lcd display driver ic factory

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

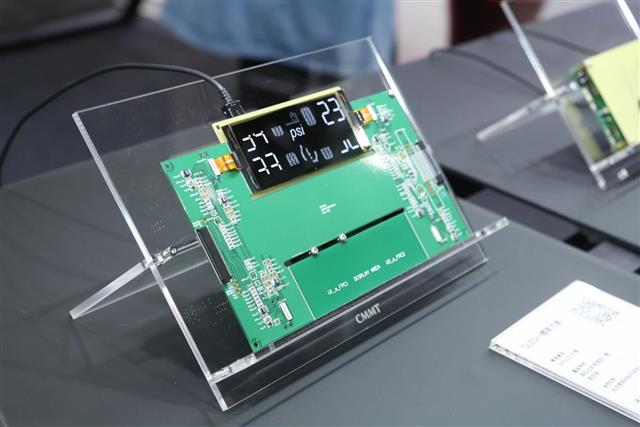

Shenzhen Chance Technology Co., LTD. is in possession of 11-year experience in designing and producing LCM in original Microview Technology (Shenzhen) CO., LTD. Thereinto, TN,STN,FSTN is manufatured by our own factory in the North of China.

1, Scope of business: We mainly focus on LCD screen for banking machines, communication tools, game machines, GPS navigator, smart watch, mobile phone, appliances, etc.

2, Competitive factors: Excellent quality, short delivery time, great pre-sale service and after-sale service. There are 6 production lines, with all full-automatic machines, lapping-machine EP0805AM, COG+FOG machine-SCL-2000G(COG)+SFB-2000J (FOG), glue dispenser-DJ800-C-G, BL assembly machine-SBL2000-H. 10+ staff in quality team and 150 employees here. While products are compliant with certificate, CE, ROHS and FCC.

3, Suppliers: Chance has materials supplied by high-class suppliers such as AUO in mainland, CPT in Taipei, LG and HItachi. Together with this reliable supply chain, we make and offer professional LCD products.

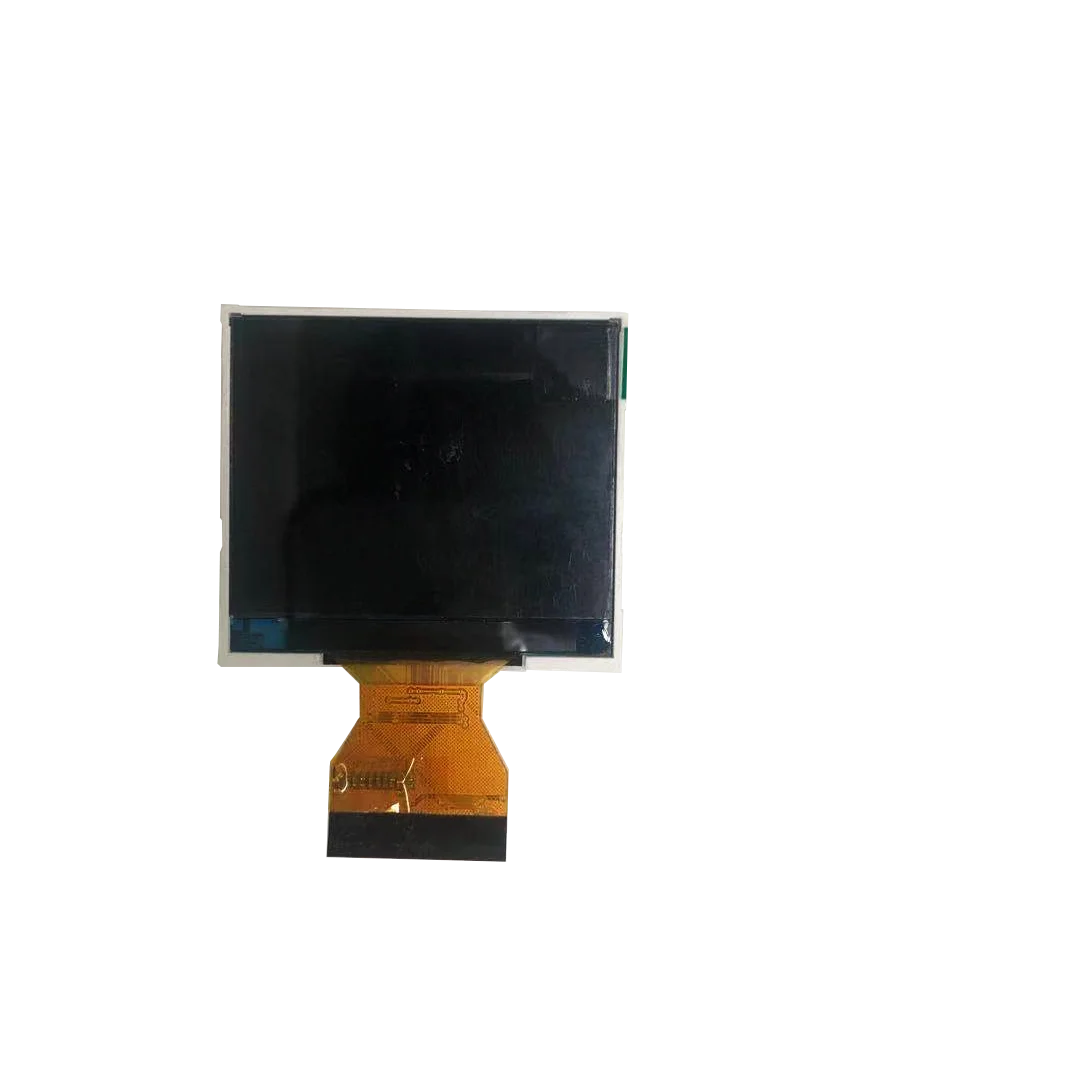

The present invention relates to a display driver integrated circuit module. More particularly, the present invention relates to a flat liquid crystal display driver integrated circuit module.

Liquid crystal is a material in between a solid and a liquid. When affected by external electric fields, magnetic fields, or heat, molecular orientation of liquid crystal is changed. The photoelectric property of liquid crystal is also varied. The variation of photoelectric property due to externally applied fields can be adjusted, and hence, produces a visual effect that is adapted for the formation of a liquid crystal display (LCD).

A LCD has a low operating voltage, emits no radiation, is lightweight, has a small volume, and has a low power consumption, in addition to other properties. Therefore, LCDs are widely used in products such as portable TVs, mobile phones, camcorders, notebooks, desktop monitors, projection TVs, and other electronic commodities and computer products. It is expected that cathode ray tube (CRT) containing devices will be gradually replaced by LCD devices, and LCD devices will become the mainstream monitor product in the future.

The manufacturing process of a LCD has been being developed in following the trench of a higher contrast ratio, a wider viewing angle, a faster response speed, a higher resolution, a full color display, etc., which yet depend on, for example, the molecular structure of liquid crystal, the color filter, the thin film transistor (TFT), the polarizer, the encapsulant, the integrated circuit mounting technology, the packaging type, etc.

In order to fulfill the requirements of high resolution and miniaturization of electronic commodities, the packaging technique has been changed from the chip on board (COB) process to the tape automated bonding (TAB) process, and further changed into the chip on glass (COG) process, also called the flip chip on glass (FCOG) process, for a very fine pitch requirement.

The COB process is the most widely used process in the early LCDs manufacturing. A chip is mounted on a printed circuit board (PCB) by means of the wire bonding process and the surface mounted technology (SMT). Connections between the PCB with a chip and a liquid crystal panel are accomplished through a flexible printed circuit board (FPCB). Such processes involve the design of the PCB, the treatment of metal layers on connection points, and the requirement of the FPCB for connections.

FIG. 1 illustrates a flow chart for the assembly process of a liquid crystal module (LCM) by means of the prior art tape automated bonding process. FIGS. 2 and 3 illustrate a top view and a schematic, cross-sectional view, respectively, of a liquid crystal module fabricated by means of the prior art tape automated bonding process.

Reference is made to FIG. 1. According to a step 100 shown in FIG. 1, bumps are fabricated on a driver integrated circuit (IC) first. An inner lead bonding (ILB) process is performed which mounts the driver IC to inner leads of a tape. After encapsulation and testing, an outer lead bonding (OLB) process is performed in which outer leads of the tape is electrically connected to terminals located on an edge of a liquid crystal panel by means of an anisotropic conductive film (ACF).

Then, a step 102 shown in FIG. 1 follows. By employing an ACF or solder, the tape with driver IC is connected to a PCB. A LCD is controlled under an active matrix driving manner by different functions ICs on the PCB and the driver IC on the tape to produce desired patterns.

A step 104 shown in FIG. 1 is performed. A backlight, a bezel, a frame, etc., the liquid crystal panel, the tape with driver IC, and the PCB together forms a liquid crystal module.

Reference is made to FIGS. 2 and 3, in which a top view and a schematic, cross-sectional view of a liquid crystal module fabricated by means of the prior art tape automated bonding process are illustrated, respectively. Driver ICs 204 are mounted on tapes 202. The tapes 202 are then respectively connected to a liquid crystal panel 200 and PCBs 206. Other ICs 208 are mounted to the PCBs 206 as well. A backlight 210 is located under the liquid crystal panel 200 in order to provide a light source.

The COG process, also named as the flip chip on glass process (FCOG), is a flip chip bonding process, which electrically connects driver chips to a liquid crystal panel by means of eutectic metals, polymer resins, or conductive adhesives as connecting media. Bumps of the chips and terminals of a panel are electrically connected for isotropic and anisotropic conduction.

Currently TFT-LCD structure mainly employs the TAB and the FCOG processes for its fabrication. Typical small and medium size (up to about 7 inches) TFT-LCDs employ the FCOG process. For large size TFT-LCDs (over about 12 inches), the TAB process is still be employed in common.

Both the COB process and the TAB process involve the use of PCBs for providing electrical connection paths between a liquid crystal panel and external circuits. However, a pitch width below 180 microns is very difficult to achieve in the PCB manufacture. The COB process can only provide low I/O lead-counts. Even the TAB process still employs PCBs. For the COG process, it involves the solder bump formation, the flip-chip bonding process, and the encapsulation process, and hence, its application in mass production of large size LCD (over about 12 inches) assembly is still not possible.

Based on the foregoing, the present invention provides a display driver integrated circuit module, which is applicable to a liquid crystal module assembly. Driver ICs are mounted to a flexible base film and electrically connected to it to form the display driver IC module. An application of the display driver IC module in the liquid crystal module assembly can reduce the amount of using PCBs, simplify the manufacturing process, reduce the production cost, the overall size and thickness, the weight, and it is suitable for large size LCD manufacture.

Accordingly, the present invention provides a display driver IC module which is applicable to a liquid crystal module assembly. The display driver IC module comprises a flexible base film and a plurality of driver ICs. The flexible base film includes an interconnecting wiring. Each driver ICs is mounted to the flexible base film, and having a plurality of input/output (I/O) pads electrically connected to the interconnecting wiring. Each driver IC is electrically connected to the corresponding input/output pads of the other driver ICs through the interconnecting wiring on the flexible base film.

Moreover, the present invention provides a structure and method of manufacturing a liquid crystal module. The liquid crystal module includes a display driver IC module, a liquid crystal panel, a backlight, etc. Driver ICs are first connected to a flexible base film to form the display drive IC module. The flexible base film includes an interconnecting wiring fabricated on it. Each driver IC includes a plurality of I/O pads electrically connected to the interconnecting wiring on the flexible base film. Each driver IC is electrically connected to the corresponding I/O pads of the other driver ICs through the interconnecting wiring on the flexible base film. Furthermore, a connecting material is employed for electrical connection between the display driver IC module and the liquid crystal panel. The backlight is located under the liquid crystal panel to form the liquid crystal module.

The accompanying drawings are included to provide a further understanding of the invention, and are incorporated in and constitute a part of this specification. The drawings illustrate embodiments of the invention and, together with the description, serve to explain the principles of the invention. In the drawings,

FIG. 4 is a flow chart showing the assembly process of a liquid crystal module by means of a display driver integrated circuit (IC) module in accordance with a preferred embodiment of the present invention;

FIG. 6B illustrates another wiring layout of driver ICs for a display driver IC module in accordance with a preferred embodiment of the present invention;

FIG. 7 is a top view of a liquid crystal module fabricated by means of a display driver IC module in accordance with a preferred embodiment of the present invention; and

FIG. 8 is a schematic, cross-sectional view of a liquid crystal module fabricated by means of a display driver IC module in accordance with a preferred embodiment of the present invention.

An object of fabricating a liquid crystal module (LCM) is to electrically connect a driver integrated circuit (IC) with a driver circuit to a liquid crystal panel for transmitting, controlling and processing electrical signals. Reference is made to FIG. 4 which illustrates a flow chart for the assembly process of a liquid crystal module by means of a display driver IC module in accordance with a preferred embodiment of the present invention.

A step 400 shown in FIG. 4 comprises the steps of providing a plurality driver ICs and a flexible base film, and electrically connecting the driver ICs to the flexible base film by means of, for example, the tape automated bonding (TAB) process or the chip on film (COF) process, to form a display driver IC module. An interconnecting wiring is fabricated on the flexible base film.

FIG. 5 illustrates a top view of a display driver IC module in accordance with a preferred embodiment of the present invention. FIG. 6A illustrates a wiring layout of driver ICs for a display driver IC module in accordance with a preferred embodiment of the present invention, and FIG. 6B illustrates another wiring layout of driver ICs for a display driver IC module in accordance with a preferred embodiment of the present invention.

Reference is made to FIG. 5, and according to the step 400 shown in FIG. 4, a display driver IC module 500 includes a plurality of driver ICs 502 and a flexible base film 504. The flexible base film 504 includes a flexible printed circuit board (FPCB) and a micro flex (MF), etc. A preferred material of the flexible base film 504 is polyimide or a flexible circuit film. Non-intersecting interconnecting wiring 506 is fabricated on the flexible base film 504 for electrical connections between the driver ICs 502 and external circuits, and between the driver ICs 502 and a liquid crystal panel. The driver ICs 502 are electrically connected to the interconnecting wiring 506 on the flexible base film 504. The driver ICs 502 are also electrically connected to one another by the non-intersecting interconnecting wiring 506. Transmitting, controlling, and processing electrical signals are accomplished by electrically connecting the display driver IC module to the external circuits and the liquid crystal panel through signal input terminals 508 and signal output terminals 510 of the interconnecting wiring 506, respectively.

The flexible base film 504 of the display driver IC module 500 shown in FIG. 5 is, for example, a single-sided board structure. In other words, the COF process is employed for the flexible base film 504 formation. However, this is just an example in the preferred embodiment of the present invention and does not intend to limit the present invention in any ways. Indeed, the flexible base film 504 can also be a double-sided substrate or a laminated substrate. Even mounting the driver ICs to both surfaces of the flexible base film 504 is allowable.

Reference is made to FIG. 6A. Input pads 602 aand an inner-connecting wiring 604 on a driver IC 600 aof the display driver IC module (item 500 in FIG. 5) have to be designed to match non-intersecting interconnecting wiring 606 aon the flexible base film (item 504 in FIG. 5). The inner-connecting wiring 604 are used to connect the input pads together 602 awithin the driver IC 600 a.The driver IC 600 ais electrically connected to the non-intersecting interconnecting wiring 606 aon the flexible base film via the input pads 602 aand output pads (not shown). Electrical connections between the input pads 602 aon the driver IC 600 aand the corresponding input pads 602 aon another driver IC 600 aare established by means of the interconnecting wiring 606 a.

Reference is made to FIG. 6B, in which a side input pad design is employed for a wiring layout of driver ICs 600 b.Similar to FIG. 6A, electrical connections between the driver ICs 600 band non-intersecting interconnecting wiring 606 bon the flexible base firm (item 504 in FIG. 5) are established by means of input pads 602 aand output pads 602 b.The input pads 602 aon opposite sides of the driver ICs are alternately formed and therefore only the corresponding pads on the same side of each driver IC are connected by the non-intersecting interconnecting wiring 606 bon the flexible base firm. The output pads 602 bare formed on the bottom of the driver IC as to connect to output terminal 610 on the flexible base film. As a result, all the driver ICs 600 bare electrically connected to one another and to the input terminal 608. Through signal input terminals 608 and signal output terminals 610 of the non-intersecting interconnecting wiring 606 b,electrical connections to external circuits and a liquid crystal panel are established, respectively, for signal transmission and processing.

In the wiring layout on the driver ICs 600 ashown in FIG. 6A, a mirror design is. employed for the I/O pads 602 arrangement. Again, this is just an example in the preferred embodiment of the present invention and does not intend to limit the present invention in any ways. Indeed, a double input pad or a side input pad (as shown in FIG. 6B) design can be employed for the wiring layout on the driver IC, in order to match the interconnecting wiring on the flexible base film (item 504 in FIG. 5) for establishing electrical connections.

Reference is made again to FIG. 4. According to a step 402, an outer lead bonding process is performed in which the interconnecting wiring on the display driver IC module described above and terminals along an edge of a liquid crystal panel are electrically connected through a connecting material. For example, an anisotropic conductive film (ACF) is employed for establishing electrical connections between outer leads of the display driver IC module and the terminals along the edge of the liquid crystal panel. A liquid crystal display is controlled by the driver IC"s under an active matrix driving manner to show a desired pattern. A step 404 shown in FIG. 4 then follows, in which a backlight, bezel, frame, etc. are assembled together with the panel and the display driver IC module to form a liquid crystal module (LCM).

FIGS. 7 and 8 illustrate, respectively, a top view and a schematic, cross-sectional view of a liquid crystal module fabricated by means of a display driver IC module in accordance with a preferred embodiment of the present invention. As shown in FIG. 7, an interconnecting wiring (item 506 in FIG. 5) is fabricated on a flexible base film 702 of a display driver IC module. Driver ICs 704 are mounted to a surface of the flexible base film 702 and electrically connected to the interconnecting wiring on the flexible base film 702. As described above, I/O pads (item 602 in FIG. 6A) of the driver IC 704 is electrically connected to the interconnecting wiring on the flexible base film 702. Electrical connections between the I/O pads on the driver IC 704 and the I/O pads on the corresponding driver IC 704 are established by means of the interconnecting wiring. Through signal input and output terminals (items 508 and 510 in FIG. 5) of the interconnecting wiring on the flexible base film 702, electrical connections to external circuits and the liquid crystal panel are established, respectively, for signal transmission and processing.

By means of a connecting material, electrical connections between the signal output terminals of the interconnecting wiring on the flexible base films 702 and terminals along edges of the liquid crystal panel 700 are established. A liquid crystal display is controlled by the driver ICs 704 mounted to the flexible base films 702 under an active matrix driving manner to show a desired pattern. As shown in FIG. 8, the electrical connection between the liquid crystal panel 700 and the flexible base film 702 are by means of the connecting material 708. Materials of the connecting material 708 include an anisotropic conductive film. A backlight is located under the liquid crystal panel 700 to provide a light source. The driver ICs 704 and the flexible base films 702 together forms a display driver IC module. The display driver IC module, the liquid crystal panel 700, the backlight, the bezel, the frame, etc. further forms a liquid crystal module.

Based on the foregoing, the present invention is applicable to the assembly of a liquid crystal module. A plurality of driver ICs is first mounted on a flexible base film such as a FPCB, a MF, etc. to form a display driver IC module, which drives and controls a liquid crystal panel. Electrical connections are then established between the display driver IC module and the liquid crystal panel. A backlight, a bezel and a frame, etc. are included to form a liquid crystal module.

By employing the display driver IC module of the present invention to assemble a liquid crystal module, the amount of PCBs required is reduced. A bonding process for connections between the PCBs and tapes is omitted. Hence, the manufacturing process is simplified and both the manufacturing and assembly costs can be reduced. Moreover, a flexible base film with an interconnecting wiring fabricated on its surface is employed as a substrate in accordance with the present invention. With the characteristics of thin, light, and flexible, the overall size, thickness, and weight of the formed liquid crystal module can be reduced, and hence, is suitable for manufacturing large size liquid crystal module.

It will be apparent to those skilled in the art that various modifications and variations can be made to the structure of the present invention without departing from the scope or spirit of the invention. In view of the foregoing, it is intended that the present invention cover modifications and variations of this invention provided they fall within the scope of the following claims and their equivalents.

Variations in display panel manufacturing and packaging can cause the display panels to deviate from their target specifications, compromising uniform display quality. NVM IPs can be used in display driver ICs to store parameters for brightness levels, contrast levels, color correction tables and more to adjust for differences in chips. Additionally, by using NVM IPs in display drivers, chip designers can correct the nonuniformity in display panels. For example, smartphones’ display driver gamma curves can be individually tweaked to compensate for variations in display quality. Gamma adjustment ensures that all phones coming off the final production line have similar levels of screen brightness and color contrast, eliminating the need for additional software configurations. Given the benefits, chip designers can use NVM IPs to effectively reduce manufacturing costs and increase production yield.

Taiwan-based display driver IC suppliers including Novatek Microelectronics, Himax Technologies and Raydium Semiconductor are actively expanding their OLED DDI offerings, all eyeing...

Most Taiwan IC design houses have seen shipments suffer a freeze in the fourth quarter of the year, and their sales are expected to stay in low gear in the first half of 2023 amid...

Display driver IC packaging materials suppliers have recently landed a pull-in of short lead-time orders, which DDI backend firms regard as a short-term phenomenon.

With display driver IC (DDI) supplier FocalTech Systems announcing plans to lay off 10-15% of employees and reduce pays for all its senior executives, market concerns are rapidly...

Display driver IC (DDI) suppliers are mostly pessimistic about sales prospects for fourth-quarter 2022, and their longer-term performance will be determined by their operation fundamentals,...

Himax Technologies believes its inventories should have hit their peak in the third quarter of 2022, when the display driver IC specialist saw its revenue and EPS both exceed the...

Display driver IC specialist FocalTech Systems swung to net loss of NT$2.77 billion (US$88.8 million) in the third quarter of 2022 from profits in the prior quarter and a year ago,...

Display driver IC suppliers have seen a pick-up in DDI demand for TV applications, even though most orders are mainly short lead-time ones, according to industry sources.

Display driver IC supplier Raydium Semiconductor remains cautious about its sales performance in the fourth quarter of 2022, citing the ongoing inventory adjustments across many industry...

Display driver IC supplier Novatek Microelectronics expects inventories held by handset and TV customers to return to appropriate levels in the first quarter of 2023 but is uncertain...

Display driver IC specialist Fitipower Integrated Technology, an affiliate of the Foxconn Group, has enjoyed a pull-in of short lead-time orders for TVs to support its sales performance...

Display driver IC suppliers have substantially scaled back wafer starts at foundries, but the efforts are still insufficient to reduce their inventory levels, according to industry...

The decline in demand for large-size display driver IC (DDI) is slowing down along with the fact that demand and prices of LCD panels for TVs, notebooks and desktops are running close...

Network IC specialist Realtek Semiconductor saw its September revenue decline 7.8% sequentially to a seven-month low of NT$9.58 billion (US$301.8 million).

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey