lcd panel production 2018 supplier

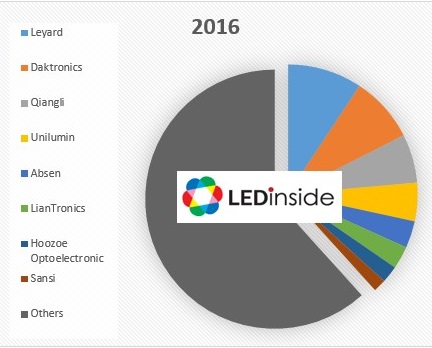

BOE Technology Group, the Chinese electronic components producer, is expected to be the leader in producing LCD display panels in the coming years, with a forecast capacity share of 24 percent by 2022. China is the country that has the largest LCD capacity, with a 56 percent share in 2020.Read moreLCD panel production capacity share from 2016 to 2022, by manufacturerCharacteristicBOEChina StarInnoluxAUOLGDHKCCEC PandaSharpSDCOther-----------

DSCC. (June 8, 2020). LCD panel production capacity share from 2016 to 2022, by manufacturer [Graph]. In Statista. Retrieved December 16, 2022, from https://www.statista.com/statistics/1057455/lcd-panel-production-capacity-manufacturer/

DSCC. "LCD panel production capacity share from 2016 to 2022, by manufacturer." Chart. June 8, 2020. Statista. Accessed December 16, 2022. https://www.statista.com/statistics/1057455/lcd-panel-production-capacity-manufacturer/

DSCC. (2020). LCD panel production capacity share from 2016 to 2022, by manufacturer. Statista. Statista Inc.. Accessed: December 16, 2022. https://www.statista.com/statistics/1057455/lcd-panel-production-capacity-manufacturer/

DSCC. "Lcd Panel Production Capacity Share from 2016 to 2022, by Manufacturer." Statista, Statista Inc., 8 Jun 2020, https://www.statista.com/statistics/1057455/lcd-panel-production-capacity-manufacturer/

DSCC, LCD panel production capacity share from 2016 to 2022, by manufacturer Statista, https://www.statista.com/statistics/1057455/lcd-panel-production-capacity-manufacturer/ (last visited December 16, 2022)

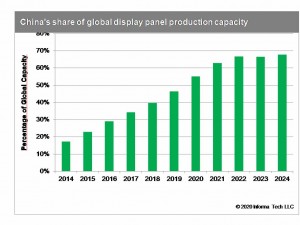

China is the leader in producing LCD display panels, with a forecast capacity share of 56 percent in 2020. China"s share is expected to increase in the coming years, stabilizing at 69 percent from 2023 onwards.Read moreLCD panel production capacity share from 2016 to 2025, by countryCharacteristicChinaJapanSouth KoreaTaiwan-----

DSCC. (June 8, 2020). LCD panel production capacity share from 2016 to 2025, by country [Graph]. In Statista. Retrieved December 16, 2022, from https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. "LCD panel production capacity share from 2016 to 2025, by country." Chart. June 8, 2020. Statista. Accessed December 16, 2022. https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. (2020). LCD panel production capacity share from 2016 to 2025, by country. Statista. Statista Inc.. Accessed: December 16, 2022. https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC. "Lcd Panel Production Capacity Share from 2016 to 2025, by Country." Statista, Statista Inc., 8 Jun 2020, https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/

DSCC, LCD panel production capacity share from 2016 to 2025, by country Statista, https://www.statista.com/statistics/1056470/lcd-panel-production-capacity-country/ (last visited December 16, 2022)

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

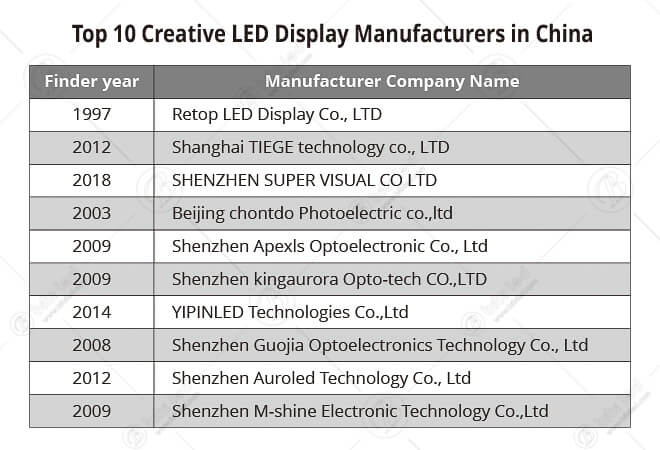

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Business Place Information – Global Operation | SAMSUNG DISPLAY". www.samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

Byeonghwa, Yeon. "Business Place Information – Global Operation – SAMSUNG DISPLAY". Samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

www.wisechip.com.tw. "WiseChip History – WiseChip Semiconductor Inc". www.wisechip.com.tw. Archived from the original on 2018-02-17. Retrieved 2018-02-17.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

BOE, China’s largest display company, was listed as a major panel supplier in Samsung Electronics’ business report. BOE has filled the vacancy created by Samsung Display’s phased reduction of large LCD panels for TVs.

The business report, which was registered with the Financial Supervisory Service’s electronic disclosure system, listed three major display panel suppliers for the company"s consumer electronics (CE) sector in 2021 -- BOE and CSOT of China and AUO of Taiwan. BOE was newly added as a major supplier. BOE surpassed LG Display in 2018 to become the world’s No. 1 LCD manufacturer.

Samsung Display decided in early 2021 to stop producing large LCD panels beginning from 2022. The decision was made to speed up its transition to next-generation QD-OLED panels as the profitability of the LCD business fell significantly due to a price war with Chinese companies.

It stopped the operation of L7 at Asan Campus in South Chungcheong Province, which had produced large LCD panels, in March 2021. An 8th-generation LCD production line at the Suzhou plant in China was sold in April 2021. However, it is still operating some of its large LCD production facilities at Asan Campus at the request of Samsung Electronics. Samsung Display is considering shutting down these facilities within June 2022.

Industry insiders say that Samsung Display"s withdrawal from the LCD business has weakened Samsung Electronics" bargaining power in negotiations with Chinese vendors.

Samsung Electronics’ price burden for TV panels has nearly doubled over the past year. The Samsung Electronics business report says that the company spent 10,582.3 billion won on purchasing display panels in 2021. This was an increase of 94.2 percent from the previous year (5,448.3 billion won). The main factor behind the increase is a rise in LCD panel prices. Samsung Electronics explained that prices of TV panels rose about 39 percent on year in 2021.

Industry insiders say one solution is to accelerate a shift to OLED-based TVs. Chinese panel makers are investing aggressively to develop large OLED panel technologies, but they have not yet reached the volume production stage.

Samsung Electronics is negotiating with Samsung Display and LG Display over the release of OLED TVs. LG Display is the only company that mass produces large OLED panels. It can produce 10 million TV panels annually. Samsung Display started mass production of large OLED panels at the end of 2021. The two Korean OLED panel makers adopt white (W) and blue (B) light sources, respectively.

Panel makers are cutting production by 16 percent on average from this month, Rong Chaoping, senior researcher at market research firm AVC Revo, told Yicai Global. Television panel makers are expected to ship 3.6 million less panels than last month.

Panel makers will reduce capacity by between 15 and 20 percent this month, said Wu Rongbing, chief analyst at Chinese semiconductor intelligence service Omdia.

TCL China Star intends to continue with its production cuts until September, while Beijing-based BOE and HKC Optoelectronics Technology have not yet decided how long they will reduce output, Rong said. None of the three companies responded when contacted by Yicai Global.

LCD TV display shipments from China’s five largest panel manufacturers accounted for 68.5 percent of the global market in April, a new high, and they were expected to exceed 70 percent this year, according to Omdia.

The global panel industry is expected to slash production by about 20 percent this year, according to Beijing-based Sigmaintell. It is the first time since 2013 that the worldwide sector has implemented such a large-scale and wide-ranging cut in manufacturing. But it should help to slow the fall in prices, Li said.

“Tumbling prices are squeezing profits,” Li said. “The price of a TV panel is now below cost price and that of some data panels is also below the manufacturing cost.”

“Panel makers are facing rising liquidity pressure and bigger losses as prices are now below cost price, so the display industry is likely to undergo another big reshuffle,” Rong said.

Panel prices are likely to stop dropping this month or next as output falls, Wu said. Whether prices will start to pick up soon depends on when demand improves.

As one of the main application markets of small and medium-sized panels, LCD display panel manufacturers never stop competing in the automotive panel display market. Especially with the development of 5G, unmanned driving, and new energy vehicles, the update and iteration of display panel technology are accelerating.

From the perspective of the automotive panel display market and research and development, a-si, TFT-LCD, LTPS, AMOLED, and Mini/Micro LED are the main technologies of vehicle display panels at the present stage. Among them, a-si and TFT-LCD markets are weakening, LTPS is on the rise, AMOLED is rising strongly, Mini/Micro LED is A forward-looking technology reserve, appearing in various exhibitions at high frequency.

Auto display panels shipped 1.615 million units in 2018, up 9.4 percent from a year earlier, according to IHS Markit.IHS notes that the global automotive LCD display panel market is entering a period of slow growth but intense competition.

But car displays panel will grow at a compound annual rate of 7 percent from 2017 to 2025, compared with weak demand for smartphones that will be hard to reverse. Demand for display panels for car and public displays, smartwatches, and OLED TVs is expected to grow faster than other applications.

Panel makers have added more screens for cars in recent years, either to expand revenue growth or to smooth out the shortcomings of smartphone panels.

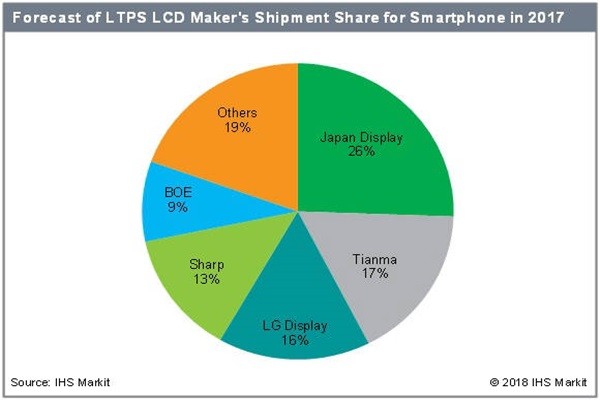

In terms of vehicle LCD display panel shipments in 2018, JDI, LGD, tianma, au optronics, and qunchuang optronics are the top five global enterprises in terms of vehicle display panel shipments, with market shares of 16.9%, 12.8%, 12.4%, 12.1%, and 11.0% respectively.

JDI and LGD are the dominant vehicle panels for LTPS. With the help of the two companies, LTPS gradually occupied A certain market share of the vehicle display panel after a-si. The advantages of LTPS are ultra-thin, lightweight, low power consumption, colorful and clearer, and the OLED panels are derived from LTPS.

According to the new display of high tech, JDI has laid out the LTPS in 2015 and made the LTPS plan for mass production for vehicle display. With its technical advantages and mass production level, JDI’s vehicle display panel business revenue exceeded 100 billion yen for * times in 2017.JDI’s automotive panel revenue plans to expand to 160 billion yen by 2020, said Holger Gerkens, JDI’s executive officer for automotive panels.

Au optronics is a late adopter of the LTPS, but its LTPS products were introduced to the full range of automotive panels in 2018. Its products are said to achieve color saturation up to NTSC * and can be switched between high-resolution images and traditional mirror mode depending on driving requirements. As au optronics Kunshan 6 generation LTPS panel factory capacity is full, it is expected that the proportion of LTPS vehicle panels is expected to increase.

Mainland panel manufacturers, TCL group subsidiary huaxing optoelectronics have expanded production of the sixth generation of LTPS display panel technology, and the product positioning includes the application of automotive display.

OLED panel has higher response speed, lower energy consumption, flexible display, non-breakable, no dead Angle and other characteristics, in the industry, its performance is conducive to improve driving safety, very suitable for the vehicle display panel market. UBI Research expects OLED to account for 10% of the vehicle display market by 2020.

Mainland manufacturers boe and vechino have both expanded production of AMOLED, and their AMOLED panels have been applied in-vehicle display, breaking the gap in technology and application in the domestic market. According to related reports, boe’s AMOLED panel is also equipped with Mini LED, in-cell, and other technologies.

Vercino AMOLED is still in its initial stage, but there is already A certain scale of the AMOLED production line, and in April this year, transparent a-pillar MVS were mass-produced to solve the problem of driving blind area.

JDI also said that it will take advantage of JOLED printed OLED technology to strengthen the development of new product technology and gradually expand the sales of vehicle panels.

From the application side, OLED display panels are currently mainly used in high-end automobile brands and new energy vehicles, occupying a limited market share. However, some industry insiders believe that OLED is expected to become the mainstream of automotive display, with technology and mass production advantages of the panel factory revenue prospects are considerable.

In addition, with the Mini/Micro LED technology increasingly mature, two technologies have become the panel factory forward-looking technology layout focus.

The car display panel is a niche market. When many enterprises develop Mini/Micro LED, they often regard car display as one of the main application scenarios. However, the Mini/Micro LED in the vehicle display market has not yet entered the commercial stage.

In the future, the vehicle LCD display panel will blossom, especially under the assistance of 5G and self-driving cars, the vehicle display technology will advance towards high specifications.

At present, markets such as large-screen TVs are still inseparable from LCD panels. Several Chinese panel manufacturers have surpassed Samsung and LG to become the main LCD panel manufacturers in recent years. Korean companies are no longer able to compete. Samsung will stop the production of LCD panels half a year ahead of schedule. Samsung used to be the largest LCD panel manufacturer, but in recent years, Chinese companies such as BOE and CSOT have rapidly expanded their market shares. Samsung and LG have continued to retreat, making BOE surpass LGD in 2018. As of now, BOE is now the world’s largest manufacturer of LCD panels.

Samsung originally planned to stop the production of LCD panels by the end of 2020. However, the LCD panel market started to increase prices in the past year or so. This made Samsung’s LCD factory continue to operate for another two years. However, the company originally plans to exit the market at the end of 2022. Nevertheless, the LCD panel market has changed since the end of last year. The price has been falling significantly and it is now on a free fall. By January this year, the average price of a 32 -inch panel was only $ 38, a 64% drop relative to January last year.

This situation is making Samsung rethink its initial exit plans. The South Korean manufacturing giant is now planning to withdraw from LCD panel production half a year ahead of schedule. It will stop production in June this year. Samsung Display, a subsidiary of Samsung Electronics, will turn to higher-end QD quantum dot panels. The LCD panels that the company needs will turn to procurement.

According to information released by Samsung Electronics, the company’s three major suppliers of LCD panels are BOE, Huaxing Optoelectronics, and AUO, all of which are Chinese companies. The first two are local companies, and they are the first and second-largest suppliers of LCD.

Due to high demand in South Kore, Samsung Display had to extend its production of Liquid Crystal Display (LCD) panels for TVs and monitors in South Korea. Its exit from the LCD market will give the company room to concentrate on more advanced technologies.

Samsung’s delay in closing the LCD panel plant will increase the production area and there is the risk of material shortages. Thus, the dipping price of LCD panels gives the company all the reasons it needs to quit the market.

In general, there are two types of displays in the market today: active matrix liquid crystal display (AMLCD) and AMOLED. In its simplicity, the fundamental components required to make up the display are the same for AMLCD and AMOLED. There are four layers of a display device (FIGURE 1): a light source, switches that are the thin-film-transistor and where the gases are mainly used, a shutter to control the color selection, and the RGB (red, green, blue) color filter.

Technology trends TFT-LCD (thin-film-transistor liquid-crystal display) is the baseline technology. MO / White OLED (organic light emitting diode) is used for larger screens. LTPS / AMOLED is used for small / medium screens. The challenges for OLED are the effect of < 1 micron particles on yield, much higher cost compared to a-Si due to increased mask steps, and moisture impact to yield for the OLED step.

Although AMLCD displays are still dominant in the market today, AMOLED displays are growing quickly. Currently about 25% of smartphones are made with AMOLED displays and this is expected to grow to ~40% by 2021. OLED televisions are also growing rapidly, enjoying double digit growth rate year over year. Based on IHS data, the revenue for display panels with AMOLED technol- ogies is expected to have a CAGR of 18.9% in the next five years while the AMLCD display revenue will have a -2.8% CAGR for the same period with the total display panel revenue CAGR of 2.5%. With the rapid growth of AMOLED display panels, the panel makers have accel- erated their investment in the equipment to produce AMOLED panels.

There are three types of thin-film-transistor devices for display: amorphous silicon (a-Si), low temperature polysilicon (LTPS), and metal oxide (MO), also known as transparent amorphous oxide semiconductor (TAOS). AMLCD panels typically use a-Si for lower-resolution displays and TVs while high-resolution displays use LTPS transistors, but this use is mainly limited to small and medium displays due to its higher costs and scalability limitations. AMOLED panels use LTPS and MO transistors where MO devices are typically used for TV and large displays (FIGURE 3).

This shift in technology also requires a change in the gases used in production of AMOLED panels as compared with the AMLCD panels. As shown in FIGURE 4, display manufacturing today uses a wide variety of gases.

The key ga susage driver in the manufacturing of displays is PECVD (plasma-enhanced chemical vapor deposition), which accounts for 75% of the ESG spending, while dry etch is driving helium usage. LTPS and MO transistor production is driving nitrous oxide usage. The ESG usage for MO transistor production differs from what is shown in FIGURE 4: nitrous oxide makes up 63% of gas spend, nitrogen trifluoride 26%, silane 7%, and sulfur hexafluoride and ammonia together around 4%. Laser gases are used not only for lithography, but also for excimer laser annealing application in LTPS.

Nitrogen trifluoride: NF3 is the single largest electronic material from spend and volume standpoint for a-Si and LTPS display production while being surpassed by N2O for MO production. NF3 is used for cleaning the PECVD chambers. This gas requires scalability to get the cost advantage necessary for the highly competitive market.

Nitrous oxide: Used in both LTPS and MO display production, N2O has surpassed NF3 to become the largest electronic material from spend and volume standpoint for MO production. N2O is a regional and localized product due to its low cost, making long supply chains with high logistic costs unfeasible. Averaging approximately 2 kg per 5.5 m2 of mother glass area, it requires around 240 tons per month for a typical 120K per month capacity generation 8.5 MO display production. The largest N2O compressed gas trailer can only deliver six tons of N2O each time and thus it becomes both costly and risky

In-fab distribution: Gas supply does not end with the delivery or production of the material of the fab. Rather, the materials are further regulated with additional filtration, purification, and on-line analysis before delivery to individual production tools.

The consumer demand for displays that offer increas- ingly vivid color, higher resolution, and lower power consumption will challenge display makers to step up the technologies they employ and to develop newer displays such as flexible and transparent displays. The transistors to support these new displays will either be LTPS and / or MO, which means the gases currently being used in these processes will continue to grow. Considering the current a-Si display production, the gas consumption per area of the glass will increase by 25% for LTPS and ~ 50% for MO productions.

To facilitate these increasing demands, display manufacturers must partner with gas suppliers to identify which can meet their technology needs, globally source electronic materials to provide customers with stable and cost- effective gas solutions, develop local sources of electronic materials, improve productivity, reduce carbon footprint, and increase energy efficiency through on-site gas plants. This is particularly true for the burgeoning China display manufacturing market, which will benefit from investing in on-site bulk gas plants and collaboration with global materials suppliers with local production facilities for high-purity gas and chemical manufacturing.

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

In 1991, a business unit called Samsung Display was formed to produce the panels used in products made by its parent company, Samsung Electronics. Afterward, it was a leading supplier of LCD panels not just for Samsung Electronics but for other companies in the industry as well.

The business received a stay of execution when the pandemic led to a global surge in demand for consumer electronics, but that demand is now declining, and projections aren"t good for LCD panel revenue.

Add to that the fact that emerging technologies like QD-OLED are the future for TV and monitors, and the case for keeping Samsung Display"s LCD business going becomes a hard one to make.

Samsung Display will now focus heavily on OLED and quantum dot. Most of the employees working in the LCD business will move to quantum dot, the publication claims.

Even if there isn"t a statement about a change in direction, the writing has been on the wall for Samsung"s LCD business. Unless something radical changes, it"s more a question of when than if at this point.

Chinese companies have gained a competitive edge in the large-screen display industry and the exit of South Korean counterparts such as Samsung Electronics and LG Display from the liquid crystal display market will bring opportunities for China"s panel makers despite the challenges posed by the COVID-19 pandemic.

Market research firm Sigmaintell said BOE Technology Group Co Ltd-a leading Chinese supplier of display products and solutions-became the world"s largest shipper of LCD TV panels for the first time in 2019.

The Beijing-based company shipped 53.3 million units of LCD panels in 2019, with production capacity increasing by more than 20 percent on a yearly basis.Chinese companies have gained an upper hand in large-screen LCD displays. Samsung and LG"s decision to exit from the LCD sector means Chinese panel makers will take a dominant position in this field

The consultancy said the LCD TV panel production area of Chinese manufacturers will account for more than 50 percent of the global total this year, surpassing South Korean competitors who are accelerating the shutdown of large-sized LCD panel production capacity due to competition from Chinese manufacturers.

It estimated the production capacity of large-sized LCD panels will continue to increase in China over the next three years. In addition, global LCD TV panel shipments stood at 283 million pieces last year, a slight decrease of 0.2 percent year-on-year. Meanwhile, the shipment area was 160 million square meters, an increase of 6.3 percent year-on-year.

"Chinese companies have gained an upper hand in large-screen LCD displays. Samsung and LG"s decision to exit from the LCD sector means Chinese panel makers will take a dominant position in this field," said Li Dongsheng, founder and chairman of Chinese tech giant TCL Technology Group Corp.

Li said South Korean firms will focus on organic LED screens and quantum dot LED displays, while Chinese TV panel makers are catching up at a rapid pace.

Data consultancy Digitimes Research said it comes as little surprise that Samsung has opted to withdraw from the LCD panel sector as its LCD business was losing money in every quarter of 2019 due to challenges from Chinese competitors.

BOE said its Gen 10.5 TFTLCD production line achieved mass production in Hefei, Anhui province, in March 2018. The plant mainly produces high-definition LCD screens of 65 inches and above. With a total investment of 46 billion yuan (US$6.5 billion), the company"s second Gen 10.5 TFT-LCD production line launched operations in Wuhan, Hubei province, in December.

The Gen 11 TFT-LCD and active-matrix OLED production line of Shenzhen China Star Optoelectronics Technology, a subsidiary of TCL, officially entered operations in November 2018, producing 43-inch, 65-inch and 75-inch LCD screens.

Chen Lijuan, an analyst at Sigmaintell, said panel manufacturers should not just invest in production lines, but also pay more attention to the establishment of the whole supply chain, including raw materials, equipment and technology.

Bian Zheng, deputy director of research at AVC Revo, a unit of market consultancy firm AVC, said China will have a 51 percent market share in global TV shipments in 2020, while South Korea will have 25 percent, adding that large-screen TV panels will bolster healthy development of the industry.

Bian said the OLED and QLED will be the next-generation flat-panel display technologies to be in the spotlight. LG Display is currently the world"s only supplier of large-screen OLED TV panels.

OLED is a relatively new technology and part of recent display innovation. It has a fast response rate, wide viewing angles, super high-contrast images and richer colors. It is much thinner and can be made flexible, compared with traditional LCD display panels.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey