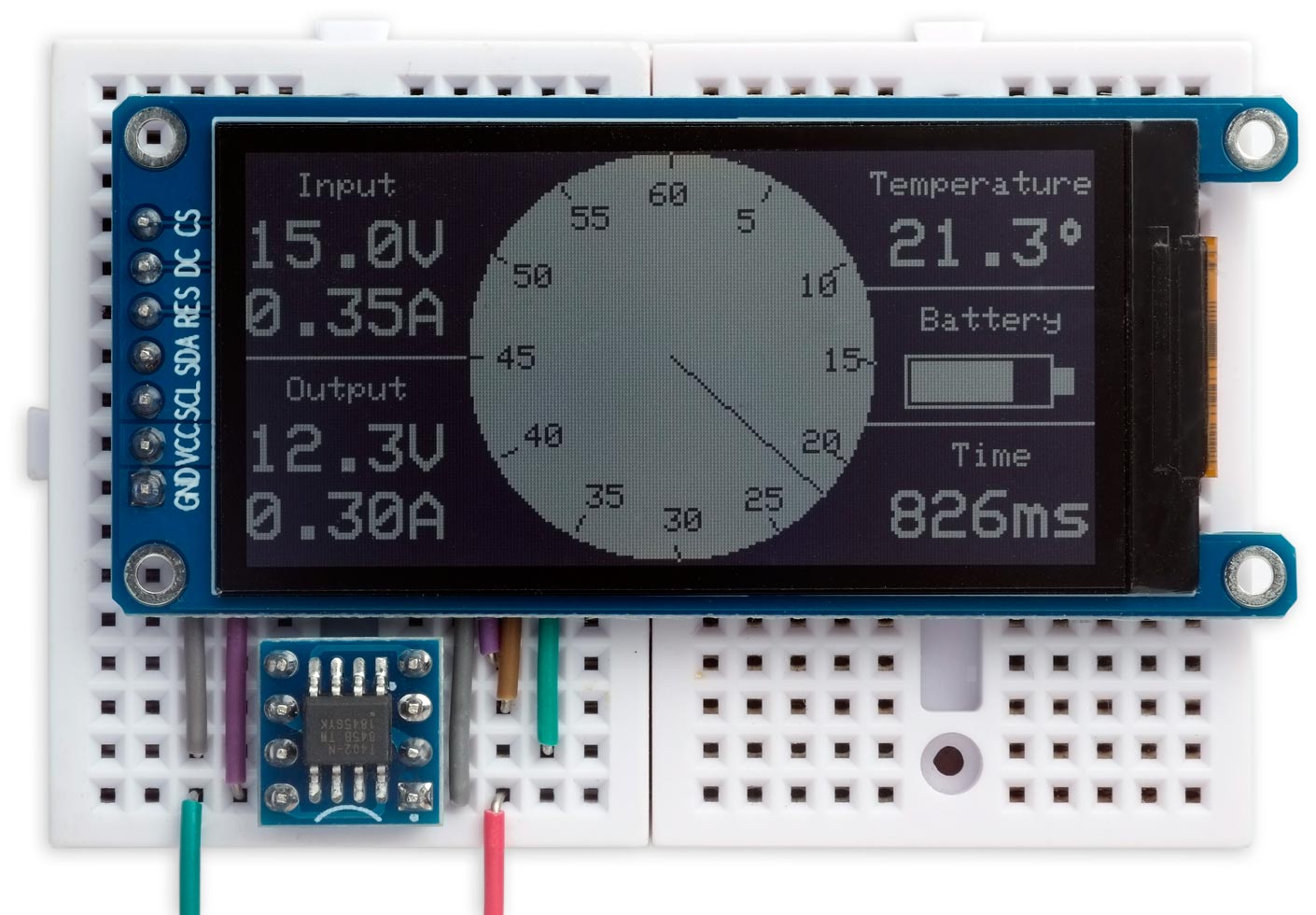

This graphic LCD module acts as a shield for Arduino Uno-style microcontrollers. The pins on the carrier board match up to the Arduino Uno"s ports, so the module simply presses on and is fully and correctly connected. Plus, this carrier board is able to be connected to either a 3.3v logic level or a 5v logic level device. (Read our blog post if you have questions about logic level.)

This module is also available with a white-on-blue graphic display, or as a fully built kit with an included Seeeduino (Arduino Uno clone) loaded with code to demonstrate the graphic display.

Do you need a display that draws the lowest current possible? Want long lasting battery-powered LCD project? Well, you have come to the right place. We compiled this list of digital displays that consume the least amount of power. These displays are perfect for when you are trying to extend the battery life of your product by pulling the least amount of current possible.

Other than a pen and paper, ePaper provides the lowest power consumption available for electronic displays. It does this via an electrochemical process that requires zero power once the pixels are in their desired location. These displays are ideal for when the content is not updated very often. Low-power ePapers only use power during updates, so the longer time between updates, the lower the power consumed.

The beauty of OLED displays and power consumption is that OLEDs only draw current for pixels that are on. For instance, when displaying a black and white checkerboard pattern, an OLED display consumes 50% less current than when displaying a completely white screen. Keeping that in mind, user interfaces can be designed to conserve as much power as possible by limiting how many pixels are lit.

Many projects benefit from a small display as a user interface. For very low power applications this is usually a no-go as the display needs too much energy. I have used e-paper displays from Kent: while these e-paper displays do not need any power to keep the image, changing the display content is not for free, plus is very slow (around 1 second needed to update the display). So I was looking for something low power and fast for a long time, until Christian (thanks!) pointed me to a display from Sharp: both very low power and fast:

And even better: Adafruit has a breakout board for that display available (https://www.adafruit.com/product/1393) :-). The display on the board is the Sharp LS013B4DN04 with 96×96 monochrome pixel resolution. The display is a cross between a e-paper and normal LCD. The ‘background’ color is a nice silver color. What looks cool with this display is that the pixels show up like little mirror:

The display has no backlight: readability is excellent (although somewhat view angle dependent) under daylight, under darker light conditions an extra illumination is needed. It has a very good contrast between the pixels:

The Adafruit breakout board comes with a level shifter so it can be used with 3.3V-5V. I’m using it with 3.3V, and only need 5 wires connected to the display:

One special thing with the Sharp Memory display is that it needs a special clock signal to generate the VCOM, an alternating signal that prevents a DC bias from being built up within the display panel. Depending on the display used, that signal or clock needs to supplied in the range of 0.5 to 60 Hz. That signal can be supplied either externally or by software, depending on the EXTMODE pin:

On the Adafruit breakout board, EXTMODE is pulled LOW: the clocking has to be provided by software. With software a special ‘VCOM’ command is sent to the display:

The ToggleVCOM() function only needs to be called if there are no other display commands sent, as the VCOM bit can be toggled while writing to the display.

Each line of the display can be updated with a command: sending line number, then the number of bytes (12 for the 96 bits) followed by a trailing 16 zero byte:

Of course I have created a new Processor Expert component for using that display. With it is only a matter of minutes to get the display up and running:

Making full updates of the display every 20 ms (50 images per second) requires 41 μA. Of course the less frequent image updates or the less lines update, the better.

That Sharp Memory Display is a really cool one. The Adafruit breakout board has its price ($39.95). It took me a while to get the protocol right, but now I have very low power display and driver in my inventory :-). There is an example project on GitHub, and the SharpMemDisplaycomponent is available on GitHub and will be part of the next McuOnEclipse component release. If you are interested in the sources only, they are available on the McuOnEclipseLibrary project.

An example of this is cell phones; we tend to like electronic products with lots of bells and whistles. This includes apps that allow you to turn on the heater at your house or alert you when someone has stolen your ID. I wonder if there is an app to run schematic capture and spice for circuit designs?

As great as it is to carry around a portable big screen TV that allows me to watch movies, check Facebook and use a GPS to find my way home. I have come to find that these new phones with supersized, high resolution color LCD displays suck power (OK, suck power is not an engineering term; maybe I should say ‘ they exhibit excessive power drain characteristics’).

Power (I2R power, not political power) is a wonderful thing, if you have unlimited amounts of it, but a majority of the new designs we receive at Focus Displays incorporating a custom LCD display module do not come with long extension cords (aka: a power umbilical cord), but are applications that need to be battery or solar powered custom LCD friendly.

At Focus Displays, many of the engineers we interface with on the designing of their custom LCD solution are limited by battery life. They all have a common goal of creating a low power LCD display module that draws as little power as possible.

Bi-stable, also called Cholesteric and e-paper, is a newer custom LCD display technology that can be found in the Amazon® Kindle. It only draws power for the display to change the image.

Downsides to this type of display are higher cost and lack of color options. The tooling cost to build a custom zero-power LCD Display can start around $7,000. Also, at this time the only options are monochrome.

At this time they are limited in size and if you need a special size or shape, the cost to build a custom OLED display solution is well . . . very, very expensive.

The lowest cost, low power option would be a custom segment display. The tooling cost hovers around the $1,000 range and this include design, support and samples. The display will operate at 3.3V and only requires an estimated 2 uA per CM2

I purchased this hat for a Pi Zero project idea I had. I"m a linux beginner, so I asked one of my advanced linux friends to help me figure out how to install the various software packages for this. We both found it impossible because of the bad English, sloppy instructions, and typos in the manuals. This isn"t like installing their 3.5" display. You have to jump through quite a few hoops to get all of your packages installed, to manually edit conf files, and test as you go.

1. Install the juj\fbcp-ili9341 driver built specifically for LCD hats like this. This mirrors all or part of your HDMI output to the LCD so that you don"t have to use proprietary libraries. The driver supports scaling your entire display down to 240x240 (typically 240x135 if you"re scaling down from 1080p) or you can get pixel perfect displays by setting the crop flag. Whatever is in the center 240x240 of your HDMI display is what gets mirrored to the hat"s 240x240 screen. For example, I use a browser in kiosk mode to display a screen-centered 240x240 div. Works great!

An import function allows additionally to use Windows fonts. With the FontEditor it is easy to generate for example Cyrillic, Greek and Arabic fonts. The preview function shows immediately the size and style in simulation window. When the testboard EA 9780-2USB is connected to the USB port, you can see the character (or any predefined text) live on the display which is plugged-in!

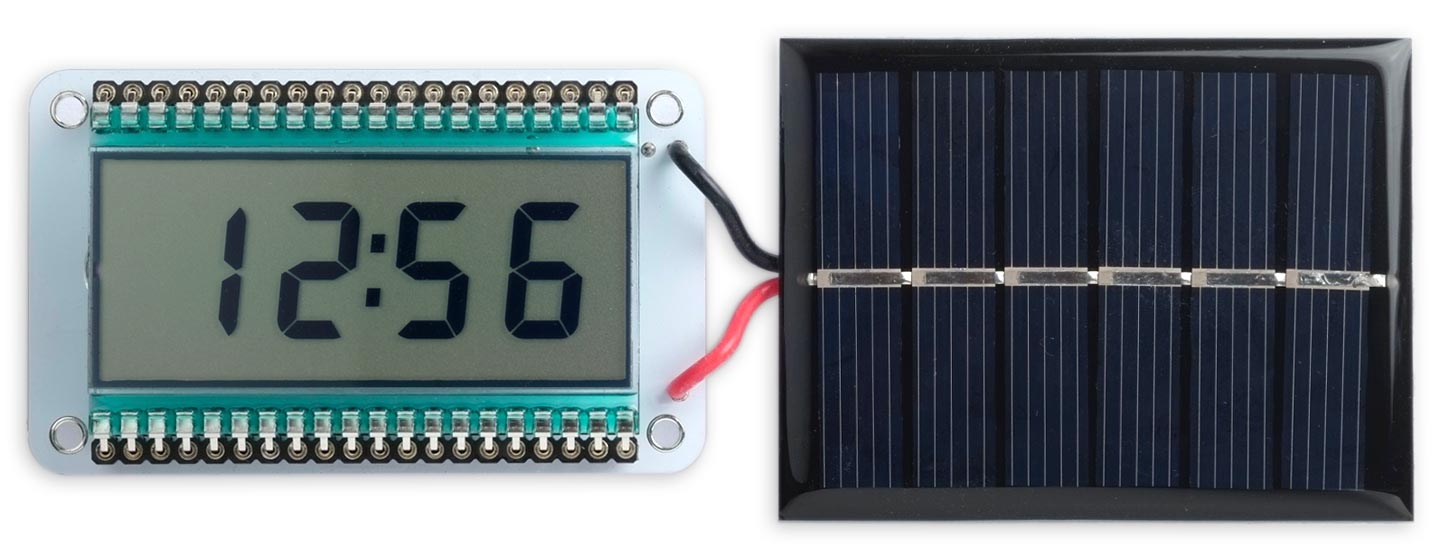

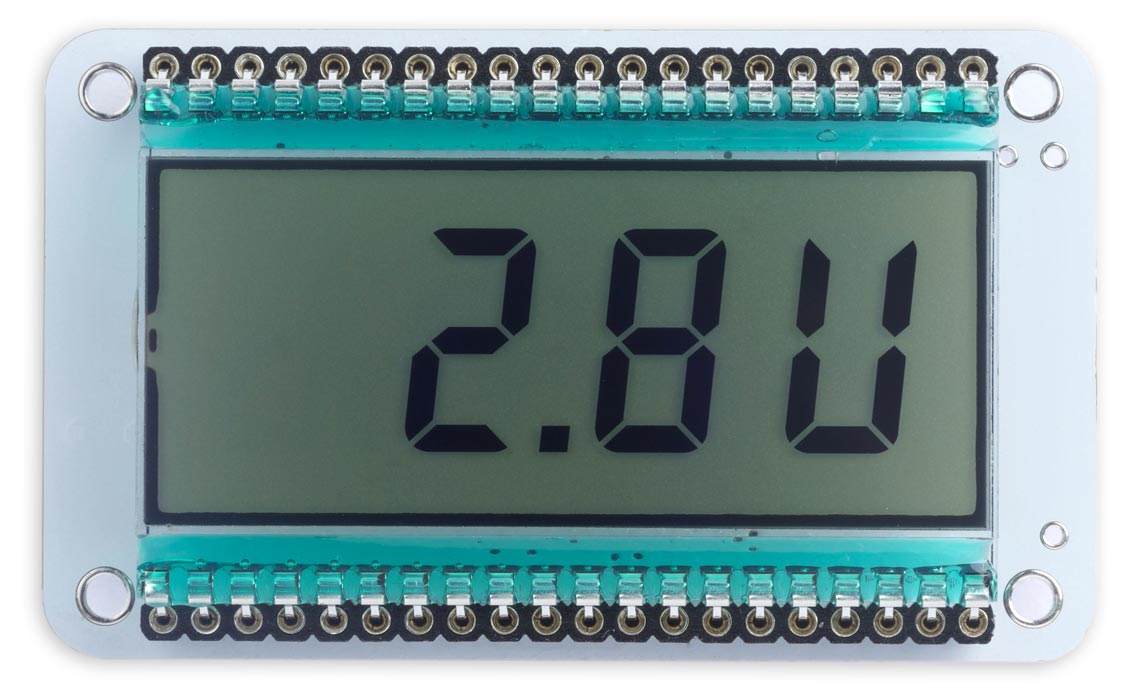

This is a very low-power LCD clock, based on an AVR128DA48, capable of running for over three years from a CR2032 button cell, or for ever from a solar cell:

Every minute it also briefly displays the temperature, using the AVR128DA48"s on-chip temperature sensor, and the battery voltage, by using the ADC to read its own supply voltage. There"s also an I2C connection so you can add an external sensor, for example to show the humidity in addition to the other readings.

Although liquid crystal displays (LCDs) are relatively old technology, they still offer several advantages over newer types of display, including low power, low cost, and readability.

I recently bought some Densitron LCD displays on eBay for a few pounds/dollars, and I"d been wanting to try building a low-power clock around them, to see just how low I could get the power consumption. The displays are a standard type, available with compatible pinouts from several manufacturers. They are called static (as opposed to multiplexed), which means that every segment comes to a separate pin on the edge connector. This makes 28 pins for the segments plus three decimal points, a colon, and a common pin, adding up to 33 pins altogether. The displays I"ve found usually have two common pins, and also typically have other special-purpose segments, such as a minus sign, in a 40-pin package.

The displays are usually clear, but when you apply a voltage of about 3.3V between a segment and the common line the segment turns black. The displays I"m using have a reflective backing; they are also available with a translucent backing so you can add a backlight behind them.

There"s one catch; you can"t use a DC voltage to turn on the segments, because this would cause electrolysis to occur which would slowly degrade the display. The solution is to use AC by switching the polarity across the segment at a low frequency; 32Hz is usually recommended. Fortunately this is easy to do in software

Most 40-pin, 33mm row spacing displays should be compatible with this board; here are some I"ve found. These all have 4 digits and 3 decimal points on pins 5 to 27, 29 to 32, and 34 to 37, and commons on 1 and 40, plus a few extra symbols as shown:

The circuit is less complicated than it looks. Each segment simply connects to one I/O line on the processor. All the segments for one digit go to the same port, with the decimal point going to bit 7, segment A going to bit 6, through to segment G going to bit 0 (with a couple of exceptions explained below).

Because of the number of interconnections I didn"t fancy prototyping this project by hand, but went straight to designing a PCB in Eagle, and I sent it to PCBWay for manufacture. I tried to make the PCB as general purpose as possible. It caters for any of the displays in the above table; to select which of the extra symbols you want to display you need to fit an 0Ω resistor to the board to act as a link.

The processor is an AVR128DA48 in a TQFP-48 package, but the PCB would work with a range of other 48-pin processors. The AVR128DB48 would be suitable, as would the lower memory versions of these two devices, down to the AVR32DA48 and AVR32DB48. However, you only save a few pence/cents by choosing the lower memory versions, so I don"t really see the point.

The ATmega4809 and its lower-memory siblings, down to the ATmega809, are pin compatible with the DA and DB chips in the same packages, and so could also be used on this board; the only restriction is that the pins I"ve used for I2C, PF2 and PF3, only support slave I2C on the ATmega4809.

Alternatively, if you want to power the clock from a 3V solar cell there are holes to allow you to fit a supercapacitor in place of the coin cell; I used a PowerStor 0.47F 5V one

The PCB also includes a 4-pin JST PH socket, providing an I2C interface compatible with Adafruit"s STEMMA system or the Grove system. You can use this to connect a sensor to the board, for example to show the humidity as well as the time and temperature, or you could use it to make the board an I2C slave so it can be used as an I2C display for other projects.

There"s no multiplexing, so to display a segment pattern we just need to write the appropriate value from the segment array, Char[0] to Char[11], to the port corresponding to the digit. Ports D, C, and A provide eight I/O lines each, so these map in a logical way to the seven segments and decimal point in digits 0 to 2. There"s a slight complexity with digit 3 because Port B only has six I/O lines available, so the segment corresponding to bit 6 is provided by PF5. The colon or other symbol is controlled by PF4.

The interrupt service routine first toggles all the I/O lines connected to the LCD segments, and the common connections. Every 32 calls, or every half second, it calculates the current time, and checks whether the buttons are pressed. If the MINS or HRS buttons are pressed it advances the time by a minute or an hour respectively. It then calls the routine DisplayTime() to update the time, or at the end of each minute it calls DisplayVoltage() to display the battery voltage for three seconds, followed by DisplayTemp() to display the temperature for three seconds:

DisplayTime() copies the digits representing the current time to the corresponding output ports, specified by Digit[0] to Digit[3]. It also flashes the colon:

Unlike earlier AVR microcontrollers, where you had to calibrate the temperature sensor, the AVR DA and DB series have been calibrated during manufacture and contain calibration parameters in ROM. The temperature display is therefore pretty accurate without any additional calibration.

The processor spends most of its time in power-down sleep mode, to save power, and is woken up by the 64Hz interrupt from the Real-Time Clock peripheral. I measured the average power consumption at 3.3V for four different clock frequencies:

Usually you"d expect the power consumption to increase with processor clock frequency, so at first sight these figures are puzzling. The explanation is that at higher clock frequencies the time taken to execute the interrupt service routine is shorter, allowing the processor to spend a higher proportion of the time asleep.

The 32.768kHz external crystal oscillator has a low-power mode, and selecting this reduced the average power consumption with a 24MHz clock from 9.5µA to 7.3µA. The AVR128DA48 datasheet doesn"t seem to mention any downside to choosing the low-power mode, so I used this setting.

With a 0.47F supercapacitor you can expect a current of 0.47A for 1 second. This gives an expected life of 0.47/7.3x10‑6/60/60 or about 18 hours, which I confirmed by testing it. This should be sufficient to keep the clock running overnight with a suitable solar cell providing power during daylight.

The HRS button doesn"t affect the seconds and minutes timing; this is designed to allow you to switch between Standard Time and Daylight Saving Time without affecting the clock setting.

Compile the programs using Spence Konde"s Dx Core on GitHub. Choose the AVR DA-series (no bootloader) option under the DxCore heading on the Board menu. Check that the subsequent options are set as follows (ignore any other options):

TFT (Thin Film Transistor) LCD (Liquid Crystal Display) dominates the world flat panel display market now. Thanks for its low cost, sharp colors, acceptable view angles, low power consumption, manufacturing friendly design, slim physical structure etc., it has driven CRT(Cathode-Ray Tube) VFD ( Vacuum Fluorescent Display) out of market, squeezed LED (Light Emitting Diode) displays only to large size display area. TFT LCD displays find wide applications in TV, computer monitors, medical, appliance, automotive, kiosk, POS terminals, low end mobile phones, marine, aerospace, industrial meters, smart homes, handheld devices, video game systems, projectors, consumer electronic products, advertisement etc. For more information about TFT displays, please visit our knowledge base.

There a lot of considerations for how to choose a most suitable TFT LCD display module for your application. Please find the check list below to see if you can find a right fit.

It is the start point for every project. There aretwo dimensions to consider: outside dimension (width, height, thickness) and AA (active area or pixel area). Orient Display’s standard product line ranges from 1.0” to 32”. Our OLED size can go down to 0.66” which fit for wearable devices.

Resolution will decide the clearance. Nobody likes to see a display showing pixel clearly. That is the reason for better resolution, going from QVGA, VGA to HD, FHD, 4K, 8K. But higher resolution means higher cost, power consumption, memory size, data transfer speed etc. Orient Display offers low resolution of 128×128 to HD, FHD, we are working on providing 4K for our customers. For full list of resolution available, please see Introduction: LCD Resolution

TFT screen brightness selection is very important. You don’t want to be frustrated by LCD image washout under bright light or you drain the battery too fast by selecting a super brightness LCD but will be used indoor only. There are general guidance listed in the table below.

Orient Display offers standard brightness, medium brightness , high brightness, and high end sunlight readable IPS TFT LCD display products for our customers to choose from.

If the budget is tight, TN type TFT LCD can be chosen but there is viewing angle selection of either 6 o’clock or 12 o’clock. Gray scale inversion needs to be taken of carefully. If a high-end product is designed, you can pay premium to select IPS TFT LCD which doesn’t have the viewing angle issue.

It is similar to viewing angle selection, TN type TFT LCD has lower contrast but lower cost, while IPS TFT LCD has much high contrast but normally with higher cost. Orient Display provides both selections.

Normal TFT LCD displays provide wide enoughtemperature range for most of the applications. -20 to 70oC. But there are some (always) outdoor applications like -30 to 80oC or even wider, special liquid crystal fluid has to be used. Heater is needed for operating temperature requirement of -40oC. Normally, storage temperature is not an issue, many of Orient Display standard TFT display can handle -40 to 85oC, if you have any questions, feel free to contact our engineers for details.

Power consideration can be critical in some hand-held devices. For a TFT LCD display module, backlight normally consumes more power than other part of the display. Dimming or totally shutdown backlight technology has to be used when not in use. For some extreme power sensitive application, sleep mode or even using memory on controller consideration has to be in design. Feel free to contact our engineers for details.

Genetic Interfaces: Those are the interfaces which display or touch controller manufacturers provide, including parallel, MCU, SPI(,Serial Peripheral Interface), I2C, RGB (Red Green Blue), MIPI (Mobile Industry Processor Interface), LVDS (Low-Voltage Differential Signaling), eDP ( Embedded DisplayPort) etc. Orient Display has technologies to make the above interface exchangeable.

High Level Interfaces: Orient Display has technologies to make more advanced interfaces which are more convenient to non-display engineers, such as RS232, RS485, USB, VGA, HDMI etc. more information can be found in our serious products. TFT modules, Arduino TFT display, Raspberry Pi TFT display, Control Board.

Touch panels have been a much better human machine interface which become widely popular. Orient Display has been investing heavy for capacitive touch screen sensor manufacturing capacity. Now, Orient Display factory is No.1 in the world for automotive capacitive touch screen which took around 18% market share in the world automotive market.

Based on the above three types of touch panel technology, Orient Display can also add different kinds of features like different material glove touch, water environment touch, salt water environment touch, hover touch, 3D (force) touch, haptic touch etc. Orient Display can also provide from very low cost fixed area button touch, single (one) finger touch, double finger (one finger+ one gesture) touch, 5 finger touch, 10 points touch or even 16 points touch

Considering the different shapes of the touch surface requirements, Orient Display can produce different shapes of 2D touch panel (rectangle, round, octagon etc.), or 2.5D touch screen (round edge and flat surface) or 3D (totally curved surface) touch panel.

Considering different strength requirements, Orient Display can provide low cost chemical tampered soda-lime glass, Asahi (AGC) Dragontrail glass and Corning high end Gorilla glass. With different thickness requirement, Orient Display can provide the thinnest 0.5mm OGS touch panel, to thickness more than 10mm tempered glass to prevent vandalizing, or different kinds of plastic touch panel to provide glass piece free (fear) or flexible substrates need.

Of course, Orient Display can also offer traditional RTP (Resistive Touch Panel) of 4-wire, 5-wire, 8-wire through our partners, which Orient Display can do integration to resistive touch screen displays.

If you can’t find a very suitable TFT LCD Display in our product line, don’t be discouraged. The products listed on our website is only small part of standard products. We have thousands of standard products in our database, feel free to contact our engineers for details.

If you like to have a special display, Orient Display is always flexible to do partial custom solution. For example, to modify the FPC to different length or shape, or use as fewer pinouts as possible, or design an ultra-bright LCD display, or a cover lens with your company logo on it, or design an extreme low power or low cost TFT display etc. our engineers will help you to achieve the goals. The NER cost can start from hundreds of dollars to Thousands. In rare case, it can be tens of thousands of dollars.

A fully custom TFT LCD panel can have very high NRE cost. Depending on the size of the display, quantity and which generation production line to be used. The tooling cost can start from $100,000 to over $1M.

We come across Liquid Crystal Display (LCD) displays everywhere around us. Computers, calculators, television sets, mobile phones, and digital watches use some kind of display to display the time.

An LCD screen is an electronic display module that uses liquid crystal to produce a visible image. The 16×2 LCD display is a very basic module commonly used in DIYs and circuits. The 16×2 translates a display of 16 characters per line in 2 such lines. In this LCD, each character is displayed in a 5×7 pixel matrix.

Contrast adjustment; the best way is to use a variable resistor such as a potentiometer. The output of the potentiometer is connected to this pin. Rotate the potentiometer knob forward and backward to adjust the LCD contrast.

Sends data to data pins when a high to low pulse is given; Extra voltage push is required to execute the instruction and EN(enable) signal is used for this purpose. Usually, we set en=0, when we want to execute the instruction we make it high en=1 for some milliseconds. After this we again make it ground that is, en=0.

A 16X2 LCD has two registers, namely, command and data. The register select is used to switch from one register to other. RS=0 for the command register, whereas RS=1 for the data register.

Command Register: The command register stores the command instructions given to the LCD. A command is an instruction given to an LCD to do a predefined task. Examples like:

Data Register: The data register stores the data to be displayed on the LCD. The data is the ASCII value of the character to be displayed on the LCD. When we send data to LCD, it goes to the data register and is processed there. When RS=1, the data register is selected.

Generating custom characters on LCD is not very hard. It requires knowledge about the custom-generated random access memory (CG-RAM) of the LCD and the LCD chip controller. Most LCDs contain a Hitachi HD4478 controller.

CG-RAM address starts from 0x40 (Hexadecimal) or 64 in decimal. We can generate custom characters at these addresses. Once we generate our characters at these addresses, we can print them by just sending commands to the LCD. Character addresses and printing commands are below.

LCD modules are very important in many Arduino-based embedded system designs to improve the user interface of the system. Interfacing with Arduino gives the programmer more freedom to customize the code easily. Any cost-effective Arduino board, a 16X2 character LCD display, jumper wires, and a breadboard are sufficient enough to build the circuit. The interfacing of Arduino to LCD display is below.

The combination of an LCD and Arduino yields several projects, the most simple one being LCD to display the LED brightness. All we need for this circuit is an LCD, Arduino, breadboard, a resistor, potentiometer, LED, and some jumper cables. The circuit connections are below.

Newhaven 128x64 graphic Liquid Crystal Display module shows blue pixels on a gray background. This transflective LCD Display is visible with ambient light or a backlight while offering a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-12864MZ-FSW-GBW-L display has an optimal view of 6:00, operates at 5V supply voltage and is RoHS compliant.

Easily modify any connectors on your display to meet your application’s requirements. Our engineers are able to perform soldering for pin headers, boxed headers, right angle headers, and any other connectors your display may require.

Choose from a wide selection of interface options or talk to our experts to select the best one for your project. We can incorporate HDMI, USB, SPI, VGA and more into your display to achieve your design goals.

Advanced LED video wall with MicroLED models in 0.6, 0.7 and 0.9mm pixel pitches, and 1.2mm pixel pitch standard LED; with powerful processing, proprietary alignment technology and off-board electronics.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

From cinema content to motion-based digital art, Planar® Luxe Displays offer a way to enrich distinctive spaces. These professional-grade displays provide vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior decor.

Advanced LED video wall with MicroLED models in 0.6, 0.7 and 0.9mm pixel pitches, and 1.2mm pixel pitch standard LED; with powerful processing, proprietary alignment technology and off-board electronics.

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

Advanced LED video wall with MicroLED models in 0.6, 0.7 and 0.9mm pixel pitches, and 1.2mm pixel pitch standard LED; with powerful processing, proprietary alignment technology and off-board electronics.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

Carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility for various installations including virtual production and extended reality.

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

Since 1983, Planar display solutions have benefitted countless organizations in every application. Planar displays are usually front and center, dutifully delivering the visual experiences and critical information customers need, with proven technology that is built to withstand the rigors of constant use.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey