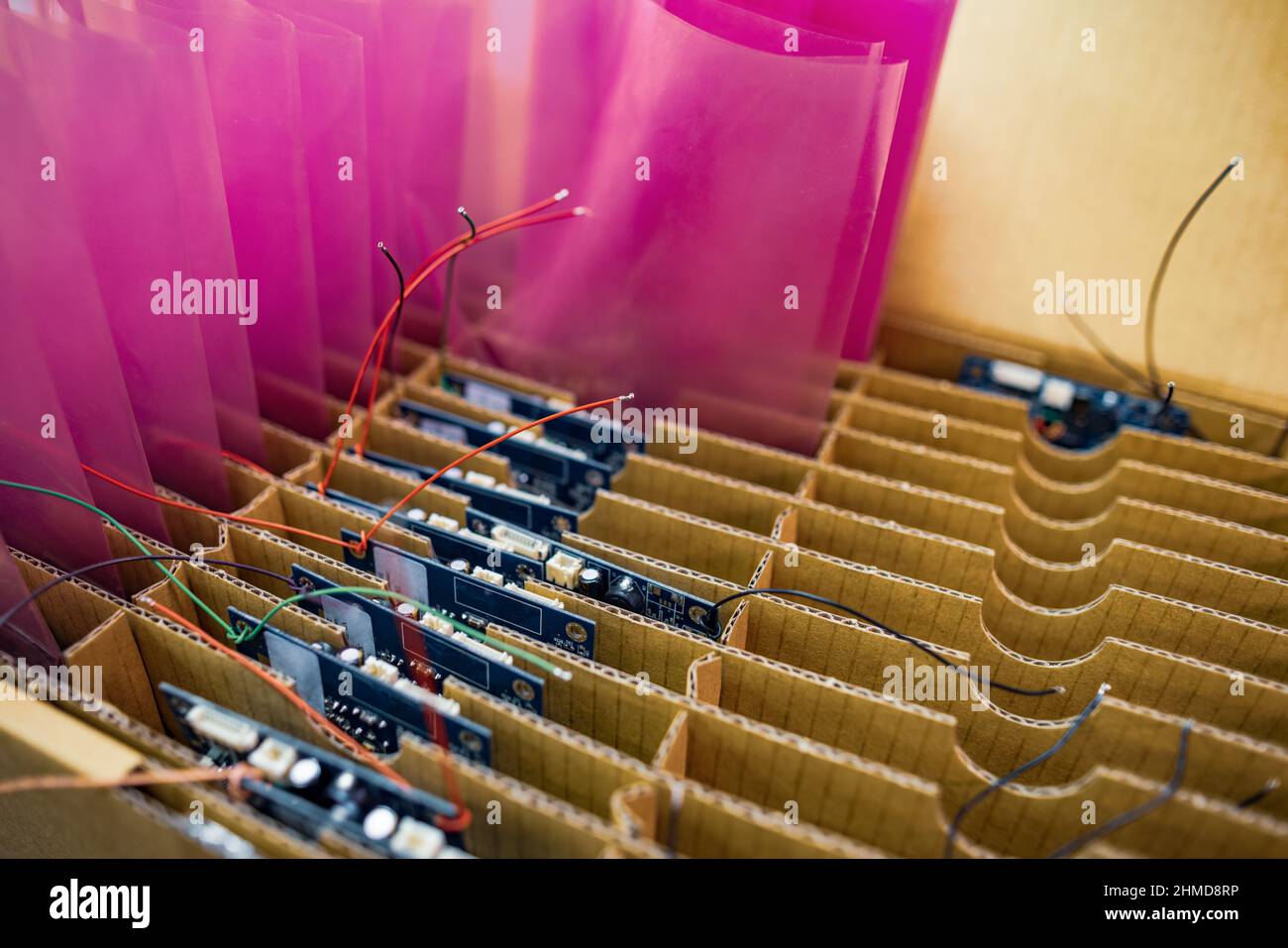

microchip tft display factory

Digital displays improve the user interface of just about any application. Segmented LCDs have historically been a popular choice of display technology. They continue to be used in a variety of medical and industrial applications. However, there has been a significant trend towards use of graphical displays—such as TFT, OLED and CSTN—in consumer, appliance and automotive applications. Today’s users prefer intuitive menus, vivid graphics, touch panel interaction and, in some cases, the ability to interact remotely with a system. Adding a graphical display presents several design challenges such as minimizing the cost of components associated with driving the display, overcoming the complexity of software needed for updating graphics, extending battery life and providing remote connectivity.

If you are looking to add newer, aesthetically pleasing and feature-rich interfaces to your products, we offer a broad portfolio of solutions that include touch sensing and display technologies. We deliver complete hardware and software solutions to get your design to market faster at a lower total system cost.

Creating professional-looking embedded Graphical User Interfaces (GUIs) has never been easier when you use the powerful and free MPLAB Harmony Graphics Suite (MHGS). Available within the MPLAB Harmony embedded software development framework, MHGS is specifically designed specifically to take advantage of the capabilities of our high-performance, 32-bit embedded graphics MCUs and MPUs. This tightly integrated system of tools and software allows you to add GUIs, animation and imagery quickly and easily to a graphical display. Its “What You See Is What You Get” (WYSIWYG)-based embedded GUI development system comes with unique features that enable you to spend less time fixing bugs and re-integrating code from external tool sets and libraries, reducing your development time, cost and risk in designing compelling new products for your end users.

The Displaytech EMB035TFTDEMO is a demonstration and development board for the Displaytech 3.5 inch color TFT display. The display is controlled by a Microchip PIC24FJ256DA210 microcontroller with integrated graphics controller. Furthermore, the demonstration board includes on-board external SRAM for extra frame-buffer memory as well as SPI flash for storing fonts and images. Capacitive touch screen is available for the 3.5" TFT display.

The Displaytech EMB043TFTDEMO is a demonstration and development board for the Displaytech DT043BTFT 4.3 inch color TFT display. The display is controlled by a Microchip PIC24FJ256DA210 microcontroller with integrated graphics controller. Furthermore, the demonstration board includes on-board external SRAM for extra frame-buffer memory as well as SPI flash for storing fonts and images.

General Specification PMS-70H-002-M is a 7"" Industrial Embedded Systems, composed of a 7” 800*480 IPS Type TFT LCD, a capacitive touch panel, a CNC front cover, a back stand, a back cover and a silicone seal. Features •Support...

General Specification PMS-70H-002-M is a 7"" Industrial Embedded Systems, composed of a 7” 800*480 IPS Type TFT LCD, a capacitive touch panel, a CNC front cover, a back stand, a back cover and a silicone seal. Features •Support...

General Specification PMS-70H-002-M is a 7"" Industrial Embedded Systems, composed of a 7” 800*480 IPS Type TFT LCD, a capacitive touch panel, a CNC front cover, a back stand, a back cover and a silicone seal. Features •Support...

General Specification PMS-70H-002-M is a 7"" Industrial Embedded Systems, composed of a 7” 800*480 IPS Type TFT LCD, a capacitive touch panel, a CNC front cover, a back stand, a back cover and a silicone seal. Features •Support...

General Specification PMS-70H-002-M is a 7"" Industrial Embedded Systems, composed of a 7” 800*480 IPS Type TFT LCD, a capacitive touch panel, a CNC front cover, a back stand, a back cover and a silicone seal. Features •Support...

General Specification The SAMA5D27- 70-CTP is a fast prototyping and evaluation platform for the SAMA5D2 based System in Packages (SiPs) and the SAMA5D27-SOM1 (SAMA5D27 System On Module)plus a 7inch 800x480 with PCAP display. The kit...

PANASYS is one of the leading microchip series intelligent display suppliers in China. With advanced technology, we can assure you the high resolution and good performance of our products. Welcome to contact us and get samples of microchip series intelligent display, as well as product price list from PANASYS.

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

For over 20 years Newhaven Display has been one of the most trusted suppliers in the digital display industry. We’ve earned this reputation by providing top quality products, services, and custom design solutions to customers worldwide.

Display screen is everywhere nowadays. Do you still remember the TVs or computer monitors 20 years ago? They were quadrate, huge and heavy. Now let’s look at the flat, thin and light screen in front of you, have you ever wondered why is there such a big difference?

Actually, the monitors 20 year ago were CRT (Cathode Ray Tube) displays, which requires a large space to run the inner component. And now the screen here in your presence is the LCD (Liquid Crystal Display) screen.

As mentioned above, LCD is the abbreviation of Liquid Crystal Display. It’s a new display technology making use of the optical-electrical characteristic of liquid crystal.

Liquid crystal is a state of substance that has both the characteristics of liquid and solid crystal. It don’t emit light itself, but it can let the light pass perfectly in specific direction. Meanwhile, liquid crystal molecule will rotate under the influence of a electric field, and then the light goes through it will rotate too. That said, liquid crystal can be a switch of light, which is the key in display technology.

STN LCD: STN is for Super-twisted Nematic. The liquid crystal in STN LCD rotate more angles than that in TN LCD, and have a different electrical feature, allowing STN LCD to display more information. There are many improved version of STN LCD like DSTN LCD (double layer) and CSTN LCD (color). This LCD is used in many early phones, computers and outdoor devices.

TFT LCD: TFT is for Thin Film Transistor. It’s the latest generation of LCD technology and has been applied in all the displaying scenario including electronic devices, motor cars, industrial machines, etc. When you see the word ‘transistor’, you may realize there’s integrated circuits in TFT LCD. That’s correct and the secret that TFT LCD has the advantage of high resolution and full color display.

In a simple way, we can divide TFT LCD into three parts, from bottom to top they are: light system, circuit system and light and color control system.In manufacturing process, we’ll start from inner light and color control system and then stretch out to whole module.

It’s accustomed to divide TFT LCD manufacturing process into three main part: array, cell and module. The former two steps are about the production of light and color control system, which contains TFT, CF (color filter) and LC (liquid crystal), named a cell. And the last step is the assembly of cell, circuit and light system.

Now let’s turn to the production of TFT and CF. Here is a common method called PR (photoresist) method. The whole process of PR method will be demonstrated in TFT production.

TFT is a Thin Film Transistor, TFT refers to each LCD liquid crystal display pixels that are driven by integration in the behind of the Thin Film Transistor. Therefore, the TFT-type display has the advantages of high responsiveness, high brightness, and high contrast, and its display effect is close to that of CRT display, TFT-LCD is one of the most liquid crystal displays.TFT display is also a kind of active-matrix liquid crystal display equipment. TFT-LCD is one of the best LCD color displays, TFT-LCD has the advantages of fine and vivid image, lightweight, low power consumption, and good environmental protection performance, widely used in TV, laptop, mobile phone, monitor, medical beauty, and other equipment.

Unlike TN, TFT displays are “backlit” – the imaginary light path is not from top to bottom, as in TN, but from bottom to top. In this way, a special light tube is set on the back of the liquid crystal, and the light source shines upward through the lower polarizer. Since the upper and lower interlayer electrodes are changed into FET electrodes and common electrodes, the performance of liquid crystal molecules will also change when the FET electrode is switched on. The display purpose can be achieved through shading and light transmission, and the response time is greatly improved to about 80ms.TFT is commonly known as “true color” because it has higher contrast and richer colors than TN-LCD, and the screen updates faster.

The main feature of TFT-LCD, as opposed to TN, is one semiconductor switch per pixel. Because each pixel can be directly controlled by point pulses. Therefore, each node is relatively independent and can be controlled continuously. Such a design method not only improves the response speed of the display screen but also can accurately control the display grayscale, which is why TFT color is more realistic than DSTN.

The TFT panel is cut from a larger substrate. LCD products also have a large array of transistors to control the three primary colors, and current manufacturing technology is difficult to ensure that tens or even hundreds of millions of transistors on a large substrate are without a single problem. If there is a problem with one of the transistors, then the corresponding color of the corresponding point of the transistor will go wrong (only a certain fixed color can be displayed), and this point is commonly called “bad point”. The probability of bad spots is not fixed in position, so a substrate is likely to be wasted a lot. Generally, LCD requires that the bad point is less than 5, and some large manufacturers have narrowed the standard to 3, or even 0, which will reduce the yield rate. Some smaller manufacturers expand the bad points, which naturally reduces costs and quality, which is one reason why some manufacturers have been able to slash prices.

Although there are many manufacturers capable of producing LCDs, there are only a handful of manufacturers capable of producing TFT panels.ACER, as a well-known enterprise in the IT industry, is quite powerful. Although IT does not have the ability to produce TFT panels by itself,

The display sets the electron, the communication and the information processing technology in one body, is considered as the electron industry after the 20th-century microelectronics, the computer another important development opportunity.

With the rapid development of science and technology, a revolution is taking place in display technology. After more than 20 years of research, competition, and development, the flat-panel display has entered the role and become the mainstream of display products in the new century. There are four types of flat-panel displays with the most fierce competition:

The principle of field emission flat display is similar to that of CRT, which only has one to three electron guns and up to six. The field emission display adopts an electron gun array (electron emission micro tip array, such as diamond film tip cone), and the display with a resolution of VGA (640×480×3) needs 921,600 electron emission micro tips with uniform performance.

Glow plasma display are through small vacuum plasma discharge excitation discharge cavity light-emitting materials, luminous effect, and low power consumption is its shortcomings (only 1.2 lm/W, and lamp luminous efficiency more than 80 lm/W, 6 watts per square inch display area), but in 102 ~ 152 cm diagonal field of the large-screen display has a strong competitive advantage.

The semiconductor light-emitting diode (LED) display scheme, due to the successful development of GaN blue light-emitting diode, has won absolute control over the market of the video display with very large screens, but this kind of display is only suitable for large outdoor displays, and video display with a small and medium screen does not have its market.

Special TFT – LCD, LCD flat panel display, is the only one in the brightness, contrast, such as power, life, volume and weight of integrated performance to catch up with and surpass that of the CRT display device, it features good performance, large-scale production, a high degree of automation, low cost of raw materials, the vast development space, will quickly become the mainstream product of the new century, is one of the highlights of the 21st-century global economic growth.

TFT-LCD, which USES liquid crystal as the excellent characteristic of the light valve, divides the luminous display device into two parts, namely the light source and the control of the light source. As a light source, no matter from luminous efficiency, full color, or life, has achieved brilliant results, but also in continuous deepening. Since the invention of the LCD, the backlight has been continuously improved, from monochrome to color, from thick to thin, from side fluorescent lamps to flat fluorescent lamps. The latest achievements in light sources will provide a new backlight for LCD. With the progress of light source technology, there will be newer and better light sources and LCD applications. Is the control of the light source, the rest of the large scale integrated circuit technology and semiconductor technology transplanted, successfully developed the thin film transistor (TFT) production technology, implements the matrix addressing the control of the liquid crystal light valve, solved the LCD light valve and the controller, so that the advantages of liquid crystal display (LCD).

The TFT thin-film transistor (matrix) — which “actively” controls individual pixels on the screen — is the origin of the so-called active matrix TFT.So how exactly do images come about? The basic principle is simple: a display screen consists of a number of pixels that can emit light of any color, and controlling each pixel to display a corresponding color does the trick. In TFT LCD, backlight technology is generally adopted. In order to accurately control the color and brightness of each pixel, a switch similar to a shutter needs to be installed after each pixel. When the “shutter” is opened, light can come through, but when the “shutter” is closed, light cannot come through.

Of course, it’s not as simple technically as that. Liquid Crystal Display USES the properties of Liquid crystals (Liquid when heated and solid when cooled)

Liquid crystal displays (LCDs) are filamentous, and their molecular structure changes as the environment change, giving them different physical properties — allowing light to pass through or block it — in the case of louvers.

You know the three primary colors, so each pixel on the display needs to be made up of three similar basic components described above, which control the red, green, and blue colors respectively.

TFT color filter is divided into red, green, and blue according to the color, which is successively arranged on the glass substrate to form a group (dot pitch) corresponding to a pixel. Each monochrome filter is called a sub-pixel. That said, if a TFT display supports a maximum resolution of 1280×1024, it needs at least 1280×3×1024 sub-pixels and transistors. For a 15-inch TFT display (1024 x 768), a pixel is about 0.0188 inches.

As you know, pixels are critical to a display, and the smaller each pixel, the larger the maximum possible resolution of the display. But because of the physical limitations of transistors, the TFT is roughly 0.0117 inches (0.297mm) per pixel, so the maximum resolution for a 15-inch display is 1,280 by 1,024.[1]

TFT technology is the basis of liquid crystal (LC), inorganic and organic thin-film electroluminescence (EL and OEL) flat panel displays.TFT is a kind of film necessary for manufacturing circuits formed by sputtering and chemical deposition process on the non-single wafers such as glass or plastic substrate, and large-scale semiconductor integrated circuit (LSIC) is produced by processing of the film. Using non-single-crystal substrate can greatly reduce the cost, which is the extension of traditional LSI to large-area, multi-function, and low-cost direction.

The first generation of large-area glass substrate (300mm×400mm) TFT-LCD production line was put into production in the early 1990s. By the first half of 2000, the area of glass substrate has been expanded to 680mm×880mm), and the recent 950mm×1200mm glass substrate will also be put into operation. In principle, there is no area limit.

The 1.3-inch TFT chip used for liquid crystal projection has a resolution of one million pixels in XGA.The resolution of the SXGA (1280×1024) 16.1-inch TFT array amorphous silicon film thickness is only 50nm, and the TAB ON GLASS and SYSTEM ON GLASS technology, its IC integration, requirements for equipment and supply technology, technical difficulty than the traditional LSI.

TFT was first used as a matrix location circuit to improve the optical valve characteristics of liquid crystals. For high-resolution displays, the accurate control of object elements is realized through voltage adjustment in the range of 0-6v (its typical value is 0.2 to 4V), thus making it possible for LCD to achieve a high-quality high-resolution display.TFT-LCD is the first flat panel display in human history to surpass CRT in display quality. Now people are starting to integrate the drive IC into the glass substrate, and the whole TFT will be more powerful than traditional large-scale semiconductor integrated circuits.

Low voltage applications, low drive voltage, solid use safety, and reliability improvement; Flat, light, and thin, saving a lot of raw materials and space; Low power consumption, its power consumption is about one-tenth of the CRT display, reflective TFT-LCD is only about one percent of the CRT, saving a lot of energy; TFT-LCD products also have specifications, models, size series, variety, convenient and flexible use, maintenance, update, upgrade easy, long service life and many other characteristics. The display range covers the application range of all monitors from 1 inch to 40 inches and the large projection plane, which is a full-size display terminal; Display quality from the simplest monochrome character graphics to high resolution, high color fidelity, high brightness, high contrast, the high response speed of various specifications of video display; Display mode has direct vision type, projection type, perspective type, and reflection type.

No radiation, no flicker, no harm to the user’s health. In particular, the appearance of TFT-LCD electronic books and periodicals will bring mankind into the era of a paperless office and paperless printing, and trigger the revolution of human learning, communication, and recording civilization.

The temperature range from -20℃ to +50℃ can be used normally, and the low temperature working temperature of TFT-LCD after temperature reinforcement can reach -80 ℃. It can be used as a mobile terminal display, desktop terminal display, and large screen projection TV. It is a full-size video display terminal with excellent performance.

Demos include Touch with Water, Knob Touch, Touch Display Optical Bonding Module, Touch Display with AG/AR/AF Surface Treatment and Displays for the industrial market

Touch with Water Demo V3 – Fannal has developed first Touch with Water Demo in 2016 and updated to V3 during this time. The V3 is developed based on latest touch controller technology from Microchip. And our engineers make great effort to achieve excellent touch experience with full water on the surface. (BTW, Fannal engineers can also support projects applied in salt water environment, touch with salt water.)

Knob Touch on Display Demo – The newly developed demo by Fannal Engineering team. The Knob Touch on Display also developed based on Microchip technology, mainly for home appliances. The tactile feedback of a traditional knob with modern interactive display to enable local control of smart home appliance. (BTW, Fannal is the Design Partner Program Member of Microchip.)

All Black Touch Display Demo – The Fannal Engineering team has developed different solutions for applications required all black effect on touch display parts, mainly for smart home and appliances. We will evaluate and suggest the right one for customer according to specific using environment.

TFT Technology– In addition to providing professional PCAP solutions, Fannal can also provide customers with one-stop-solution of Capacitive Touch Panel Air/Optical Bonded with TFT according to customers special requirements and applications. Fannal team has dedicated extensive efforts to in-house development and manufacturing capabilities, ensuring ongoing advancement of its TFT display products. With continuous improvements, Fannal can offer high quality, customized TFT solutions across numerous industrial applications. Here below are samples that we will show at this event.

Established in 2007, Raystar has built its reputation by offering advanced products in PMOLED display and modules as well as in FSTN / STN LCD Display Module, COG LCD, TFT LCD Display.

Every valued customer of Raystar plays a key role in our current success. We promise to keep growing as your most trustworthy partner for display solutions in the decades ahead.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey