prusa mk2 lcd panel free sample

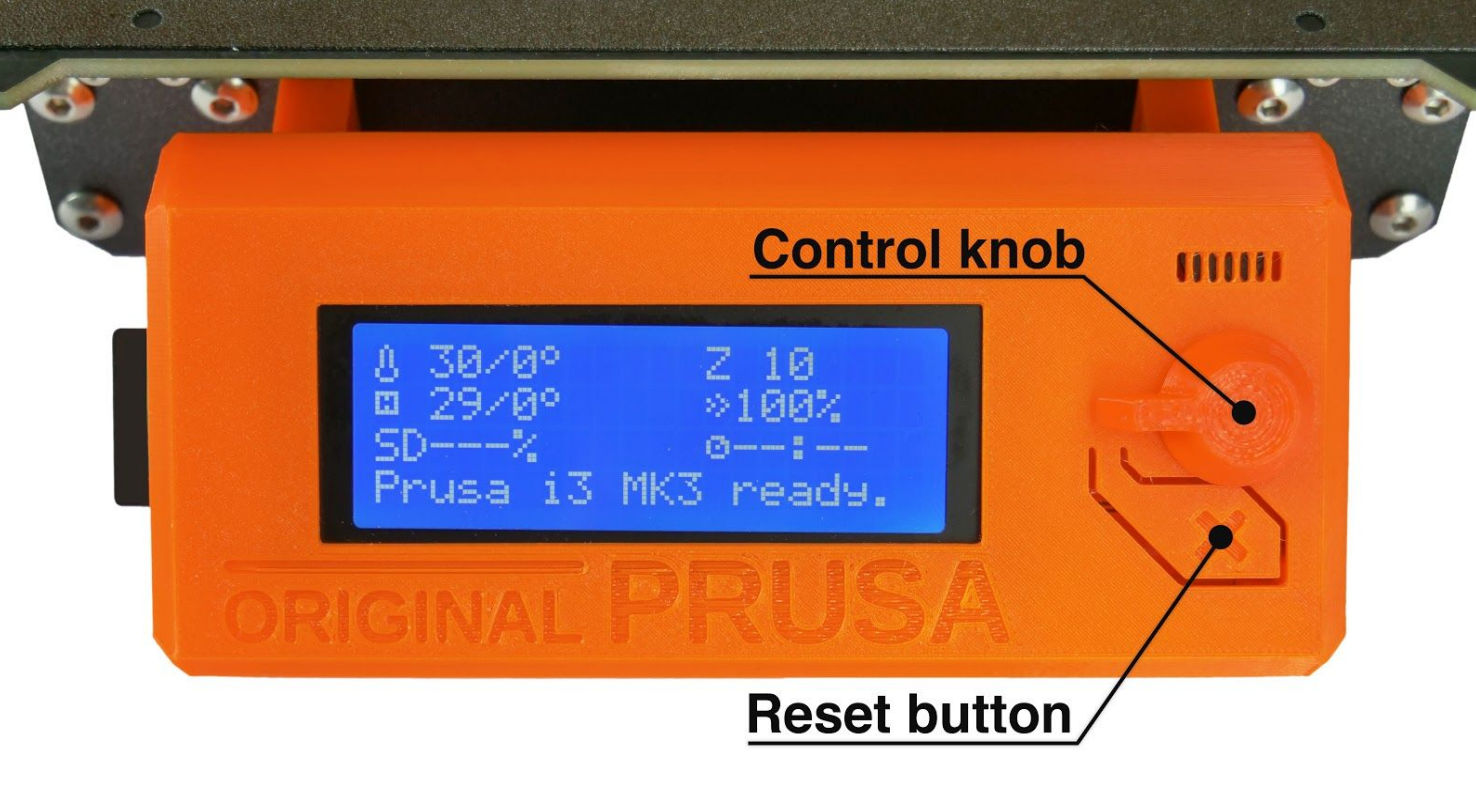

Controlling the LCD screen is done by a single control element: a rotational knob that you press to confirm the selection. By single pressing the control button on the information screen, you enter the main menu.

Settings saved in EEPROM persist across reboots and still remain after flashing new firmware, so always send M502, M500 (or “Reset EEPROM” from the LCD) after flashing.

This is the name of your printer as displayed on the LCD and by M115. For example, if you set this to “My Delta” the LCD will display “My Delta ready” when the printer starts up.

Enable PID_AUTOTUNE_MENU to add an option on the LCD to run an Autotune cycle and automatically apply the result. Enable PID_PARAMS_PER_HOTEND if you have more than one extruder and they are different models.

M301 can be used to set Hotend PID and is also accessible through the LCD. M304 can be used to set bed PID. M303 should be used to tune PID values before using any new hotend components.

Even if you have no bed probe you can still use any of the core AUTO_BED_LEVELING_* options below by selecting this option. With PROBE_MANUALLY the G29 command only moves the nozzle to the next probe point where it pauses. You adjust the Z height with a piece of paper or feeler gauge, then send G29 again to continue to the next point. You can also enable LCD_BED_LEVELING to add a “Level Bed” Menu item to the LCD for a fully interactive leveling process. MANUAL_PROBE_START_Z sets the Z-height the printer initially moves to at each mesh point during manual probing. With this disabled, the printer will move to Z0 for the first probe point. Then each consecutive probe point uses the Z position of the probe point preceding it.

These offsets specify the distance from the tip of the nozzle to the probe — or more precisely, to the point at which the probe triggers. The X and Y offsets are specified as integers. The Z offset should be specified as exactly as possible using a decimal value. The Z offset can be overridden with M851 Z or the LCD controller. The M851 offset is saved to EEPROM with M500.

Use these settings to specify the distance (mm) to raise the probe (or lower the bed). The values set here apply over and above any (negative) probe Z Offset set with Z_PROBE_OFFSET_FROM_EXTRUDER, M851, or the LCD. Only integer values >= 1 are valid for these settings. Example: M851 Z-5 with a CLEARANCE of 4 => 9 mm from bed to nozzle.

These settings reverse the motor direction for each axis. Be careful when first setting these. Axes moving the wrong direction can cause damage. Get these right without belts attached first, if possible. Before testing, move the carriage and bed to the middle. Test each axis for proper movement using the host or LCD “Move Axis” menu. If an axis is inverted, either flip the plug around or change its invert setting.

AUTO_BED_LEVELING_UBL (recommended) combines the features of 3-point, linear, bilinear, and mesh leveling. As with bilinear leveling, the mesh data generated by UBL is used to adjust Z height across the bed using bilinear interpolation. An LCD controller is currently required.

#if ENABLED(LCD_BED_LEVELING) #define MESH_EDIT_Z_STEP 0.025 // (mm) Step size while manually probing Z axis. #define LCD_PROBE_Z_RANGE 4 // (mm) Z Range centered on Z_MIN_POS for LCD Z adjustment //#define MESH_EDIT_MENU // Add a menu to edit mesh points

These are the default values for the Prepare > Preheat LCD menu options. These values can be overridden using the M145 command or the Control > Temperature > Preheat Material X conf submenus.

Choose your preferred language for the LCD controller here. Supported languages include: Code Language Code Language Code Language en English (Default) an Aragonese bg Bulgarian

The SDSUPPORT option must be enabled or SD printing will not be supported. It is no longer enabled automatically for LCD controllers with built-in SDCard slot.

Disable all menus and only display the Status Screen with NO_LCD_MENUS, or just remove some extraneous menu items to recover space with SLIM_LCD_MENUS.

This option reverses the encoder direction for navigating LCD menus. If CLOCKWISE normally moves DOWN this makes it go UP. If CLOCKWISE normally moves UP this makes it go DOWN.

The duration and frequency for the UI feedback sound. Set these to 0 to disable audio feedback in the LCD menus. Test audio output with the G-code M300 S

Marlin includes support for several controllers. The two most popular controllers supported by Marlin are: REPRAP_DISCOUNT_SMART_CONTROLLER A 20 x 4 character-based LCD controller with click-wheel.

REPRAP_DISCOUNT_FULL_GRAPHIC_SMART_CONTROLLER A monochrome 128 x 64 pixel-based LCD controller with click-wheel. Able to display simple bitmap graphics and up to 5 lines of text.

LCD_I2C_PANELOLU2 PANELOLU2 LCD with status LEDs, separate encoder and click inputs. The click input can either be directly connected to a pin (if BTN_ENC is defined) or read through I2C (with BTN_ENC undefined). Requires LiquidTWI2 library v1.2.3 or later.

#if EITHER(ULTIPANEL, EXTENSIBLE_UI) #define MANUAL_FEEDRATE { 50*60, 50*60, 4*60, 60 } // Feedrates for manual moves along X, Y, Z, E from panel #define SHORT_MANUAL_Z_MOVE 0.025 // (mm) Smallest manual Z move (< 0.1mm) #if ENABLED(ULTIPANEL) #define MANUAL_E_MOVES_RELATIVE // Display extruder move distance rather than "position" #define ULTIPANEL_FEEDMULTIPLY // Encoder sets the feedrate multiplier on the Status Screen #endif

#if ENABLED(LCD_PROGRESS_BAR) #define PROGRESS_BAR_BAR_TIME 2000 // (ms) Amount of time to show the bar #define PROGRESS_BAR_MSG_TIME 3000 // (ms) Amount of time to show the status message #define PROGRESS_MSG_EXPIRE 0 // (ms) Amount of time to retain the status message (0=forever) //#define PROGRESS_MSG_ONCE // Show the message for MSG_TIME then clear it

Show a progress bar on HD44780 LCDs for SD printing. Sub-options determine how long to show the progress bar and status message, how long to retain the status message, and whether to include a progress bar test in the Debug menu.

Add an option for the firmware to abort SD printing if any endstop is triggered. Turn on with M540 S1 (or from the LCD menu) and make sure endstops are enabled (M120) during SD printing.

This option makes it easier to print the same SD Card file again. Whenever an SD print completes the LCD Menu will open with the same file selected. From there you can click to start a new print, or you can navigate elsewhere.

#define DGUS_UPDATE_INTERVAL_MS 500 #if EITHER(DGUS_LCD_UI_FYSETC, DGUS_LCD_UI_HIPRECY) #define DGUS_PRINT_FILENAME #define DGUS_PREHEAT_UI #if ENABLED(DGUS_LCD_UI_FYSETC) //#define DGUS_UI_MOVE_DIS_OPTION

#if ENABLED(CLCD_USE_SOFT_SPI) #define CLCD_SOFT_SPI_MOSI 11 #define CLCD_SOFT_SPI_MISO 12 #define CLCD_SOFT_SPI_SCLK 13 #endif #endif //#define TOUCH_UI_INVERTED

Babystepping enables M290 and LCD menu items to move the axes by tiny increments without changing the current position values. This feature is used primarily to adjust the Z axis in the first layer of a print in real-time. Warning: Does not respect endstops!

Experimental feature for filament change support and parking the nozzle when paused. Adds the M600 command to perform a filament change. With PARK_HEAD_ON_PAUSE enabled also adds the M115 command to pause printing and park the nozzle. Requires an LCD display. Note that M600 is required for the default FILAMENT_RUNOUT_SCRIPT. Requires LCD display and NOZZLE_PARK_FEATURE.

#if PIN_EXISTS(BUTTON1) #define BUTTON1_HIT_STATE LOW // State of the triggered button. NC=LOW. NO=HIGH. #define BUTTON1_WHEN_PRINTING false // Button allowed to trigger during printing? #define BUTTON1_GCODE "G28" #define BUTTON1_DESC "Homing" // Optional string to set the LCD status #endif

The MMU2 LCD menu allows you to load filament to the nozzle. The MMU2 will transport the filament all the way to the extruder gears. The required extruder steps to load it into the hotend have to be defined in Marlin.

To unload filament using the LCD menu a generic ramming sequence will be executed before the MMU2 will retract the filament. The steps to do so are defined using

We have been testing the new Prusa i3 Mk2 extensively over the last two months. This printer has outperformed EVERY printer we have used, and straight out of the box was printing beautifully. We’ve been tinkering with the stock Prusa Slic3r settings, and have found that with some minor tweaks, the quality gets even better. Just by reducing all extrusion width settings from the stock 4.5mm to 4mm, we were able to achieve top surfaces that were almost completely smooth when using Hatchbox PLA filament. .2mm prints off of the Prusa are looking as good as .15mm prints from other printers, meaning you can print models much faster and maintain excellent results. Below is a 3/4″ test cube, and the top surface is the smoothest we have ever seen off of a FDM printer. This was printed using Hatchbox silver PLA, 205˚, 30mm/sec print speed, 8 top layers, .1mm layer height. Prusa stock settings that were changed: perimeters were changed from 3 to 2, all extrusion widths changed to .43mm (formerly .45).EDIT: I have been toying with Prusa’s originally recommended .45 extrusion width more, for some models .45 works best, for others .43 does.The Prusa isn’t the cheapest printer out there, but it is worth every penny. The printer features 9-point auto leveling, so even if your print bed is slightly warped or your axis alignment is slightly off, the printer firmware accounts for this during the print process for a perfect print every time. We had a glitchy LCD on our first one (it wouldn’t always read the SD card, and would lose contact with the main board), and Prusa customer service got us a replacement immediately. A couple screws and plugging it into the Rambo board, and we were back up and running in no time. This printer is extremely easy to work on, all major components are easy to access and replace if necessary. While many people love the PEI print bed surface, we still routinely use blue painters tape on ours (remember to adjust your z-height calibration slightly if you do this- our setting was raised up by .095mm to account for the tape height.) When printing our 15mm scale troops for World War Tesla, even their NOSES printed successfully (for those of you used to standard 28mm scale D&D miniatures, this one is HALF that height!) The Prusa i3 Mk2 is available as a kit ($699) or fully assembled ($899). The only downside is that the printer is proving to be so incredibly popular, there is currently an 8 week wait to get one (but it is worth it.) For those going the kit route, I’m including a diagram at the bottom of this post from a Mk2 Facebook group that will be extremely beneficial to getting everything perfect.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey